Siemens-Energy is one of the leading technology companies in the world. One of the areas of specialization for the firm is industrial gas turbine manufacturing. According to Sadler (2020), Siemens has emerged as one of the preferred brands in the industrial gas sector. The company has two major production plants where it manufactures gas turbines. One of the plants is in the United States while the other is in Germany. The industrial gas turbine industry has become increasingly competitive as new firms continue to emerge while the existing corporations seek to expand their territories (Sayigh, 2018). It means that a firm must find a competitive edge over its rivals to remain sustainable in such a market. One of the areas that a firm can achieve sustainable advantage is to ensure that it has an efficient supply chain management system. The research seeks to assess how project management techniques be used to improve supply chain management, specifically focusing on industrial gas turbines project at Siemens-Energy.

A supply chain system creates a coordinated platform linking an organization with other entities to ensure that raw materials are obtained, processed, and the finished product is made available to customers at the right time. It starts with the identification and engagement of specific suppliers who can deliver the needed materials regularly and reliably (Ceyhun, 2020). A firm then has to put in place measures to ensure that the needed materials are availed at the production plant. Delivery of products can be done by the supplier, the buyer, or through third parties (Didonet and Díaz, 2012). A firm must choose the approach that maintains the cost as low as possible without compromising the reliability of the process.

Processing is often considered part of supply chain management. The raw materials should be consumed to help in the production of the industrial gas turbine (Kerzner, 2017a). At the production stage, the focus is to maintain high levels of efficiency to ensure that the best products are delivered at the lowest cost possible. It is at this stage that the management must ensure that cases of theft and unnecessary destruction of materials are eliminated as much as possible. Prolonged storage of raw materials should also be eliminated because it increases warehousing costs.

Distribution of the finished products is the next phase in the supply chain management system. As mentioned above, Siemens has its production plants in the United States and Germany. The company’s Giga factory in Berlin, Germany is intended to facilitate increased production (Siemens-Energy, 2022b). Once the industrial gas turbines are produced in these production plants, they have to be distributed to all the markets where the company operates (Saad and Asmuin, 2014). The Middle East, especially Qatar, the United Arab Emirates, Saudi Arabia, Jordan, Kuwait, and Egypt are currently the most attractive markets for these products. India, China, Japan, and the Philippines are the other major Asian markets. When it comes to international distribution of the products, many companies prefer using logistics companies such as Supply Chain & Global Forwarding, Nippon Express, or Kuehne + Nagel (Hanne and Dornberger, 2017). The preferred choice should offer the highest level of efficiency possible.

Once they arrive at the destination country, Siemens will need to ensure that they reach retailers. A firm may choose to have its retail offices or choose specialty shops in the foreign market (Alfoqahaa, 2018). It is the responsibility of the management of this company to ensure that the selected channel will ensure that products reach the client when in the right state. Clients for industrial gas turbines are often organizational buyers. In most cases, the client would be the government of a specific country (Rao, 2018). In other cases, the client may be large companies or non-governmental organizations producing energy for consumption or commercial purposes. The company has to ensure that the product reaches customers in time and that any assistance that may be needed for the installation and maintenance is provided. Ideally, such activities should be designed as projects to enhance their efficacy.

Project management has become a standard practice among companies, irrespective of their size when undertaking major activities. It helps in defining specific resources that should be used, a timeline of activities, and the goal that should be realized upon completion (Wysocki, 2019). It is an effective strategy when a firm intended to conduct a cost-benefit analysis of a major initiative before its implementation. The approach that a firm takes in project management depends on various factors such as the size of the company, resources available, the nature of the project, and the expertise of the team involved in the implementation.

The supply chain management in the industrial gas turbines at Siemens-Energy will ensure that there is proper coordination of activities from the initial stage of sourcing for raw materials to the final stage of installing the turbines. It is comprehensive coordination of activities of various experts in different parts of the world to ensure that clients are satisfied (Klumpp and Ruiner, 2018). It requires close cooperation of the team members involved in undertaking specific activities. They need to maintain close communication and sharing of data to ensure that mistakes are avoided as much as possible. The success of the project depends on the efficiency and effectiveness of the stakeholders involved in the entire supply chain (Barrett, 2018). The goal of this dissertation is to discuss how to use project management techniques to improve the supply chain process of the industrial gas turbine project at Siemens-Energy. It shall involve a critical evaluation and analysis of the supply chain path of gas turbine parts, from assembling, manufacturing, installation, commissioning, and maintenance processes.

