Introduction

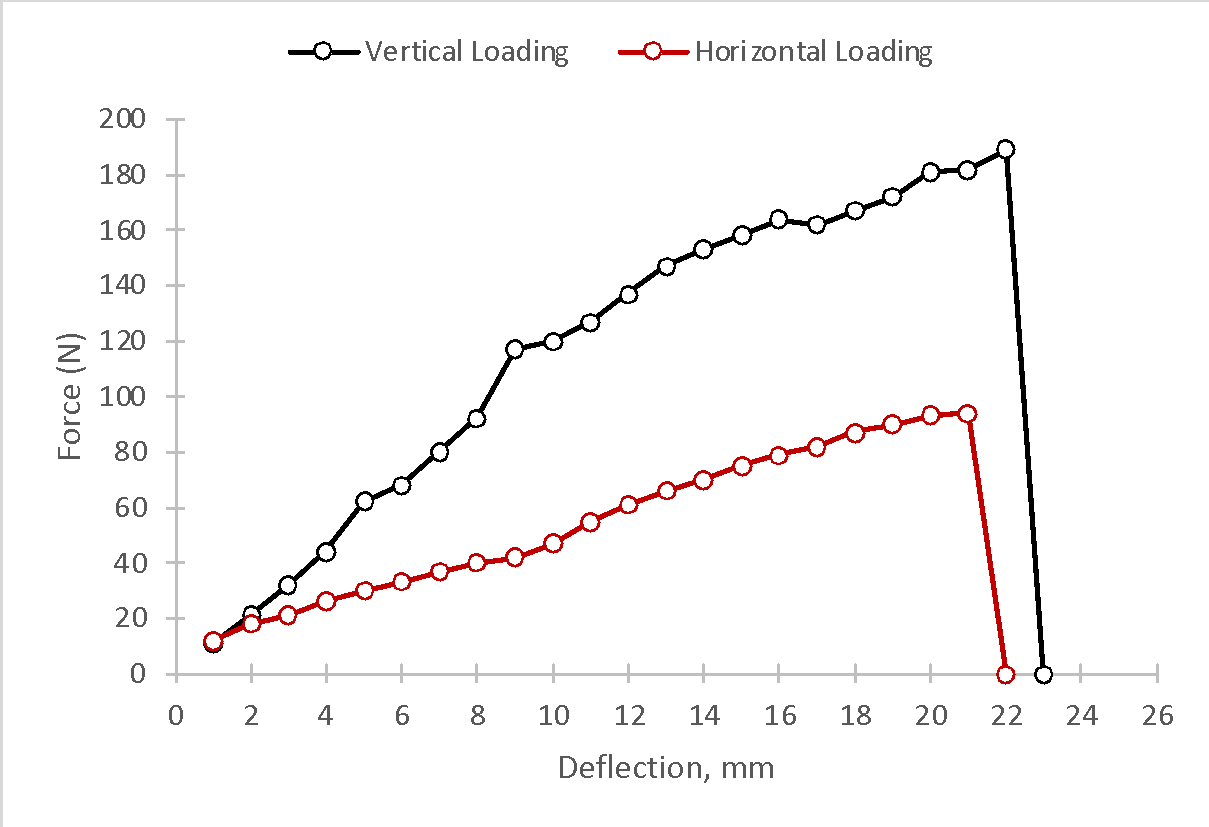

Table 1 summarizes the applied force as a function of plastic frame deflection. The first conclusion that can be drawn from the results is that it took less force to break the portal horizontally (a maximum of 94 N) than to break it vertically (a maximum of 189 N). This can be clearly seen visually in Figure 1 because, for the same deflections of the plastic gantry, the applied vertical load is higher than the horizontal.

Table 1: Initial results of the experiments performed

In general, both lines of dependence have an ascending linear trend, which means that when the deflection of the plastic portal increases, the applied force increases, and vice versa.

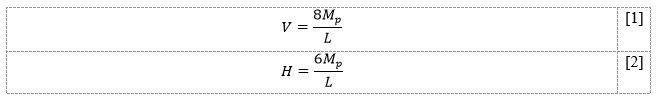

The data obtained can be used to evaluate the behavior of the plastic frame according to the theoretical information. The equations shown in [1] and [2] should be used for this check.

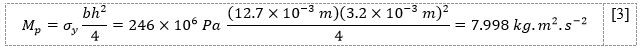

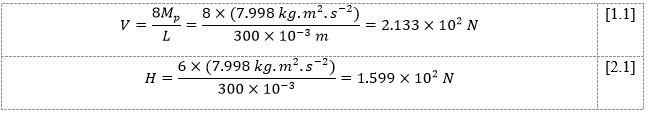

These equations can be used to calculate the fracture load, that is, the minimum force that can be applied to the material to fracture it. L corresponds to the width of the plastic frame, and Mp is the plastic moment (Nm), which must be calculated separately using [3].

Then the vertical and horizontal deflections are:

Discussion

The purpose of this work was to evaluate the behavior of the plastic gantry when vertical and horizontal forces were applied to it before the moment of collapse and to evaluate the results obtained with theoretical expectations. According to the calculations, the vertical collapse load was 213 N, and the horizontal load was equal to 160 N. At the same time, the real collapse load found by the experiment was 189 N for vertical deflection and 94 N for horizontal displacement. This suggests that the real results differed by almost 52% for horizontal deflection, and collapse in both directions occurred at lower forces than expected.

Some sources of error that may have influenced the deviation of the practical results from the expected ones could be systematic instrumental errors of the load cell, testing conditions, including non-ideal anchoring of the frame in the tripods, or failure to account for the material of which the plastic gantry is made. The onset of an “earlier” collapse may indicate a more brittle material or an initial lack of alignment of the plastic gantry, which may have caused the collapse at lower force values. It is also possible that the lack of repetition of the experimental tests may have been responsible for the bias in the data.

Conclusion

The goal set in this paper, namely, to study the behavior of the plastic gantry when the load is applied to it in two directions, has been achieved. The experiment showed that the plastic frame failed when 189 N and 94 N were applied in vertical and horizontal deflections, respectively. However, compliance with theoretical expectations was not achieved, as the deviation between practical and theoretical results reached almost 52%. Otherwise, the experiment can be considered a success because it allowed us to estimate the bending limits of the plastic gantry based on a single sample of results. In addition, the results suggested what mistakes were made, which means improvements can be made in future iterations.

Comments

The most important improvement in this experiment would be to increase the number of repetitions, such as three for each direction. This would reduce the potential for errors and distortions in the results, which would have a positive effect on the overall gains of the lab experiment.