Abstract

Casing design in field development is a critical task of a competent approach to well construction. Lack of proper attention, lack of resources, and ignoring the importance of comprehensive evaluations and audits can cause environmental and industrial damage to both the company and local communities and nature. This research paper examines the fundamentals of casing design, evaluating different approaches to the design and selection of casing materials.

This study focuses on Saudi Arabia because the local areas have colossal oil and associated gas reserves, and the geological and petrophysical conditions are of particular practical value. The study is based on integrating secondary and primary results to build a methodological algorithm for casing design decisions. The secondary data was obtained through an extensive literature review, while the primary data was obtained through interviews with four professionals from the oil and gas sector of Saudi Arabia. The study’s main result is the creation of a visualization of the methodological tree that minimizes the likelihood of environmental, economic, and technogenic risks and improves overall well performance.

Introduction

Background Information

Oil, gas, and water development requires special structural design considerations because it involves grave risks not only from environmental but also from industrial aspects. Improperly chosen design of structural elements can be the cause of unsuccessful drilling, which includes loss of drilling mud, formation damage, deterioration of access to the extracted resource, and the onset of environmental disaster.

One of the most essential elements of such design is the casing, elongated cylindrical structures inserted into the wellbore to prevent its destruction and ensure the integrity and absence of mixing of layers between each other. More specifically, oil, gas, and water wells are drilled in sections from the surface to the target formation zone. Thus, each section of the drilled formation must be isolated with cement and casing.

The casing provides the necessary support for weak and cracked formations, prevents contamination of the freshwater formation zone, isolates zones of abnormal pressure and loss of circulation, and provides passages within the wellbore that facilitate the flow of fluids and gases into and out of the formation. Cement is necessary to fill the annular space between the formation and the casing, which prevents corrosion and achieves the integrity of the structure being introduced into the wellbore. Given the benefits this type of structural element creates, casing design is one of the critical challenges in field development design.

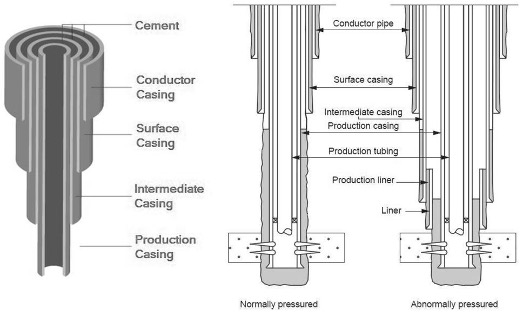

The classic use of casing is to use several types of casing, each running down to a specific depth. In particular, a conductor string is initially installed into the surface layers of the field formation up to the casing point, which delimits the pay zone to the formation — this zone is drilled below the conductor string level. Inside the conductor pipe of wide diameter, a surface string is installed, which has a smaller diameter but a greater length, so it completely covers the previously drilled-out area of the formation. The space between the conductor pipe and the surface pipe is completely cemented to prevent drilling fluid from leaking or compromising the integrity of the rig.

The cementing process is motivated by installing a top plug, which pumps all the cement into the interstitial space of the structure due to the pressure difference. By analogy, additional columns with even smaller diameters are installed, namely the intermediate column and the production column, which closes the overall structure. Thus, in terms of classical design, the borehole is represented by four successive types of casing, differing in length and diameter, the space between which is cemented.

The selection of specific casing points, casing depths, and casing material is based on the interaction of factors that determine the nature of the formation. Key among these factors are reservoir pressure, a fracturing of the reservoir, reservoir temperature, and fluid type in the reservoir. Considering the variety of predictors of successful drilling in the field, the drilling engineer in charge of well design gathers the necessary data from a geologist, production engineers, and reservoir engineers to design the well correctly and efficiently. Casing design is a crucial factor in drilling a well safely, efficiently, and cost-effectively.

Problem Statement

The variety of factors involved in casing design decisions and differences in environmental predictors, with a focus on preserving the environmental and industrial sustainability of fields, creates uncertainty for drilling engineers. Universal design rules cannot be used for each specific field because of their differences. This research report aims to review in detail the stages of casing design planning and methodology. Fields in the Kingdom of Saudi Arabia were selected for the specificity of the study, which implies an analysis of climatic, geological, and soil features of the local drilling conditions.

The report contains an analysis of interviews with four experts from Saudi Arabia with varying backgrounds as drilling engineers, offering their perspectives on crucial casing design considerations and risks associated with field development. The motivation for choosing this topic is based on a desire to summarize the evidence published in academia and draw conclusions specific to Saudi Arabia in the face of a scarcity of unique data. By interviewing experts directly involved in the field development industry, it is possible to cover the lack of helpful knowledge and build recommendations for choosing the right casing design.

Objectives

- Review published evidence on the issue of casing design, primarily for Saudi Arabia.

- Conduct interviews with experts involved in oil and gas field development.

- Summarize the results obtained from the literature search and thematic analysis of the interviews to construct a decision tree in the context of casing design.

Literature Review

Review of Casing Design

Casing design is a critical aspect of the oil and gas industry because it is crucial in ensuring the structural integrity of oil and gas wells. Casing and tubing in oil and gas wells are designed to withstand pressure loads and axial tension. Structural reliability theory can assist the designer in striking the appropriate balance between cost and level of safety when designing casing. During drilling, the casing system is exposed to extreme conditions such as high pressure and high temperature and corrosion due to hydrogen sulfide gas. Therefore, to ensure an acceptable level of risk in the process of well casing design, calculated safety factors are applied.

In addition, studying and evaluating casing integrity after wear or corrosion is necessary to provide a basis for casing design and safety assessment. Casing wear and corrosion are significant factors affecting casing integrity, especially in ultra-deep wells, directional wells, and horizontal wells in deep drilling. Therefore, pipes and joints, which are the main elements of the casing system, must be designed to withstand external and internal loads. The design of production casing in gas horizontal wells must consider hydraulic fracturing pressure and sustained pressure in the casing, and casing failure in gas horizontal wells prevents effective gas development.

Types of Drilling Fields

Oil and gas wells are drilled in two fields, which is vital in choosing the right casing design. There are exploration and production fields, which have various processes and purposes. Exploration drilling is conducted in areas where the presence of oil or gas is uncertain or unknown; therefore, the process is to find oil or gas in a new area. It involves drilling a test well to determine if there is commercial viability in the region. Exploratory drilling is a high-risk project because there is no guarantee that oil or gas will be found. Given the high risks, the cost of such drilling is relatively high, and in addition, it may take years to find a commercially viable reserve. Nevertheless, exploratory drilling can lead to the discovery of rich deposits, justifying substantial risks.