It is necessary to mention the merit of the topic as a research. The topic focuses on how two management tools, which are project management and supply chain management, can be used to help enhance the success of Siemen’s industrial gas turbine project. Most studies have looked at how the two tools can be used independently to ensure the success of a project. This research takes a different approach, looking at how they can be intertwined to enhance the success of a project.

The Rationale of the Research

Project management and supply chain management are some of the areas of study which have gained massive popularity over the recent past. While project management is considered an effective tool in undertaking major investment activities within a specific timeline using the available resources, supply chain management focuses on enhancing efficiency in the entire process of making a product available to customers. Combining the two in facilitating an effective process of sourcing for materials, manufacturing, and making available industrial gas turbines for Siemens-Energy is critical (Ahmad, 2018). This company is operating in a highly competitive industry. As such, it is constantly under pressure to lower the cost of production as much as possible while at the same time maintaining high quality for its products.

The industrial gas turbine project can help transform the fortunes of this company in the energy sector if it is done properly. It can help the firm to create a unique market niche and to develop a unique pool of loyal customers in the market (Sadler, 2020). These two management tools can help the firm to achieve the required level of success (Kerzner, 2017b). Project management will help in defining specific activities that should be conducted in the industrial gas turbine initiative. It will also determine the resources needed and the specific goals that should be realized. On the other hand, supply chain management will help determine how the entire project should be conducted, from accessing the materials, manufacturing, storage, transportation, and distribution of the finished products in the market (Kerzner, 2018). The research is important because it will help in defining how the management of Siemens-Energy will use the two tools to ensure that the industrial turbine gas project is a success.

Case Study

Siemens-Energy WWL is a technology company that has been operating in Qatar since 1970. The firm has a large product portfolio in the fields of transport, infrastructure, and industry. For the past 30 years, the company has been keen on using innovative technologies to transform transport and manufacturing sectors not only in Qatar but also in other parts of the world (Sadler, 2020). It has partnered with other companies to find ways of reducing the emissions of greenhouse gases while at the same time enhancing efficiency and productivity in these sectors. Siemens-Energy reports that the company has ventured into the production of batteries for electric cars and ferries (Weimoth, 2022). Figure 1.1 below shows an all-electric ferry that relies on Siemens battery. The goal is to be at the forefront in the fight against global warming.

In the energy sector, Siemens is involved with generation, transmission, and industrial applications. It has also made major investments in the new energy business and the renewable energy sector as a way of helping its clients to reduce their reliance on renewable energy. This project primarily focused on the industrial application sector of the company. The company acknowledges that the industrial sector is one of the largest consumers of energy, leading to massive emissions of carbon dioxide gases. As the sector continues to play a critical role in the growth of the economy, it is essential to find ways of providing renewable energy to it to help protect the environment.

