Introduction

It is important to note that modular construction (MC) or modular integrated construction (MIC) is a novel and promising method of hastening the construction process by making it more effective and efficient. The theoretical context of the research project is primarily focused on the supply chain and transportation aspects of MIC, which will be defined and described in greater detail in the following section. The main reason is that these elements are the most problematic issues of modular construction, which is why they will be used to frame the problem and formulate the research. In the case of practical context, the organization of interest is King Wai Group (KWG), which is a real estate developer in China, Shanghai, Chengdu, Shantou, and Tianjin, and it is headquartered in Hong Kong. The action project researcher and the project author’s current role at KWG is Managing Director.

The currency of the project is manifested in the fact that the supply chain and transportation of MIC are core hindrances of practical implementation because modules need to be delivered to the site of construction or customer. The delays and mechanical challenges incur a high cost on the operational effectiveness of the organization, which is why the problem needs to be addressed and resolved immediately. The research project is valuable because more effective methods of supply chain and transportation will enable a profitable and positive operational outcome with multiple beneficiaries, such as KWG, homebuyers, and the government. The critical evaluation of the entrepreneurial opportunity is manifested in addressing the homebuyer community’s needs for quick and cheap housing options in the market. The main stakeholder, KWG, was directly involved in order to address its modular transportation risk factors under robust optimization with the use of external and internal data.

Real estate under the current economic conditions is becoming practically unaffordable for major segments of the population, where the costs are partially increased due to the length and complicatedness of the purely onsite construction process. Modular construction provides a cheaper and faster alternative for homebuyers by assembling modules offsite with a focus on efficiency. However, transportation still remains to be the most vulnerable and high-risk aspect of module shipping, which is why providing a more resilient framework of operations for the given transportation issue not only benefits the stakeholder but the community as well. Thus, it is a vital and critical entrepreneurial opportunity to seek and investigate the value behind it.

Modular Construction

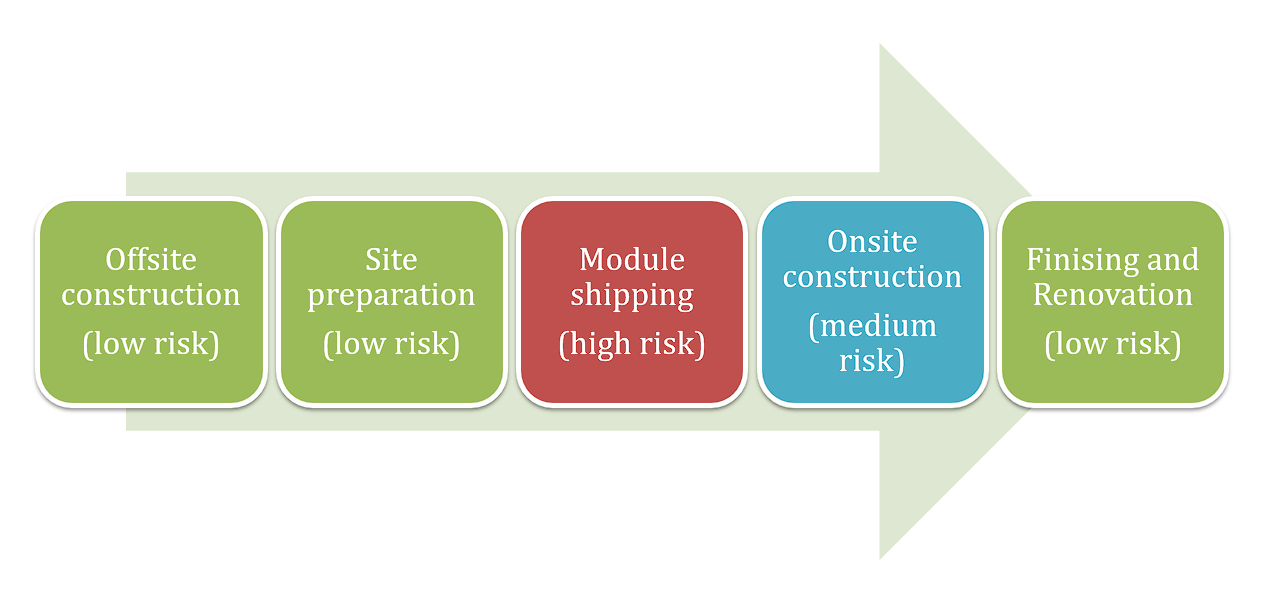

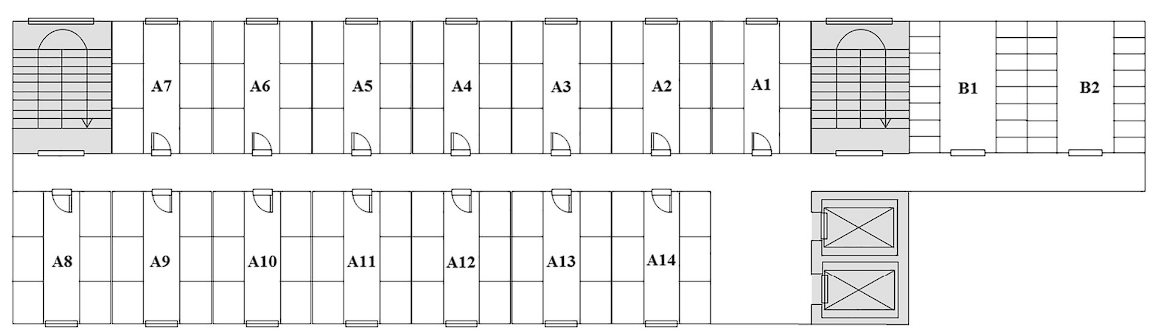

Modular construction technology is the process of erecting a building from pre-made house parts that must be connected into a single structure, as shown in Image 1 above. As a rule, such houses do not require expensive foundations because of their lighter weights. Typically, such solutions do not require significant efforts and can additionally take into account the constraints of the site. This allows an organization to save financial resources already at the initial stage of the value chain. Modular construction technology allows KWG to take into account the problems that arise during the construction of other types of building as well. The number of actions that need to be performed by the customer is reduced to a minimum. Thus, the technology of modular construction is maximally simplified. This leads to cost savings at the main stage of building construction.

Issue

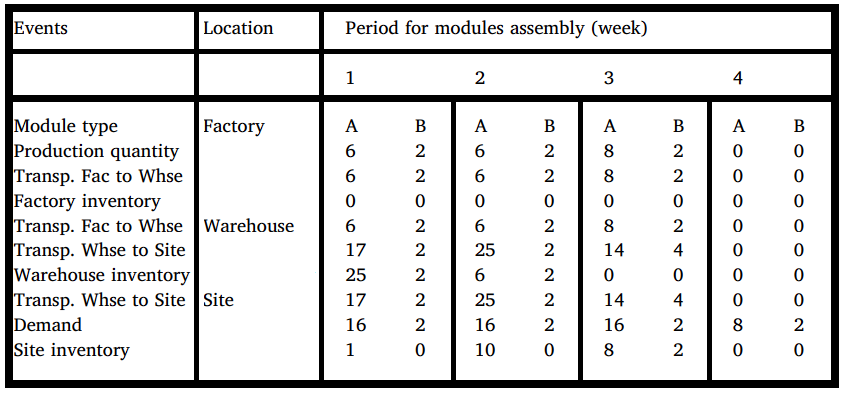

The main issue is the fact that KWG, as any other construction company is interested in a modular framework, is faced with challenges of transportation of the modules and subsequent risk management problems. The visual demonstration of the complicatedness of the transportation aspect of the modular construction is shown in Image 2 above. The value chain diagram for the modular construction is shown below in Figure 1. The modules are built offsite before there are incorporated into a building onsite. However, the modules are most vulnerable and prone to damages and other risk factors during their shipping, which creates a significant challenge for the overall risk as well as cost management efforts.