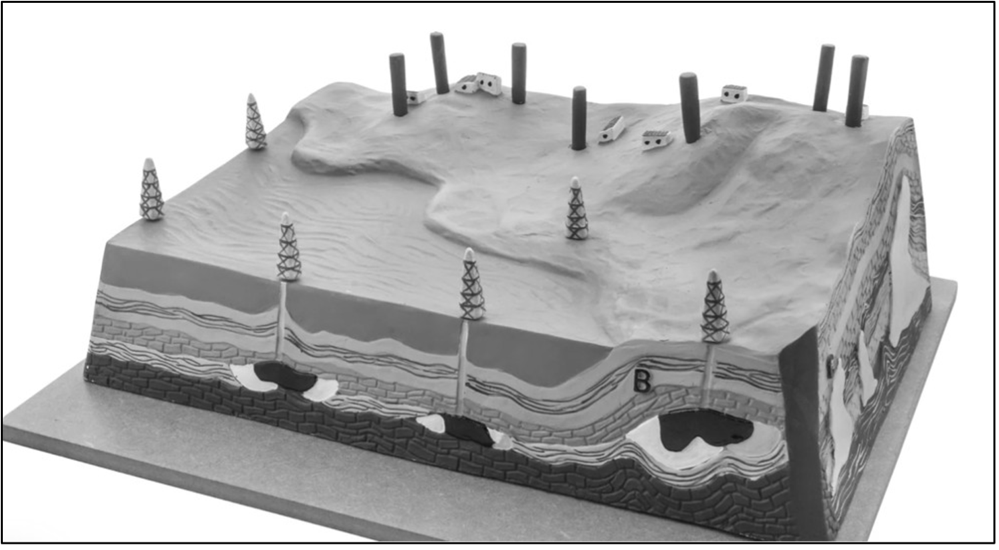

Conversely, exploratory drilling is carried out in regions where the existence of gas or oil has already been established. Its process consists of drilling several wells in the same location to maximize the recovery of oil or gas already found. This mechanics is based on the evidence that fields are often not located in a single area but rather in neighborhoods, forming a tree-like or disordered structure, as shown in Figure 1. This type of field is much less risky because the presence of oil and gas has been previously confirmed, and reserves have been estimated. Thus, drilling in such fields aims not to explore areas and find undiscovered reserves but to produce the maximum amount of the resource.

Drilling Methods and Well Trajectory

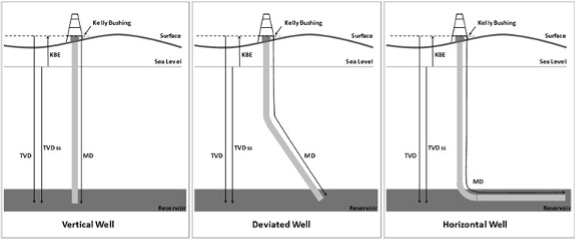

When planning to drill, engineers need to consider the type of field being treated and the reservoirs’ geological and petrophysical characteristics. As shown in Figure 2, several types of drilling differ in terms of casing trajectory. These include vertical drilling, directional drilling, and horizontal drilling.

Vertical Drilling

This method of drilling is the most traditional and simple method, in which, on the plan of the well trajectory, the measurement depth is equal to the actual vertical depth. It is used mainly on shallow wells, exploration, and development fields when the target formation is directly below the surface. In most cases, the exploration well is planned to drill vertically to the formation. Then logging is performed, the purpose of which is to measure the geophysical properties of the borehole using downhole sensors. Such sensors include a resistivity meter, a sound velocity meter, and a material porosity meter. The data are automatically recorded and subsequently used to evaluate potential field finds and make decisions about further drilling trajectory.

Deviated Drilling

This method of drilling is used when the target layer is not reachable by vertical drilling. It is more common in developed fields where the area is clogged with existing wells, and there is data on the reservoir in that area. The well is drilled vertically to a depth called the starting point, and then the well is continued with special directional equipment to the target total depth of the well. Thus, the borehole trajectory plan is developed based on the actual vertical depth direction, the degree of inclination from the vertical direction, and the azimuth. The degree of inclination in this method of drilling ranges from 50° to 70° degrees.

Horizontal Drilling

This method of drilling is similar to the directional drilling method in terms of site conditions and planning, except that this method is used to drill wells with an increased radius, with the degree of inclination varying from 70° to 90°. Using horizontal drilling is expedient when only a vertical or directional algorithm is not enough for effective oil and gas production. Horizontal drilling becomes especially relevant in cases of oil and gas accumulations in fractures and small pores.

Casing and Well Design

When planning a new well, a review and study of existing offset wells are conducted to understand the nature of the field and common drilling problems. This review and research will help select the appropriate well/casing design for safe drilling and well integrity. This is because it is not possible to drill a well from the surface to the point of oil and gas in one pipe size. Therefore, different sizes of casing are used to create a conical shape at the end of the well. The casing starts with a large size called conductor casing, then surface and intermediate casing, and finally, production casing, as demonstrated in Figure 3.

Conductor Casing

The conductor string is the first large-diameter string that descends from the surface to shallow depths to protect the unconsolidated formation, seal the shallow zone, protect shallow gas streams, and stabilize the rig’s foundation. It is also used as the foundation for a blowout preventer, which is a set of large valves used to shut down a well to control gushing gas or oil coming from the ground with high pressure and wellhead equipment. The casing of this type ranges in depth from 40 to 120 feet and in diameter from 30 to 18 5/8 inches, depending on the casing design.

Surface Casing

This casing is run after the conductor casing to a depth of 1,000 to 4,000 feet, where a competent formation will be reached to prevent a collapse of the weak formation, extensive washout of the unconsolidated formation, and protection of the freshwater aquifer. After the casing is run, the casing is cemented at the surface to increase its stiffness and strength to withstand compressive loads. This casing varies in diameter from 24 to 13-3/8 inches.

Intermediate Casing

This type of casing depends on the geology of the drilling area. Its casing point is usually installed in a transition zone either below or above the formation with anomalous pressure (4,000 to 7,000 feet). Therefore, the primary function of this casing is to isolate problem formations, protecting the formation beneath the surface casing from the increased pressure that may be encountered when drilling new areas. The diameter of the casing ranges from 18-5/8 to 13-3/8 inches. This casing is cemented at the surface to prevent communication behind the casing between the hydrocarbon zone and the upper water formation.

