Executive summary

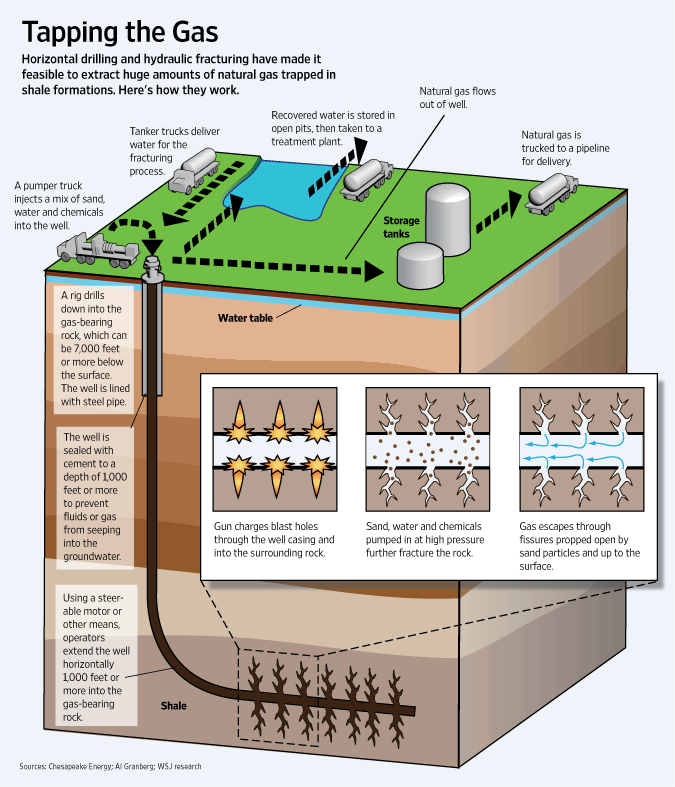

This report looks into the emerging role of shale gas within unconventional gas plays from a technological, commercial and geo-political perspective. Shale gas is currently a major contributor of natural gas in United States, Australia, China and Europe. Technological advances in the field of hydraulic fracturing and horizontal drilling have facilitated the growth of shale gas in the energy industry. This report conducts a review of relevant literature regarding the technological advances associated with recovery of natural gas from unconventional reservoirs, critical analysis of environmental concerns and the role of government regulation in the new and emerging shale gas plays. The potential of shale gas contributing to the export sector in United States is studied from the perspective of economic and political resources available. Research and development is emphasized as the most salient pillar for a future gas-oriented power sector in the world. The danger of groundwater contamination associated with hydraulic fracturing techniques is investigated for the purpose of ensuring the benefits accruing from shale gas plays outweigh the negative aspect of environmental and technological risks. The probability of United States being an exporter of shale gas is explored in view of the challenges brought about by climate change and the increasing cost of oil production.

Introduction

Natural gas is a product of carbon and hydrogen derived from organic matter usually embedded in geological rock formations. Natural gas is a safe and reliable energy resource. Traditional extraction techniques have focused on conventional gas which is easily recovered from permeable geologic rock formation made up of carbonates, sandstones and siltstones (Net, 2010). However, technological advances in extraction techniques for gas and oil resources have led to exploration and recovery of natural gas from unconventional rock formations. Unconventional rock reservoirs consist of impermeable materials which do not contain sufficient porosity for extraction of commercial quantities of natural gas. Horizontal drilling and fracturing has made it possible for commercial extraction of unconventional gas from impermeable rock formations.

Unconventional gas reservoir refers to a low-permeability reservoir which can supply high quantities of natural gas. Low-permeability reservoirs available include sandstone, low-permeability carbonates, shales and coalbed methane (Mills, 2010). Vertical well drilling into unconventional gas reservoir is accompanied with hydraulic fracturing and stimulation procedures producing commercial gas volumes. Horizontal wells can also be drilled through fractured unconventional gas reservoirs which are equally stimulated through hydraulic fracturing techniques. Geoscientists and engineers provide the expertise required to determine the optimal number and locations of wells within unconventional gas reservoirs before drilling is done. They also design drilling and completion procedures since the process of recovering commercial gas flow rates from unconventional gas reservoirs is much more sophisticated and expensive as compared to conventional reservoirs which are more permeable.

