Introduction

Honda Motor Co., Ltd., hereafter referred to as Honda, is one of the leaders in the global automotive market operating in all continents. In 2019, the company produced 5,170,595 automobiles in its facilities that are located worldwide (Honda, 2020b). In 2020, the company had rather challenging times, as well as the rest of the global economy, but Honda managed to address the issues and minimise its losses, which can be illustrated by its revenue decline that reached 10.1% (Honda, 2020b). Although the company did not avoid certain negative outcomes associated with the COVID-19 pandemic, it still had considerable successes in optimising its operations, which made the pandemic-related burden less pronounced. Supply chain management was one of the spheres that made these improvements possible.

Honda Logistic Network

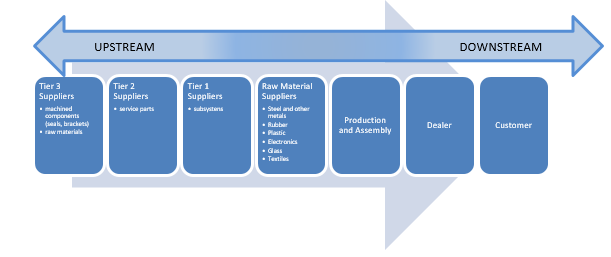

Honda has an extensive network of suppliers across the globe. For instance, in the USA, the company’s supplier network includes more than 735 companies, Honda’s purchases of materials and parts from these organisations reached almost $33 billion in 2019 (Honda, 2020b). The company had tier 1, 2, and 3 suppliers, and it also has raw materials suppliers providing their products directly to Honda plants (see Figure 1). This diverse network ensures supply chain flexibility that became critical in 2020 due to considerable restrictive quarantine measures that led to disruptions in many areas. The company has a limited number of distribution centres due to its focus on lean management that encompasses the reduction of wastes and quality improvement.

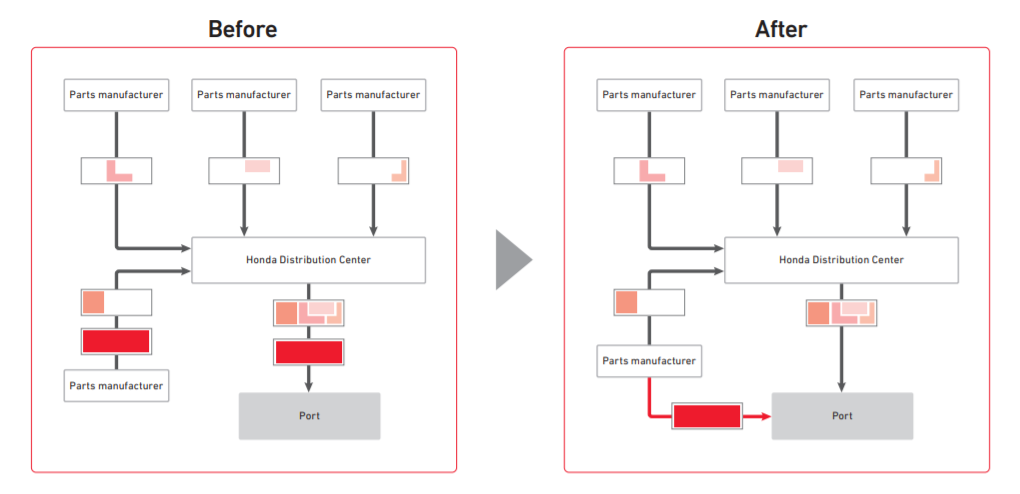

By 2020, the company managed to optimise its logistics operations by improving its supply change management (see Figure 2). Proper information flow is another component of effective supply chain management. One of the successful projects that led to improved supply organisation is the collaboration with a software developer, resulting in the introduction of the Global Supplier Network (NTT Communications, 2014). The network ensured the smooth cross-regional flow of big data through a network of data centres.

Honda employs a combination of vertical and forward integration supply chain management. On the one hand, the carmaker focuses on cooperation and collaboration with its suppliers, launching diverse projects, including but not confined to R&D programs, sustainability and corporate social responsibility initiative (Honda, 2020b). For instance, Honda launches numerous incentives aimed at the creation of a supplier network, such as annual Honda Partnership Network that connects Tier 1 suppliers of the company with existing and potential partners (Honda, 2021). On the other hand, Honda implements numerous acquisitions to ensure enhanced control of its operations worldwide.

