Abstract

An effective supply chain management can be considered one of the fundamental aspects of all business companies. To a greater degree, it is preconditioned by the increased sophistication of the business environment characterized by complex relations between various agents and the existence of many barriers that should be eliminated by engaging in particular cooperation. Moreover, rivals and companies functioning in the same sphere try to use new practices working with suppliers to generate a competitive advantage. In such a way, the problem of effective supply chain management acquires the top priority.

It becomes one of the possible ways to decrease spending and increase income. For this reason, the given project is devoted to the comprehensive investigation of the end-to-end supply chain management and its critical peculiarities using such examples as the purchase of the liter of fuel and hand-made sofa. The paper promotes a better understanding of all cross-functional factors impacting the given aspect of companies’ functioning and its use.

Introduction

The modern supply chain management is a complex process that demands an improved understanding of how companies function, what actors play a critical role in its development, and what channels can be used to attain the best possible result. At the same time, it requires the enhanced vision of the modern business environment and all relations between firms, suppliers, and retailers to guarantee the creation of the most effective chain that will create the basis for the company’s evolution and further rise.

The problem is complicated by the fact that every product demands a new and unique supply chain needed to ensure its appropriate delivery to consumers and the generation of high revenues. One of the most important elements of management is to consider all cross-functional factors that might impact the effectiveness of supply chains and minimize the probability of unexpected situations or outcomes. The given work conducts an in-depth analysis of the supply chain’s functioning, management, and other factors associated with this topic.

Aims

The scope of the researched problem and its topicality for the modern business word demand introduction of several aims. The first one is to conduct the analysis of the current supply chain management in terms of various industries and products as it will help to familiarise with the most topical concepts of this field and promote a better understanding of the issue.

The second purpose of the paper is to investigate the triple bottom line approach as one of the most frequently used today. The fact is that this model is widely used in various spheres and significantly affect supply chain management. For this reason, its evaluation is fundamental regarding the main focus of the given study.

The third aim is to discuss the importance of the modern supply chain management, problems that might emerge while organizing this element of the companies’ functioning, and how different cross-functional factors can impact this field. For this reason, the discussion of all the concepts presented in the paper is initiated.

Objectives

Previously formulated aims precondition the central direction of the paper and also impact the emergence of certain goals and objectives that should be mentioned during the analysis. The objectives are:

- Analyze the concept of supply chain.

- Outline the main elements of supply chain management and approaches to it.

- Compare two different end-to-end supply chains for a liter of fuel and a hand-made sofa to formulate the difference between the utilized models.

- Create a theoretical background for the analysis and discussion by analyzing the relevant research literature.

- Delve into the triple bottom line concept.

- Understand the impact cross-functional factors have on supply chain management.

In such a way, using the given objectives, credible information about the research literature can be collected and analyzed to create the basis for the following discussion and the improved understanding of the concept, its importance, and formulation of the relevant conclusion.

Theoretical Framework

The theoretical framework for the given paper was created via the review of the literature devoted to the problems of supply chain management and the main issues associated with the given topic. The fact is that the discussed problem is topical for the business world as it is one of the fundamentals of companies work and their further rise (Chopra & Meindl 2015). The emergence of every new business venture should be preceded by the analysis of the current market situation, forces impacting the sphere, and the existence of actors that can potentially become partners when aligning the supply chain (Chopra & Meindl 2015).

For this reason, the pivotal task of any manager responsible for the creation of the appropriate business model is the creation of the effective supply chain model and elaboration of the approaches to its management (DuBrin 2016). Armstrong and Kotler (2016) outline many methods that can be used regarding the situation and the current needs; however, they are also united in the opinion that every specialist should be ready to focus every element of the would-be supply chain to attain success.

In such a way, relations with theoretical suppliers, shippers, and retailers should be given the top priority. In accordance with the existing paradigm outlined in the literature, this cooperation is a key factor preconditioning the further success of the whole project as it determines the degree to which the consumers’ needs will be satisfied (Gamble, Thompson Jr & Williams 2016). That is why, prices for the initial product, delivery, and terms are critical elements of the supply chain that become are considered while analyzing the current model and looking for the improvement options (Hugos 2018).