Thus, it is necessary to consider all the advantages and disadvantages, as well as the potential for using modular construction, and it can be concluded that these technologies can be used in almost all areas of construction. Considering the need to increase the residential market of Hong Kong, as well as the tight deadlines for the implementation of government plans, it is important to note that this technology will be widely used in the implementation of projects. This is plausible since the low construction time, and high factory requirements for the quality of the modules will allow the tasks to be carried out properly. However, for the full use of this technology, it is necessary to adapt the regulatory legal framework and consolidate the necessary provisions regarding modular construction.

Theoretical Context

The core theoretical context of the project is centered around robust optimization applied to KWC in regard to its integral transportation and logistical challenges. Robustness is a state in which the characteristics of a system, process, or product are insensitive to the effects of destabilizing environmental or transportation factors. Robust optimization makes it possible to develop a framework that is stable to variations in disruptive factors. The procedure is applicable to both designing a new module shipping system and enhancing the existing one on the basis of the resources available to KWG. The robust optimization method can be utilized to improve the module transportation process’s parameters with minimal conduction of trials, which makes it suitable for the case study format on an already operating business.

Experiments can be performed in a multitude of methods, which can be divided into two major categories. The first one is done through theoretical modeling or optimization on the basis of collected data within the relevance range. Such modeling is applicable if there is a comprehensive model of the process that links the quality-based indicator with the core measurable parameters affecting the problem. However, alternatively, an action research project can be conducted with a physical simulation as well, which is more accurate in identifying unaccounted factors, but costlier as a result. The given project will focus on the former due to its practicality and applicability as well as constraints associated with the physical approach.

When it comes to the robust optimization process, one of the first measures includes allocating all input variables capable of explaining the result of an experiment within a categorical matrix. These can be divided into two core groups where the first category is comprised of elements that KWC manages. However, the second group consists of the parameters the company cannot impact or influence. For example, KWC might not be able to decrease the scale of each module due to its implications on the structural integrity of the final building. Thus, the input variables with the values change in a corresponding manner during the action research making them control parameters. Factors outside the company’s control can be referred to as noise or disruptive factors (Yanikoglu, 2018). At the stage of selecting noise factors and control parameters, it is necessary to identify them correctly. The method is based on the use of orthogonal matrices, which are a minimal set of experiments with different combinations of parameter levels.

Thus, the variation of the set of values of the objective function simulates the output of the values of the quality index for the given control parameters. The set of observations for each set of parameters is used to calculate a criterion called the output statistic. The calculated values of the output statistics are used to estimate the optimal values of the control parameters. The signal-to-noise ratio SN is used as the output statistic (Bertsimas, Gupta, and Kallus, 2018). This ratio is expressed through the standard deviation from the middle of the tolerance field of the quality indicator. In order to interpret the experimental results of a robust experiment, an analysis of variance is used. Analysis of variance is a numerical approach used to analyze the individual influence of independent variables on an objective function. The purpose of the analysis is to determine the value of the test for each control parameter. The factor with the smallest p-value has the greatest effect on the output characteristic.

A robust experiment is associated with two matrices, and they include a control parameter matrix and a noise factor matrix. The matrix of control parameters determines their experimental values. Its columns represent control parameters, and its rows represent various combinations of parameter values. The noise factor matrix determines the experimental values of the noise factors. Its columns represent noise factors, and its rows represent various combinations of noise factor values (Yanikoglu, 2018). Each row of the control parameter matrix is combined with all rows of the noise factors matrix. The implemented robust design plan is the product of the matrix of control parameters and the matrix of noise factors.

Practical Context

The creation of more complex units, assemblies, and mechanisms with a new level of consumer properties and the desire to minimize the costs and risks of transporting modules determine the trend of constantly tightening requirements for quality indicators of modular products. In this regard, for modular construction enterprises, the issues of ensuring a specific level of module properties of new types of systems are vital. Delivery of modular products is characterized by a wide range of standard sizes, individual characteristics of each product, as well as multi-stage production (Agha et al., 2021). Under these conditions, it is effective to manage quality already at the stage of technology design. When designing technological processes for hardware production, there are always inaccurate initial data associated with the uncertainty of environmental conditions, the uneven quality of raw materials, and the imperfection of technological equipment. Under the conditions of the existing parametric uncertainty, the process control must be sustainable, and thus, the model must provide a given level of quality indicators.

The project proposes a methodology for designing modular transportation framework processes based on robust optimization. The robust approach can be effectively used in relation to the development of new and improvement of existing processes for the delivery of modular products. The practical application of this methodology will significantly reduce the time for making technological decisions to ensure a given level of quality of the finalized system (Yanıkoğlu, Gorissen, and Hertog, 2019). The use of robust experiment planning makes it possible to establish the stability of quality indicators to various types of noise impacts at the design stage of the technological process.

Existing methodologies for designing modular transportation processes are not flexible enough since they require a large amount of statistical data for analysis and decision-making. The factors do not allow quality control at the stage of technology development, thereby slowing down the exit to the stage of mass production. In this regard, today, an urgent task is to develop a modular transportation design methodology that takes into account the parametric uncertainty of the initial data, which makes it possible to improve the efficiency of delivery, as well as reduce the cost of technology design.

Research Value

The potential value of the research is manifested in the fact that it will establish a better way of addressing the housing problem since it is a major challenge in the modern world. It is especially true when it comes to highly urbanized cities with limited land. The price of homes is constantly increasing, and such a rise makes apartments and houses unreachable for average consumers. Therefore, any form of optimization of risks in the supply chain and logistics of MIC can lead to a reduction in costs for such construction businesses. In return, the home prices of well-optimized enterprises can be lowered since the price reduction is among the strongest advantages of modular construction, which plays a role in the industry’s competitiveness framework.

There is also a significant economic value in the research because it is practical and case-based. In other words, the applicability of the outcomes is high since real-life examples will be utilized for research purposes as data entries. The hypothesis of robust optimization is measured on data derived from MIC organizations, and any improvement is indicative of existing supply chain and logistics flaws. Therefore, the beneficiaries are both MIC companies and home buyers. The former will be able to have a potential solution to their supply chain, logistics, and transportation risks through better optimization. The latter group will be able to buy more affordable homes to improve their quality of life and financial position. In addition, one of the strengths of modular construction is the speed of construction because the modules are premade off-site prior to their assembly on-site. This, the rate of home building in an urbanized area will be able to increase and even keep pace with the increasing demand.

Research Currency

The research’s currency and timeliness are relevant due to the precise focus on a single organization’s one category of business with a narrower focus on a specific issue of modular transportation. In addition, the currency is further substantiated by the fact that the data complementary to the project has been derived from publications or internal knowledge since 2017 with no utilization of any information from the previous dates. The combined use of newly published literature and up-to-date data on modular construction alongside the stakeholder’s endeavors ensures that the research currency is kept timely.

Project Stakeholder: King Wai Group

The core stakeholder and the organization of interest for the project are King Wai Group, a Hong Kong-based multinational company with several subsidiaries across the Asian continent. Its products and services can be divided into four major categories. These include real estate, general insurance, life insurance, and asset management (KWI, 2022). The given action project is primarily concerned with King Wai Group’s real estate segment, where modular construction is already being developed and implemented as a more effective method of construction. However, in all the construction endeavors managed by the company, transportation of the modules remains the core issue, which requires an effective and superior solution.

