Introduction

MovingSeas Ltd. is an engineering firm specializing in subsea inspection. The business has been in operation for over 20 years and has consistently remained at the forefront of technological advancements. Recently, they have been using an ROV vessel to undertake surveillance in offshore wind farms. Although the employment of ROV vessels has been demonstrated to be effective and offers tremendous field resilience, several drawbacks exist, including the need for support services, high daily expenses, Health, Safety, Environment, and Quality (HSEQ) risks, a significant carbon footprint, and lengthy turnaround periods.

Operators of offshore wind farms also strive to achieve solutions with lower prices and carbon footprints. The board has assigned some of the organization’s executive directors the responsibility of creating a service that utilizes small, uncrewed vessels to monitor the offshore properties of wind farms, thereby mitigating these concerns. A high-level service architecture concept is presented in this report, together with solution proposals for the new or modified services, administrative technology systems and programs, technological architectures, management architectures, necessary procedures, and measurement methodologies and metrics.

Problem Statement

Due to the significant carbon footprint, logistical support, HSEQ hazards, turnaround times, and operational expense associated with deploying a big ROV vessel, MovingSeas Ltd., a submarine inspection engineering company, is facing several difficulties with its offshore wind farm inspection services. It must provide a new inspection service utilizing small, uncrewed ships to meet the demands of operators seeking low-carbon services.

The organization aims to reduce logistical support, increase service frequency, minimize risk, minimize environmental impact, and involve fewer personnel in the process. This report aims to provide a high-level service design that addresses the challenges faced by MovingSeas Ltd. and meets the needs of offshore wind farm operators, while also considering the impact of sustainability and environmental legislation on business operations.

Service Solutions for the New or Changed Service

A service that employs a few unmanned crafts to assess offshore assets in wind farms must be offered by MovingSeas Ltd. The primary goals of the new service are to reduce logistical support, increase service frequency, mitigate risk, minimize environmental impact, and eliminate human intervention. To find any burial and cable protection issues, the new service should include a visual assessment of the pile, turbines, and the entire cable route.

MovingSeas Ltd may utilize the following service solutions to accomplish these objectives: Using autonomous surface boats (ASVs) outfitted with cameras, sensors, and other technology to conduct visual assessments of the pile and turbines as well as the entire cable route to find any issues with the burial and cable protection is one way to accomplish this goal (Vaaland et al., 2017).

ASVs are a viable alternative to ROV vessels since they are smaller, require less logistical support, and have a lower carbon footprint. They utilize high-resolution cameras and advanced sensor technology to capture comprehensive images and data. UAVs offer a better view of wind turbines and piles because they can fly near them (Norouzi, Jayaraman, and Collette, 2014). Additionally, UAVs can visually inspect the pile and turbines for fractures or defects.

USVs, or Unmanned Surface Vehicles, can monitor the cable path. They have sensors that can detect wire breakage caused by their equipment. The cable’s depth, temperature, and pressure can also be measured by USVs, enabling comprehensive details about the cable’s condition. AUVs, or Autonomous Underwater Vehicles, can investigate a structure’s submerged components. They have sensors that identify damage to the structures and wires below the surface. AUVs can measure the water’s temperature and pressure to get extensive data about the underwater environment.