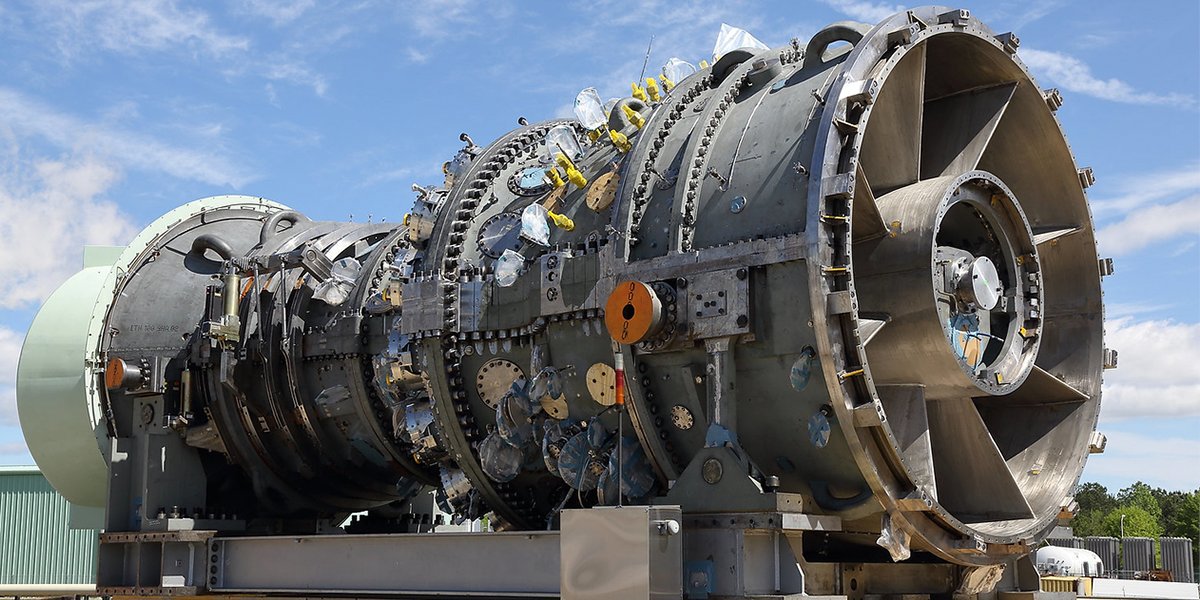

Siemen’s Industrial Application Division was created to find innovative ways of addressing energy needs for these companies. “Our portfolio includes mission-critical rotating equipment that we maintain throughout its lifecycle with our comprehensive fleet of services, and electrical, automation, and digital offerings that optimize both this equipment and services,” (Siemens-Energy, 2022b, para. 5). Figure 1.2 below shows an industrial gas turbine produced by Siemens-Energy. The company has put in place a mechanism to ensure that it serves the different needs of its customers in the supply chain of renewable energy. These services and products are available throughout the Middle East and other parts of the world where Siemens operate.

In this case study, the focus was on the industrial gas turbines project. The company manufactures various types of gas turbines, which include heavy-duty gas turbines, industrial gas turbines, and aero-derivative gas turbines among others. Some of these turbines are built in Berlin, Germany, while others are manufactured in Charlotte, North Carolina in the United States. Once manufactured, the company must ensure that these gas turbines are made available in specific places where they are needed (Sivaram, 2018). Although a significant number of this equipment are used in the country where they are manufactured, others have to be transported across the world.

Supply chain management is a major concern for the company as it seeks to revolutionize industrial power production in the renewable sector (Ward, 2018). On the one hand, the firm has to ensure that all the raw materials needed for the production of the gas turbines are made available to the company at the right time. On the other hand, the firm has to ensure that once the turbines are manufactured, they have to be moved safely and efficiently to clients all over the world. As Zwikael and Smyrk (2019) observe, a weak supply chain system can have a devastating impact on a manufacturing plant. The needed raw materials should be made available at the right time, meeting specific quality requirements (Earley, 2014). The firm’s cost of production can significantly increase if there is an oversupply of the raw materials because the items will have to be kept in a warehouse until they will be needed.

Just-in-time (JIT) is a technique that has been popularly used in various major companies around the world to ensure that the supply chain is as efficient as possible. It involves making available the materials when they are needed (Chung, 2021). It ensures that the raw materials are not delivered in excess. The strategy eliminates unnecessary pilferage, damage caused by excessive handling, and the high cost of warehousing. JIT requires an effective communication system between various stakeholders in a firm (Hellingrath and Lechtenberg, 2019). The production unit should provide information about the needed materials to the procurement department (Toorajipour, et al., 2021). The same information should be immediately available for the finance department responsible for releasing funds, and the transport unit that will facilitate the movement of the same. The same information should also be relayed, in real-time, to the suppliers so that they know the needed quantity and quality of the products (Spalek, 2019). Such an effective system of communications eliminates cases of delays or delivery of wrong products.

Research Questions and Objectives

It is important to define the research questions that will guide the process of data collection in this research. As Davidson (2019) observes, research questions help in defining the kind of information that needs to be collected from the field. A researcher can easily collect irrelevant data if there are no specific guidelines to be followed. The questions help in addressing that challenge. The following are the specific research questions that the researcher seeks to answer using both primary and secondary data:

- How can Siemens-Energy use project management techniques to improve the supply chain process of industrial gas turbine projects?

- What is the supply chain path of the gas turbine part, from assembling, manufacturing, installation, commissioning, and maintenance?

- What are the challenges that Siemens-Energy can face in the project management approach on supply chain management of industrial gas turbines?

- What are the ways in which this company can overcome the identified challenges?

