The heuristic model is one technique that businesses can use to solve their planning and scheduling issues. It can be defined as an approach to problem-solving that utilizes “rules of thumb” to create a feasible and quick but not optimal solution to a problem and obtain fast results (Langley et al., 2020). This model is used to solve large problems because it helps to break them into more manageable issues.

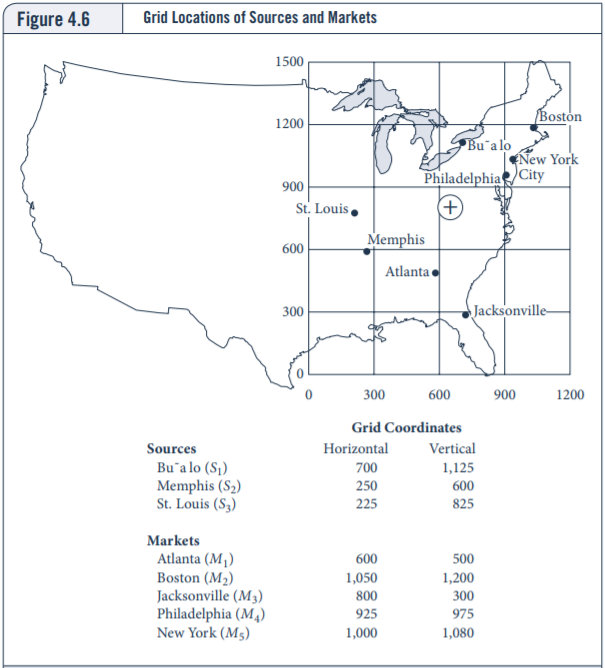

One example of the heuristic model is the grid technique (see Figure 1). It is often used to help companies determine the least-cost location for their facilities (Langley et al., 2020). The purpose of this technique is to identify the center of gravity for finished products and raw materials, that is, a location in which the company’s transportation costs will be minimized (Visser, 2019). This location is calculated based on the coordinates of main sources of raw materials and markets determined from the grid.

The decisions that can be made using the heuristic model are mainly concerned with large or urgent problems. For example, this approach is often used to identify the appropriate locations for plants or warehouses, select suppliers, and provide short-term scheduling solutions. The main benefits of this model are that it allows for dividing complex problems into manageable parts and reduces the number of alternatives for further consideration (Langley et al., 2020). For example, when deciding on the location of the plant, this model can be used to select only those options that fit certain criteria, such as the proximity to markets and the airport. The disadvantage of the heuristic model is that it does not provide optimal solutions to the problem and lacks flexibility (Visser, 2019). It means that the solution developed using this problem will not be able to serve the company for a long time. If there are changes in organizational processes, the model will have to be applied anew because the old solution may be no longer viable.

References

Langley, C. J., Novack, R. A., Gibson, B., & Coyle, J. J. (2020). Supply chain management: A logistics perspective (11th ed.). Cengage Learning.

Visser, H. (2019). Logistics: Principles and practice. Taylor & Francis.