At the same time, the vehicle manufacturer pays special attention to its customers’ needs and preferences, responding to new trends and shifts. The focus on sustainability, high quality, and design are the concepts valued by modern customers, and Honda places these values to the fore (Honda, 2020b). Therefore, the current characteristic of the company’s logistics management is the outward arc of integration.

Some of the logistics management goals are associated with environmental sustainability and consist in the reduction of CO2 emissions by 1% annually (Honda, 2020b). The company also participates in the CDP’s supply chain initiative (where companies agree to disclose data on their climate change policies) and aims at encouraging all its partners to join in. Honda developed diverse sustainability and legal requirements and standards for its partners (such as Chemical Substance Management Standard) (Honda, 2020b). Third-party audits of Honda’s suppliers were introduced in 2016 and led to considerable improvement of suppliers’ compliance and overall quality.

Importantly, the company’s glocalisation efforts and the development of an extensive network of partners enabled the company to respond to the challenges of COVID pandemic effectively. Mukherjee (2020) reported that Honda’s operations in China were disrupted during several weeks in February, but they did not have meaningful impact on processes that took place in other locations. According to BBC (2020), The company managed to continue deliveries within several weeks during December 2020 irrespective of certain freight difficulties and British ports congestion related to quarantine measures and associated worries as well as Brexit-related regulations.

The downstream network structure is also characterised by efficiency and the focus on sustainability. Honda has a network of dealers and sells its products directly to its customers (individuals and businesses). As mentioned above, the company has a network of distribution centres and plants worldwide, which is instrumental in undisruptive (or rather almost undisruptive) delivery of goods and services. Company’s glocalisation efforts have proved to be effective, which was specifically evident during the 2008 crisis (Chopra, 2018). It proved to be beneficial during the COVID-related situation when the vehicle manufacturer managed to recover within several weeks (Honda, 2020a).

The deliveries were not interrupted for more than several weeks (which was a great result compared to other carmakers). The company also introduced a number of incentives aimed at responding to customers’ needs in terms of the pandemic (Honda, 2020a). For example, the company promptly introduced the necessary changes to its information system to ensure contactless orders. Customers could order products from the company or dealers without leaving their homes.

Importantly, the company aims at enhancing its outward integration as Honda establishes important goals related to improving its circular supply chain model. The latest advances in packaging are instrumental in achieving this objective. For instance, Honda uses returnable steel cases and containers, which contributes to the development of the circular supply chain (Honda, 2020b). The company has diverse communication channels with its customer, some of these being its corporate website and direct communication. Customers are fully informed about relevant changes and initiatives, as well as have an opportunity to address the company for more information or provide feedback.

Honda Marketing Channel Network

Honda aims at becoming a “company that society wants to exist” (Honda, 2020b, p. 15). This vision and direction for the twenty-first century shape the way the company develops its marketing channel network. Collaboration and cooperation mark the overall value creation process as Honda establishes close relationships with its partners and customers to co-create value. As mentioned above, one of the potent communication channels used to communicate with customers and partners is the company’s official website. The company also has an effective information system that ensures the proper flow of information, including communication between the company and other stakeholders.

In addition to this domain, Honda utilises other platforms, including meetings, digital spaces, and different types of media. Several years ago, the company adopted “advocacy approach” and story-telling rather than the attention-grabbing model (Rogers, 2019). This strategy encompasses giving customers more freedom to manage content by employing numerous content hubs. One of such hubs is Shorthand and its own Engine Room platform. The manufacturer also has various partnerships (including sponsorships) with Virgin Radio, AutoCar, WhatCar, as well as Classic FM (Rogers, 2019).

The company is active at the major social media networks such as Twitter, Facebook, YouTube, Instagram, and LinkedIn, among others. Honda has launched diverse venues related to different areas and topics starting with the promotion of its products and ending with sport and volunteer events. Honda marketing officials reported that research suggested customers’ preferences to be active when consuming content (Rogers, 2019). The development of technology with its sophisticated information systems and such digital hubs as Shorthand ensure the successful implementation of the company’s strategy aimed at giving more freedom and choices to its customers and partners.

Again, the focus on glocalisation helped the company address the challenges linked to restrictive quarantine measures. The company’s presence in major locations made closer communication with its partners and customers possible. For example, Honda in North America was able to respond quickly to the needs of the major cities and communities in that country (Honda, 2020a). Honda facilities produced the necessary equipment for many healthcare-related organisations, while Honda associates played an active role in the life of communities.