Report Outline

The given action project report can be navigated through the Table of Contents after the title page for a reader’s convenience. The paper begins with an introduction section comprised of important information about the core stakeholder or organization of interest, the issue identification, theoretical framework, theoretical and practical contexts, and definitions of the modular construction. The section is followed by the narrative, and critical literature review, where applicable, a recent and relevant body of credible literature is presented, divided into subsections in accordance with the subtopics presented. The methodology and findings are provided subsequently to demonstrate the overall outcome and analysis of the project’s results. The last part of the report includes a conclusion with recommendations derived from the acquired knowledge, insights, and understandings.

Research Questions, Aims & Objectives

Research Aims

The research is primarily focused on optimizing the transportation and supply chain elements of Modular Integrated Construction. The aim is to identify the most efficient and resilient method of manufacturing, storing, delivering, and transportation modules in accordance with the schedule with minimum disturbances, delays, damages, and costs. It is important to note that modular construction is a framework under which separate modules of a building are constructed off-site. These modules are later transported to the construction site to be assembled into an apartment, house, or any other building. The key benefits include standardization, lowered costs, and speed of construction. In other words, a modular construction method can build a building cheaper and quicker. However, since the standardization and economies of scale are prime reasons for these strengths of MIC, customization is minimal. Therefore, the research objective is to apply a robust optimization model for the currently existing MIC organizations to assess how the logistics and supply chain can be optimized under the existing conditions.

Research Objectives

The research objectives are as follows:

- Explore the intrinsic and inherent strengths of modular construction.

- Examine the intricate details of the supply chain and transportation aspects of MC.

- Research effective ways to address supply chain and transportation issues.

- Develop a comprehensive framework for practical application of the identified method in a project-based plan.

Research Questions

The research questions are as follows:

- What are the advantages of modular construction?

- Why supply chain and transportation aspects of MC are problematic?

- What are effective ways to address supply chain and transportation issues?

Literature Review

Introduction to the Review

One of the key aspects of any comprehensive and extensive research endeavor includes a systematic literature review on the topic. The given section is a result of the narrative literature review search since it is not pursuant of the knowledge gap identification but rather seeks to extract practical information about the subject in a critical manner (Saunders, Lewis, and Thornhill, 2016). The commonly known scholarly source search engines, such as Google Scholar, as well as specific credible journal websites, were searched with the use of keywords. The latter consisted of but was not limited to words and phrases, such as ‘modular construction,’ ‘modular integrated construction,’ ‘modular construction transportation,’ ‘robust optimization,’ ‘module logistics,’ and others.

In addition, specialized books, textbooks, and online documents were consulted to obtain more technical knowledge on the specifics of the methodology in order to apply it to the King Wai Group’s case. The literature review is solely interested in the recent body of knowledge, which is why all searches were constrained, with the earliest year of publication being 2017. Any material older than the provided date was deemed outdated and irrelevant in order to ensure that only fresh and recent developments, studies, and writings were built into the review.

The literature review begins with the general topic of modular construction, followed by its assessment in terms of advantages in order to provide a strong justification for why the framework is critical despite its existing challenges. The subsequent subsections address the problems and transportation-related risks in order to ensure a thorough analysis within the context of the project. The topics of MIC and modular logistics are highly intertwined and interconnected, mandating an in-depth literature review for both.

Modular Construction: Essence

Modular construction is a process in which a building is built off-site, under the controlled conditions of a factory, using the same materials, to the same codes and standards as traditional structures, but about twice as fast. Buildings are manufactured in modules that, when assembled on site, reflect the identical design intent and characteristics of the most complex site-built facility. A critical perspective reveals that one of the main advantages of using modular construction methods over traditional ones is that the work can generally be completed much faster, suffering from much fewer delays than a conventional project. It is stated that “modular construction is considered a game-changing technology since it offers faster construction, safer manufacturing, better quality control, and lower environmental impacts compared with the traditional onsite construction” (Thai, Ngo, and Uy, 2020, p. 1265). Studies have shown that modular projects are completed 50% faster than traditional construction methods (Innella, Arashpour, and Bai, 2019). This reliability can be very helpful in successful project planning. The weather does not interfere with the work of the construction company, so there are no delays in this process either.

Research Question One: Optimization Aspect of MC

Process optimization not only reduces the time it takes to complete a project, and it reduces cost. Minimizing the deliveries, delays, and waste materials that are typically associated with building design and construction means that choosing a modular design can cut costs by up to 20% (Wrigley et al., 2018). It is stated that it is “a process in which a building is constructed off-site, under controlled plant conditions, using the same materials and designing to the same codes … but in about half the time” (Modular Building Institute, 2022, para. 1). Traditional construction produces a huge amount of waste, most of which ends up in landfills, polluting the environment. Thus, “shifting construction away from traditional sites and into factories could dramatically … make a sustainable impact” (Bertram et al., 2019, para. 1). Therefore, the process is environmentally-friendly and has a higher degree of sustainability.

One needs to be aware that most benefits are inherent to modularity itself. MC’s “benefits include greater worker safety, improved productivity, increased schedule certainty, and improved cost predictability” (Cao, 2020, para. 6). Since most of the construction process takes place in a controlled facility, modular design is able to minimize the amount of waste generated and can prevent contaminants from entering the soil, air, or groundwater (Ferdous et al., 2019). By doing everything away from the project site, many of the risks of injury are reduced, not only for workers but for the general public. Falling materials or noxious fumes can cause fatal injuries, and doing a lot of work away from the site is among the many positive aspects of modular construction.

Research Question Two: Key Issues in MC and Its Problematic Elements

Modular buildings are not without gripes and problems, and each construction method has its pros and cons, but it is important to know and study the cons of these buildings. It is stated that “since modules are prefabricated in factory miles from the job site, they need to be transported either directly to the job site or staged at a place nearby and then set in place” (Real Projectives, 2019, para. 16). There are a few downsides to being aware of, and the first downside to using modular design methods can be size limitations due to shipping issues. The presence of large dimensions for transportation can be problematic (Olawumi et al., 2022). Another problem that modular buildings currently face is a lack of confidence in the quality of the objects, which leads to a decrease in the resale value (Nabi and El-Adaway, 2020). It is reported that “manufacturing and transportation restrictions can limit the size of each modular unit, which can impact room sizes” (TWI, 2019, para. 7). Thus, a critical review shows that Many financial institutions may be hesitant to lend to such a home. Banks are generally unfamiliar with the modular process of building a house and the fact that most payments must be made in advance.

Research Question Three: Current Aspects of Addressing the Issues

Today one can observe the constant evolution of new technologies in a rapidly growing world. The high rate of expansion of new forms of housing is combined with our high-tech capabilities (Bayliss and Bergin, 2020). Interest in modular buildings should definitely create a bright future for construction, and most building projects are switching to this fast, cost-effective, and sustainable building process (Swiszczowski, 2020). The research is valuable due to the relative scarcity of literature in regards to the objectives. Firstly, it is stated: that “as the supply chain constitutes linked segments, a higher degree of stability and coordination is required to facilitate the free flow of information, materials, services, and funds among project participants” (Wuni, Shen, and Mahmud, 2019, p. 142). In other words, the supply chain for MIC is a complex system, which tends to be fragile and vulnerable to disturbances and transportation risks.