The dissertation will focus on achieving specific objectives based on the research questions above. The primary aim of the research is to find a solution towards reducing the lead time of parts used in the operation and maintenance of industrial gas turbines, and other factors affecting industrial gas turbine projects ranging from installation, commissioning, operation, and maintenance. The researcher will use survey to achieve the aim and objectives of the dissertation. Chapter 3 provides a detailed explanation of the methods used to collect and process data. Upon the completion of this research, the following objectives should be realized:

- To critically assess how Siemens-Energy can use project management techniques to improve on the supply chain process of industrial gas turbine project;

- To critical analyze the supply chain path of gas turbine parts, from assembling, manufacturing, installation, commissioning, and maintenance;

- To critically evaluate the challenges that Siemens-Energy can face in the project management approach on supply chain management of industrial gas turbines;

- To determine ways in which this company can overcome the identified challenges;

- To contribute to the existing knowledge on how project management can enhance supply chain management within an organization

Dissertation Structure

The dissertation has been divided into five main chapters addressing specific issues. Chapter 1 provides the background of the study and addresses the rationale for the topic. Research objectives and questions are also presented in the chapter to help understand the goal that it seeks to realize. A brief case study about Siemens-Energy WWL is also addressed. The second chapter provides a detailed review of the literature. The researcher uses this chapter to discuss what other scholars have found out in this field or other related fields. It helps to identify the existing knowledge gaps or conflicts. It also eliminates the possibility of duplicating the already existing information.

The third chapter outlines the activities involved in the data collection and analysis in this project. The method used to collect, analyze, and present data are discussed in detail. Issues about research design, reliability, validity, and generalizability are explained. Limitations and challenges faced and how they were overcome in the study are also addressed in the chapter. It also addressed the ethical considerations that the researcher observed in the study. The fourth chapter involves the presentation of the results from the analysis of primary and secondary data. It helps in addressing knowledge gaps identified in the review of the literature. The final chapter of the dissertation presents the conclusion and recommendations.

Literature Review

The previous chapter provided background information about the topic, its rationale, the aim, and the objectives that should be realized. This chapter focuses on reviewing the literature to determine what other scholars found out about this topic and the existing knowledge gaps and contradictions. The review is important because it not only facilitates the identification of knowledge gaps but also avoids duplication of already existing pieces of information. Information collected from secondary sources helps in defining the focus of primary data collection. As mentioned in the previous chapter, the primary aim of the research is to find a solution towards reducing the lead time of parts used in the operation and maintenance of industrial gas turbines, and other factors affecting industrial gas turbine projects ranging from installation, commissioning, operation, and maintenance.

The scope of the research was limited to industrial gas turbine projects. The themes presented in this chapter include supply chain management, project management approaches, and challenges in the supply chain of industrial gas turbines. The chapter also provides a theoretical framework, critically evaluates how the study relates to the literature in general, and how it relates to previous studies. Key themes and gaps in the literature are identified before providing a summary of the chapter.

Supply Chain Management

Supply chain management (SCM) has emerged as a field in management that facilitates the flow of goods and services from one location to another. According to Camarinha-Matos, Almeida, and Oliveira (2019), SCM involves managing the flow of products, and it includes all processes involved in the transformation of raw materials into finished products. It involves deliberate efforts to streamline supply activities with the primary goal of maximizing customer value. By streamlining the activities, wastes will be eliminated while efficiency enhanced to ensure that a firm can charge competitive prices without compromising on its profit margin (Agarwal, Sharma, and Mathew, 2016). With high-quality products and relatively fair prices, a firm can achieve a competitive advantage over its rivals in the market (Chung, 2021). It will be able to offer its clients maximum value for every product that they purchase.

