Introduction

Delmarva is a peninsula that is situated at the East Coast of the United States. It covers vast areas of Delaware, Maryland, and Virginia. The farming area is about 24 kilometers long and 113 kilometers wide. It borders Chesapeake Bay on the western side. Delaware River, Delaware Bay, and the Atlantic Ocean lie on the eastern side of the peninsula while Elk River borders it on the north. The area has an even geography that promotes slow drainage. Various streams of Chesapeake and Delaware rivers supply the area with plenty of water that favors farming in Delmarva. This essay provides an exploration of Delmarva area farming with a view of elaborating on the hydroponics system in vegetable and fruit production.

Types of Produce Grown in Delmarva Area

Delmarva area farming is a primary source of various vegetables and fruits such as watermelons, cantaloupes, sweet corns, cabbage, green beans, potatoes, peppers, tomatoes, pumpkins, peaches, apples, and strawberries among others (Hochmuth & Hochmuth, 2012). Various seasons dictate the production of vegetables and fruits in this area. These spells are categorized into summer, spring, winter, and fall. As a result, farmers are supposed to possess knowledge about the patterns of the seasons to ensure timely farming (Lin, Lucier, Allshouse, & Kantor, 2001).

Summer Planting Season

Planting of summer vegetables is usually accomplished between the onset of July and early August. Cool season crops are also grown during this time to prepare for fall harvests. Timely planting is critical to prevent crop damages that are caused by frost. Vegetable plants such as corns are susceptible to spoilage prior to maturity, especially when they are exposed to chilly weather. Late planting must also be done in the course of the summer season to account for reduced heat unit (HU) accumulations that are experienced as the farming spell elapses. For instance, sweet corns should be planted around mid-July to harvest them in early September. Other vegetables that should be planted during the same period include cucumbers, summer squash, snap beans, broccoli, cabbage, cauliflower, kales, collards, turnips, mustard greens, beets, green onions, bulb onions, spinach, lettuce, and strawberries among others (Hochmuth & Hochmuth, 2012).

Hot Season Vegetables

In Delmarva, hot season vegetables are usually cultivated in shade-cloths (sheltered) to reduce greenhouse temperatures that are experienced during the summer spell. The leafy green production is realized is beneficial to the farmers since it extends the yields of lettuces. It also enables the production of day-neutral strawberry, quality pepper, and tomatoes. Various farmers in Delmarva use the technique in tunnels by placing shade-cloths over plastic covers during summer (Hochmuth & Hochmuth, 2012). Examples of crops that are cultivated using this method include lettuces, cabbages, tomatoes, cucumbers, beans, and pepper among others.

The below table summarizes cultivation patterns of various vegetables that are carried out during different months and/or seasons in the Delmarva region.

Table 1: Summary of Cultivation Patterns on Vegetables and Fruits during Various Seasons

Statistics of Delmarva Produce Production

A research that was conducted by the Food and Water Watch organization revealed that when 11.5-percent of the cultivation land in Maryland (located on the Eastern Show of Delmarva) was used to grow vegetables and fruits in 2007, farms sold as much as 137 million dollars above the total sales of other income-generating sources (Rich, 2012). This situation enabled more allocation of cultivation lands to expand cultivation of vegetables in an attempt to offset losses that were incurred in other sectors. This case study was used to examine the cost of economic consolidation in the U.S. food and agricultural sector (Rich, 2012).

Revenue

The local food sales that result from Delmarva area farming amount to approximately 5 billion dollars per year. 65-percent of these sales are obtained from vegetables, fruits, and nuts (Low & Vogel, 2011). The farmers do not depend on off-farm income since agribusiness is their main occupation. According to Low and Vogel (2011), both local and regional sales promise the farmers nearly equal profitability metrics. However, they are faced with inaccessibility of risk management. This situation derails expansion of agricultural bases. To resolve this issue, the USDA insured the revenues of Delmarva farmers against risks that arise from diversified practices such as increased taxations (Hart, Hayes, & Bacock, 2006).