Production Casing

This casing is the last casing run in the well. The location of this casing depends on the type of well, whether it is a gas or oil well. In an oil well, the casing point is set above the reservoir zone; in a gas well, the casing point is set above the formation with abnormal pressure. Production casing is called production casing because it houses completion equipment that allows produced fluid to flow to the surface, so it is the most critical type of casing on a well. It is usually 9-5/8 inches in size, which is cemented at the surface.

Features of Saudi Arabian Fields

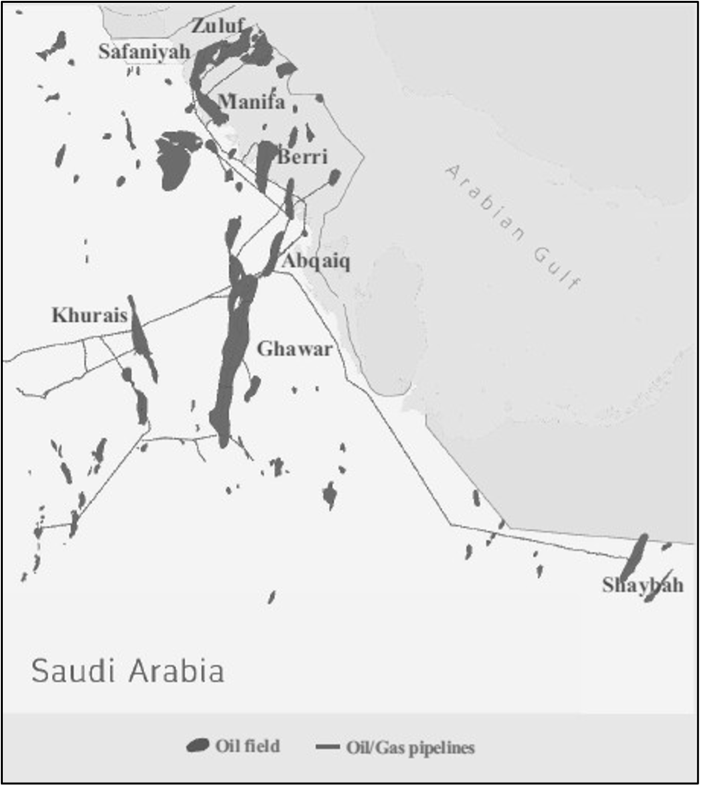

In selecting the optimal casing design, including directional trajectory, material, and depth, the drilling engineer must analyze the petrophysical and geological features of the fields. The Saudi Arabian fields are characterized by massive sedimentary rock strata represented by shale, limestone, or sandstone. Such deposits are typical of local areas and have low moisture content. In addition, rocks near deposits are characterized by general heterogeneity, vertical distribution of stylolites, and moderate microporosity.

The significant oil and gas deposits in Saudi Arabia were formed during the Mesozoic Era and are preserved in large sedimentary basins. The formation of such basins resulted from the collision of the African and Arabian tectonic plates, so the country is rich in multiple oil and gas deposits found everywhere, as shown in Figure 4. In particular, Saudi Arabia, at the end of 2020, had the second largest proven total oil and gas reserves, and the total number of discovered fields exceeds 130.

Within Saudi Arabia, the key fields are concentrated in the Arabian and Khuff formations and in areas of the Jurassic carbonate reservoirs. Table 1 ranks the eight largest proven fields producing both ultra-light and ultra-heavy crude oils. Notably, the Arabian Formation is one of the richest in the context of oil fields and the shallowest, whereas the other two mentioned formations are predominantly gas sources and are located at much deeper levels.

Table 1 – Key oil fields in Saudi Arabia.

The petrophysical features of Saudi Arabian fields must also be taken into account when designing casing design. Salih et al. report that local rock porosity is generally low-to-moderate and does not exceed 20%, with permeabilities ranging from 0.002 mD to 1.9 mD. Importantly, sandstone-rich basins traditionally have higher permeability than those containing a lot of carbonates. Mineral analysis of the rocks shows a predominance of calcite and quartz. In terms of the qualitative composition of produced oil and gas, local reserves contain high-quality resources by market metrics with low sulfur content and high API density, as shown in Table 2.

Table 2 – Characteristics of some types of Saudi oil.

Casing Design and Selection

Casing design should be based solely on a synthesis of considerations about the industrial benefits of their use and the geological and petrophysical properties of a particular field. The critical task to be accomplished with the casing is to achieve high stability of the borehole, preventing unplanned cave-ins, leakages, corrosion, and mixing of layers. To achieve this goal, the drilling engineer must select the proper casing parameters, whether their material, weight, size, and grade, which are chosen depending on the strength, temperature, and porosity of the rock in the field.

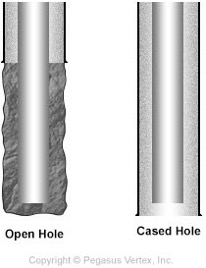

Pipe Completion

The operable casing has installation alternatives, depending on the type of field to which it is applied. Figure 5 shows two options for production casing completions, namely open-hole or cased-hole completions. The difference between the two completions is the cementing of part of the final casing: in open-hole, the zone “might be left completely bare, but some sort of sand-control and/or flow-control means are usually incorporated,” whereas in cased-hole, the design “involves running casing or a liner down through the production zone and cementing it in place. The use of an uncased completion

makes sense in formations that are highly stable because the end of the borehole fits freely into the rock. In contrast, the use of a cased completion is most appropriate for less stable rocks since the casing cladding allows for increased stability of the structure.

Formation Strength

An important characteristic when selecting a casing design is the strength of the formation that is proposed for drilling when oil and gas deposits are suspected. In particular, the strength of such a formation, which is the total characteristic of permeability, porosity, and moisture content, determines the requirements for the casing diameter. The universal rule is that the more friable and unstable the rock is in the section, the larger diameter should be used for casing construction. This relationship is due to the increased total contact area of the rock with the pipe, which significantly reduces the probability of wellbore collapse at any level. By analogy, excessive casing diameter is not required for more stable rocks since structural stability is also guaranteed at small diameters. At the same time, reducing the diameter of the pipe allows for to reduce of the material consumption for its production, optimizes the operation, and reduces the economic burden.

Pressure and Temperature

Reservoir pressure refers to the pressure exerted on internal rock components and is the motivating force behind the formation of minerals or other natural resources, including oil and gas. Higher reservoir pressures obviously require more reliable casing materials. It is noteworthy that Saudi Arabian fields are traditionally characterized by high reservoir pressures due to the great depth of the basins and high levels of geological pressure.