Management Information Systems and Tools

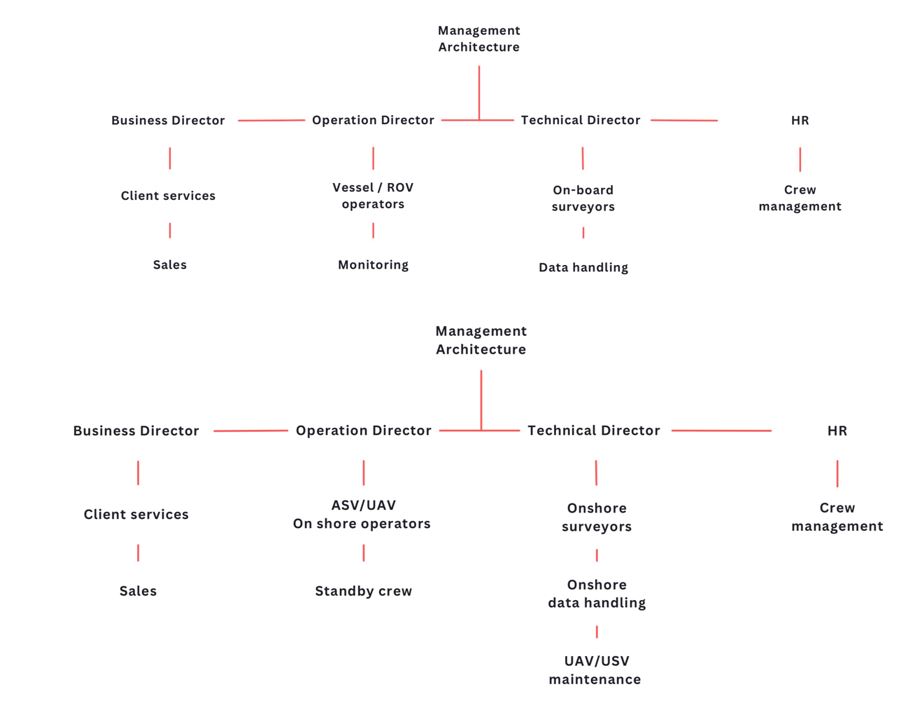

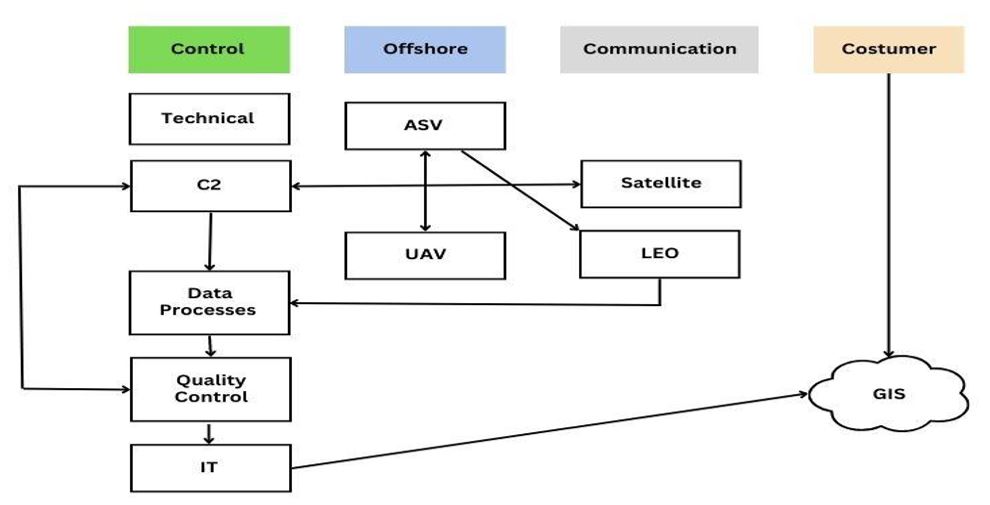

MovingSeas Ltd. will need the proper management information systems and tools in order to efficiently administer the new service, as shown in Figure 1. A remotely operated vessel control system is one of these tools that permits remote monitoring and control of ASVs (RenewableUK, 2019). This solution can offer real-time details on the whereabouts, health, and data collection of the ASVs, facilitating enhanced operational efficiency and decision-making. The information can be utilized to create reports, spot trends, and raise the level of service quality overall (Zhang and Jiang, 2016).

MovingSeas Ltd. must create a service management system (SMS) to oversee the new service. Modules for managing UAVs, ASVs, and AUVs should be included in the SMS. Modules for controlling the service schedule, service requests, and service delivery should also be included in the SMS. The company must create an asset management system (AMS) to handle the new assets (Neugebauer and Seebacher, 2016). The AMS should have control modules for UAVs and USVs.

Lesson Learnt

Some of the lessons learnt include that the new inspection system needs to be sustainable as well as environmentally conscious, ensuring it considers environmental legislation and its effect on business operations. In addition, the main aim of the service adopted should be to decrease logistical support, enhance service frequency, decrease risk, and remove humans from the loop. Another great lesson that can be inferred is that MovingSeas Ltd will need an appropriate management information system and tools to ensure it administers the new service efficiently.