A well drilled in unconventional gas reservoir produces lesser gas volumes over a long period of time as compared to conventional gas reservoirs with higher permeability (Witte& Goldthau, 2010). As such, more wells with smaller spacing must be drilled in unconventional gas reservoirs in order to recover significant volumes of gas. Shale gas is extracted from shale. Exploration and drilling of shale for production of natural gas is a lucrative business in North America in general and the United States in particular. The Obama administration believes that increased utilization of shales as a source of natural gas “will help reduce greenhouse emissions” (Prakash, Goeppert & Olah, 2009).

Shales are not commercial sources of natural gas since they constitute unconventional gas reservoir with insufficient permeability. “Shale has low matrix permeability, so gas production in commercial quantities requires fractures to provide permeability” (Net, 2010). Modern technology in the recent past is facilitating the hydraulic drilling process for both vertical and horizontal drilling procedures. Shale resources that provide commercial quantities of natural gas are rich in organic material and are hosted on mature petroleum rocks. “A thermogenic gas window exists in such mature petroleum rocks where intensive heat and pressure necessitates the conversion of petroleum to natural gas”. (Net, 2010). Open fractures also exist in such high organic carbon materials.

Natural gas is emitted through pores embedded within organic layers of shale rock formations during hydraulic fracturing. According to Society of Exploration Geophysicists (2010), optimum drilling, completion and stimulation techniques applied in the process of recovering natural gas from unconventional reservoirs is a factor of reservoir characteristics and the prevailing economic circumstances. The Federal government of the United States extends tax credits to companies that explore and recover natural gas from unconventional resources. Extensive research and development in geologic controls and recovery technologies, with respect to the unconventional gas reservoirs in the United States, is responsible for the emerging industry of gas production from unconventional reservoirs. Natural gas operators are benefitting from the limited information obtained from recent research and development to develop the industry. Essentially, limited information on unconventional gas reserves, inadequate gas policies and market constraints for shale gas production has reduced the potential of tapping natural gas from the long-lived reserves.

The table below indicates the distribution of unconventional gas reservoirs in the world.

Table 1: Distribution of unconventional gas reservoirs in the world.

Prior perception was based on the premise that conventional gas is a low-cost source of natural gas. However, new understanding has appreciated the role of shale gas as abundant source of natural gas which is even much cheaper. The graphs below illustrate this shift in perception taking into consideration a comparison of gas prices.

US Gas Supply Curve

Prior Perception New Understanding

Hydraulic Fracturing

Process

This is the process of drilling fractures in rocks. Hydraulic drilling is the main technique used to extract natural gas (Center & Deitche, 2010). Fractures are created in wellbores drilled in rock reservoirs during oil and gas production. Hydraulic fractures are either natural or man-made. Hydraulic fracturing is done by application of internal fluid pressure into a borehole targeting the rock reservoirs where gas resources can be found. Fracturing fluid is mixed with a proppant which keeps drilled wells from closing in. Proppant include materials such as sand or ceramic. Volcanicity and weathering creates natural fractures within geologic formations.

However, hydraulic fracturing technology faces critical environmental safety and health concerns in the society. Essentially, hydraulic fracturing facilitates the process of recovering oil, gas or water from underground reservoirs such as the unconventional shale rocks and coal beds (Wietschel& Ball, 2009). Environmental pollution is thought to occur when fracturing chemicals and fluid byproducts contaminate groundwater. Shale reservoirs are found in deep underground rock formations which can only be harnessed through techniques such as hydraulic fracturing that increases porosity and permeability of the shale reservoirs. Natural gas is therefore harnessed through well bores created through the fracturing process. The fracture creates a permeable path connecting to the shale reservoir increasing production of oil wells from the bedrock.