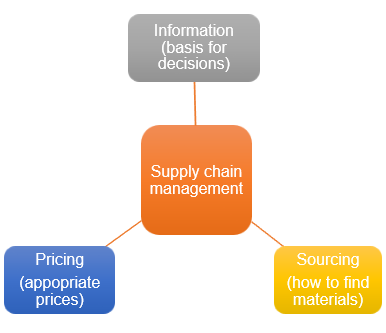

At the same time, multiple cross-functional factors such as information, sourcing, and pricing also correlate with the forces impacting the supply chain model and its effectiveness (Hugos 2018). In such a way, the current theoretical background proves the importance of the discussed aspect and its dependence on multiple factors.

Nevertheless, one of the main reasons for the creation of supply chains and their management is the ability to generate a significant competitive advantage to the increased attention given to all meaningful details that can impact the final result and precondition the emergence of unexpected problems. The creation of an effective strategy demands the comprehensive evaluation of the current market situation, power of suppliers, their ability to provide high-quality materials, shipment prices, and terms (Armstrong & Kotler 2016).

All these aspects and pillars of the successful companies’ management as they help to forecast their evolution and create solutions effective in various conditions (Armstrong & Kotler 2016). For this reason, the majority of modern organizations devote significant attention to the given aspect of their functioning. Moreover, regarding the importance of the competitive advantage in the modern business world, this aspect becomes an integral part of the sector’s evolution because of the tendency towards the increased sophistication in relations between agents and companies.

Litre of Fuel’s Supply Chain Analysis

As it has already been stated in the introduction, goals, and aims sections, the paper presupposes the in-depth evaluation of the two end-to-end supply chains to compare differences, discuss the existing elements, and conclude about the used approaches. Thus, evaluating the supply chain presupposing a customer’s purchase of a liter of fuel, one should delve into the mechanics and basic aspects of the usual retailer company functioning in the sphere.

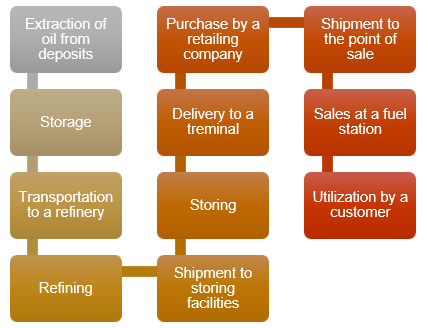

The fact is that the analysis of the supply chain presupposes tracing the whole life-cycle of a sold product from the beginning to its end which is impossible without the assessment of manufacturers, shippers, and retailers (Kotler & Keller 2015). The high level of development and sophistication peculiar to the oil and gas sector demands the appropriate changes into the structure of the supply chain and comprehensive analysis of all stages (Ahmed 2013). At the same time, rivalry peculiar to the sphere demands a choice of the most effective ways to cooperate with partners and considerably complex supply chains. For this reason, regarding all these aspects, the following structure related to the purchase of a liter of fuel can be suggested:

As can be seen from the figure, the given process consists of at least 11 stages because of various factors that impact the sphere and the work of companies belonging to it. The final stages presupposing the delivery of ready products to fuel stations and its sale can be considered a result of a complex preliminary work that encompasses a number of processes and elements. That is why the given supply chain helps to avoid chaos in the relationship between agents and aligns the needed structure.

First of all, oil has to be refined to become the fuel that can be used by consumers. Oil-producing companies become the first agent needed to create an effective supply chain (Sultan 2017). They are responsible for the discovery of oil deposits, extraction of crude oil, and its refinery (Savitz 2013). All these stages should be included in the scheme as they are essential for the creation of the final product and its offering to a customer. Another factor that becomes clear due to the given chain is that the product should be stored at a minimum two times soon after its extraction and refinery (Shaffer 2018). This aspect becomes vital for planning the supply and delivery to the areas where fuel is needed.

