Introduction

Smelting iron is a critical process in the industry. It turns iron ore into usable iron metal, which is needed in many areas. I need to understand the chemical reactions because they are crucial for improving the process. The results can reduce its impact on the environment. The research included in the study shows the use of computer assistance and making design changes to reduce the amount of carbon dioxide. These actions are the starting point for creating a more environmentally friendly iron smelting industry.

The Reduction Process of Iron Ore

Smelting iron is critical in producing iron metal, which is widely used in various industries. The reduction of iron ore is central to the smelting process. I have found that the process comes from hematite (Fe2O3) (Zabalza et al.). This reduction process involves the reaction between iron(III) oxide and carbon monoxide: Fe2O3 + 3CO → 2Fe + 3CO2 (Zabalza et al.). Carbon monoxide (CO) reduces and supplies electrons for iron(III) oxide reduction to elemental iron (Fe) (Zabalza et al.). These reactions occur at high temperatures within a big heater.

Active Dynamics

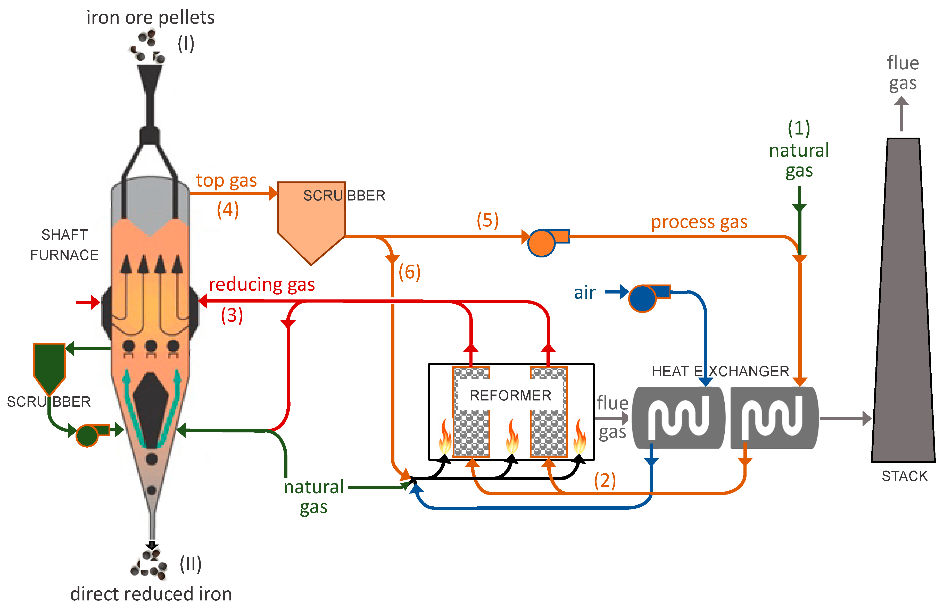

It is essential to consider the active dynamics for me to understand the process of iron ore reduction. The high temperatures within the boiler promote the breakdown of carbon dioxide (CO2) into carbon monoxide (CO) and oxygen (O2) through the Boudouard reaction: 2CO2 ⇌ 2CO + O2 (Zabalza et al.). The carbon monoxide moves electrons from carbon to iron(III) oxide (see Figure 1). It will reduce iron(III) oxide to iron metal and the simultaneous separation of oxygen from the iron ore.

Conclusion

In conclusion, iron smelting plays an essential role in the industry. It makes iron ore usable iron metal and is a basic item in various sectors. Complex chemical reactions in this process are important in optimizing smelting operations and minimizing their effect on the environment. Using computer-aided optimization and design adjustments becomes critical for prioritizing the reduction of carbon emissions. The results will form a road to a more environmentally sustainable iron smelting industry.

Works Cited

Béchara, Rami, et al. “Carbon Impact Mitigation of the Iron Ore Direct Reduction Process Through Computer-Aided Optimization and Design Changes.” Metals, vol. 10, no. 2020, p. 367, MDPI. Web.

Zabalza, Ignacio, et al. “A Review on CO2 Mitigation in the Iron and Steel Industry Through Power to X Processes.” Journal of CO2 Utilization, vol. 46. 2021, p. 101456, Elsevier BV. Web.