Describe how the auto industry might work differently if it were designed by the Dell Model

The Ford motor company has existed since 1903 (Dornbach, Slade & Thorpe, 2009, p.4). It has had a series of success stories-revenues of more than 144 billion, operation in over 200 countries of the world, and a labor force of at least 370 000 employees. The company enjoyed success in the early 120th century until the global market began to alter. New competitors emerged into the ring of designing, manufacturing, supplying, and delivering the same products as Ford. Worse still, the international market began to stall and with the introduction of foreign players into the US market, Ford had to go back to the drawing board and carve out a new strategy to secure the future of Ford. More importantly, there was a need for reformation of how the company associated with its suppliers.

Modern Technology

The incorporation of modern technology into high tech industries was an idea that Ford wanted to adapt. Unfortunately, due to the long term engagement in the market, certain historical hitches could not allow it to readily implement the idea. Dell did forward its recommendations to Ford; but as expected the company was divided as to the way forward. One side contended that the incorporation of Dell’s ideas into the company would put Ford onto the map of high tech industries. The proponent of Dell’s model argued that Ford needed to make the drastic reforms within itself or risk being left behind.

The other side argued that Ford was so close and so integrated into its history that it could not afford to adapt to the changes proposed by Ford. The opponents of the Dell model-based their arguments on the extensive relations and networks of chains of suppliers that Ford had built over the last century. They chose a cautious approach to the matter and advised that there was no definite limit to which the reforms were to be done. As a result, the risk ought not to be taken and that Ford had to exploit other options (Applegate, 2009).

The Dell Model

The Dell Model was aimed at exploiting both human resources and other resources to the maximum. It did not matter that the resources were confined to its possession or that of its suppliers (Shelley, 2010, p.1). The main of the model was to ensure that Ford maintained its profits but at the same time adapt a modern method of conducting its daily routine.

The Dell Model necessitated a complete makeover of the whole system of operations at Ford. If adopted the model would have affected Ford in two major ways: at the supply level and in the organizational structure. As far as the supply chain was concerned, Ford had amassed several suppliers who delivered components (Binsfeld & Williams, 2003, p.1). In the early 1990s, it restructured its supply base by reorganizing them into two classes: tier 1 and tier 2 suppliers.

It provided the mechanisms and facilities for the proper functioning of this organization. Ford only dealt with tier1 suppliers directly whereas tier2 suppliers liaised with tier 1 to deliver their components. In return, Ford received annual price reductions on the supplies. The Dell supply base re-structured the whole system by breaking the hierarchy and introducing a centralized system. This was a great shift from the system that Ford was already familiar with.

The second impact was on the organization. The structure of organization development was significantly autonomous. It did not rely on the purchases at all. This had been the trend since the formation of Ford over a century ago. The Dell Model introduced a system that saw the goings-on of purchasing reported to the product development organization. Ford dealt with volumes of purchases per given time. Purchasing agents negotiated the prices with the suppliers as this resulted in cost savings. The Dell model did not reflect on how this position would be maintained.

The Pros

Hierarchical models have now been overtaken by events. Modern technology has come into play and necessitated the need for a central control for multinational corporations. The modern practice is inclined towards: fast processing, working in teams, and quick cycle organizational models. The creation of virtual organizations has increased competence with which work is done.

If the Del model had been implemented at Ford, then there would have been a need for the implementation of a centralized networked information and communication system. This means that the whole organization needed to have undergone a total redesign, including both the supply base and department structures. All the stakeholders at Ford—managers, employees, and suppliers would have undergone extensive training to familiarize them with the new systems of operation.

In the big picture, the reorganization of the systems of Ford by the Dell model would have called for a need for a central controlling unit. In this regard, the Ford companies situated outside the US, for instance, would act at the decentralized companies while a central base would have been set up in the mother country. Breaking down the small chains of suppliers everywhere would have been hectic. The leverage Ford has—is a $150 billion company—over their suppliers would have lowered; a necessary evil for a greater end.

All these firms would have had the opportunity to share one hub—and in real time—where they could all gain real-time data on market changes, control, and performance. This is vital because it enables real-time planning and performance monitoring. What is more, the system allows suppliers, employees, customers, and partners to access information quickly. This gives room to fast correspondence and the parties get a chance of devising ways of working together.

Perhaps the greatest advantage that Ford would have had through the implementation of the Dell model is to cut the running head costs. As the company stands, the company spends a lot just managing the production organization structure that deals with: production problems related to communications, coordination, and control. Implementation of a virtual integration takes care of all these needs without any cost as to the overhead. In essence, therefore, instead of clinging on to savings that result from the bargaining of purchasing agents, why not eat the cake and have it? Deploy the virtual integration, suffer a little through the lack of purchase agents, and gain more through cutting the overhead costs.

The Challenges

If Ford had gone ahead and bought the Dell Model, its operations would have radically changed. The company would have equally adapted to the changing times and practices in high tech enterprising. Management costs would have reduced and efficiency equally has increased.

There are several challenges that it would have faced in light of adapting the model. For one, designing the structure and implementing is just the beginning of using the structure. The challenge is in maintaining it and constantly evolving the structure and systems that enable it to execute its strategies and accomplish its goals. This is a problem shared by many other high tech and multi-billion companies.

This is not to say that the task is impossible. The results given by virtual integration are precise. This affords the relevant stakeholders with an opportunity to determine a problem beforehand and solve it before any damage is suffered.

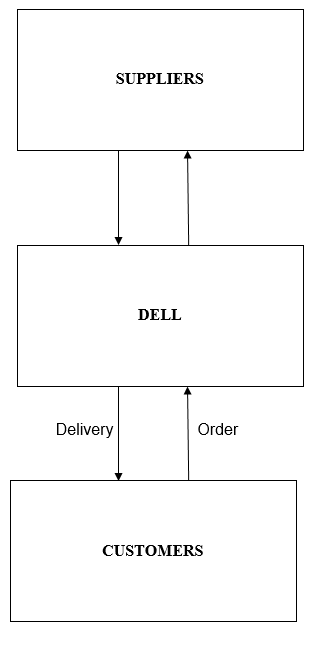

Using the Microsoft Visio tool (or Ms-Word), create a flow chart of a supply chain process for Ford Motor Company based on the Dell model

References

Applegate, L.M., Austin R.B. & Soule, D.L. (2009). Corporate Information Strategy and Management.Harvard, Massachusetts: McGraw-Hill International

Binsfeld, J. & Williams, J.P. (2003). Case Presentation: Ford Motor Company – Supply Chain Strategy. Web.

Dornbach-Bender, R., Slade, B. & Thorpe, J. (2009). Strategic Report for Ford Motor Company. Web.

Shelley, M. (2010). Ford Supply Chain Case. Web.