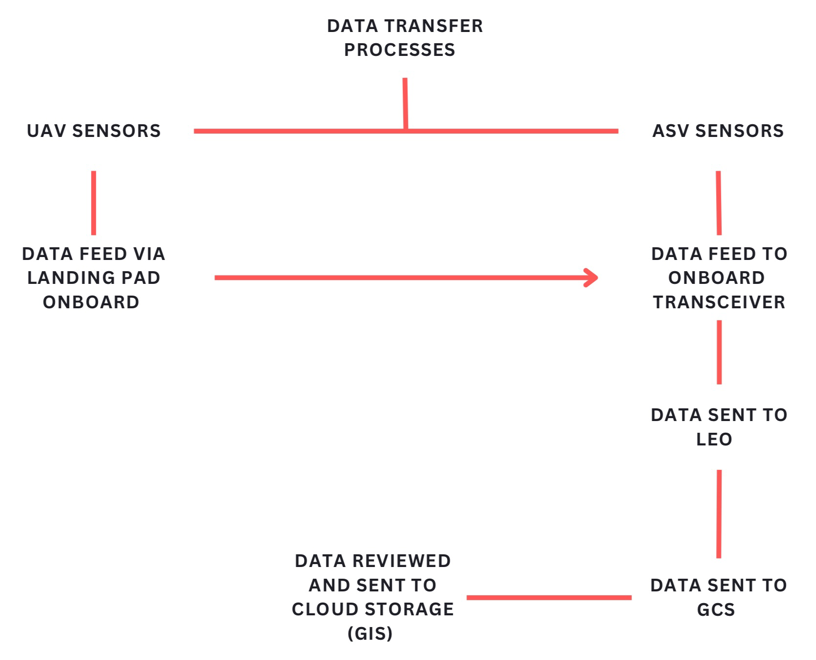

Data Transfer

Data collected from UAV/ASV will be huge, so it needs to be transferred through a LEO satellite to the base station. The communication between them will be through satellite. LEO would be used as a backup plan for communication loss. The technical architecture is as illustrated in Figure 2.

Technology and Management Architectures

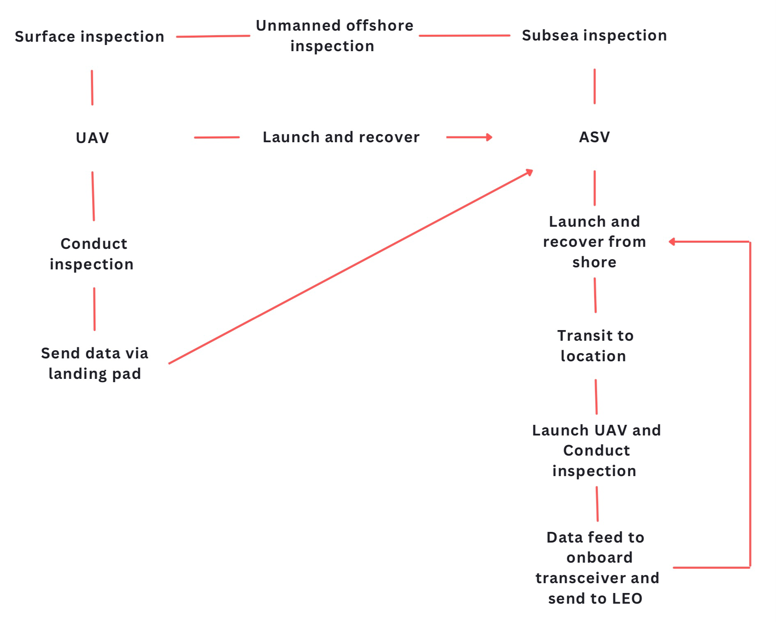

The company’s technology and management systems will need to be updated during the deployment of USV/USV. To ensure the proper operation of uncrewed boats, remote monitoring systems will be deployed. These remote monitoring systems will be equipped with sensors to report and identify environmental changes. When a problem is detected, the staff will be notified by the monitoring system, and the staff can then take the appropriate action.

The monitoring system will need to have a mechanism for controlling the unmanned craft (RenewableUK, 2019). The new architecture with the remote monitoring system will need to include the capability to schedule repairs, servicing, and monitor the location and performance of the unmanned craft. This new architecture will also require tracking the unmanned craft’s accessibility and will conduct inspections, as shown in Figure 3.

Procedures Required

The development of various new procedures is needed to achieve the execution of the autonomous craft inspection service. These procedures will entail pre-inspection planning, which will include the formation of a detailed inspection strategy that stipulates the parameters of inspection, the particular tools that will be employed, and the path the unmanned craft will take (Fugro, 2023). It will also have emergency response strategies, detailed safety protocols, and the roles and duties of the individuals participating in the operation.

Independent craft operations involve the unmanned craft operating independently (United Nations Framework Convention on Climate Change, 2015). It will involve the vessels landing, finding the inspection location, and conducting the examination on its own (Chan, 2006). Data management entails handling the information that has been gathered during the inspection. The data should be examined, saved, and arranged to discover any problems within the wind farm assets (IEC 60092-504, 1999).