Secondly, the management process of transportation patterns can be a major challenge. A study suggests that “using robust optimization, the model accounts for common causes of schedule deviations in construction sites, including inclement weather, late deliveries, labor productivity fluctuations, and crane malfunctions” (Hsu, Aurisicchio, and Angeloudis, 2019, p. 1). The size of the modules require optimization as well since they restrict their delivery. It is stated that “the size and properties of each element must be considered, to determine a transportation method that will not cause damage” (Muresan, 2020, para. 22). Thus, the source assesses supply chain elements of modular construction as well. Thirdly, the Modular Suitability Index will be used for evaluations. A critical perspective reveals that it measures five dimensions such as connections index (CI), transportation dimension index (TDI), transportation shipping distance index (TSDI), crane cost penalty index (CCPI), and concrete volume index (CVI) (Salama et al., 2017). Thus, there are three specific examples of sources that can be used in the project. Since the search procedure was based on the use of key words on Google Scholar, these particular sources were selected due to their comprehensiveness and relevance to the research questions.

Core Advantages

A characteristic feature of the recent development of construction is the expansion of the use of not only conventional, traditional, and capital buildings and structures but also unusual, non-traditional, alternative construction projects. These include premade and mobile complexes (Liew, Chua, and Dai, 2019). Existing capital construction systems have the following main disadvantages. These are long construction periods, the significant weight of structures exerting great pressure on the ground, and the impossibility of quick disassembly of elements if it is necessary to change planning solutions (Goh and Goh, 2019). In addition, it is important to note the increased financial and labor costs for the transportation of heavy elements and the lack of planning and design solutions for the transformation of the premises.

Mobile complexes eliminate these shortcomings and are characterized by the following advantages. This includes the possibility of dismantling without significant destruction of materials and rational redeployment by serial types of road, rail, air, and water transport (Loizou et al., 2021). It should be noted that this is accompanied by a rapid change in the space-planning solution, depending on the dynamics of people’s needs. There is a problem with the presence of built-in elements and the possibility of installation without the use of heavy crane equipment manually (Xu, Zayed, and Niu, 2020). However, the result is determined by the transformation of a static and unchanging artificial habitat into a new, adaptable and dynamic space.

A critical assessment of the literature reveals that in the real estate market, such key factors as reducing construction time and reducing costs come to the fore. For these goals to be achievable, developers need new technologies through which they can keep the margins of their construction projects at an acceptable level (Nabi and El-adaway, 2021). Modular housing construction is the technology through which builders will have a strong competitive advantage in the market. King Wai Group is capable of specializing in individual monolithic housing construction and, at the moment, has already been able to build a large number of socially significant objects. Nevertheless, none of the mass-produced and experimental pre-fabricated systems does fully satisfy the entire set of modern technical requirements for them (Shahtaheri et al., 2017). This includes functional, construction and technical, economic, security, and others. The existing theoretical developments lack scientifically based principles for creating new types of modules and models for their development, and no methodological basis has been created to predict their improvement in the future.

Building a house using modular construction technology can last from 1-2 days to a week. The timeline is substantially different from similar brick and concrete-based buildings (Taghaddosa, Hermannb, and Abbasi, 2018). The degree of prefabrication of buildings manufactured using modular construction technology is very high, and it is this that reduces the time required to build a house. An almost finished house arrives from the factory. It is only necessary to connect its parts and connect engineering communications to existing networks (Kamali, Hewage, and Sadiq, 2019). It is important to note the fact that the assembly of the building at the factory allows KWG to minimize the release of harmful particles polluting the environment. This is especially true for wooden structures, where it is necessary to exclude the ingress of moisture (Enshassi et al., 2019). The assembly of the building at the factory also makes it possible to eliminate the accumulation of debris in the place where the future building will stand, and it is much easier to eliminate dirt at the production site.

The next advantage of modular construction technology is the number of financial investments that must be made for its implementation. A huge disadvantage that stops many people at the stage of an idea is the large and frightening amount of money needed to build a building (Deng et al., 2017). Another advantage of modular construction technology is the ability to expand the building during operation. If suddenly there is a need to add a few more rooms to an already built building, this is not a problem for buildings built using modular construction technology. It is these factors that take into account the technology of modular construction (Hsu, Angeloudis, and Aurisicchio, 2018). If the customer has a financial opportunity to expand the building, then one can order additional modules and attach them to an already finished building. Thus, the buildings are designed with possible expansion as an option.

Global Context

The following literature review will be based on grey sources to add more context and highlight the international trends in regards to the modular construction as a concept and practical endeavor. Globally, modular buildings in their application cover a wide area such as from industrial and factory buildings to residential tourist bases, mobile offices, and commercial city pavilions. The structural features and technical characteristics of the materials of mobile structures allow them to be built temporarily, dismantled, or, if necessary, transferred to another location, which categorically increases the demand for such buildings in the world market (Liu et al., 2018). Choosing a foundation for a modular building is not an easy decision, as the wrong construction approach can detract from the intense advantage of these structures over passive buildings.

The global practice of using modular construction technologies makes it possible to determine the advantages and disadvantages of a particular technology. The advantages of modular construction technologies are the aggregation of all types of work and the preliminary ensuring that technological indicators comply with regulatory requirements. It is important to note the reduction in the number of possible threats of physical or mechanical damage when using the parallel-series construction method (Roy, 2017). There is a factor in reducing the labor costs of construction workers during the direct construction of a building or structure due to the preliminary preparation of structural modules, which is a consequence of reducing the cost and duration of execution (Subramanya, Kermanshachi, and Rouhanizadeh, 2020). In addition, an important advantage is the reduction of the negative impact on the environment.

Potential Issues

The disadvantages include the fact that the necessary financial investments are preliminary, and they are carried out before the start of construction work. In the current construction market, there is an urgent need to modernize the production capacities and technological base of contractors (Subramanya, Kermanshachi, and Rouhanizadeh, 2020). Any development is permanent in the field of modular construction, and measures must be taken to reduce the duration of specific production operations and reduce the entire production cycle (Yang et al., 2021). One of the main tasks in the implementation of the idea of modular construction is to find the best ways to deliver these structures to the pre-assembly site.

Mobility and versatility are characteristic and significant features of modular buildings. Although they fuel the interest of specialists in experiments, at the same time, they often provoke questions among stakeholders. Based on the foregoing, it can be noted that the main goal of the above framework is the relevance of the desire of the consumer, to explain the characteristic features of modular buildings and the specific advantage of a prefabricated foundation (Lee and Hyun, 2019). It is important not only to highlight the definition and functions of this type of foundation but also to talk about its advantages, disadvantages, and correctness in choosing specifically for the construction of modular houses.

Transportation

The feature of the type of mobility is responsible for the relocation of the modular building, the design features of which provide such an opportunity. The sign is divided into two types such as container and collapsible (Pervez, Ali, and Petrillo, 2021). The mobile container building consists of a block container of full factory readiness, relocated on any suitable vehicles, including on its own running gear. Buildings of collapsible type of mobility consist of separate block containers, flat and linear objects, and their combinations, and further, they are assembled at the place of operation. There are a number of signs of mobile buildings characterized by the degree and type of climatic impact and load on the structural system. In order to comply with all norms and regulations, it is important that the technical solutions in the process of building a modular building are based on this feature (Almashaqbeh and El-Rayes, 2021). The category is subdivided into the following criteria such as outdoor design temperature and wind load effects.