These communication networks were properly used during the pandemic crisis, which helped the company retain and even enhance its positive image. The company’s donations and contribution to healthcare facilities (in funds and equipment) were publicised through news media, Honda website, partners’ websites, and social media. One of such projects was the collaboration with Dynaflo Inc. to provide diaphragm compressors (Honda, 2020a).

Honda has also contributed considerably to the development of communities. In addition to millions of dollars to healthcare facilities and communities (to ensure the provision of medication, equipment, food, and other necessities), the carmaker has encouraged its associates to volunteer. Honda associates have taken part in various projects, including but not confined to helping the elderly (grocery shopping), distributing food to those in need, maintaining areas, and other activities.

Aligning “Circular Economy” and “Industry 4.0” with the Company’s Current Supply Chain Dimensions

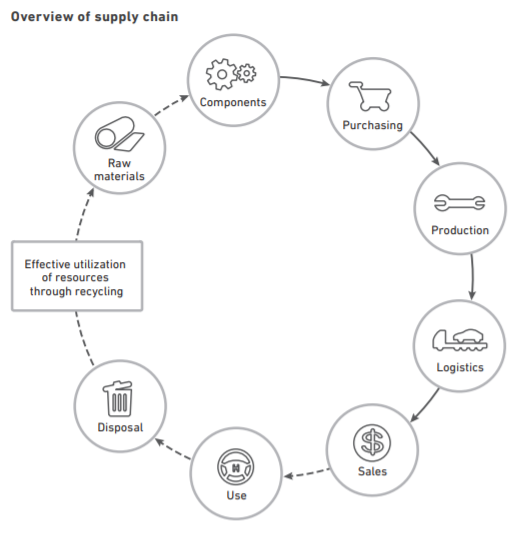

As mentioned above, Honda strives for becoming a company characterized by sustainable operations and handful contribution to the community (see Figure 3). The vehicle manufacturer is heading to the circular economy and Industry 4.0 practices. The circular economy is now seen as the major trend among many multinationals in diverse spheres, including car-making (Kumar, Singh and Kumar, 2021). The adopters of this approach (both developed and developing economies) aim at increased energy efficiency, resource circularity, higher profits, and appropriate relationships with communities (Agyemang et al., 2019).

It is noteworthy that Industry 4.0 is seen as the pathway to building circular economy as information technologies ensure the rapid and flawless flow of data, which is the necessary ground for effective operations especially when it comes to logistics (Esmaeilian, Sarkis, Lewis and Behdad, 2020; Kumar, Singh and Kumar, 2021). The major barriers to the successful implementation and alignment of circular economy and Industry 4.0 with companies’ supply chain management include ineffective strategy, short-term goal orientation, the lack of workforce, and ineffective performance frameworks (Kumar, Singh and Kumar, 2021). Honda addresses these challenges effectively through the alignment of supply chain operations with industry 4.0 and circular economy.

Honda aims at becoming a sustainable company and undertakes different steps to achieve this goal. The company’s implementation of the just-in-time system and lean manufacturing is facilitated by its involvement in waste reduction incentives (Honda, 2020b). Honda provides clear guidelines and strict rules to its partners as well due to its belief that a truly sustainable company cannot collaborate with non-sustainable partners. Importantly, third-party audits of Honda partners’ operations ensure visible shifts in this respect as suppliers and other stakeholders are encouraged to comply with standards and employ sustainable practices (Honda, 2020b). The major focus is on the use of raw materials, such sources as water, and waste and CO2 emissions reduction.

The improvements in packaging and supplies (and products flow) is another illustration of effective implementation of lean manufacturing leading to the circular economy. Honda uses reusable packaging, which enables the company to reduce wastes associated with package considerably (Hinda, 2020b). A more efficient delivery of products and materials contributes to the reduction of CO2 emissions as less transportation is employed. Clearly, sophisticated information systems that can be regarded as an example of Industry 4.0 ensure the undisrupted flow of information and supplies with better routes and effective use of resources.

Blockchain is one of the technologies associated with the development of Industry 4.0 (Esmaeilian, Sarkis, Lewis and Behdad, 2020). Honda acknowledges the potential of this system and has become a part of a far-reaching project involving major carmakers (Ledger Insights, 2020).

Honda, as well as such giants as GM, BMW, and Ford, collaborate on the initiative of an automotive blockchain consortium. The companies comply with the blockchain Vehicle Identity (VID) standard, contributing to the creation of the basis for further development of blockchain in the automotive industry. The companies are enthusiastic about this incentive as they have already adopted some blockchain-associated techniques and applications. Therefore, it is possible to note that Honda uses innovation-led lean manufacturing to reduce its tangible and intangible wastes and become a sustainable company in many dimensions.