Procedure

Hydraulic fracturing increases access into a targeted rock formation through the drilled wells which provide a favorable channel through which natural gas or oil can be harnessed. Hydraulic fractures are generated by “pumping the fracturing fluid into the well bore at a rate sufficient to increase the pressure down hole to a value in excess of the fracture gradient of the formation rock” (Leggett, 2005). The targeted rock is therefore forced to crack extending the fracturing fluid further into the shale reservoir. A solid proppant is usually mixed with the fracturing fluid in order to maintain the fracture open after drilling has been done. The fracture therefore acts as a conduit whose permeability has been increased by the proppant allowing a gradient which facilitates fluid flow into the well bore.

Hydraulic fracturing is a preferable technique to drilling since the latter involves applying pressure downwards on a drill bit that creates rock chips and particles which can interfere with permeability of the wellbore (Cunningham, 2010). As such, a drilled well is partially sealed reducing the rate of fluid flow. Hydraulic fracturing facilitates economic extraction of shale gas. Fracturing fluid includes carbon dioxide, nitrogen, foams as well as water. Proppant consist of materials such as sand and artificial ceramic which is applied within the fractures depending on the desired permeability levels. Radioactively-labeled sand can be used as a proppant in order to determine how far the extraction process has reached.

Micro-seismic monitoring is a technique used to measure physical size and shape of the hydraulic fracture. Geophones arrays in the wellbore facilitate the process of measuring micro-seismic activity associated with the growing hydraulic fracture (Meador& Gordon, 2009). As such, the seismic events can be mapped towards estimating the fracture geometry. Hydraulic fracturing equipment is therefore composed of “fracturing tanks, high pressure treating iron, fluid density, low pressure gauges for monitoring the flow rate and a micro-seismic monitoring unit which determines the fracture geometry” (Meador& Gordon, 2009). Bridge plugs are used to hold fractures from leaking extracted fluids into previous drilled wells as the production process proceeds. Advanced completion technology permits precise positioning of fractures within the wellbore for enhanced production of natural gas over a short period of time. High tech completion systems allow for sustained stimulation to take place in a single day.

The diagram below illustrates hydraulic fracturing and horizontal technique in the extraction of shale gas from underground impermeable unconventional reservoirs.

Global Shale Gas plays

Uncertainty looms over commercial implications for gas prices due to the multiplicity of factors which include the “global carbon policy, world economic growth, technologies for extracting shale gas from impermeable rock reservoirs and global availability for liquefied natural gas supplies” (Leggett, 2005). It is obvious that economic strategies and contracts may need to be reviewed in order to ensure that the benefits accruing from the increasing role of shale gas in the world market can be harnessed fruitfully. A major shift towards gas-dominated power supply could lead to a spot price onslaught and significant price adjustments for renewable energy products which could destabilize the world economy. That notwithstanding, the supply of more shale gas in the global economy shall lead to shale gas stability. The current trend where gas prices are ever escalating in a global economy which is directly affected by energy trends, increasing supply of shale gas will stabilize LNG prices towards a position of self-sufficiency. It will also promote local and international generation of electricity. Development of advanced completion technologies has drastically reduced the cost of mining shale gas. Technological advantages are also minimizing the negative effects associated with hydraulic fracturing on the environment.

The rise in unconventional gas production is a relief to the energy industry which is currently being faced with declining oil reserves coupled to an increasing cost of oil production. Shale gas production paves way to a shift towards lower carbon emissions in energy production. The power sector is therefore shifting towards abundant natural gas sources away from dependence on nonrenewable petroleum. On the other hand, the rapid increase in production profile of the shale gas plays demands for continual investment in piecemeal projects making them vulnerable to the threat of a financial crisis. High up-front capital costs during the exploration and production process demands for increased spending on the part of the players in the natural gas sector (Brown, 2009). Exploration prospects in regions with high population density present a challenge of accessing land.