An alternative classification category is a sign of the functional purpose of modular buildings, and this has fairly extensive systematics and is based on the similarity of the application of a certain type of building and the area in which it is used. There are several categories of modular buildings, such as industrial buildings, which are considered to be one of the earliest applications of modular buildings on the market. These include various repair shops, maintenance and repair stations, laboratories, installations, and boiler rooms. For example, warehouse modular buildings are responsible for providing premises for warehouses, pantries, and various tool-distributing standard sets of mechanisms. Auxiliary buildings are buildings of a small area oriented to a narrowly focused functionality. These are control rooms, buildings for cultural events, dressing rooms, latrines, dispensing canteens, and first-aid post-isolations (Lee and Lee, 2021). One of the new and growing areas is modular residential buildings, which category includes single-family, multi-family living quarters, and dormitories. Public modular buildings include many municipal and socially used premises, schools, first-aid posts, hospitals, mixed trade shops, and consumer service centers.

Based on the features described above, it can be noted that modular construction is used everywhere, taking into account climatic and territorial features, covers many areas of production, domestic and industrial, has many functional purposes, and the introduction of this type of construction has been developing in the modern world continuously for the past few years. In accordance with the current requirements of the legislation, the manufacture of blocks for the construction of modular buildings is currently carried out by manufacturers in accordance with the technical specifications for their products, approved in the prescribed manner (Almashaqbeh and El-Rayes, 2021). In order to improve the quality of the design work performed, and reduce the time and cost of design, standard solutions based on unified methods and technologies are used.

Alternative Problem Identification

Although the body of literature and the value chain analysis clearly demonstrates that the core risk management problem is found in the module delivery stage, an alternative assessment and theorization should not be dismissed. It is possible that another explanation could be found in the module manufacturing itself, which makes it highly vulnerable and fragile to transportation. In other words, the high-risk zone should be highlighted in the first step of the value chain in Figure 1 above instead of the third stage. However, such an explanation is still less plausible to the transportation issue since module size and module unity are critical for modular construction. Further dividing a module into smaller submodules would hinder the structural integrity of the final building (Lee and Kim, 2017). In other words, the modules should not be and cannot be scaled down or made more resilient without compromising the safety and cost efficiency of the final building.

Action Research Design & Methodology

Action Research Defined: Relevance

Action research or action project research is a unique method of studying a specific topic with a practical implication behind it. It can be defined as “an approach in which the action researcher and a client collaborate in the diagnosis of the problem and in the development of a solution based on the diagnosis” (Business Research Methodology, 2022, para. 1). Therefore, one of the key elements of action research is a presence of the collaborator aspect between a researcher and the organization of interest. Although action research is already a subfield of general research, the given project is specifically concerned with critical action research. The latter is “a specific type of action research that adopts a critical approach towards business processes and aims for improvements” (Business Research Methodology, 2022, para. 5). The critical action research framework is highly relevant to KWG’s case since the project seeks to improve its modular integrated construction processes by making its module transportation measures more resilient and robust to risk factors.

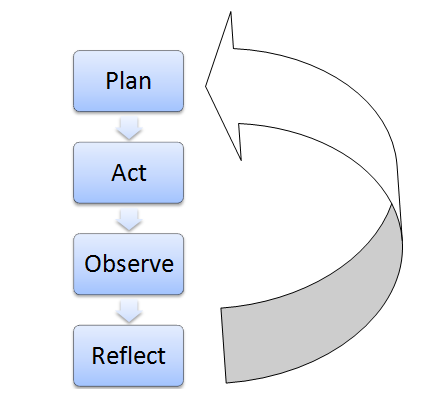

The action project research is conducted in four major steps, illustrated in Figure 2 below. The first phase is about planning the research design and methodology, gathering resources, and findings relevant frameworks. The second phase of action involves applying the identified systems, such as robust optimization, to the stakeholder of interest. The outcomes are observed in the third phase in order to proceed with conclusions in the last reflective step. The conclusions and recommendations comprise the reflection of the action project.

Research Design

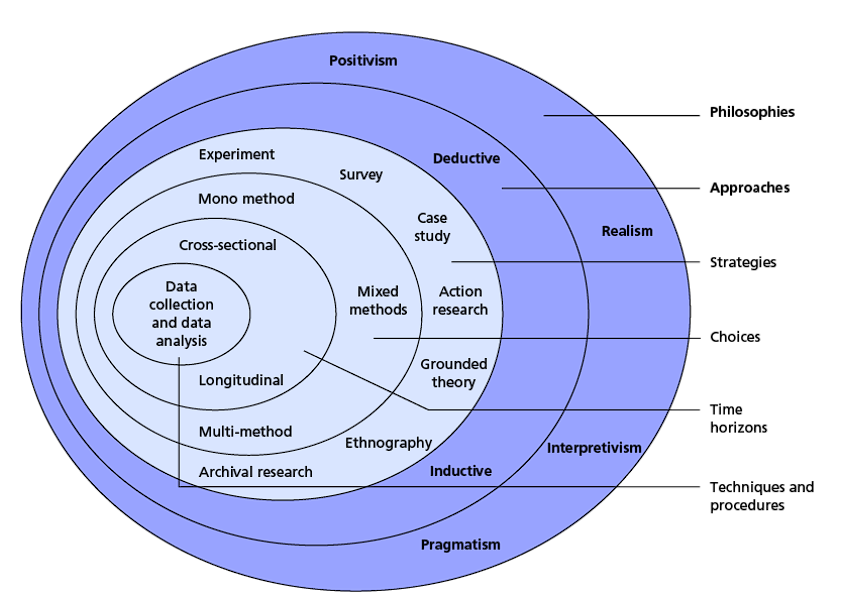

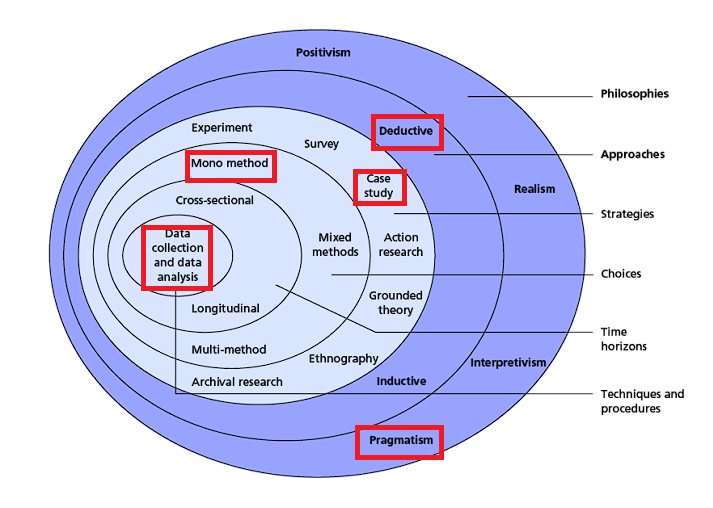

The chosen methodology components include research philosophy, approach, and design. In the case of the former, the identified philosophy is pragmatism because the project is to be conducted on real-life local MIC construction companies (Saunders, Lewis, and Thornhill, 2016). As indicated in the title of the project, this is an exploratory case study. The approach is deductive since the hypothesis is based on robust optimization providing a better supply chain and logistics with fewer risk factors in MIC. The design is based on a case study, where the focus is put on MIC organizations. Both the research design and philosophy complement each other because the core of the research is the practicality of the observations, analyses, and recommendations. The data collection is based on quantitative mono-method research, which is expressed in a numerical form (Saunders, Lewis, and Thornhill, 2016). It will be cross The selection is due to the methodology’s reliance on robust optimization as well as the use of the Modular Suitability Index or MSI. The research onion framework is shown in Figure 3 below.