To put it differently, the selection of highly stable casing materials that prevent wellbore instability is accurate for Saudi Arabia. In addition to pressure, reservoir temperature also plays a role in casing composite selection. In particular, Saudi Arabia, which is characterized by high-temperature formations, requires the use of the most reliable materials that are resistant to high temperatures. It is interesting that higher reservoir temperatures make requirements for the cementing phase as well because, at high temperatures, the cement may not entirely cure or stick to the casing walls.

The Environmental Risks of Improper Design

An earlier literature search demonstrated that one of the main criteria in casing design is to ensure maximum safety of the drilling facility. Safety in this context has traditionally been used in an environmental sense, that is, the prevention of any risks that might harm the environment. The academic review has shown that the main types of threats to nature from improper casing design are wastewater contamination, air pollution, worker injury or death, and the release of hazardous materials.

Groundwater Contamination

Gravity waters of the first beneath the surface of the aquifer naturally accompany micro-basins in the fields. Formed by the infiltration of atmospheric precipitation and infiltration of river and seawater, groundwater forms aquifer systems that are used in urban drainage systems and rural areas. Typically, oil and gas reservoirs are much lower than aquifers, so drilling can disrupt the natural flow of groundwater. On the one hand, this can lead to water release into the wellbore, which worsens access to the drilling mix and reduces production efficiency. On the other hand, improper casing design can release contaminants (oil, hydrocarbons, associated substances, and minerals) into groundwater, resulting in contamination of the aquifer.

Air Pollution

Drilling operations release significant quantities of dust and sediment into the air, which can be picked up by the wind and cause local air pollution. A serious problem is disturbed well design, which can result in the release of produced associated gas into the atmosphere or products of its combustion. The issue of pollution is especially acute for fields located near urban agglomerations since the air quality in them may be a problem from the very beginning.

Injuries or Deaths of Workers

Anthropogenic errors resulting in injury or death of field workers are also consequences of improperly designed well designs. The main hazards are the combustion of flammable organic components of oil and associated gas or structural collapse and health damage to workers due to falls. It is noteworthy that health risks can manifest themselves both in the short term and in the event of an emergency and be cumulative. Studies show that such consequences should include cancer, immunodeficiency diseases, and chronic liver inflammation due to the accumulation of contaminants in workers’ blood.

Study of Catastrophic Experience

Critical in the design and planning of field well designs is the study of the experience of past field emergencies. It is reported that of all causes of emergencies in oil production wells, human error, including improperly designed wells, accounts for more than 70% of all cases. For Saudi Arabia, the tragic experience of the 1991 disaster is best known. During the Persian War, in January 1991, more than 460 million gallons of crude oil from an offshore well were spilled onto the surface of the Persian Gulf as a result of deliberate sabotage. Soon, the oil spilled and spread on the surface of the water, catching fire and further compounding the damage caused by the catastrophe.

Globally, several disasters are known to have caused damage to the environment and the health of both workers and local communities. In 2010, for example, the largest oil spill in history occurred at the Deepwater Horizon, an offshore well, also due to improper design. In particular, it is reported that the management of the oil production platform deliberately went for higher-risk casing materials, even though they had the selection to use more reliable ones. Cementation was not uniform enough, resulting in gaps in which gas accumulated. Studying these and similar disasters is a necessary step to draw conclusions and ensure proper safety on projected wells.

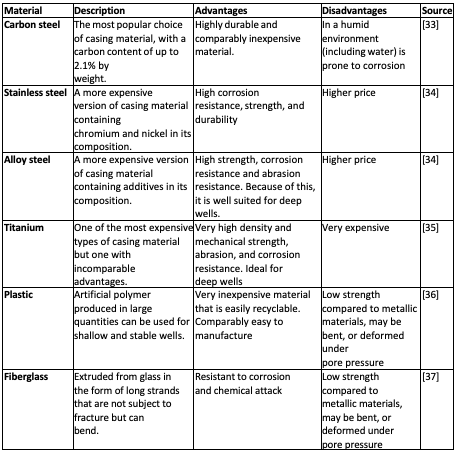

Casing Construction Materials

One of the central and frequent questions in academic and applied discourse is the selection of a reliable structural material based on geological, petrophysical, and industrial characteristics. Based on an extensive academic search, Table 3 was prepared to summarize the primary materials already used in field drilling. The choice of a particular casing material to manufacture and use depends on individual field conditions and the mining company’s budget, so there are no universal rules for their selection. Nevertheless, carbon steel is used most often because it is a trade-off in price/performance ratio.

The Latest Technologies in Casing Design

The oil industry is one of the most technologically advanced and advanced in the entire world, with an economy tied to the export and import of oil, associated gas, and high hydrocarbons. Despite the crises that have affected the industry, namely the COVID-19 pandemic and the Russian-Ukrainian conflict, global oil demand has quickly rebalanced. It is estimated that by 2026, global oil demand could grow by more than 5%, and the industry will continue to rationalize and technologize. In this connection, scientific sources emphasize the increased demand for the improvement of existing oil and gas production systems. This can be realized through the use of more optimized materials, computational technologies, the introduction of intelligent solutions, and the creation of advanced casing systems.

First, finding and using materials that are critically resistant to corrosion and mechanical damage, as well as economically viable, is a significant challenge for the oil and gas industry. Such materials as titanium and alloyed steel have sufficient characteristics but, from the economic point of view, are invalid. For this reason, the search for new composites combining the necessary characteristics is an unfinished part of the current applied research.

Second, many authors have reported on the advanced possibilities of using machine learning and artificial intelligence for casing design. For example, Liang et al. demonstrate how machine learning can be used to make decisions about continuing or suspending drilling activities during logging or using case completion. Noshi et al. and Carpenter report on how machine learning and artificial intelligence can be successfully used to predict casing failures in order to minimize risks of collapse or flooding.

Third, to improve the integrity and overall reliability of the casing structure, it is acceptable to use better sealing materials than cement. Such threaded and coupling materials improve the torque of the structure and allow it to retain increased stability during earthquakes or during shocks caused by the displacement of layers in the field.

Conclusion

A large-scale literature search of scientific research has demonstrated several conclusions applicable to this research report. First, there is no one-size-fits-all rule for casing design because each specific design depends on individual conditions. These conditions include petrophysical, geological, industrial, environmental, and economic considerations.