Environmental and Health Concerns

The basic concerns relating to environmental pollution and health hazards associated with hydraulic fracturing include “mishandling of solid toxic wastes, deterioration of air quality, contamination of groundwater and the unintentional transfer of fracturing chemicals and gases within restricted drilling zones” (Paterson& Kassler, 2009). The resultant cost of environmental clean-ups, land value compensations and resolving human and animal health problems is exorbitant. That notwithstanding, hydraulic fracturing beneath the earth surface may be considered comparatively safer because the fracturing zones are quite isolated from human residence and fresh water zones. However, there are instances where explosion of hydraulic fluids and hot water from the well fractures has been reported in Pennsylvania. In addition, seismicity is associated with surface subsidence due to lowering of reservoir pore pressure from erupting fluids.

Hydraulic fracturing fluids are also thought to have significant health and environmental hazards. According to Intergovernmental Panel on Climate Change (2007), it is estimated that about 40% of the chemicals and fluids get deposited below the earth surface while the remainder constitute toxic chemicals which resurface through porous wells or as a result of condensation processes. The process of stimulating water wells during hydraulic fracturing produces a mixture of water and disinfectant bleach. This procedure can be applied to produce clean water from such contaminated zones. Disinfecting bacteria can also be injected through the hydraulic fracturing process for remediation purposes.

Environmental activists have alleged that the mystery behind the content of the chemicals used during the hydraulic fracturing process complicates prevention and treatment interventions. They have alleged that fracturing chemicals contain carcinogens, toxins, heavy metals and explosive gases which can easily leak into surrounding water wells contaminating water for human drinking (Brown, 2009). According to intellectual property rights, the disclosure of patented information regarding nature and content of chemicals used during hydraulic fracturing is constrained.

Environmental hazards reported in Pennsylvania and Colorado are attributed to the carcinogenic substances and pollutants which contaminated wells used to supply water for human drinking. Medical personnel were equally constrained from administering appropriate therapeutic interventions to patients since they lacked specific information on the nature of the chemical constituents used during hydraulic fracturing. Some nurses also complained of having been contaminated by cloths contaminated with fracturing chemicals (Reilly& Edmonds, 2009). Ground water contamination requires further investigation from the background that water sources are attributed to underground water table.

New and Emerging Gas Shale plays

The prospects of recognizing and obtaining economic volumes of shale gas from unconventional gas reservoirs is a reprieve to an industry which requires more reserves and a shift towards low carbon energy. The discovered shale gas plays present opportunities for harnessing natural gas from untapped sources. Increased production of shale gas is attributed to innovative drilling techniques and stimulation technologies targeting the interior rock reservoirs (Heapes& Campbell, 2008). Significant production levels are recorded through horizontal drilling in addition to traditional vertical drilling process. Commercial quantities of shale gas are currently being recovered from horizontal wells coupled to the advanced slick-water fracturing. The increasing demand for natural gas in the United States and the world at large is being met by the large quantities of shale gas onshore.

For along time, the US economy has been reliant on imported sources of natural gas diverting substantial resources towards importation of liquefied natural gas. Shale gas is therefore an economic alternative of natural gas being produced locally thanks to extensive exploration and production strategies. Shale gas is a secure source of natural gas with low carbon emissions (Saigo& Cunningham, 2009). Apart from offsetting energy demands, shale is contributing to increased industrial and economic development. Research and development into hydraulic fracturing techniques and completion technologies has facilitated economic production of shale from unconventional reservoirs. “The combination of horizontal drilling and fracturing technology has improved the US potential to recover natural gas from the unconventional gas sources” (Saigo& Cunningham, 2009)..

Unconventional gas reservoirs refer to those beneath the earth surface characterized by low permeability of the host formation rocks (Heapes& Campbell, 2008). Shale gas is recovered from perforations and fractures located within organic layers of the unconventional reservoir. Horizontal wells provide the channel for harnessing shale gas from the rock fractures. According to United States Congress House Committee on Resources Subcommittee on Energy and Mineral Resources (2003), by the year 2007, the average cost of recovering unconventional gas drop was comparably lower than that of conventional gas. Natural gas operators have therefore shifted their business prospects from conventional gas to unconventional sources such shale gas. This is also attributed to the rapid increase in natural gas prices.