Methodology

The data is to be collected from the relevant government departments as well as specific MIC organizations or businesses. The nature of the data will include variables such as time of delivery, average module weight and dimensions, the mean route distances, the vehicle number, average speed, and total module need for each site. These metrics will enable a greater understanding of key chokepoints and bottlenecks of the supply chain and transportation. Since the organization of interest is already selected, the sampling principle will not be randomized, but it will be large enough to make conclusive statements. Depending on the availability and accessibility of data, the case study will contain at least one case from KWG.

Potential Issues

Some potential problems might arise in regards to data access constraints due to the company’s unwillingness to disclose all essential information. The data analysis will be primarily based on a robust optimization model. It was chosen because “robust optimization is an emerging area in research that allows addressing different optimization problems and specifically industrial optimization problems where there is a degree of uncertainty in some of the variables” (Ser and Osaba, 2018, p. 2). The core limitation of the research project is that it might have narrow applicability for other construction organizations seeking to use MC since it is solely based on KWG’s case. There are no major ethical considerations to be made since both the university and organization approval was received, and there are no human subjects. Confidentiality and sensitivity of data and legal and reputational issues will be avoided due to the strict use of approved information. The research onion with the corresponding selection diagram is shown in Figure 2 below.

Research Philosophy and Justification

The research onion with a diagram of the approach is shown in Figure 4 below. It is important to note that doing action research in one’s own organization requires the identification of a clear research pathway toward the methods utilized justified by the corresponding subject or topic (Coghlan and Brannick, 2009). Therefore, the following subsections will primarily discuss the reasoning behind the selection for each layer of the research onion in accordance with the diagram in Figure 4.

Pragmatism

The first most outer layer of the research onion is pragmatism, which is selected primarily due to the main focus of the project being put on practical aspects of the analysis. It is stated that for pragmatism, “the tests of validity it applies to research philosophies are rooted in practical outcomes for human endeavors (such as businesses), and not in layers of argument derived from the philosophical tradition” (MBA, 2019, p. 9). In other words, it “supports the ‘contingency’ approach; select a research philosophy that matches your research aims, and helps deliver the practical outcomes your research is attempting to generate” (MBA, 2019, p. 9). The core objective of pragmatism is to derive conclusions and recommendations from practical perspectives instead of excessively focusing on the philosophy itself.

Deductive Reasoning

When it comes to the reasoning approaches, there are two major ways to conduct such an effort. One can reason inductively by beginning with pure factual data and proceeding with a theory development on the latter. Alternatively, a researcher can create or design a theory first and subsequently apply it to the relevant facts in order to observe if the theory is substantiated by the factual information or refuted by them (MBA, 2019). The given action research project utilizes deductive reasoning primarily due to the more practicality of deduction since an organization such as KWG is complex and has many facts to build upon. Thus, it is more effective to apply a specific theoretical framework first and extract the relevant data for further substantiation or rebuttal.

Case Study

The action research project is solely interested in assessing and solving the issues affecting King Wai Group specifically. It is stated that a case study “aims to gain in-depth insight into a single situation, organization, group of people, etc. It may have strong elements of description and exploration, but may also use more systematic design elements” (MBA, 2019, p. 16). Since the project is focused on a single company, the case study is the most appropriate and relevant selection for the third layer of the research onion framework.

Mono Method: Quantitative

The fourth layer of the onion is the mono method pertaining to a quantitative approach, which leads to the center of the framework on data collection and analysis. It is stated that “quantitative research focuses on the collection and analysis of data that can be represented through processes of counting and measurement, or through human judgments expressed in the numerical form” (MBA, 2019, p. 9). The theoretical basis for the identified issue on modular transportation requires robust optimization, which is a highly numerical form of assessment and evaluation.

Project Plan

The key tasks include preparation, project initiation, and project execution, and each one will require 18 days, four months, and 26 days, respectively. A detailed Gantt Chart can be accessed in Table 1 below. Only one to two-day float or variability will be allowed, except for tasks with critical deadlines. The key milestones include feedback from the supervisor after a major set of tasks is completed and approved by the instructor. The tasks are broken down in such a manner because they enable detailed tracking of the progress (Walliman, 2011). The allocated periods are appropriate since they include an account for unexpected barriers, and thus, all variations are included within the set timelines. It should be noted that the upcoming elements might be completed before the stated deadlines.

Results and Discussion

Findings

The analysis of the current modular construction systems utilized at KWC indicates the use of six warehousing units at the outer boundaries of the city with several construction sites located within the central regions. The average distance from the warehousing units storing the modules to construction sites ranges from 15 km to 30 km. The transportation is further complicated by the fact that the roadmap to the destination might require circling the city, extending the overall distance by almost 50 km. Table 2 below shows the company’s approved data on warehousing unit specifications.

Moreover, modules are categorized in accordance with their model and utility within the construction process. Module group X is comprised of foundation modules, which are required to be delivered before any other category since the foundation is built first. Module groups A and B consist of the building itself, which are further differentiated in accordance with their typologies, such as walls, internal planning, floor, and orientation. For example, Figure 5 below shows a typical floor plan comprised of several modules from the A and B categories.

The identified factors and standard floor plan requirements were used as core parameters for robust optimization processing of the acquired data points. The Robust Optimization Made Easy, or ROME software, was used to conduct the modeling and optimal model design for KWG’s case. The results or optimal model with the focus on risk aversion and minimization is shown in Table 3 below. The findings indicate the need for a multi-stage planning process, where both module groups A and B are assembled simultaneously, while module X is kept within the current system of module shipping. In other words, foundation modules still need to be delivered first in bulk, and thus, there is no optimized model for X modules being co-delivered in the findings.

However, the table shows that a 4-week period is the most effective and risk-averse measure to minimize the transportation risks and module damages, which means that the current company’s three-week timeline of delivery is suboptimal for risk control. The outcome is that loads are reduced, and both module types are delivered with a specific proportion depending on the location, which differs between factory, warehouse, or construction site. The model shows that the robustness requires warehouses to be fully or almost fully loaded, which is seconded by the construction site. The factory itself should not keep any modules for later delivery as it delays the shipping and causes other risk factors to be more expensive as a result. The factory inventory must be kept at zero, whereas the production quantity mandates the manufacturing rate of 2 for module B and 6-8 for module A per week.

Disruptions: Work, Weather, and Transportation

Despite the fact that the transportation of modules poses a major risk for KWG, the risk factors can be further divided into three subtypes. Firstly, the modeling, literature review, and internal company data assessment showed that worker efficiency is still an issue requiring consideration. Although modular construction offers a novel way to introduce higher efficiency of assembly and manufacturing through offsite constrictions, the operations remain highly reliant on manual work and machinery. Therefore, labor productivity is critical even for the modular framework indicating the importance of ensuring work efficiency. Unsafe, ineffective, or poorly executed work protocols can cause disruptions in the delivery process by damaging the modules before or at the beginning of the shipping process.

Secondly, weather-related conditions play a significant role in causing disruptions within the module transportation chain networks. Strong winds, rainfall, heat, or even floods can severely influence the risk management capabilities of KWG in regard to its module shipping process. Therefore, the assembly rate needs to be reduced in accordance with weather forecasts on the basis of rainfall or wind speed metrics. For example, the robust optimization and internal company analysis revealed that high rainfall days with a probability of around 85% for 5 mm rainfalls could cause disruptions for 35 modules. The latter number can additionally be affected by strong winds with speeds up to 35 km per hour. Therefore, the correct course of action would be to account for weather forecasts or shift towards container-based module transportation, where the latter will require some additional investments.