Distribution of Produce

Vegetables and fruits are delivered to retailers by either wholesalers or shippers. The farmers grow the crops in large tracts of lands. Furthermore, some of them have established affiliations with other growers to form consolidations. Most shippers have formed powerful alliances that promote bulk transportation and distribution of products in markets that are more consolidated. As a result, they are able to meet the volume and service requirements of national chains. Most of the fruits and vegetables are distributed and sold through contracts. However, some of these conventions are explicit; hence, they constrain the choices of the farmers. Other contracts, especially those that deal with processing of set inputs, set payment schemes that offer bonuses and impose penalties based on produce quality (Martinez, 2007).

Summary of Commercial Vegetable Consumption in U.S.A

Table 2: Vegetable Consumption in U.S.A

The tables show fresh vegetable consumption for total commercial production from 2004 to 2013 (World Agricultural Outlook Board, 2003).

Benefits of a Centralized Farming Operation

Centralized farming operations can greatly benefit farmers in areas such as economies of scale, costs of inputs and expenses, technology, easy accessibility of finance, and location of markets among others.

Economy of Scale

Economy of scale is an efficient approach that results from large-scale production and sales. Large-scale farming entails relatively reduced farm operations. This situation results in increased output levels. As a result, farmers realize improved productivity due to increased flow of farm produce (Filatotchev, Strange, Piesse, & Lien, 2007). Centralized farm operations have united many Delmarva farmers. This situation has enabled the large-scale farmers to have a collective and competitive bargaining power. Economical purchases, profits, and returns that arise from product circulation have also increased collectively (Filatotchev et al., 2007).

Costs of Inputs and Expenses on Services

The vast farms in Delmarva area require many inputs that include fertilizers and agrichemicals in each season. However, these inputs are usually obtained at low costs since the farmers purchase them in bulk. Fuel for running agricultural machines is also cost-shared amongst the various farmers. Services that are incurred during various operations such as transportation and supervision among others are minimized due to a consolidated system that enhances collective accomplishment of farming activities (Filatotchev et al., 2007).

Technology Use Agreements

New crops and other commodities are easily introduced in centralized farming operations. However, these commodities are based on certain guidelines and restrictions that govern their usage. Nonetheless, centralized farm operations enable stakeholders to implement such procedures more easily than decentralized methods of acquisitions where growers have to follow considerably long channels to accomplish the same goals (Filatotchev et al., 2007).

Easy Accessibility of Finance

Centralization of farming activities brings about easy access to finance. Large farms currently rely on credits to purchase agrichemicals, irrigation apparatus, machineries, and supplies among other inputs. Farmers who operate on commercial scale should have a stable base for acquiring such agricultural resources (Filatotchev et al., 2007).

Location of Economies

Location of economies is concerned with establishing the geographical location of a certain trade and industry. In this case, the economy can be determined by assessing the metropolitan area of the commercial activity. For instance, a farmland that is surrounded by vast municipalities tends to have moderately lower costs in terms of transportation to reach the market. Farmers who practice centralized farming operations use the economics of location strategy to ensure production of products that are almost similar. This situation creates a culture of monopolistic competition. As a result, the farmers concentrate on crops that yield the highest values in the market in an attempt to increase their income (Filatotchev et al., 2007).

Another importance of centralizing farming operations is the continued ability of the state to finance whole services and operations in the field. This strategy enables centralized fiscal operations where the government cannot abandon the agricultural and market processes. There are quick responses to the farmers who have centralized agricultural systems as compared to those who adopt decentralized systems (Filatotchev et al., 2007).

Production and Distribution Strategies for Small and Medium Size Farming

A distribution strategy is a technique that presents a business entity with a framework to move its products to consumers, intermediaries, and/or retailers. Various strategies are used by both medium and small-scale farming operations.

Push and Pull Strategy

The push-pull strategy is a ploy that dictates the flow of supplies from the producers to the end consumers. In a normal supply chain, push operations apply where production depends on forecasting demands while pull techniques are based on consumed demands. The combination of the two strategies culminates into a push-pull strategy (Hopp & Spearman, 2004). In Delmarva area farming, small and medium farming practices are strategized in a market where both non-interactive and interactive communication modes play an important role in product advertising. Push-pull strategies are suitable when there is a high degree of demand uncertainty. The economy of scale is used in reducing production or delivery costs (Harrison, 2005).

