Introduction

The supply chain is used in every type of business. And the supply chain is followed in all spears of a business. The term “supply chain management” has two parts – “supply chain” and “management”. Supply chain is the circle where the work of passing the raw material, work in progress and finished goods happened. Another most important thing is that the finance of a company also runs through this circle. Usually the following types of things are circled through a supply chain (Christopher, 1992):

- Raw material

- Work in progress (WIP) or half-finished goods finished goods and

- Finance of a company

Definition of Supply chain management (SCM)

Supply chain management is some sort of flow of product or service or raw products (can be convertible into the consumer good) from one source to another. Here source can be a manufacture, service provider or maybe the final consumer. Some include information supply is in the criteria of SCM. SMC is a process of supply the materials, information and “finances as they move in a process from supplier to manufacturer, to wholesaler to consumer” (Renganathan, n.d.). It is a work of coordinating. A good chain of supply always makes the company profitable. As it does not save any excess material or good and always save as much as the company needed. And Beamon (1998) asserts that for this reason the company should not invest excess money for the reason. If there is no proper chain management the company should not understand where to invest and where not.

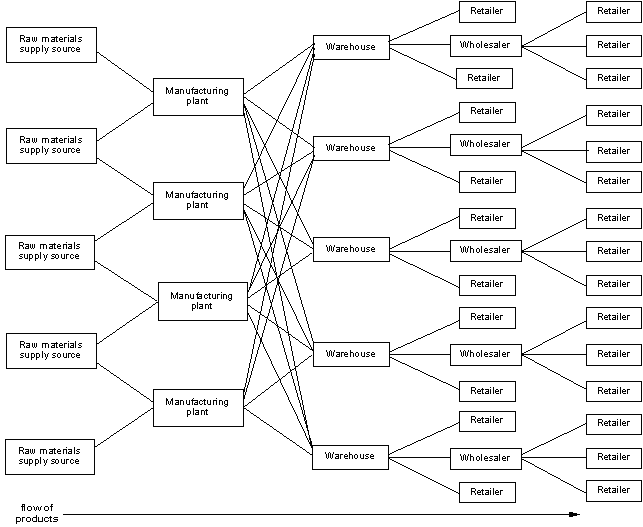

To show the chain supply management there is example shown on the next page. An example is the supply management of a warehouse (TU Delft TBM, n.d.a). The example showing that the raw material is supplied by the sources to the manufacturing plant, and the manufacturing plant pushes it to the warehouse, and the product being produced is distributed to the retailers of wholesalers. If the product belongs to the wholesalers then they supply it to the retailers and finally it is sold to the consumers. It is the flow of products from the source to the consumers. But there is another flow that happened to the chain. And the flow is financial flow. That works just opposite of it. Consumers purchase by cash it has been gathered by the retailers. And the chain began from last stapes and complete to the first point. These are the form of chain works in it.

Works of supply chain management

Works of supply chain management are also reflected in the definition of the supply chain management. Though works of supply chain management is briefly indicated by Joshi (2000) in following ways:

- Purchasing: The first work is to purchase product or raw material from the source of from the producer (like- farmer, collector of raw material )

- Supply to the next source: After further processing or if the purchaser is only seller then the goods or raw material should be supply to the next source.

- And after the proper processing when product is ready to sell then it should be sold to the final consumer and finance is collected.

The supply chain management has lot of dimensions. Most important work of supply chain management is to control the supply or material transferred from the previous source. We can group supply chain management in the following criteria (by controlling):

The supply procedure that can be controlled

Usually the supply chain is controllable in the internal dimension. The internal environment includes manufacturing, distribution or retail capacity. Improving performance in those areas has, to date, been the priority of most supply chain management initiatives (Dorf, (1992). The supply is controllable as proper account is maintained. For supply chain management the product design process, including market requirement analysis, manufacturability and the ease with which the product can be distributed throughout the supply chain. Companies can use concept to consumer approach and maintain the life cycle of the product to run everything properly.

Partial Control

Here the company does not have full control on the supply chain. But the company has an influencing power to the supply. As for that it can be called that the company has a partial control on the supply chain. Someone has also named it as customer dimension. And it is also said that here the administration has influencing power but does not have total control.

Dimension that cannot be controlled

On the external dimension a company does not have any control. Though it is told there is a very small control on the factors. As a result the external dimension has been a lower priority or absent from supply chain.

For example we can show a lot of supply is maintained by Electronic Data Interchange (EDI) technology in the automotive supply chain and radio frequency identification device (RFID) technology, which is emerging as a mandatory requirement in some consumer goods and retail supply chains.

The problem

The problem is mainly related to the internal control of supply. The recommendation of put off the problems by surveying some journals is given below.

Need a supervisor

Though there is no supervisor, the situation is not properly under control. Supervisors can save data of taking the supply or needed elements. And after one month observation the supervisor can tell actual or an around figure of supply needed. The supervisor should be under control of the board of control or under the proper administration. Data that are saved by the supervisor should be maintained in the following way:

Every type of item should be saved in the following way. Though it is a little bit costly but it can be fruitful for saving supply.

Proper research on quantity needed

There is no actual research for the quantity needed for regular use. The authority should arrange a research for calculating how much supply the medicine organization needed. And the ordering quantity will not be less able.

Access restricted

Access should be restricted by the administration. And no one can enter in to the rooms without permission of the clerks who are employed. And for two rooms there are two clerks who are already employed.

Overall review systems

Overall review systems and proper control should be taken to face the problems. And the control area should be properly maintained by the authority. A fruit full control can very easily maintain every trouble.

Work distribution and accountability for the related persons

Work is distributed according to the post and status. And also administration should show their accountability. And admin should make signal about their responsibility and accountability.

Conclusion

Control-able procedures can prevent all kinds of problems created by the employee. But actual steps should be made against the systematic troubles.

Then the supply chain management will be able to come in a successful position.

References

Beamon, B. M., (1998). “Supply Chain Design an Analysis: Models and Methods”, International Journal of Production Economics, Vol.55 No. 3, 1998, pp. 281-294.

Christopher, M., (1992). Logistics and Supply Chain Management. Strategies for reducing costs and improving services. London, FT Prentice Hall, 1992.

Dorf, R. C., (1992). Modern Control Systems. Addison-Wesley, 1992.

Joshi, Y., V., (2000). Information Visibility And Its Effect On Supply Chain Dynamics”, MSc Thesis, Massachusetts Institute of Technology, 2000.

Renganathan, Rajiv. (n.d.). Supply Chain Management for Beginners. Web.

TU Delft TBM (n.d.a). Global Supply Chain Game. R.H. Smith School of Business. Web.

TU Delft TBM. (n.d.). Supply chain management. R.H. Smith School of Business. Web.