Thirdly, the transportation itself is a disruptive factor, which is linked to the idleness of the trucks, fuel costs, and accidental crashes. Although the latter is the least probable aspect, it incurs the highest costs due to additional delays. In addition, the idleness factor of each transportation unit is estimated to cost around $500 per hour, which is significant if the system is non-optimized and inefficient. The fuel costs apply constant financial pressure, and one might consider as an unavoidable operational expense. However, more effective route planning alongside more fuel-efficient transportation units can save a significant amount of resources for KWG.

Discussion

The practice of using economic and mathematical methods has formed two concepts for constructing an optimal plan for the functioning of the transport system. The first one describes the planning object as a single model necessary for building, in particular, modular transport module groups. The second concept considers the issues of constructing an optimal plan for the functioning of the transport network by describing the planning object through a system of the factory-warehouse-site system for planning the operation of individual links of the transport infrastructure along the entire route of the locations.

Thus, on the basis of the factory-warehouse-site transport systems, a multi-stage planning process of the transportation itself can be organized, for which it is necessary to consider the production capabilities of the modes of transport and their transshipment nodes on the delivery route in conjunction with adjacent modes of transport. When organizing several routes, each of them is evaluated separately in order to then choose one in which there is no need to revise the parameters of its usefulness. The issues of assessing the capabilities of means of transport and routing modules through cargo flows are interrelated. On the one hand, routing introduces restrictions that determine the throughput and other parameters, and on the other hand, it is the route that characterizes the speed of delivery of modules (Wallance, 2021). An assessment of the possibility of a joint solution to the previously mentioned issues needs to be integrated on the basis of an analysis of the elements of the transport infrastructure of the existing transport space. Thus, the transport space of modules includes the union of interconnected transport elements, from which a certain number of alternative transport systems can be formed.

The criteria for the optimal functioning of the considered factory-warehouse-site transport system can be the speed of delivery, the distance of delivery of modules deep into the site, the time spent on transportation, and the cost of transport services. At the same time, the main indicator of the usefulness of introducing new means of enlarging premade modules is the possibility of increasing the shoulder for delivering modules using robust technologies, and hence, accordingly, other advantages of this most advanced method of transporting goods.

The transport services market assumes a multivariate supply of works and services related to the transportation of goods. Therefore, the determination of the possibilities of the necessary technical and economic indicators of potential transport systems of modules is a search process since only it assumes compliance with the result obtained or the requirement of the best indicator. For example, the cost of transporting a combined batch of modules up to the maximum possibility of using a linear pattern is lower than transporting the same batch of cargo in in-container modules (Wallance, 2021). However, the delivery of modules through this ensures transportation over longer distances without additional reloading using a set of robust technologies. At the same time, after the expiration of the term of use of the linear container, the combined batch of modules can follow the route in a packaged form, which will lead to an increase in the cost of such an organization of transportation.

Risk Management

Supply chain and MIC risks are diverse, and for the adoption of effective management methods, they should be divided into categories depending on the classification feature. There are external and internal, permanent and temporary, insured and non-insurable risks, and systematic and specific risks. These can be risks as a single link in the logistics system, such as planning risks, transportation risks, storage risks, and risks of interaction with suppliers, as well as risks of the logistics system as a whole. According to the degree of impact, the scale of logistical risks starts from zero, minimal, acceptable, and ends with critical and catastrophic ones. With respect to the results of the logistics activities of the system, commercial, technical, environmental risks, risks of loss of property, and others are distinguished. The functioning of the supply chain is additionally affected by sanctions pressure in the world. There are restrictions on the capacity of transport capacities, rising fuel prices, an imbalance in supply and demand, a gap in business processes, macroeconomic instability, and currency risks. Restoring the work of all the logistics links in the chain will require a lot of time and financial resources.

Despite the shortcomings of the quantitative models used for risk assessment, their potential value in implementing an effective corporate risk management function should be recognized. Due to the high degree of subjectivity in risk assessments, risk management is more of an art than a science. Such a judgment begins with the recognition that, among many management disciplines, risk management is one where measurement is especially difficult and, indeed, a source of problems in itself. Measurement usually involves an attempt to quantify events or phenomena that have already happened or are currently happening. However, risk management takes into account future events that have not yet occurred and may never occur. In many, if not most, cases involving risk management, completely objective measurement is clearly not possible. Thus, a significant element of subjectivity and personal judgment should not be the part that dominates the analysis in such cases.

Conclusion

In conclusion, King Wai Group is a large enterprise operating in several markets, among which is the modular construction business. The action project research was a case study utilizing deduction and pragmatism as its core research philosophies due to its applicability to KWG’s situation. Only the mono-method of quantitative data was used due to the inherent numerical nature of the issue of transportation. The key theoretical framework was robust optimization, which is mainly used to ensure a system becomes resilient to disruptive risk factors.

The extensive literature review revealed that modular construction has a wide range of advantages over standard purely onsite construction frameworks primarily due to higher efficiency, speed of construction, and fewer costs. The result is that homebuyers can purchase more affordable and quickly built homes, which offers substantial market competitiveness to the builder. However, one of the most problematic aspects of modular construction, which is affecting KWG as well, is module transportation or shipping. Modules are large units built at a great distance from the construction site, which need to be transported safely and quickly. One of the main risks includes module damages and costs of delays, which can hinder the modular framework’s advantageousness severely. The vulnerability of modular transportation requires superior risk management systems of delivery, which is why the given action project research utilized a robust optimization model to KWG.

The findings indicate that KWG’s current module transportation system is suboptimal for risk aversion. The model showed that the framework with minimal risk is to load the warehouses and ensure that factory inventories are kept close to zero. It additionally promoted a multi-planning process, where both categories of modules A and B are assembled and delivered simultaneously at differential rates and proportions. The optimization indicated that the timeline of the entire delivery process requires extending the existing three-week schedule to four weeks in order to reduce the general load of transportation units. Three major disruptive factors were identified through the review of literature, model, and company data, which include work efficiency, weather, and transportation itself.

Recommendations

On the basis of the findings, discussion, and critical reflections obtained through the literature, robust optimization, and internal company data, five key recommendations can be made as follows:

- KWG should utilize warehouses to the maximum capacity intensifying the delivery process between the warehouse units and construction sites.

- KWG should keep the factory inventory close to zero in order to ensure maximum efficiency and minimum transportation vulnerability.

- KWG should invest in closed specialized container trucks designed for module transportations in order to remove the weather-related disruption almost completely due to their substantial impact on risk management.

- KWG should minimize idleness and plan routes to the construction sites with consideration of fuel and idleness costs.

- KWG should ensure the work efficiency at the factory itself alongside the multi-planning process, where modules A and B are made and shipped simultaneously at different rates.

It should be noted that logistical risks have a mostly negative outcome, which has a strong impact on the stability and efficiency of the economic system. This emphasizes the importance of system management tools as a whole, and logistics risks are a broad category of threats that may arise in individual links of the logistics chain and have their own characteristics and specifics. Under conditions of uncertainty, the sustainability and efficiency of the logistics system will depend on the right risk management tools and a more accurate assessment of its level. The right steps in risk management will make the system more transparent and flexible to changing external conditions.

At the same time, some risk management systems adhere to the framework of quantitative risk minimization. The most important role of the corporate risk management function is to identify and then measure risks. Such risk metrics rely on their ability to express risks in the form of statistical distributions, including correlations between them, for the use of systems in specific cases. This is a comparison of the expected results of risky alternatives and an assessment of the impact of risky investments on the cost and risk level of the entire portfolio of transport assets of the enterprise. Comparative analysis of the company’s total exposure to risk with its risk tolerance is important. The future studies in the area of interest will focus on the applicability of robust optimization with the use of primary research frameworks.