The techniques for extraction of shale gas are quite invasive and require a considerably large landscape which can take care of the extensive drilling operations and the huge number of wells in order to obtain appreciable amounts of gas. Fractural techniques also utilize large amounts of water which presents disposal challenges. However, advances in technologies are associated with lower quantities of fracturing water. Contamination of the ground water is another disadvantage of techniques used for shale gas production. Contamination is caused by fracturing chemicals which leak into the water table and subsequently into water supply channels such as wells for drinking water. Fracturing water is alleged to contain carcinogenic substances such as benzene which is attributed to significant water contamination (Leggett, 2005).

Apart from the land and water challenges that face hydraulic fracturing processes, there is a resilient problem of poor infrastructure since extraction sites are quite remote. The current output of shale gas from the recently discovered unconventional reservoirs may not justify huge budgetary investment into transport and communications linking the exploration zones with appropriate markets. However, Canada and the United States have engaged in interstate partnership for construction of an integrated pipeline system making it easier for transporting liquefied natural gas from the extraction zones to the market (Meador& Gordon, 2009). Thirteen thousand mile interstate pipeline system has already been constructed between the two countries resulting in a four-fold increase in production of liquefied natural gas.

Horizontal drilling is a preferable technique to vertical gas drilling because it requires fewer wells to access a substantial amount of natural gas. Increased shale production in United States is therefore attributed to horizontal drilling and fraccing technologies (Wietschel& Ball, 2009). However, increased production of shale gas further reduces permeability of the available reservoirs calling for increased investment in research and development for sustainable extraction technologies. The energy market in North America is therefore dependent on the supply of natural gas which is currently the domain of shale gas resources. Investors are also encouraged to inject more financial resources in the lucrative shale gas industry courtesy of a stable economic environment. Interstate infrastructural and natural gas policies have also combined with existence of regulatory policies to enhance the energy industry.

The issue of diminishing water resources is an emerging challenge to the fracturing and drilling processes which require substantial amounts of water. Hydraulic fracturing requires less quantities of water as compared to gasification and liquefaction procedures applied in extracting coal. Environmental sustainability of water resources is therefore directly associated with a developed shale gas production. Technology has also provided for recycling procedures of the extraction water from the drilled fractures. The nascent energy market in United States is therefore privileged with the shale gas technologies and reservoirs (Net, 2010). Substantial shale rock formations are actually feasible around the world apart from United States.

Europe, China and Australia are equally developing drilling sites for shale production courtesy of technological breakthroughs of the recent past. Shale is therefore being economically extracted from unconventional reservoirs around the world through environmentally friendly procedures. The power sector is therefore shifting from reliance on oil resources to the emerging gas sector through developments in shale gas production. The power sector can therefore be projected to be gas-dependent especially in the transportation segment particularly due to the low carbon footprint of natural gas as compared to coal (Center & Deitche, 2010). However, it is still unpredictable to establish a total shift from oil-propelled automobiles to ones that entirely utilize natural gas.

Conclusion and recommendations

Federal legislative regulatory policies are necessary in order to alleviate pollutants from hydraulic fracturing fluids during shale production. Chemicals such as “kerosene, benzene, toluene, xylene and formaldehyde” present in fracturing fluids are thought to have significant environmental and health damage if not disposed properly (Mills, 2010). The major concern with regard to environmental pollution and health hazard is connected with alleged contamination of drinking water meant for animal and human consumption. Heath care providers, state and local officials in addition to landowners and neighboring communities need to be provided with relevant information regarding the chemical constituents of fracturing fluids intellectual property rights notwithstanding.

Since there are fracturing sites identified in areas where large populations of people reside, the demand for environmental protection and access to information relevant to the hydraulic fracturing process by the society is justified. Safe drinking water is central for both human and animal life. The purported contamination of ground water resources due to dangerous chemicals leaking into the drilled wells requires further investigation and regulation in order to protect life. North American governments should therefore pursue regulatory policies which go beyond intellectual property rights in order to protect environmental integrity and health standards. On the other hand, sustainable supply of natural gas from unconventional reservoirs is a reality if the Federal government invests in research, development and application of modern technologies towards the shale and natural gas industry (Center & Deitche, 2010). The possibility of United States becoming an exporter of natural gas is feasible if shales and other unconventional gas resources are not only identified but also harnessed through safe and technologically sound procedures.