Second, designing a reliable design is a vital industry challenge because it can otherwise cause environmental, industrial, and human-made disasters. Third, there is a vast variety of design attributes, from choosing the primary casing material and the type of bonding mortar to the casing installation trajectory and determining the most optimal completion. With this in mind, and given the context of the Saudi Arabian environment, additional research is needed. This will provide conclusions relevant to the Saudi fields that are lacking in published studies, which can then be used in practice as a decision-making tree.

Significance of the Research Project

A literature search revealed a dearth of unique data specific to Saudi Arabia on the one hand and an overabundance of diverse knowledge that cannot be classified on the other. As a consequence, the applied meaning of such studies may exist to solve some highly specialized problems, but no study qualitatively explains the algorithm of steps for casing design selection. Therefore, it was decided to conduct an initial study, the endpoint of which is to create a methodological decision tree to determine what casing design is the most relevant based on a synthesis of various factors. The research project will significantly expand the field of published knowledge, summarize existing evidence, and add input in the form of data from individuals directly involved in the Saudi Arabian oil and gas industry and decision-makers in well design.

In addition, the study will improve decision-making practices by providing a methodological framework that can be applicable not only to local fields but also to a global context, providing some universal rules of selection. At the same time, the findings will also be applicable to areas of Saudi Arabia, the second largest field area in the world, which is expected to significantly reduce drilling accidents, reduce risks, and increase production productivity. To summarize, the research project builds on the foundation of previous studies, puts the identified beneficial knowledge deficit at the center of the research, and brings valuable methodological contributions to the academic and applied discourse.

Methodology

The methodological basis for this research project was to determine the state of the current academic and industry agenda on optimal casing design for Saudi Arabia and to create a universal methodological rule for design choices. With this in mind, the work was carried out in two phases: a literature search and primary data acquisition. This chapter provides a detailed description of the methodology of the research project, specifies the materials and algorithms for data collection, and discusses the type of analysis used for the data collected.

Data Collection Mechanism — Literature Review

The first step for data collection was a literature search, which was implemented through the Google Scholar digital library, ResearchGate, and Elsevier. The literature search was designed to identify the current state of academic discourse, identify the main topics of interest to the authors, and identify potential knowledge gaps. The criteria for inclusion in the scholarly search were the year of publication (no earlier than 2013), writing in English, and authors’ authority. The latter criterion was checked by examining the correspondence between the topic of the academic journal in which the material was published and the subject of the article itself. In addition, as an additional check, the publicist biography of the first author was examined to determine the overall range of their academic interests. After applying the inclusion criteria and reviewing all papers, a literature review was written and divided into thematic sections based on where the authors’ conclusions were similar.

Data Collection Mechanism — Interviews

A structured interview mechanism was used to obtain primary data. In this form, the questions were prepared in advance, and the order of the questions was not changed during the conversation with the respondent. The expediency of using the structured interview method was to standardize and systematize the responses received, which optimized the process of their further processing and ensured that each expert could share his/her professional opinion on the question being asked.

Recruitment was conducted on LinkedIn and Facebook platforms: using the filtering features of the output, candidates were found who had experience in the oil and gas industry strictly in Saudi Arabia and who had been hired as a drilling engineer (or semantically similar) at least a year and a half ago. This ensured that the interview experts had at least minimal work experience, had completed an internship, and could provide valuable insights for an ongoing research project.

In this search, 11 candidates were selected, each with a welcome letter. The total number of people who agreed to the online meeting was four (36.4%). A short online interview was conducted with each of the four experts at the appointed time, lasting 20-25 minutes. Depending on the communication format preferred by the respondent (text correspondence, audio, or video call), with the consent of the expert, all data were recorded and formed into a single text document.

Data Analysis

The collected data were subjected to primary processing, which was necessary to remove uninformative details, reduce further work, and optimize the raw data. Such processing included removing any emotional interjections or pauses from each respondent’s responses, retaining only textual responses, and distributing all data in a “Question: Four Responses” format. Thematic analysis was used to conduct a statistical analysis of the data used. The thematic analysis consists of several sequential steps and includes a general review of respondents’ answers, coding key phrases, grouping specific codes into unique themes, viewing unique themes, and interpreting the results. The choice of this methodological design was based on a small sample size (N = 4), a small number of questions per expert (N = 10), and a structured interview method that meets the condition that all experts will answer the same questions.

It is important to emphasize that thematic analysis as a way of handling qualitative data has some disadvantages. More specifically, this type of analysis involves a high degree of subjectivity due to the mechanics of selecting codes and combining them into themes, which can lead to oversimplification and lack of transparency. Despite this, thematic analysis has saved time, optimized data processing, and virtually guaranteed that data have not been lost during coding and interpretation.

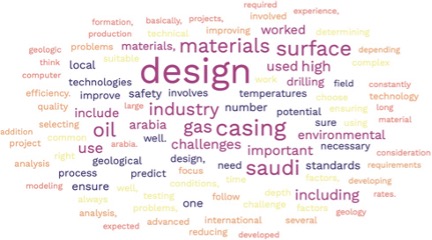

Materials Used

Google Scholar, ResearchGate, and Elsevier were used to collect secondary data (literature search). All of the sources found were either in the public domain or obtained through university subscriptions. Text messengers on Facebook and LinkedIn platforms, as well as Zoom for video calling, were used to collect primary data. The free online service Word Cloud Generator was used for a visual representation of the data. In addition, Adobe Photoshop was used to build a methodological decision tree.

Results and Discussion

The Literature Review section provided the results of the first phase of the research project, namely determining the current state of the academic agenda. This chapter, on the other hand, provides a detailed description of the primary findings of the thematic analysis. The first part of this section provides data on the demographic and professional attributes of the experts who responded to the interviews. The second part of the chapter describes the results of the thematic analysis, indicating the themes found. In addition, the chapter explains how each finding is valuable to the academic community and how it contributes to, agrees with, or contradicts the results of published scholarly sources.

Demographic Characteristics of the Sample

Four experts, each with professional experience in the oil industry in Saudi Arabia and whose work is directly related to casing design and whole-well design, were invited to conduct structured interviews. Depending on the company where the experiment worked, their job titles varied, but the broad set of responsibilities and job functions were virtually identical. In order to maintain the confidentiality of each of the experts’ identities, their names and profiles were not disclosed. However, other demographic characteristics (age, position, and work experience) are summarized in Table 4.

Table 4 – Demographic and occupational information about the sample.

Results of Thematic Analysis

Table 5 contains the results of the thematic analysis with a description of the themes identified for each of the ten questions and a detailed description of each theme in light of the interview experts’ responses. After conducting an in-depth thematic analysis, nine key themes were identified based on all respondent responses:

- professional experience,

- achieving sustainability,

- accounting factors,

- process steps,

- challenges,

- safety and compliance,

- trends,

- communication,

- training.