Finally, there are critical peculiarities of shipment. The concentration of oil areas in the modern world results in the disproportional distribution of energy sources which means that there is the need to deliver them to areas that have a high demand for it (Szekely, Dossa & Hollender 2017). That is why the majority of retailers should be ready to consider this aspect while planning their spending and income. In such a way, the end-to-end supply chain involving the purchase of a liter of fuel is characterized by the increased sophistication and complexity.

However, regardless of the existing perspective on the functioning of companies stating that too high sophistication is a drawback because of the need to align every single moment and monitor multiple aspects at the same time, concerning the given case such a developed structure helps to minimize risks and consider cross-functional factors (Kotler & Keller 2015). As has already been stated, information, sourcing, and pricing are critical elements for supply chain management. The proposed supply chain helps to consider them all. First, the existence of multiple components promotes a better collection of information about the functioning of the industry and its current trends. The cooperation with the oil-producing company improves sourcing strategy while the exclusion of third parties improves pricing (Armstrong & Kotler 2016). In such a way, the in-depth analysis of the sector along with the attention to details helps to create an effective pattern that takes into account the most important elements needed for successful growth.

The factor mentioned above becomes the critical advantage of this approach to supply chain management. A manager can use a more flexible approach while creating a new way of cooperation with suppliers, shippers, and retailers. Increased attention to the cross-functional factors helps to avoid the development of unexpected situations characterized by the failures of some strategies or too high spending (Jones & George 2014).

Moreover, there are more options for the selection of partners, shippers, and storing capacities to make sure that these fit the existing demands of the company and can be used to generate competitive advantage (Armstrong & Kotler 2016). Furthermore, this supply chain presupposes that there are no other parties or agents that should be paid to align the cooperation which is the guarantee of the stability of the selected strategy and consumers’ satisfaction via the in-time delivery of all needed products.

One of the possible drawbacks of the given supply chain is the need for extensive training and additional planning. The existence of a developed structure and multiple stages presupposes that a specialist responsible for the evaluation of its effectiveness and functioning should possess an enhanced understanding of all peculiarities of the sphere, how it works, and current tendencies (Harrington 2018).

Otherwise, the lack of information will result in the inability to manage this supply chain and promote the collapse of the company focused on fuel sales (Armstrong & Kotler 2016). Another possible drawback is that it is too dependent on oil prices set by a particular oil-producing company which is the main supplier (Hugos 2018). The introduction of higher prices will result in a decrease of final income and a necessity to reconsider the existing approach to the firm’s development. That is why supply chain management acquires the top priority.

Hand Made Sofa’s Supply Chain Analysis

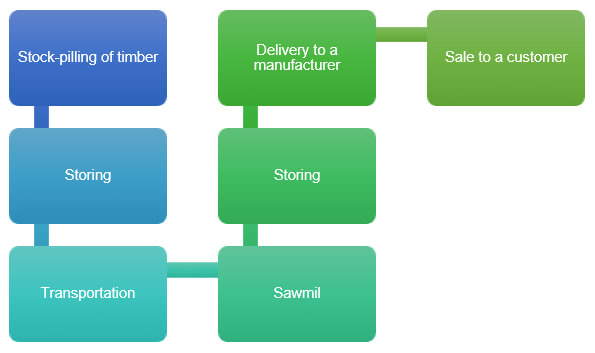

Analysis of the second supply chain presupposing the sale of a handmade sofa should also be performed to compare differences and figure out its peculiarities. The scheme can be presented in the following way:

There are only 7 elements in the given supply chain because of the critical differences between the discussed industries. The level of complexity is much lower as wood is more available and affordable resource than oil. At the same time, the production of the final product is a less technological process which means that fewer phases are needed to move through all stages of the handmade sofa lifecycle and deliver it to a consumer (Carlsson 2015). It also indicates that manufacturers have a more advantageous position as the availability of high-quality resources preconditions their more effective functioning.