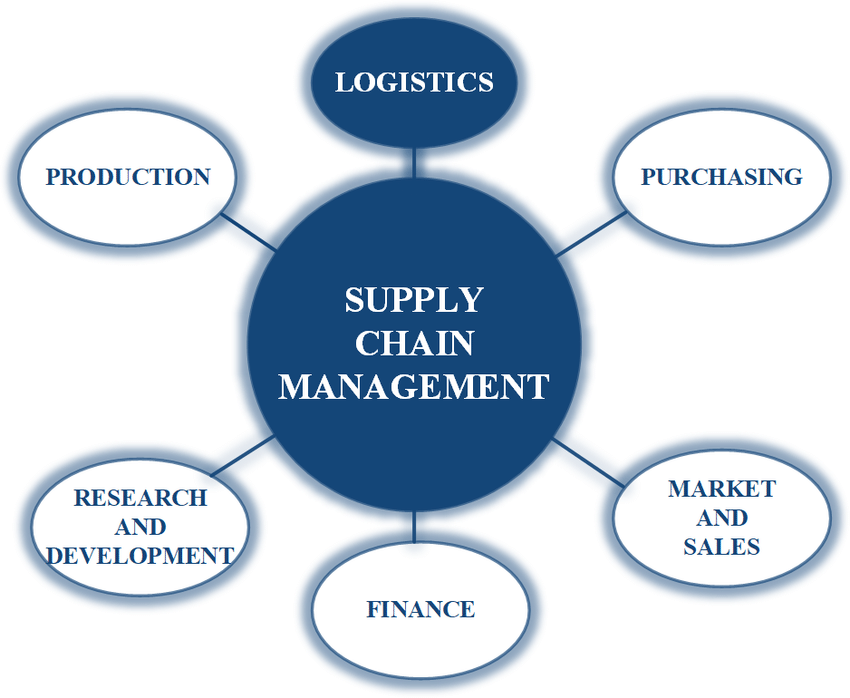

Supply chain management involves numerous activities, as shown in figure 2.1 below, meant to ensure that products are made available to customers in the market. It starts with the procurement of the raw materials that are needed at the production plant (Didonet and Díaz, 2012).

The procurement unit must ensure that it finds reliable suppliers that can provide quality products at all times. Once purchased, the raw materials have to be delivered to the production plant so that they can be processed (Toorajipour et al., 2021). The actual processing of the raw materials, known as the production process, is also considered part of the SCM (Hanne and Dornberger, 2017). The finished products must then be transported to the market for the convenience of customers. It is equally important to ensure that there is regular research conducted to help develop the system by eliminating weaknesses and wastes while improving the ability to respond to emerging customers’ needs (Hellingrath and Lechtenberg, 2019). The activities identified above must be resourced, which means that activities in finance department are support functions of the SCM.

Supply Chain Path of Industrial Gas Turbine Parts

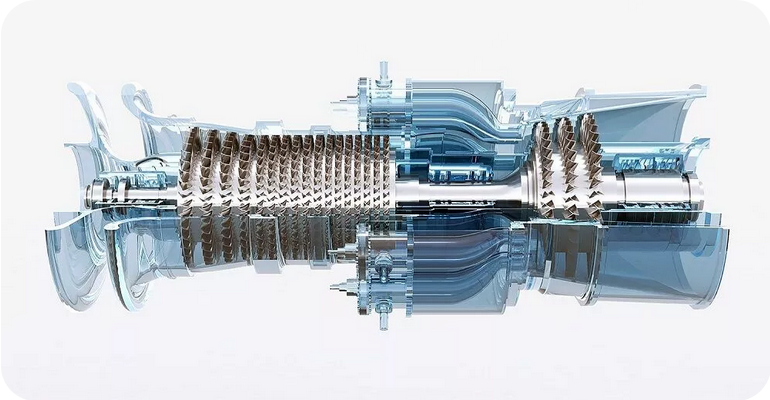

The demand for gas turbines has been growing steadily in the global market, as Fouquet (2018) reports. A complete gas turbine has several parts, from an air inlet, a compressor, the combustion chamber, turbine section, an exhaust, and accessories section. However, developing a complete gas turbine requires the assembling of several parts. The supply chain path of industrial gas turbines parts involves several activities (Klumpp and Ruiner, 2018). Iqbal (2020) emphasizes the need to understand the activities involved and how they are related. It starts with assembling the needed parts, some of which have to be sourced from other manufacturers. The procurement and logistics departments are responsible for ensuring that these parts are made available at the production plant.