References

Agha, A. et al. (2021) ‘Modular construction in the United Kingdom housing sector: barriers and implications’, Journal of Architectural Engineering Technology, 10(2), pp. 236–244. Web.

Almashaqbeh, M., and El-Rayes, K. (2021) ‘Optimizing the modularization of floor plans in modular construction projects’, Journal of Building Engineering, 39, p. 102316. Web.

Bayliss, S. and Bergin, R. (2020) The modular housing handbook. London: RIBA Publishing.

Bertram, N. et al. (2019) Modular construction: from projects to products. Web.

Bertsimas, D., Gupta, V., and Kallus, N. (2018) ‘Data-driven robust optimization’, Mathematical Programming, 167, pp. 235–292. Web.

Business Research Methodology. (2022) Action research. Web.

Cao, L. (2020) Why choose modular construction? Web.

Coghlan, D., and Brannick, T. (2009) Doing action research in your own organization. Newbury Park: SAGE Publications.

Deng, E. F. et al. (2017) ‘Analytical and numerical studies on steel columns with novel connections in modular construction’, International Journal of Steel Structures, 17, pp. 1613–1626. Web.

Enshassi, M. S. A. et al. (2019) ‘Integrated risk management framework for tolerance-based mitigation strategy decision support in modular construction projects’, Journal of Management in Engineering, 35(4), pp. 1-9. Web.

Ferdous, W. et al. (2019) ‘New advancements, challenges and opportunities of multi-storey modular buildings – a state-of-the-art review’, Engineering Structures, 183, 883-893. Web.

Goh, M., and Goh, Y. M. (2019) ‘Lean production theory-based simulation of modular construction processes’, Automation in Construction, 101, pp. 227-244. Web.

Hsu, P. Y., Angeloudis, P., and Aurisicchio, M. (2018) ‘Optimal logistics planning for modular construction using two-stage stochastic programming’, Automation in Construction, 94, pp. 47-61. Web.

Hsu, P. Y., Aurisicchio, M., and Angeloudis, P. (2019) ‘Risk-averse supply chain for modular construction projects’, Automation in Construction, 106, pp. 1-12. Web.

Innella, F., Arashpour, M., and Bai, Y. (2019) ‘Lean methodologies and techniques for modular construction: chronological and critical review’, Journal of Construction Engineering and Management, 145(12), 1-18. Web.

Kamali, K., Hewage, K., and Sadiq, R. (2019) ‘Conventional versus modular construction methods: a comparative cradle-to-gate LCA for residential buildings’, Energy and Buildings, 204, p. 109479. Web.

KWI. (2022) Our businesses. Web.

Lee, D., and Lee, S. H. (2021) ‘Digital twin for supply chain coordination in modular construction’, Applied Sciences, 11(13), p. 5909. Web.

Lee, J. S., and Kim, Y. S. (2017) ‘Analysis of cost-increasing risk factors in modular construction in Korea using FMEA’, KSCE Journal of Civil Engineering, 21, pp. 1999–2010. Web.

Lee, J., and Hyun, H. (2019) ‘Multiple modular building construction project scheduling using genetic algorithms’, Journal of Construction Engineering and Management, 145(1), pp. 1-8. Web.

Liew, J., Chua, Y., and Dai, Z. (2019) ‘Steel concrete composite systems for modular construction of high-rise buildings’, Structures, 21, pp. 135-149. Web.

Liu, Z. et al. (2018) ‘Intermodal transportation of modular structure units’, World Review of Intermodal Transportation Research, 7(2), pp. 99-123. Web.

Loizou, L. et al. (2021) ‘Quantifying advantages of modular construction: waste generation’, Buildings, 11(12), p. 622. Web.

MBA. (2019) Entrepreneurial action MOD007666: topic 3 – research methods.

Modular Building Institute. (2022) What is modular construction? Web.

Muresan, F. (2020) What is Modular Construction? Types of Modular Construction. Web.

Nabi, M. A., and El-Adaway, I. H. (2020) ‘Modular construction: determining decision-making factors and future research needs’, Journal of Management in Engineering, 36, 1-21. Web.

Nabi, M. A., and El-adaway, I. H. (2021) ‘Understanding the key risks affecting cost and schedule performance of modular construction projects’, Journal of Management in Engineering, 37(4), pp. 1-12. Web.

Olawumi, T. O. et al. (2022). ‘Automating the modular construction process: a review of digital technologies and future directions with blockchain technology’, Journal of Building Engineering, 46, 1-17. Web.

Panel Built. (2022) Prefabricated buildings | Prefab building. Web.

Pervez, H., Ali, Y., and Petrillo, A. (2021) ‘A quantitative assessment of greenhouse gas (GHG) emissions from conventional and modular construction: a case of developing country’, Journal of Cleaner Production, 294, p. 126210. Web.

Real Projectives. (2019) The advantages and challenges of modular construction. Web.

Roy, S. (2017) Consider modular plant design. Web.

Salama, T. et al. (2017) ‘Near optimum selection of module configuration for efficient modular construction’, Automation in Construction, 83, 316–329. Web.

Saunders, M., Lewis, P., and Thornhill, A. (2016) Research methods for business students. Harlow: Pearson Education.

Ser, D. J. and Osaba, E. (2018) Nature-inspired methods for stochastic, robust and dynamic optimization. London: IntechOpen.

Shahtaheri, Y. et al. (2017) ‘Managing risk in modular construction using dimensional and geometric tolerance strategies’, Automation in Construction, 83, pp. 303-315. Web.

Subramanya, K., Kermanshachi, S., and Rouhanizadeh, B. (2020) ‘Modular construction vs. traditional construction: advantages and limitations: a comparative study’, Proceedings of the Creative Construction e-Conference, 2020(12), pp. 11-19. Web.

Swiszczowski, M. (2020) What is modular construction. Web.

Taghaddosa, H., Hermannb, U., and Abbasi, A. B. (2018) ‘Automated crane planning and optimization for modular construction’, Automation in Construction, 95, pp. 219-232. Web.

Thai, H. T., Ngo, T., and Uy, B. (2020) ‘A review on modular construction for high-rise buildings’, Structures, 28, 1265-1290. Web.

TWI. (2019) What is a modular building? A guide to modular construction. Web.

Wallance, D. (2021) The future of modular architecture. London: Routledge.

Walliman, N. S. R. (2011) Your research project: designing and planning your work. Newbury Park: SAGE Publications.

Wrigley, P. A. et al. (2018) ‘Off-site modular construction and design in nuclear power: a systematic literature review’, Progress in Nuclear Energy, 134, 1-15. Web.

Wuni, I. Y., Shen, G. Q. P., and Mahmud, A. T. (2019) ‘Critical risk factors in the application of modular integrated construction: a systematic review’, International Journal of Construction Management, 22(2), pp. 133-147. Web.

Xu, Z., Zayed, T., and Niu, Y. (2020) ‘Comparative analysis of modular construction practices in mainland China, Hong Kong and Singapore’, Journal of Cleaner Production, 245, p. 118861. Web.

Yang, Y. et al. (2021) ‘Sources of uncertainties in offsite logistics of modular construction for high-rise building projects’, Journal of Management in Engineering, 37(3), pp. 1-15. Web.

Yanikoglu, I. (2018) Optimization techniques for problem solving in uncertainty. Hershey: IGI Global.

Yanıkoğlu, I., Gorissen, B. L., and Hertog, D. (2019) ‘A survey of adjustable robust optimization’, European Journal of Operational Research, 277(3), pp. 799-813. Web.