Efficient Hydroponic Systems for Small and Medium Farming Operators

Hydroponics is a farming technique that uses nutritionally dense water to grow crops rather than soils (Bridgewood, 2003). The effectiveness of this method does not depend on natural precipitation or rich soil. Majority of the people who dwell in arid and semi-arid areas can effectively utilize hydroponic systems to grow food crops for both family consumption and commercial purposes.

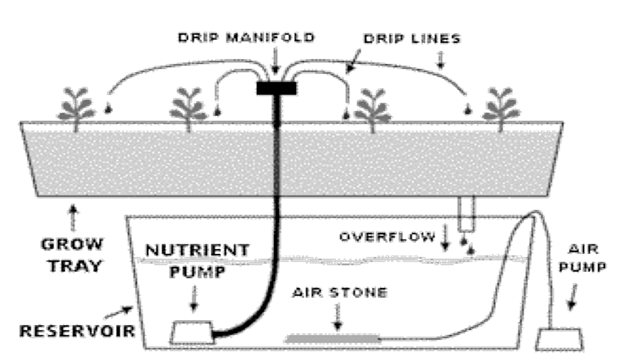

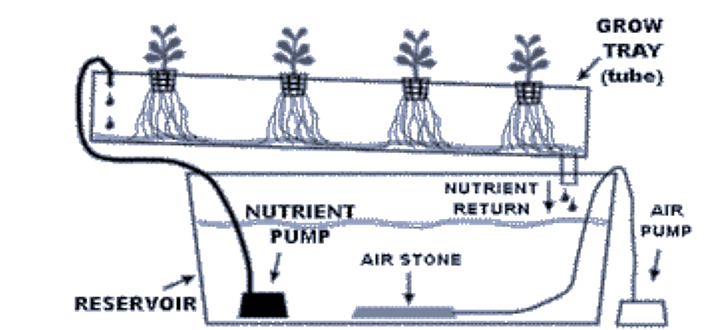

Hydroponics is usually based on eutrophication of nutrients due to the re-use of water. Therefore, it reduces water and land pollution since it prevents runoff. The cultivation technique can utilize artificial lighting systems; hence, it can be used efficiently in urban setups that have limited space and high population densities (Despommier, 2009). The following diagrams illustrate the benefits of hydroponic systems.

Limitations of Water Wastages

Hydroponic systems also enable pollination through machinery. The wires that are used for supporting the plants can be moved to escalate air pollination (Williams & Bolton, 1991). In addition, it can be used to reduce transpiration; hence, it increases productivity.

The various types of hydroponics that are energy efficient include indoor and vertical systems that use limited space to grow vegetables such as tomatoes and lettuce among others. Goins and Yorio (2000) reveal that the use of HID and CFL lights together with LED and plasma technology to grow fruits and vegetables significantly improves the yield.

Examples of Companies in Canada that Deal with the Effects of winter

Various companies that are based in Canada deal with the effects of cold winter. At the outset, the Bustan Company uses hydroponic systems, organic gardening supplies, complete indoor grow rooms, horticulture lightings, mechanized ventilations, and environmental controllers among others to curb winter effects. Other companies include the Soave Enterprise (the Ontario Green house) and the Great Northern Hydroponics (an affiliate company of the Soave Enterprise).

Current Trends in Vertical Hydroponic Farming

Hydroponic farming is a type of horticulture that is currently incorporating unique ornamental aspects. This fact has been noted in various structures. Many consumers choose hydroponic innovations not only for growing vegetables but also for beautification (Carruthers, 2002).

The use of commercial hydroponics has increased by about four times in the last ten years internationally. Various countries that have such markets include Canada, Spain, Japan, and Australia among others. A minimal number of crops that are used in hydroponic structures include tomatoes, cucumbers, lettuce, capsicum, and cut flower among others. The international integration of production and marketing strives to minimize producers who are not in better positions to command large-scale hydroponic systems (Carruthers, 2002).