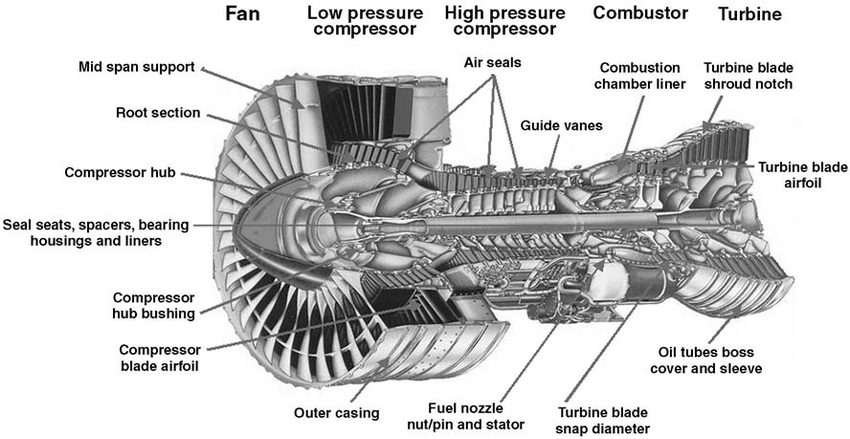

The next step in this path is the manufacturing and installation of parts to have a complete system. At Siemens-Energy, manufacturing activities of the firm are undertaken in Berlin, Germany (Siemens-Energy, 2022a). The size and capacity of the gas turbine will depend on the purpose it will serve. Figure 2.2 below shows different parts of a complete gas turbine that is ready for installation. Once the complete system is developed, the next phase is the transportation and subsequent installation at a client’s premises. The system has to be properly installed as per the specifications of customers. Once installed, the system will need commissioning after its functionality is tested. During the commissioning, the manufacturer will be handing over controls of the gas turbine to the client. There should be an arrangement made between the client and the manufacturer on how the system will be maintained regularly to ensure that it functions properly for as long as possible.

Project Management Approaches

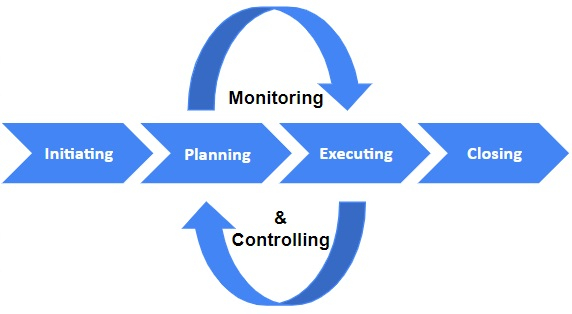

A project manager has an important responsibility of selecting an appropriate project management approach that can help in achieving specific goals. When selecting the approach, various factors have to be put into consideration, as Kerzner (2017a) observes. The budget for the project, the size of the team involved in the project, the ability to take risks, and flexibility are some of the major factors that have to be considered. One also has to take into consideration the time within which activities have to be completed and client or stakeholders’ collaboration. However, Kerzner (2017) warns that while it is important to take into consideration the above factors, each project is unique and should be treated as such. The following are some of the popular project management approaches that can be considered in an industrial gas turbine project.

Agile

This approach has become one of the most popular project management methods in various fields. Badiru (2021) explains that the method was developed by critics of linear strategy as defined in the linear approach. It emphasizes the need for collaboration among all the stakeholders involved. It creates a platform where information from clients, employees, managers, and suppliers is used to make necessary adjustments in the project when necessary (Ma and Rong, 2022). The approach values quick decision-making based on data that has been collected from the field.

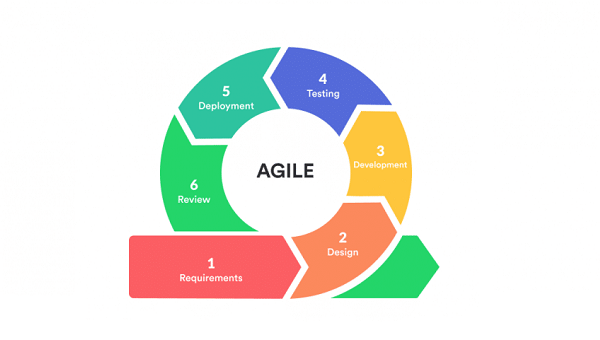

As the name suggests, this approach involves having short phases of specific activities and requires regular testing and assessment to determine if the team is on the path to achieving the primary goal (Davidson, 2019). It is a highly flexible strategy and data-driven. Dobie (2020) and Clegg et al. (2020) argue that the fact that this approach takes into consideration the views of many stakeholders may make it a time-consuming method of implementing a project. Cases often arise where individuals have conflicting views on a given issue. Despite this challenge, the method is preferred because upon completion of the project, the majority of the relevant stakeholders will be satisfied because their views were taken into consideration. Figure 2.3 below summarizes the cyclic nature of an agile project management approach.