Additionally, quality control helps ensure that the requirements for value are met. It will involve reviewing the inspection data to ensure that all necessary inspections were completed and to verify the accuracy of the gathered information. Lastly, a report that compiles the inspection results will be created as part of this procedure. The wind farm operator will receive the report containing suggestions for upkeep or repairs.

Measurement Methods and Metrics

Several criteria will need to be established to gauge the efficacy of the autonomous craft inspection service. These measurements will comprise:

- Inspection Coverage: This parameter counts the proportion of the wind farm’s assets examined by uncrewed aerial vehicles.

- Inspection Time: The duration of the examination will be gauged by this metric.

- Inspection Accuracy: This metric evaluates the precision with which the inspection’s results were gathered.

- Maintenance Cost: This metric will assess the expense of infrastructure, infrastructure costs, and people costs associated with sustaining the unmanned craft inspection service.

- Customer Satisfaction: This indicator measures how happy the wind farm owner is with the service of providing unmanned craft inspections.

- Downtime: Determining availability is essential, and measuring downtime can be a reliable indicator to do so. This measurement shows the unusable or non-operational period of a system or equipment. It is important to measure downtime so that companies can assess the potential loss in productivity, operations, and revenue that can result from system failures.

- Turnaround: For gauging efficiency and effectiveness, the turnaround time of a process, system, or activity holds great significance. The time span for completing a task or a process in its entirety, inclusive of all activities and necessary procedures, is what it refers to.

- HSEQ: It refers to a general term utilized to define a complex system of policies and norms that set the standard for Health, Quality, Safety, and Environment within an organization. The aim of developing these standards is to ensure the highest level of employee health and safety, protect the environment, and maintain superior quality standards. It is intended to provide a comprehensive suite of policies that cover both the physical and psychological safety of workers, as well as the environmental impacts of operations.

Additionally, rigorous quality requirements must be met in order to produce products and services that are of the highest caliber. To ensure these standards are upheld, periodic reviews must be conducted to assess the effectiveness of the HSEQ protocols in place, as shown in the figure below.

Conclusion

MovingSeas Ltd. has been offering subsea inspection services for more than 20 years, and they have always maintained a flexible approach to new technology developments. The company plans to offer small autonomous vessels for monitoring offshore wind farms to decrease logistical support, enhance service frequency, decrease risk, lessen environmental impact, and remove humans from the process. The employment of autonomous small ships equipped with sensors and cameras for monitoring monopiles, turbines, and cables in offshore wind farms is part of the company’s comprehensive service design for the new service.

Remote monitoring systems must be installed, technological and management architectures must be updated, new procedures must be developed, and new metrics and measurement techniques must be developed for the new service. Using small unmanned craft will reduce the need for logistical assistance, boost service frequency, lower risk, have less environmental impact, and involve fewer people (International Marine Contractors Association, 2019). The new service will provide wind farm operators with more dependable and precise data, enabling them to make more informed decisions regarding their assets. By lowering operating expenses and improving efficiency, the new service will also help MovingSeas Ltd. maintain its competitive advantage in the market.

Reference List

Chan, A. P. C., and Wong, F. K. W. (2006). ‘Environmental assessment of prefabricated modular construction in Hong Kong,’ Environmental impact assessment review, 26(1), 62-74.

Fugro (2023) Remote Inspection. Web.

IEC 60092-504. (1999). ‘Electrical installations in ships – Part 504: Special features – Electric propulsion plant,’ Geneva: International Electrotechnical Commission.

International Marine Contractors Association. (2019). ‘IMCA guidelines for safely and efficiently operating remotely operated vehicles (ROVs),’ London: IMCA.

Neugebauer, S., and Seebacher, R. (2016). ‘Managing knowledge for sustainable development. Journal of Cleaner Production,’ 139, 1026-1038.

Norouzi, N., Jayaraman, R., and Collette, J. P. (2014). ‘Life cycle assessment of offshore wind farms in the Belgian part of the North Sea. Energy,’ 67, 269-278.

RenewableUK. (2019). ‘Offshore wind operations and maintenance: An industry report,’ London: RenewableUK.

United Nations Framework Convention on Climate Change (UNFCCC). (2015), ‘Paris Agreement’. Web.

Vaaland, T. I., Utne, I. B., and Boks, C. (2017). ‘Robotic ships and the future of maritime transportation,’ Marine Policy, 75, 1-6.

Zhang, L., and Jiang, Y. (2016). Environmental Benefits of Adopting Prefabricated Modular Construction in Hong Kong. Habitat International, 57, 1-9.