Quantitatively, the most frequently used topic for respondents’ responses was Achieving Sustainability (30%), followed by Challenges (15%). It follows that respondents were most likely to discuss measures that improve well performance, optimization, and sustainability, as well as challenges they faced during projects. Interestingly, content analysis for respondents’ responses showed that the most common word patterns included “Design” (4.9%), “Casing” (2.8%), “Surface” and “Saudi” (2.4% each), and “Oil” (2.3%).

Could you tell us about your experience in casing design in the oil and gas industry, particularly in Saudi Arabia?

Theme: Professional Experience

Description

Each expert had a different experience in the oil and gas industry. All but the second expert had extensive work experience (≥15 years). According to Expert 1, the work of the drilling engineer is associated with field activities and office work on the computer. From the words of Expert 2, the work is associated with close cooperation with other specialists, and decisions are made jointly. From the responses of Expert 3 and Expert 4, working in the industry requires in-depth knowledge and consideration of multiple factors.

What are the typical issues with casing design in Saudi Arabia’s oil and gas sector, and how are they resolved?

Theme: Achieving Sustainability

Description

Expert 1 points out the need to select high-quality construction materials and testing. Expert 2 stresses that stability is achieved by considering extreme geological, climatic, and petrophysical conditions. Expert 3 said optimistically, “With the right materials and enough attention, any problem can be overcome!” Expert 4 summarized the conclusions of Experts 1 and 2, pointing out the need to consider extreme conditions and use suitable materials.

What factors do you consider when selecting the optimal casing design for a particular oil and gas well in Saudi Arabia?

Theme: Accounting Factors

Description

All but the fourth expert named temperature and pore pressure. Experts 1 and 2 points to the amount of drilling required, the depth (thickness), and the quality of the rock present. Expert 3 also names the need for experience and intuitive understanding, and Expert 4 adds the need to consider local regulatory frameworks and any environmental and social considerations.

Tell me about the casing design process for an oil and gas well in Saudi Arabia.

Theme: Process Stages

Expert 1 indicates four steps: geological data analysis, surface engineering, determination of suitable materials, and testing. Expert 4 expands to indicate geologic and engineering analysis, casing design, material selection, and installation. Expert 2 supports the idea of data analysis and adds the need to determine available materials to make decisions. Expert 3 points to the need for psychological preparation for planning.

Theme: Achieving Sustainability

Expert 2 talks about the importance of maintaining well integrity and achieving the set KPIs.

Theme: Challenges

Expert 3 talks about the difficulty of planning and the need for psychological preparation, and Expert 4 talks about the need to adhere to local regulatory rules and the length of the process.

How do you ensure casing design safety and reliability in the Saudi Arabian oil and gas industry?

Theme: Safety and Compliance

- Expert 1: quality materials and testing.

- Expert 2: quality materials, adherence to industry standards, cooperation with drilling and completion crews, use of modern software.

- Expert 3: materials analysis, adherence to industry standards, strict adherence to safety practices, regular equipment inspections.

- Expert 4: proper use of equipment, regular examination of equipment.

What are the recent technological advances in casing design for the oil and gas industry in Saudi Arabia and how are they improving the efficiency and effectiveness of the industry?

Theme: Trends

Experts 3 and 4 emphasized that the main trends are to reduce costs, improve environmental safety, well efficiency, and optimize materials used.

Theme: Achieving Sustainability

Experts 2, 3, and 4 pointed to finite element analysis, advanced analytics, machine learning, and machine learning.

What are some of the environmental problems associated with casing design in the oil and gas industry, and how are they being addressed in Saudi Arabia?

Theme: Challenges

Expert 3 mentioned that improperly designed or operated wells could lead to surface pollution. Expert 4 gave a broader answer and named air, water, and soil pollution, as well as habitat destruction, as significant sources of environmental damage.

Theme: Achieving Sustainability

Expert 3 stated that strict emission control protocols must be used in the field under development. Expert 4 pointed out that proper disposal and reuse of materials minimize environmental risks.

Can you describe a specific project in which you were involved in the process of designing casing for the oil and gas industry in Saudi Arabia and what lessons were learned from that experience?

Theme: Safety and Compliance

Experts 1 and 3 stress the importance of following international standards and safety practices.

Theme: Achieving Sustainability

Expert 4 cites the importance of teamwork as a necessary skill for working in hazardous fields.

Theme: Challenges

All experts (except the third) cited barriers and difficulties: preventing damage to workers’ health, lack of personnel, and harsh weather conditions.

What are the current trends and outlook for casing design in the Saudi Arabian oil and gas industry?

Theme: Trends

All four experts point to the trend of technologicalization, and Expert 3 says: “I believe that the demand for technology in Saudi Arabia and the world, in general, will increase shortly.

Theme: Achieving Sustainability

All experts (except Expert 4) emphasize increasing well efficiency. Expert 4 pointed to a trend toward greater well sustainability and risk reduction.

Lastly, what guidance would you offer someone who is just beginning their career in Saudi Arabia’s oil and gas industry’s casing design?

Theme: Training

Expert 1: “continue to learn and keep abreast of the latest technologies and standards in the industry” and “work on developing technical and communication skills. Expert 3: “take care to continually update knowledge, learn from mistakes, and try new techniques. Expert 4: “I would advise focusing on building a strong foundation in engineering and materials science.”

Theme: Communication

Expert 4: “Developing strong communication and collaboration skills is important. Expert 1: “There is a need to expand the network of social connections.”

Theme: Professional Experience

Expert 2: “Using past experiences and developing them.” Expert 1: “Design problems can only be overcome by taking advantage of practical experience.”

It is important to note that the experts’ answers agreed well with the data published in previous studies. Each of the experts interviewed noted, to a greater or lesser extent, the trend of digitalization and technologicalization of the well development process, and this trend is heterogeneous. According to Expert 1, digitalization is relevant now since the drilling engineer works equally in the field and on the computer in the office. At the same time, most experts expect that the introduction of machine learning, AI, and deep analytical models will have a positive impact on the industry and optimize production operations while reducing risks — these conclusions are supported by research.

At the same time, it was common for experts to point out the key factors to be considered in proper casing design: they named extreme conditions, pore pressure, temperature, and rock quality, which is supported by the results of the literature review. Experts also discussed environmental safety risks to varying degrees, citing threats of water pollution, air pollution, and habitat destruction. Worker injury experience was cited as one predictor of improving current safety and operational performance at the well by Expert 1. Notably, each expert touched on the issue of selecting high-quality and corrosion-resistant materials, but none of them named the specific composites used to make the casing.