When using this approach, it is important to note that it also has disadvantages. One of the main weaknesses of this model is that team members can easily get sidetracked because of lack of standard process that should be followed. Voehl and Harrington (2017) explain that there is also the risk of incremental delivery when handling long-term projects. These challenges should be effectively managed by the responsible parties to ensure that a given project achieves the intended goals.

Waterfall

This approach is one of the most common methods of project management that has been traditionally used in the manufacturing sector. It takes a linear approach, where activities in one stage have to be completed before moving to the next. As shown in figure 2.4 below, the first step is idea engineering where the team is expected to define what is expected in the project. The next step is system design, where the team develops a system that is based on the idea developed. The implementation phase involves putting into practice the plan that has been developed in the project. There is the testing and validation phase where the team is expected to determine if the system is working as per the expectation.

The last phase is maintenance to ensure that the entire system remains efficient (Nicholas and Steyn, 2021). The approach is simple to implement in the manufacturing and construction sector, which explains why it has remained popular, but Barrett (2021) warns that it is a simplistic approach, especially when handling complex projects. It can be considered in the supply chain management of industrial gas turbine projects. Ajam (2021) explains that one of the major disadvantages of this approach is high rates of uncertainty. The uncertainty causes serious risks to the successful completion of long-term projects.

Lean

Lean project management is another strategy that is popular when managing major projects. As the name suggests, the primary focus of this project management strategy is the minimization of waste when undertaking a project. The trend started in Japan and gained acceptance around the world as a means of maximizing the value for investors (Clegg, Skyttermoen, and Vaagaasar, 2020). When using the method, a project manager is expected to ensure that they consistently investigate and eliminate any form of waste in the project. This way, it becomes possible to continuously improve the quality of products while at the same time reducing the cost of production. It classifies waste management in a project into three categories. The first is called Muda, which involves activities and processes which are considered not to add value to the project. Activities such as overproduction and over-processing fall into this class.

Mura is another way of eliminating wastes, which involves eliminating delays that may affect activities down the line of production. The goal is to ensure that there is an effective and smooth flow of activities without any delays (Zwikael and Smyrk, 2019). The team may need to assist the department that is identified as slowing activities in the production line. The third strategy, which is called muri, focuses on the elimination of inefficiency among managers. Sometimes a project may be delayed by slow decision-making, micromanaging activities of employees, time-wastage, and poor organization (Meredith and Shafer, 2021). It is essential to eliminate such poor leadership practices to enhance efficiency in project management.

The overall goal of lean project management is to enhance operational efficiency at the lowest cost possible. It is the only way of ensuring that investors get the highest value for their investment. One of the major limitations of lean project management is the overemphasis on efficiency in the use of resources (Vanzant, 2020). It is possible that employees may be forced to sacrifice quality to limit the use of resources. Figure 2.5 below shows activities involved in lean project management approach. It may also have a negative effect between a project manager and team members when there is immense pressure to cut expenditure.

Scrum

Scrum, as an approach to project management, has also gained massive acceptance. Although it is based on some of the agile project management principles, it is unique in many ways. As Ahmad (2018) explains, the method emphasizes the need for accountability, collaboration, and enhanced interaction among stakeholders involved in the project. It holds the belief that success can only be achieved when stakeholders in the project work as a team, and information is effectively shared as necessary. It is based on five principles of courage, openness, respect commitment, and focus. Courage is needed because sometimes the team difficult decisions that may not be pleasant to everyone. If it is the right decision, then the team may have to choose it even if it is unpopular among a section of the stakeholders (Spalek, 2019). Openness is encouraged to avoid misinformation and misunderstanding that may arise.

Every stakeholder is expected to remain committed to the project and focused on achieving the set organizational goals. Scrum encourages both the managers and junior officers to maintain respect as a way of enhancing teamwork. One of the challenges of this strategy is that it does not prioritize timely delivery of projects. As such, chances are always high that a delay could occur when undertaking major projects. It also fails to outline how teams can cooperate to achieve intended goals.

