Problem

The issue of human activities’ impact on the environment has become particularly topical in the 21st century. Simultaneously, the detrimental impact of industries is on the increase, consisting of air pollution, carbon emissions, and irresponsible handling of waste. Construction is one of the areas, which demonstrate significant growth while negatively affecting the environment. This sector’s impact is caused by the large-scale extraction of raw materials, extreme energy consumption, and high waste production (Braga et al. 529). The situation is particularly grave in developing countries, where construction rates are extremely high (Akan 1195). Simultaneously, modern society demonstrates an increased demand for green initiatives, as the detrimental effect of humanity on climate and the environment becomes apparent. Amid the pursuit of sustainability, the construction industry devotes increasing attention to environmentally friendly practices.

The construction industry utilizes large amounts of resources and energy supplies. While it appears impossible to ensure the proper functioning of the sector without such resources, the process must be organized efficiently. Modern technological advancements propose a range of solutions, which would allow for a gradual transition toward environmentally aware practices. Concrete materials serve as the cornerstone of construction, being actively used worldwide. Accordingly, the most effective green initiatives would consider the lower impact of concrete production, use, and maintenance to be a matter of high priority. Indeed, this material surrounds people in the modern urban setting, hence the concept of the concrete jungle. It is used to construct residential buildings, skyscrapers, factories, and sidewalks, which is why effective green initiatives related to concrete will positively affect humanity in general.

Technical Section

Concrete Production Cycle

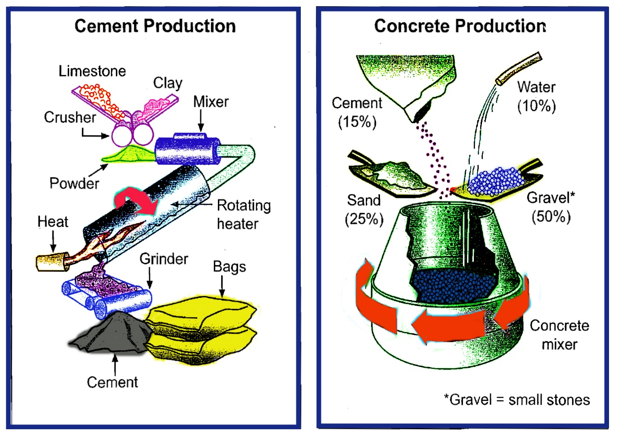

Concrete production is a complex process, which involves several particular steps. Each stage is important to the overall procedure, ensuring the quality of the construction material and the durability of the product. First of all, cement is the primary element of concrete, meaning that it accounts for the first major stage of its production. Figure 1 describes each step, from raw materials to the final product. Limestone and clay serve as the main sources of cement in modern practice. In order to be used, they must be extracted, and this stage poses considerable ecological threats. While these materials are abundant on Earth, their extraction damages the environment. Large-scale extraction leaves colossal empty spaces in the soil, and the amount of waste left after the procedure might reach critical levels. As a result, entire ecosystems are affected, while structural damage to the soil entails sinkholes and landslides.

Once limestone and clay are extracted, they are mixed and turned into cement via heating and grinding. This process happens at specialized factories, which serves as the primary source of carbon dioxide emissions. Accordingly, the second stage of cement production is also detrimental from an ecological point of view. When cement is prepared and packed, it is possible to turn it into the concrete. In fact, as shown in Figure 1, it only amounts to fifteen percent of the product. Gravel and sand serve as the main ingredients mixed with water in a special device on-site. This stage accounts for increased water consumption, while energy is widely used across all steps of the process. Therefore, concrete production has both a direct and indirect impact on the environment, which is why potential solutions should encompass all stages. At the same time, cement and concrete are widely used by modern industries, which is why it is important to consider the options, which will not negatively affect the economy and workers’ jobs. In addition, the durability of each structure built of “green” concrete cannot be compromised, as it would endanger people’s lives.

Relevant Resources for Structural Engineers

Multiple industries have been searching for ways to optimize their operations within the framework of green initiatives. The construction sector has followed the global tendency, devoting considerable attention to the discussed issue. The Construction and Building Materials periodical has seen an increase in relevant publications, which explore the possibilities of sustainable practices in the industry. The article by Wang et al. follows the general trend and discusses the issue of recycled materials in the context of their durability and quality. Resources, Conservation, and Recycling does not specialize in construction, as it is an ecological journal, most of all. However, its issues contain interesting findings related to the objective of this research, such as the article by Omran et al. It authors propose a list of alternative materials consisting of fly ash, Haydite lightweight aggregate, and Portland limestone cement. These periodicals are well-respected, peer-reviewed journals, providing valid insight into the nature of the problem, and confirming its relevance in today’s landscape.