Although the results of the interviews agreed well with the results of the literature search, the experts added some new information. In particular, Experts 1, 3, and 4 reported that one of the main attributes of successful construction of reliable casing construction is continuous training and up-to-date knowledge. Meanwhile, Experts 1, 2, and 4 at various times pointed to the need to develop communication and teamwork skills, as no project can be expertly completed by just one professional. The development of practical experience was also cited as one of the guarantors of success by the experts.

In addition to what was not found in the literature review, the experts often referred to the need to comply with international and local legal and environmental regulations. The implication is that such practices allow for the alignment of interests among the various stakeholders and increase the safety of the well project. Thus, the main themes that were new to this study included continuous learning and improvement of practical experience, communication and teamwork, and compliance with international standards.

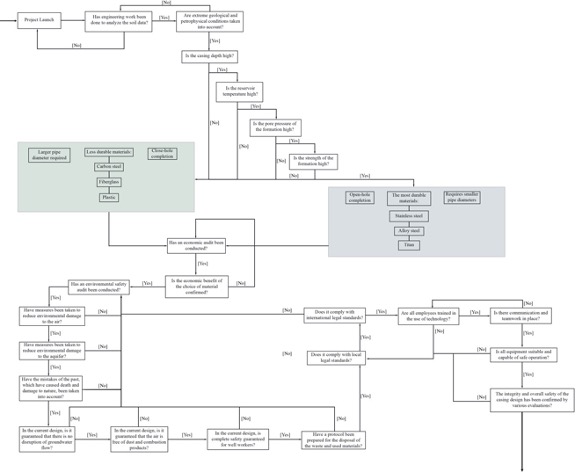

Methodological Decision Tree

Based on the integration of the literature review and the results of expert interviews, a decision tree was built, a comprehensive flowchart that allows a universal approach to the selection of casing design — the final decision tree is shown in Figure 7. Methodologically, the diagram contains the necessary selection alternatives from project start-up to the completion of theoretical discussions and expertise to the practical implementation of the selected design.

Structurally, the diagram can be divided into several phases: selection of material and casing characteristics and verification of compliance and safety. The comprehensiveness of the created diagram allows us to expect that the implemented well designs will be characterized by high economic, environmental, and technical safety, minimizing any risks and guaranteeing increased productivity.

Conclusion and Recommendations

When designing wells in oil and gas fields, the most significant attention should be paid to the correct casing design. Failure to select the right material and characteristics of such tubing, expert judgment, and auditing based on geological, petrophysical, and climatic conditions of the area is guaranteed to cause a technogenic and ecological disaster. Given the importance of proper and comprehensive casing design, this research project conducted an extensive literature review, which nevertheless showed a lack of universality. This uncertainty complicates the decision-making process and potentially leads to design errors.

As part of the project, four interviews were conducted with experts in drilling engineering and casing design from Saudi Arabia. Based on the results of the interviews and in integration with the results of the literature review, a methodological flowchart was constructed to serve as a universal tool for decision-making and casing design selection. The advantage of the flowchart created is that it is not only suitable for Saudi Arabian conditions but contains steps that can be applied to any field.

Students, engineers, and other stakeholders directly or indirectly involved in casing engineering and design may find the built helpful methodological algorithm. Although it is universal, it is recommended that it be used as a guideline in each case and adapted to the conditions of the field under development. Expert risk assessment and auditing are critical steps in improving well development, and the viability and sustainability of structures depend on the results of such audits. For this reason, it is recommended that several independent expert panels be used. In addition, continuous training and communication between the employees involved and the exchange of views should be ensured at project start-up, as this can uncover potentially hidden problems and establish efficient production.

References

N. Mohamadian, H. Ghorbani, D. A. Wood, M. Mehrad, S. Davoodi, S. Rashidi, A. Soleimanian, A. K. Shahvand, “A geomechanical approach to casing collapse prediction in oil and gas wells aided by machine learning,” Journal of Petroleum Science and Engineering, vol. 196, pp. 1-21, 2021.

Industrial3D Inc. (2020). The casing & cementing process in oil & gas drilling engineering animation. Web.

IET. (2022). How to become a successful drilling engineer. Web.

GLA. (2021). Chapter 6 structural reliability. Web.

Z. Yan, C. J. Okere, X. Zeng, Z. Yao, G. Su, M. Gan, Y. Fu, X. Tao, L. Zheng, “Preventing sour gas kicks during workover of natural gas wells from deep carbonate reservoirs with anti‐hydrogen sulfide fuzzy ball kill fluid,” Energy Science & Engineering, vol. 10, no. 8, pp. 2674-2688, 2022.

C. Sahu, R. Kumar, J. S. Sangwai, “Comprehensive review on exploration and drilling techniques for natural gas hydrate reservoirs,” Energy & Fuels, vol. 34, no. 10, pp. 11813-11839. 2020.

L. Wang, D S. Oliver, “Efficient optimization of well-drilling sequence with learned heuristics,” SPE Journal, vol. 24, no. 05, pp. 2111-2134, 2019.

EISCO. (2022). Underground deposits model. Web.

Dutton, J. A. (n.d.). 7.4: Well orientation. Web.

Slide Player. (n.d.). Casing. Web.

M. Dutkiewicz, I. Shatskyi, O. Martsynkiv, E. Kuzmenko, “Mechanism of casing string curvature due to displacement of surface strata,” Energies, vol. 15, no. 14, pp. 1- 12, 2022.

V. Chandra, A. Petrovic, P. Khanna, AI. Ramdani, B. Yalcin, V. Vahrenkamp, T. Finkbeiner, “Impact of depositional and diagenetic features on petrophysical and rock mechanical properties in Arab-D reservoir equivalent upper Jubaila Formation, Saudi Arabia,” Marine and Petroleum Geology, vol. 129, pp. 1-19, 2021.

D. O. Lirong, W. E. Zhixin, W. A. Jianjun, W. A. Zhaoming, H. E. Zhengjun, L. I. Xiaobing, N. Zhang, “Analysis of the world oil and gas exploration situation in 2021,” Petroleum Exploration and Development, vol. 49, no. 5, pp. 1195-1209, 2022.

EIA. (2021). Background reference: Saudi Arabia. Web.

Powers, R. S. (2019). Saudi Arabia. Web.