The given model includes the main processes needed for the creation of a final product regarding the given sector. These are harvesting of timber, its preparation, delivery, and manufacturing. All these stages are critical for a company that works in the sphere because they impact the final result (Wild & Wild 2018). The existing supply chain model presupposes that these processes are in direct correlation which is the key to enhanced management and better outcomes (Cummings & Worley 2014). The degree to which success is attained during all phases is fundamental for the quality of the handmade sofa, customer satisfaction, and his/her desire to come back and buy a new piece of furniture.

Regarding the cross-functional factors peculiar to the industry, the given model also helps to consider them. As for the sourcing opportunities, it is the first stage of the supply chain as a manufacturer selects the most appropriate company responsible for timber harvesting (Carlsson 2015). It also means that all critical information needed to engage in the cooperation is also collected during this very stage (Hugos 2018). The approach to pricing can also be varied regarding the existing demand for furniture and offerings regarding wood. In such a way, the chain helps to consider all critical factors and avoid deterioration results due to their negative impact.

The most obvious advantage of this approach to supply chain organization is its simplicity and exclusion of unnecessary elements from its structure. All stakeholders responsible for the functioning of a company producing handmade sofas can engage in direct cooperation with each other on terms they find appropriate for them (Hugos 2018). At the same time, shipment becomes another advantageous option because of the comparatively small distances that should be covered. It contributes to the generation of a stable and high income which is the critical element of any firm’s functioning and promotes its further growth. Moreover, it can promote the generation of the competitive advantage needed to hold leading positions.

The drawbacks are not so obvious as the given supply chain does not presuppose an extreme complexity. However, one of the possible disadvantages is the existence of dependence from the only supplier responsible for the provision of the needed materials (Hugos 2018). It can result in a decreased quality of sofas if the provided wood has inappropriate quality. Moreover, the same drawback as in the previous case can be observed as a manager should possess a perfect understanding of how the sphere functions to introduce appropriate alterations in the course of the company and respond to all unexpected changes to ensure that the success will be attained and customers will remain satisfied.

Comparison of Supply Chains

The given supply chains have differences that arise from the peculiarities of the industries in which hypothetical companies function and the complexity of various processes. In the first case, more stages are observed because of the high level of sophistication peculiar to the oil and gas sector if to compare with the manufacturing of furniture. Thus, extensive training is demanded from managers working with both supply chains to guarantee that all factors are considered and the most effective strategy is selected. Both these cases prove the idea of the increased importance of supply chain management in the modern business world and the necessity to apply its basic concepts to real-life scenarios.

Supply Chains and Cross-Functional Drivers

In the previous analysis of the cases, the issue of cross-functional drivers has already been addressed. That is why the impact of information, sourcing, and pricing on industries and companies working there can be proved by using these very cases. In the majority of cases, the planning phase is characterized by the consideration of these elements to create the most effective supply chain and a company’s development strategy. In other words, the existing information about the situation in the sector preconditions the success of a new venture (Hugos 2018). At the same time, the location of facilities depends on current approaches to pricing and sourcing as much spending can be expected from shipping and purchase of needed materials (Hugos 2018). It can be presented in the following graph:

The given cross-functional factors can be considered determinants of achievement and the company’s ability to grow.

Triple Bottom Line

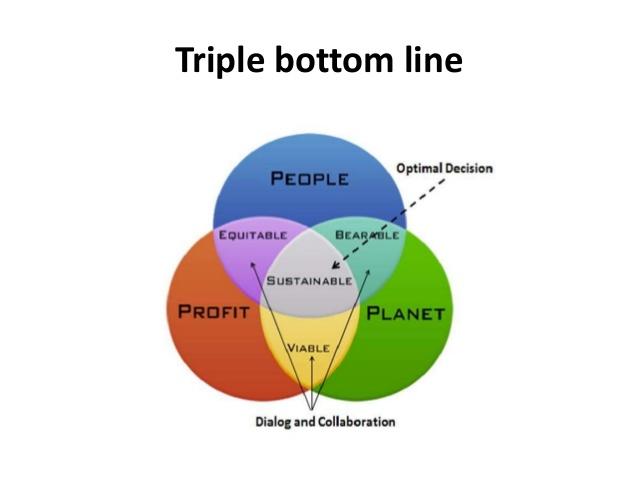

The concept of a triple bottom line is also applicable regarding the effective supply chain management. It is defined as the combination of social, environmental, and financial aspects within the same company.