Nowadays, plants that are cultivated using vertical hydroponics are notable on many tall buildings. Aeroponics gardening is also a new form of horticulture that combines both hydroponics and vertical growing where the plants’ roots hang in the air and the solutions of nutrients are applied to the roots directly. These trends are currently noted in Japan, South Korea, and England among other places. Singapore uses low carbon hydraulic water-driven tropical vegetable in vertical hydroponics. On the other hand, Sweden uses helix-shaped architecture that can be translated into a big Plantascraper (Goins & Yorio, 2000).

Conclusion

Current trends of cultivation are aimed at applying simple techniques that provide greater benefits without incurring high costs on farm operations and other related services. The use of hydroponic systems and greenhouse cultivation methods has recently increased in areas such as towns where land is scarce and pressure of population is experienced. They are also applied in areas that are characterized by extreme natural conditions such as floods and winters. Various forms of technology have also been applied to enhance the quality vegetable and fruit production. For instance, the use of plasma and LED lights in hydroponics provides artificial light and warmth to plants. More researches are still required to enhance the efficiency of hydroponics and horticulture production.

Reference List

Bridgewood, L. (2003). Hydroponics: Soilless gardening explained. Ramsbury: Crowood Press.

Carruthers, S. (2002). Hydroponics as an agricultural production system. Practical Hydroponics and Greenhouses, 63(1), 1.

Despommier, D. (2009). The rise of vertical farms. Scientific American, 301(5), 80-87.

Dimitri, C., & Oberholtzer, L. (2008). Using vertically coordinated relationships to overcome tight supply in the organic market. Web.

Filatotchev, I., Strange, R., Piesse, J., & Lien, Y. (2007). FDI by firms from newly industrialized economies in emerging markets: corporate governance, entry mode, and location. Journal of International Business Studies, 38(4), 556-72.

Goins, G.D., & Yorio, N.C. (2000). Spinach growth and development under innovative narrow-and broad-spectrum lighting sources. Web.

Harrison, T.P., Lee, H.L., & Neale, J.J. (2005). The practice of supply chain management: where theory and application converge. New York, NY: Springer.

Hart, C.E., Hayes, D.J., & Babcock, B.A. (2006). Insuring eggs in baskets: should the government insure individual risks? Canadian Journal of Agricultural Economics, 54(1), 121-37.

Hasanuzzaman, M., Nahar, K., Alam, M., Roychowdhury, R., & Fujita, M. (2013). Physiological, biochemical, and molecular mechanisms of heat stress tolerance in plants. International journal of molecular sciences, 14(5), 9643-84.

Hochmuth, G., & Hochmuth, R. (2012). Design suggestions and greenhouse management for vegetable production in perlite and Rockwool media in Florida. Web.

Hopp, W.J., & Spearman, M.L. (2004). To pull or not to pull: what is the question? Manufacturing & Service Operations Management, 6(2), 133-48.

Lin, B., Lucier, G., Allshouse, J., & Kantor, L. (2001). Fast food growth boosts frozen potato consumption. Food Review-Washington DC, 24(1), 38-46.

Low, S., & Vogel, S. (2011). Direct and intermediated marketing of local foods in the United States. Washington, DC: USDA Economic Research Service.

Martinez, S.W. (2007). The US food marketing system: recent developments, 1997-2006 (No. 55962). United States Department of Agriculture, Washington, DC: Economic Research Service.

Phillips, P., Denver, J., Shedlock, R., & Hamilton, P. (1993). Effect of forested wetlands on nitrate concentrations in ground water and surface water on the Delmarva Peninsula. Wetlands, 13(2), 75-83.

Rich, B. (2012) Eastern Shore Farms Could Earn More With Fruits and Vegetables. Web.

Simply Hydro. (2008). Basic hydroponic systems and how they work. Web.

World Agricultural Outlook Board. (2003). Situation and Outlook Yearbook: Vegetables and melons. New York, NY: Economic Research Service.