Introduction

All products have a life cycle which is the period between their launch in the market and the final withdrawal after completing all the phases. A product moves in different phases depending on how it is performing in the market. The manufacturing companies introduce a product in the market after carrying out a thorough market research and then continue to assess how the product is performing in the market. Product life cycle involves a number of stages, right from designing to the disposal or recycling point. Analyzing the life cycle of a given product will help in the management of the product line(Funk, 2004, p.142).This research paper will analyze the product life cycle of a compact disk (CD) right from the design stage to the waste disposal destination.

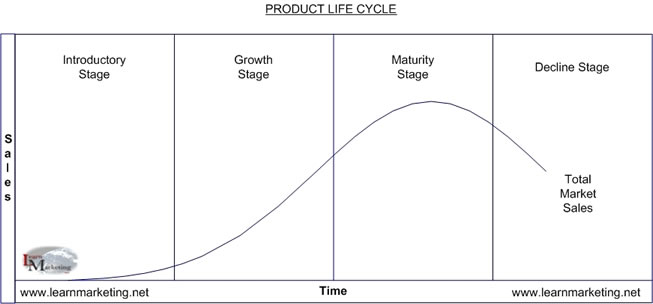

Product life cycle curve

The curve can be summarized into four stages which include introductory, growth, maturity and decline stage (Nadeau & Casselman 2008, p. 401). These stages are subdivided subject on the type of the product under study.

Product life cycle of a compact disk can be divided into eight stages as illustrated below.

- Design

- Materials Acquisition

- Materials Processing

- Manufacturing

- Packaging

- Distribution

- Uses

- Disposal ,Recycle or Reuse

- Design- this stage involves designing of the new product by the designers and the product engineers (Eder 2001, p.657). The model of the CD is developed and then tested before its mass production.

- Material acquisition- materials for manufacturing the new product are acquired on a large scale in order to manufacture the required number of units. These materials are artificially made or excavated from the natural resources. Materials required in the manufacture of CD include aluminum, gold, dyes, polycarbonate, among others. Materials chosen in this stage ought to be recyclable or environmentally friendly to ensure that their waste does not pollute the environment (Bovea & Wang 2007, 4057).

- Manufacturing- in this stage raw materials are processed in the factory to make the required product. This stage may involve a number of processes in different lines of production. The manufacturing processes involved when making a CD includes; injection moulding, metallizer, lacquer and screen printing.

- Packaging – in this stage, finished products are packaged in preparation for their distribution. In case of a CD, the finished compact disks are packaged in jewel cases, cardboard boxes and shrink- wrapping for them to be distributed to the customers.

- Distribution – in this stage, finished products are distributed to different locations where they are sold. CDs are transported to different destinations using plane, truck and train depending on the market distance.

- Use – customers use the finished products in order to meet their needs or wants. The use will depend with the purpose for which the product was made. CDs are used for data storage like in movies and music. The product must be used and kept according to manufacturers’ instructions for them to meet their purpose.

- Recycle/reuse or disposal – this is the final stage of the product life cycle where the product is disposed of after use. Recycling and reusing will depend with how the product was made and if there is any possible use of the used product material. After using a CD you can share it with somebody else or it can be collected by the recycling companies for other uses such as making plastic and office equipment.

Theory of product life cycle

The product life cycle of any product can be compared with the human life cycle from birth to death. A product design is comparable with the birth of a human being and its disposal compared with the death of a person. New products are designed and developed to meet the needs of the market. Market research is conducted before introducing a new product in the market in order to assess the needs of customers which are not met by the products already offered in the market. As Calantone, Yeniyurt, Townsend and Schmidt (2010) note, proper timing is very crucial when introducing the new product (p.349).This will also ensure that product is developed in line with the needs of the customers. The developed product may also be attempted in different market segments before producing it in large scale. Most of the time, new product is usually launched in the home market before taking it to other foreign markets. In addition, many products are introduced in the developed economies where consumers have high income to try new products.

Increased revenue from the sale of new products in the local market drives the manufacturing companies to look for foreign markets through exports (Hultman, Robson& Katsikeas 2009, p.1). This expansion happens in the maturing stage where production and design of the product is stable. Increased market size reduces the cost of labor and transport for each unit of the product produced. This continues to increase the profitability of the product. In the growth stage, new markets are invented as the companies continue to explore new markets. The decline stage begins after the product becomes saturated in the market and competition from similar products exerts pressure to the product (Soo, 2010, p.641). Many companies start looking for ways to reduce costs rather than to increase the volume of sale. The customers of the product also decline as new products enter the market.

Advantages and disadvantages of using PLC to predict future trend of a product

PLC helps companies to know how their product will fare in the market at different stages. This will enable them to control their production since the level of quantity produced is predictable hence avoiding any loss due to excessive production (Cucchiella, Gastaldi & Lenny 2010, p.301). The model will also help to predict the right to design a new product as the former product begins to decline. PLC will also help management to understand appropriate strategy to apply (Ilić, Milićević & Cvetković 2010, p.193).On the other hand, the model may mislead companies when they use it to predict the trend of their products in the market. Many products may not follow that trend since there are many other factors that may affect the performance of a product in the market. Product-cycle mismatch may also occur especially in electronic products (Bradley & Guerrero 2010, p.497).

Conclusion

To recap it all, the product life cycle helps in predicting how a given product will fare in the market. This enables the management to plan the production and sale of the product as well as reducing costs that result from overproduction. Compact disc life cycle is a good example of how a product rotates from its designing to disposal point. However, PLC may mislead the management of a company due to inaccurate prediction.

References

Bovea, M. D. & Wang, B., 2007. Redesign methodology for developing environmentally conscious products. International Journal of Production Research, 45 (18/19): 4057-4072.

Bradley, J. & Guerrero, H., 2008. Product Design for Life–Cycle Mismatch. Production & Operations Management, 17(5): 497-512.

Calantone, R., Yeniyurt, S., Townsend, J. & Schmidt, B., 2010. The Effects of Competition in Short Product Life–Cycle Markets: The Case of Motion Pictures. Journal of Product Innovation Management, 27 (3): 349-361.

Cucchiella, F., Gastaldi, M. & Lenny K., 2010. Performance improvement: an active life cycle product management. International Journal of Systems Science, 41(3), pp.301-313.

Eder, W., 2001. Designing and life cycle engineering—a systematic approach to designing. Proceedings of the Institution of Mechanical Engineers — Part B — Engineering Manufacture (Professional Engineering Publishing), 215(5): 657- 672.

Funk, J., 2004. The Product Life Cycle Theory and Product Line Management: The Case of Mobile Phones. IEEE Transactions on Engineering Management, 51(2): 142-152.

Hultman, M., Robson, M. & Katsikeas, C. 2009. Export Product Strategy Fit and Performance: An Empirical Investigation Journal of International Marketing, 17(4): 1-23.

Ilić, B., Milićević, V. & Cvetković, N.,2010. Strategic Cost Management and the Product Life Cycle Concept. Megatrend Review, 7(1): 193-207.

Nadeau, J. & Casselman, R., 2008. Competitive Advantage with New Product Development: Implications for Life Cycle Theory Mitch. Journal of Strategic Marketing, 16(5): 401-411.

Soo, C., 2010. Product life cycle theory and the maturation of the internet. Northwestern University Law Review, 104 Issue 2, 641-670,