Recently, there has been a surge in the popularity of specialized publications. Journal of Cleaner Production is an excellent example of such a periodical, providing scientific evidence to the importance of environmental concrete production and utilization. As this problem is global in nature, the particular value of this journal is justified by the international perspective it provides. Journal of Cleaner Production provides its readers with the global experience of green concrete product use through the prism of peer-reviewed research. The journal contains promising research concerning high technology materials, such as the ultra-high performance concrete examined by Shi et al. The proposed material reduces the industry’s impact on the environment while being durable and crack-resistant. Overall, the amount of research dedicated to green construction industry operation is on a steady increase, providing a range of opportunities for structural engineers aspiring to achieve environmental efficiency.

Implementation of Environmentally Friendly Concrete

The essence of environmentally friendly concrete production methods consists of encompassing all stages of the process, as the detrimental impact is observed at each point. In most cases, such recycled materials, as fly ash, are used during the first stages of the process, reducing demand for limestone and clay will decrease. Therefore, it will not be necessary to extract it in such large quantities, damaging the environment, and leaving waste. Secondly, the production rate of cement factories and plants will also be lower, meaning that carbon dioxide emissions will be reduced, as well. Shi et al. propose ultra-high performance concrete, which is less resource-consuming than traditional materials. However, such sophisticated solutions often require considerable expenses, and not all organizations can afford them. The alternative material use discussed by Omran et al. seems to be a viable option, as it allows producers to replace some cement components with recycled materials. In this case, cost-efficiency can be optimal on the condition that the structural engineers’ decisions do not compromise the quality and durability of concrete. As important as environmental protection is, safety must remain the cornerstone of all human activities.

At the same time, the process does not end with the implementation of environmentally friendly concrete products. Accordingly, the maintenance will be an important aspect of engineers’ work, as well. In the process, it is vital to observe the structural durability of concrete, as well as its reaction to extreme loads and weather conditions. If the characteristics of the chosen material are not on par with regular concrete, policymakers may see its implementation as an inefficient initiative. Consequently, all efforts aimed at environmentally responsible operation may end in failure, once more impeding the positive development in this area.

Conclusion and Recommendations

The thoughtful implementation of environmentally friendly concrete products will benefit the Earth while meeting the needs of the construction industry and its clients. The effectiveness of prior green initiatives is proved, but these efforts did not suffice (Reis et al.) Common alternatives include the use of recycled materials in order to optimize the consumption of concrete. Nevertheless, most of them are associated with poorer characteristics of the construction material, thus entailing higher maintenance costs. Modern advancements allow structural engineers to conduct comprehensive research and opt for an efficient, innovative solution. The success of the green concrete product implementation will be determined by careful analysis. Structural engineers should begin by using recycled material in concrete production. However, the proportions must be carefully examined to preserve the product’s durability. If the organization can afford significant expenditures, it is possible to test ultra-high performance options, utilizing modern high-tech solutions. Overall, environmentally aware concrete production will be a significant step toward eradicating the ecological problems, which is a priority of the 21st century.

Works Cited

“Cement Production and Concrete Production.” IELTS Adviser, Web.

Akan, Mahmure Ö. A., et al. “Greenhouse Gas Emissions in the Construction Industry: An Analysis and Evaluation of a Concrete Supply Chain.” Journal of Cleaner Production, vol. 167, 2017, pp. 1195-1207.

Braga, Anna M., et al. “Compared Environmental and Economic Impact from Cradle to Gate of Concrete with Natural and Recycled Coarse Aggregates.” Journal of Cleaner Production, vol. 162, 2017, pp. 529-543.

Omran, Behzad A., et al. “Comparison of Data Mining Techniques for Predicting Compressive Strength of Environmentally Friendly Concrete.” Journal of Computing in Civil Engineering, vol. 30, no. 6, 2016.

Reis, Daniel C., et al. “Influence of Cement Strength Class on Environmental Impact of Concrete.” Resources, Conservation and Recycling, vol. 163, 2020.

Shi, Ye, et al. “Design and Preparation of Ultra-High Performance Concrete with Low Environmental Impact.” Journal of Cleaner Production, vol. 214, 2019, pp. 633-643.

Wang, Liang, et al. “An Environmentally Friendly Method to Improve the Quality of Recycled Concrete Aggregates.” Construction and Building Materials, vol. 144, 2017, pp. 432-441.