What is the luggage spring balance?

The Salter brothers invented the spring balance in Bilston in 1760 (British history online 2013). There are several kinds of spring balances that are used for different purposes. This report seeks to discuss a luggage spring balance. A simple definition of a luggage spring balance describes it as an instrument to determine the weight of an object. It is commonly used in households and laboratories to weigh objects where the accuracy up to decimal points is not required. Following are examples of a luggage spring balance:

A luggage spring balance works on a very simple mechanism that is based on the third law of motion. The third law of motion suggests that when an object applies force/pressure on another object, the object (on which the force/pressure is applied) reverts back by applying the same amount of force/pressure on the object (that applies the force/pressure). The third law of motion further suggests that both these forces apply the force with the same intensity, though their directions, in which the force is applied, are opposite to each other (Zou n.d.).

In our day-to-day life, we come across several incidents where we have to apply force to either push or pull an object in order to alter its state of motion; force refers to this pull or push. No one has ever seen force, but we all have experienced its effect. So, it can only be understood by explaining the effect of a particular force. In addition to changing the state of motion of an object, force can also change the shape of an object. In a luggage spring balance, when a force is applied (i.e., when an object is hanged), the spring expands according to the mass of the object (figure 1).

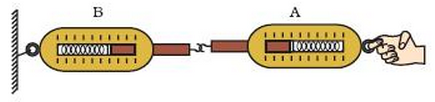

The mechanics of a luggage spring balance can be understood in a better way by taking an example where two spring balances are attached to each other and pulled in opposite directions. This will even confirm the third law of motion. Consider figure 2 that shows two spring balances ‘A’ and ‘B,’ where the balance ‘B’ is attached to a hook in a wall, and balance ‘A’ is pulled manually. What will we observe when a force is applied? Both the balances will depict similar readings, and this means that though we have applied force only on balance ‘A,’ balance ‘B’ is also experiencing the same force as balance ‘A’ (but in the opposite direction). This small experiment confirms the third law of motion.

It is understood that if we replace the balance ‘A’ with an object, the same law of motion will apply. The only difference will be that the object will not display any reading. But as we have seen earlier, balance ‘B’ will show the reading of force that is being applied by the object. So, in this manner, we will get the mass of the object.

It should further be understood that spring is designed to return to its equilibrium position once the force ceases to be applied. The spring stretches according to the force applied. More the force more will be the extension (reading in case of a spring balance) of the spring. This means that the reading that a spring balance shows is actually the quantum of force applied (Pearson Education 2010). That’s the reason why a spring balance shows different readings for different objects with different weights. It should be understood that a spring balance gives almost accurate results under ideal conditions, but there should be precision in reading the scale as well (Collins & Atwood 1981).

What is the material used for a luggage spring balance?

The biggest advantage of a luggage spring balance is that it is economical and easy to carry. But there are certain disadvantages as well in using such a spring balance. The material from which the spring (the main part) is manufactured plays a vital role in its performance. First of all, the spring balance will perform well only until the spring is in good condition. With the passage of time, the spring gets worn-out, and the balance becomes faulty. Secondly, there is a limitation for a spring balance to measure weights. A spring balance will depict correct results only until the spring’s material’s elasticity is reached.

Trying to weigh objects that are heavier than the designed load-bearing capacity of the spring might lead to the breaking of the spring. As such, a lot of care is taken while selecting the material for the spring. Generally, the spring is made out of stainless steel. But metals such as aluminum or a combination of aluminum and steel are also used, depending on the proposed capacity of the spring balance. The motive behind preferring steel and/or aluminum for the spring is that both these metals are considered to be rust-free; since the durability of the spring is of great importance in a spring balance, the material has to be rust-free. This particular feature becomes more vital when a spring balance is used for industrial purposes, where accuracy is not that important.

References

British history online. 2013. Web.

Collins, C & Atwood, J 1981, ‘Weighing with spring balances: Biases and errors’, North American Bird Bander, vol. 6. no. 1, pp. 8-11. Web.

Pearson Education 2010, Equilibrium and elasticity. Web.

Zou, J n.d., Newton’s third law of motion. Web.