Recommendations

The company uses certain industry benchmarks (sophisticated information systems, blockchain, waste reduction) related to lean manufacturing, circular economy, and Industry 4.0. However, Honda can adopt other practices, including but not confined to the increasing use of electric transport, the development of more efficient routes, investment in infrastructure and collaboration with authorities, blockchain-based technologies. These are operational solutions that will require certain investment, but they will be beneficial in the mid- and long-term perspective.

Transportation Innovations

Collaboration is one of the priorities the company under analysis promotes. Hence, Hinda can develop partnerships with companies producing or operating zero-emission trucks. Numerous manufactures across the globe, including Tesla and Volvo, have already created trucks that can deliver considerable amounts of cargo across significant distances (Downing, 2020). First, Honda can encourage its partners to utilise zero-emission transport, which will contribute to its effort to reduce 1% (and even more) of CO2 emissions each year. The company will also become a model for other manufacturers, as well as customers, to choose sustainable practices.

The increase in the utilisation of electric or hydrogen-fuelled fleet may require innovations in the current infrastructure, which is specifically urgent in developing countries. Honda can collaborate with authorities and invest in the development and implementation of plans aimed at innovating the infrastructure by establishing more charging points, developing more efficient routes, and even constructing roads.

Blockchain

Honda’s involvement in the blockchain project mentioned above can be a roadmap for the introduction of the company’s own incentives aimed at making its products’ lifecycle visible to the public. The company can manufacture vehicles and power products with specific identification. The creation of the Honda platform based on the blockchain technology will enable the manufacturer to showcase its compliance with circulation economy principles. Customers will be able to trace every stage of their products’ lifecycle and make sure that items or their components are recycled and reused. This incentive will become a considerable contribution to the industry as Honda’s competitors and partners are likely to follow in order to satisfy consumers’ needs of being sure about the sustainability of this or that company or product.

Conclusion

To sum up, it is possible to state that Honda is adopting sustainable practices effectively. The manufacturer can be regarded as a model global actor contributing to the creation of circular economy facilitated by the technologies offered by Industry 4.0. Honda has achieved its target in reducing wastes (CO2 emissions, materials, packaging), recycling (packaging, components), and becoming a company communities need to exist.

The shocks of the COVID pandemic enabled the company to see the gaps in its operations, including supply chain management, and develop various strategies to address these gaps. Honda is the company that sees collaboration as the basis for its own success and the overall wellbeing of communities. Therefore, the company collaborates with its partners, customers, and competitors to contribute to the development of the circular economy that is seen as the most appropriate solution to the challenges humans have to solve.

Reference List

Agyemang, M., Kusi-Sarpong, S., Khan, S. A., Mani, V., Rehman, S. T. and Kusi-Sarpong, H. K. (2019) ‘Drivers and barriers to circular economy implementation’, Management Decision, 57(4), pp. 971-994.

BBC. (2020) ‘Honda to resume UK output after problems at ports’, BBC News. Web.

Chopra, S. (2018) Supply chain management: strategy, planning, and operation. 7th edn. New York, NY: Pearson.

Downing, S. (2020) ‘8 electric truck and van companies to watch in 2020’, Green Biz. Web.

Esmaeilian, B., Sarkis, J., Lewis, K. and Behdad, S. (2020) ‘Blockchain for the future of sustainable supply chain management in Industry 4.0’, Resources, Conservation and Recycling, 163, pp. 1-15.

Honda. (2020a) Honda responds to COVID-19 with support to customers, Honda associates, business partners and local community organizations. Web.

Honda. (2020b) Honda sustainability report 2020. Web.

Kumar, P., Singh, R. K. and Kumar, V. (2021) ‘Managing supply chains for sustainable operations in the era of industry 4.0 and circular economy: analysis of barriers’, Resources, Conservation and Recycling, 164, pp. 1-12.

Ledger Insights. (2020) BMW, Ford, GM, Honda collaborate on blockchain trial for vehicle identity. Web.

Mukherjee, S. (2020) ‘Leveraging global supply chain to avert Covid-19 impact: Honda’, The Economic Times. Web.

NTT Communications. (2020) Honda Motor Co., Ltd. Web.

Rogers, C. (2019) ‘How Honda shifted its content strategy from ‘attention-grabbing’ to storytelling’, Marketing Week. Web.