M. Salih, J. J. Reijmer, A. El Husseiny, M. Bashri, H. Eltom, H. A. Mukainah, M. A. Kaminski, “Controlling factors on petrophysical and acoustic properties of bioturbated carbonates: Upper Jurassic, central Saudi Arabia,” Applied Sciences, vol. 11, no. 11, pp. 1-25, 2021.

A. Mady, O. Mahmoud, A. S. Dahab, “Nanoparticle-based drilling fluids as promising solutions to enhance drilling performance in Egyptian oil and gas fields,” International Journal of Industry and Sustainable Development, vol. 1, no. 1, pp. 23- 48, 2020.

M. A. Ali, M. A. B. Siddiqui, S. M. Zaidi, “Thermal analysis of crude oils and comparison with SIMDIST and TBP distillation data”, Journal of Thermal Analysis and Calorimetry, vol. 51, pp. 307-319, 1998.

Pegasus Vertex Inc. (n.d.). Cased hole. Web.

D. R. Prasad, M. G. Rao, M. M. Anuprakash, “Review on open hole and cased hole well completion systems in oil and gas wells,” International Journal of Research and Analytical Reviews, vol. 7, no. 1, pp. 336-341, 2020.

H. Zhang, C. C. Hadlock, J. E. Bickel, E. van Oort, “Risk assessment of cement placement failure due to cement loss caused by design changes in deepwater well construction,” Journal of Petroleum Science and Engineering, vol. 192, pp. 1-12, 2020.

A. A. Abdelkarim, M. H. Makkawi, O. M. Abdullatif, “Insights on spatial variography and outcrop-subsurface relationship of sandstone reservoir properties: A case study from the Late Triassic Minjur Formation, central Saudi Arabia,” Journal of African Earth Sciences, vol. 153, pp. 173-184, 2019.

A. M. Nour. (2013). Seismic attributes and advanced computer algorithm to predict formation pore pressure: Qalibah formation of Northwest Saudi Arabia. Web.

H. Ouadi, S. Mishani, V. Rasouli, “Applications of underbalanced fishbone drilling for improved recovery and reduced carbon footprint in unconventional plays,” Petroleum & Petrochemical Engineering Journal, vol. 2, pp. 1-22, 2023.

O. M. Raimi, C. I. Ezekwe, A. Bowale. (2021). Statistical and multivariate techniques to trace the sources of ground water contaminants and affecting factors of groundwater pollution in an oil and gas producing wetland in Rivers State, Nigeria. Web.

A. Vengosh, R. B. Jackson, N. Warner, T. H. Darrah, A. Kondash, “A critical review of the risks to water resources from unconventional shale gas development and hydraulic fracturing in the United States,” Environmental Science & Technology, vol. 48, no. 15, pp. 8334-8348, 2014.

D. P. Nolan, Handbook of fire and explosion protection engineering principles: For oil, gas, chemical and related facilities. Norwich: William Andrew, 2014.

A. Faturos, G. Bodor, L. Proe, S. Lathrop, “Occupational mortality in the New Mexico oil and gas industry,” Journal of Forensic Sciences, vol. 66, no. 6, pp. 2283- 2288, 2021.

J. E. Johnston, E. Lim, H. Roh, “Impact of upstream oil extraction and environmental public health: A review of the evidence,” Science of the Total Environment, vol. 657, pp. 187-189, 2019.

M. Alkhaldi, C. Pathirage, U. Kulatunga, (2017). The role of human error in accidents within oil and gas industry in Bahrain. Web.

Barber, N. (2018). 1991 Gulf war oil spill. Web.

Urbina, I. (2010). BP used riskier method to seal well before blast. Web.

Z. Zhang, Y. Zheng, H. Zhang, L. Zhang, D. Hou, Y. Li, “The influence of hydrogen sulfide on internal pressure strength of carbon steel production casing in the gas well,” Journal of Petroleum Science and Engineering, vol. 191, pp. 1-12, 2020.

C. Ren, M. Zhu, L. Du, J. Chen, D. Zeng, J. Hu, T. Shi, “Two-metal corrosion of casing pipe joint in CO2/H2S environment,” International Journal of Electrochemical Science, vol. 10, pp. 4029-4033, 2015.

F. Yuwei, Z. Liping, Z. Yabing, Z. Haiying, C. Jian, C. Mingjun, “Application foreground of titanium alloy in petroleum exploration and development,” Oil Drilling & Production Technology, vol. 39, no. 5, pp. 662-666, 2017.

B. Li, M. Li, L. Zheng, L. Wang, G. Xu, “Polyethylene/Aluminum/Polyethylene Composite pipe for fuel gas application,” Journal of Materials Science and Engineering, vol. 9, no. 5-6, pp. 98-108. 2019.

E. Engelskirchen, R. Gibson, A. Stubblefield, B. Glynn, “Challenges and solutions for carrier pipe design and installation in tunnels.” Pipelines, vol. 2022, pp. 283-292, 2022.

IEA. (2021). Oil 2021: Analysis and forecast to 2026. Web.

L. Liang, T. Lei, A. Donald, M. Blyth, “Physics-driven machine-learning-based borehole sonic interpretation in the presence of casing and drill pipe,” SPE Reservoir Evaluation & Engineering, vol. 24, no. 02, pp. 310-324. 2021.

C. Noshi, S. Noynaert, J. Schubert, “Data mining approaches for casing failure prediction and prevention,” International Petroleum Technology, pp. 1-9. 2019.

C. Carpenter, “Data mining effective for casing-failure prediction and prevention,” Journal of Petroleum Technology, vol. 71, no. 07, pp. 55-56, 2019.

A. N. Corina, N. Opedal, T. Vrålstad, R. Skorpa, S. Sangesland, “The effect of casing-pipe roughness on cement-plug integrity,” SPE Drilling & Completion, vol. 35, no. 02, pp. 237-251, 2020.

R. J. Adams, P. Smart, A. S. Huff, “Shades of grey: Guidelines for working with the grey literature in systematic reviews for management and organizational studies,” International Journal of Management Reviews, vol. 19, no. 4, pp. 432-454, 2017.

H. Kallio, A. M. Pietilä, M. Johnson, M. Kangasniemi, “Systematic methodological review: Developing a framework for a qualitative semi‐structured interview guide,” Journal of Advanced Nursing, vol. 72, no. 12, pp. 2954-2965, 2016.

REV. (2022). How to analyze interview transcripts in qualitative research. Web.

V. Clarke, V. Braun, N. Hayfield, “Thematic analysis,” Qualitative Psychology, vol. 2, pp. 222-248, 2015.

Free Word Cloud Generator. (n.d.). Paste/type text. Web.