Bulk production of liquefied natural gas demands market regulation in order to allow established producers to propel the energy industry to a new level. Independent companies should be licensed to play a major role exploration and extraction of shale gas from mature basins. However, a concerted approach is necessary in streamlining the production sector with service industry for purposes of financial and technological development (Wietschel& Ball, 2009). Participation in the international energy market depends on how efficient technology collaboration is realized in a regulated field of production. Strategic planning is the way forward integrating all of the underlying factors in policy making process. Professional humanitarian and trade organizations, government research institutions and players in the energy industry need to communicate effectively on the most appropriate technologies for harnessing natural gas from unconventional resources.

Reference List

Brown, M. W., 2009. Petroleum Prices: Past, Present, and Prospective. California Hudson Institute.

Center, T. & Deitche, S. M., 2010. Green Collar Jobs: Environmental Careers for the 21st Century. Vancouver: ABC-CLIO.

Cunningham, W. P., 2010. Understanding Our Environment: an Introduction. Minnesota: Wm. C. Brown Publishers.

Heapes, S. & Campbell, C. J., 2008. An Atlas of Oil and Gas Depletion. London: Jeremy Mills Publishing.

Intergovernmental Panel on Climate Change (2007). Climate Change 2007 – Mitigation of Climate Change: Working Group III Contribution to the Fourth Assessment Report of the IPCC. London: Cambridge University Press.

Leggett, J. K., 2005. The Empty Tank: Oil, Gas, Hot Air, and the Coming Global Financial Catastrophe. New York: Random House.

Meador, R. & Gordon, H., 2009.Perspectives on the Energy Crisis: Mankind’s Energy Challenge, Fossil Fuels, Solar, Nuclear, Regional/National Responses. Wisconsin – Madison: Ann Arbor Science Publishers.

Mills, R. M., 2010. The Myth of the Oil Crisis: Overcoming the Challenges of Depletion, Geopolitics, and Global Warming. Michigan: Praeger.

Net, T., 2010. Energy: Natural Gas: The Production and Use of Natural Gas, Natural Gas Imports and Exports, EPAct Project, Liquefied Natural Gas (LNG) Import Terminals and Infrastructure Security. Washington, DC: The Capitol Net Inc.

Paterson, M. & Kassler, P., 2009. Energy Exporters and Climate Change. Michigan: Royal Institute of International Affairs, Energy and Environmental Programme.

Prakash S. G. K., Goeppert, A., & Olah, G. A., 2009. Beyond Oil and Gas: The Methanol Economy. London: Wiley-VCH.

Reilly, M. J. & Edmonds, J., 2009.Global Energy: Assessing the Future. Michigan: Oxford University Press.

Saigo, W. B. & Cunningham, W. P., 2009. Environmental Science: a Global Concern. London: WCB/ McGraw-Hill.

Society of Exploration Geophysicists (2010). The Leading Edge, Volume 26, Pages 1- 800. Michigan: Society of Exploration Geophysicists.

United States Congress House Committee on Resources. Subcommittee on Energy and Mineral Resources (2003).The Growing Natural Gas Supply and Demand Imbalance: the Role that Public Lands & Federal Submerged Lands could Play in the Solution: Hearing before the Subcommittee on Energy and Mineral Resources of the Committee on Resources, U.S. House of Representatives, One Hundred Seventh…, Volume 4. New York: U.S. G.P.O.

Wietschel, M. & Ball, M., 2009. The Hydrogen Economy: Opportunities and Challenges. London: Cambridge University Press.

Witte, J. M. &Goldthau, A., 2010. Global Energy Governance: The New Rules of the Game. New York: Brookings Institution Press.