This model presupposes that the work of any company should meet the three basic requirements. First, it should be environmentally friendly and try to reduce the harm done to the area (Bals & Tate 2016). Second, it should be sustainable to improve the lives of communities affected by its functioning and engage in cooperation with them. Finally, it should be profitable to continue its evolution and rise (Hugos 2018).

This idea should be considered when planning a particular supply chain. A manager responsible for this task should select among the suppliers and shipment options to reduce the negative impact. Additionally, support to local manufacturers can be given to promote the rise of communities. For instance, regarding the second analyzed supply chain, wood can be bought from local manufacturers.

Conclusion

Altogether, the modern approach to supply chain management comes from the idea of the increased rivalry and the necessity to generate a competitive advantage to overcome other companies that work in the same sphere.

For this reason, numerous attempts to optimize the functioning of companies via effective management are performed. However, it is also critical to consider the existing cross-functional factors that affect the evolution of the sphere to avoid unexpected complications or problems in the future. Finally, the triple bottom line approach as the model of an exemplary company that considers all aspects of its functioning should be taken into account. There is a critical necessity to align the work of the company regarding these peculiarities as they contribute to better outcomes.

Recommendations

The paper helps to delve into the peculiarities of the supply chain management and its basic aspects. Nevertheless, there are still many options for future projects focused on the investigation of the same issue. It is possible to recommend to assess other industries to compare if there are differences in the methods used by managers to ensure positive outcomes and companies’ success. It will help to attain an enhanced understanding of the issue and its fundamentals.

Reference List

Ahmed M 2013, Project management: critical success factors for projects in oil & gas sector of Kuwait, LAP LAMBERT Academic Publishing, Saarbrücken.

Armstrong, G & Kotler, P 2016, Marketing: an introduction,13th edn, Pearson, New York, NY.

Bals, L & Tate, W 2016, Implementing triple bottom line sustainability into global supply chains, Greenleaf Publishing, Sheffield.

Carlsson, M 2015, Strategic sourcing and category management: lessons learned at IKEA, Kogan Page, London.

Chopra, S & Meindl, P 2015, Supply chain management: strategy, planning, and operation, 6th edn, Pearson, New York, NY.

Cummings, T & Worley, C 2014, Organization development and change,10th edn, Cengage Learning, Thousand Oaks, CA.

DuBrin, A 2016, Essentials of management, 10th edn, Wessex Press, London.

Gamble, J, Thompson Jr, A & Williams, M 2016, Essentials of strategic management: the quest for competitive advantage, 5th edn, McGraw-Hill Education, London.

Harrington, J 2018, Innovative change management (ICM): preparing your organization for the new innovative culture, Productivity Press, New York, NY.

Hugos, M 2018, Essentials of supply chain management, Wiley, Hoboken, NJ.

Jones, G & George, J 2014, Essentials of contemporary management, 6th edn, McGraw-Hill Education, London.

Kotler, P & Keller, K 2015, Marketing management,15th edn, Pearson, New York, NY.

Savitz, A 2013, The triple bottom line: how today’s best-run companies are achieving economic, social and environmental success, Jossey-Bass; San Francisco, CA.

Shaffer, G 2018, Creating the sustainable public library: the triple bottom line approach, Libraries Unlimited, Santa Barbara, CA.

Sultan, S 2017, Project management in oil and gas industry, Expert of Course Publishing, New York, NY.

Szekely, F, Dossa, Z & Hollender, J 2017, Beyond the triple bottom line: eight steps toward a sustainable business model, The MIT Press, London.

Wild, J & Wild, K 2018, International business: the challenges of globalization, 9th edn, Pearson, New York, NY.