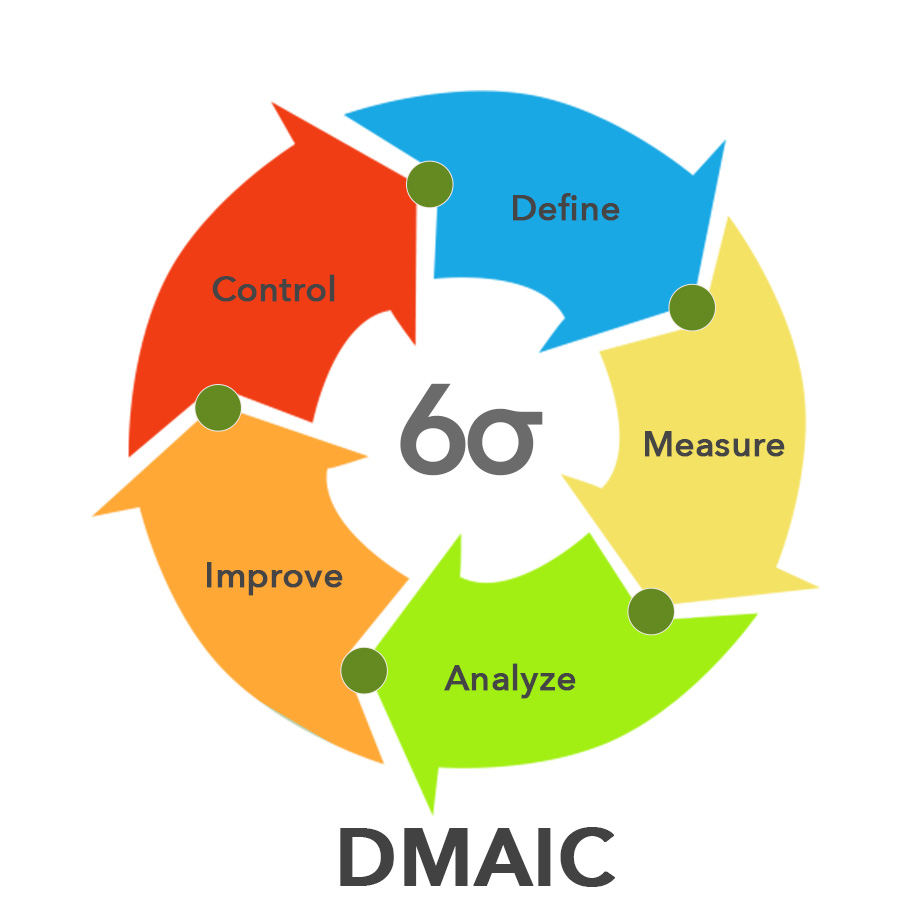

Six Sigma

The tool has widely been used to improve quality and production processes in an organization. It identifies six stages that a project management team should follow to help eliminate challenges and improve efficiency in a given project. As shown in figure 2.6 below, it starts by defining the problem and goals that should be achieved. This step helps in ensuring that all stakeholders understand what needs to be achieved through the project (Barrett, 2021). The second step is to measure aspects of the existing variables to identify any weaknesses that may need improvement. The third step involves analyzing data to have a detailed understanding of the causes of the problem with the current process. At this stage, stakeholders get to understand specific problems of the current system and how they affect the overall success of the entire system.

The fifth step involves making the necessary improvements based on the data collected. The improvement made should address the challenges of the current system as identified in the analysis. The last stage, as shown in the figure below, is to control how various activities will be done in the future (Helgi, 2020). The goal at this stage is to ensure that past mistakes that led to the emergence of the problems identified are eliminated. The process is cyclic, as shown in the figure, which means that once a problem is identified and addressed, the team needs to reexamine the system once again to identify the possible weaknesses. Excellence is achieved through such a detailed process of constantly improving the system.

One of the biggest challenges when using this model is that it is likely to cause resistance to change. Its radical proposals for change ignores internal culture, which some stakeholders may find repulsive. Vanzant (2020) explains that the concept is also not data-driven, which means that it is possible to have inconsistencies when it is used. The strategy may not be easy to apply in some instances, especially when handling blue-collar employees with limited academic achievements.

Challenges in Supply Chain of Industrial Gas Turbines

The supply chain of industrial gas turbines has numerous challenges that a company has to find a way of addressing to enhance efficiency. From sourcing for the raw materials to ensure that there is efficient processing and timely delivery of products to customers, many challenges may arise. It is essential to identify these challenges to ensure that the company can eliminate them to enhance its performance.

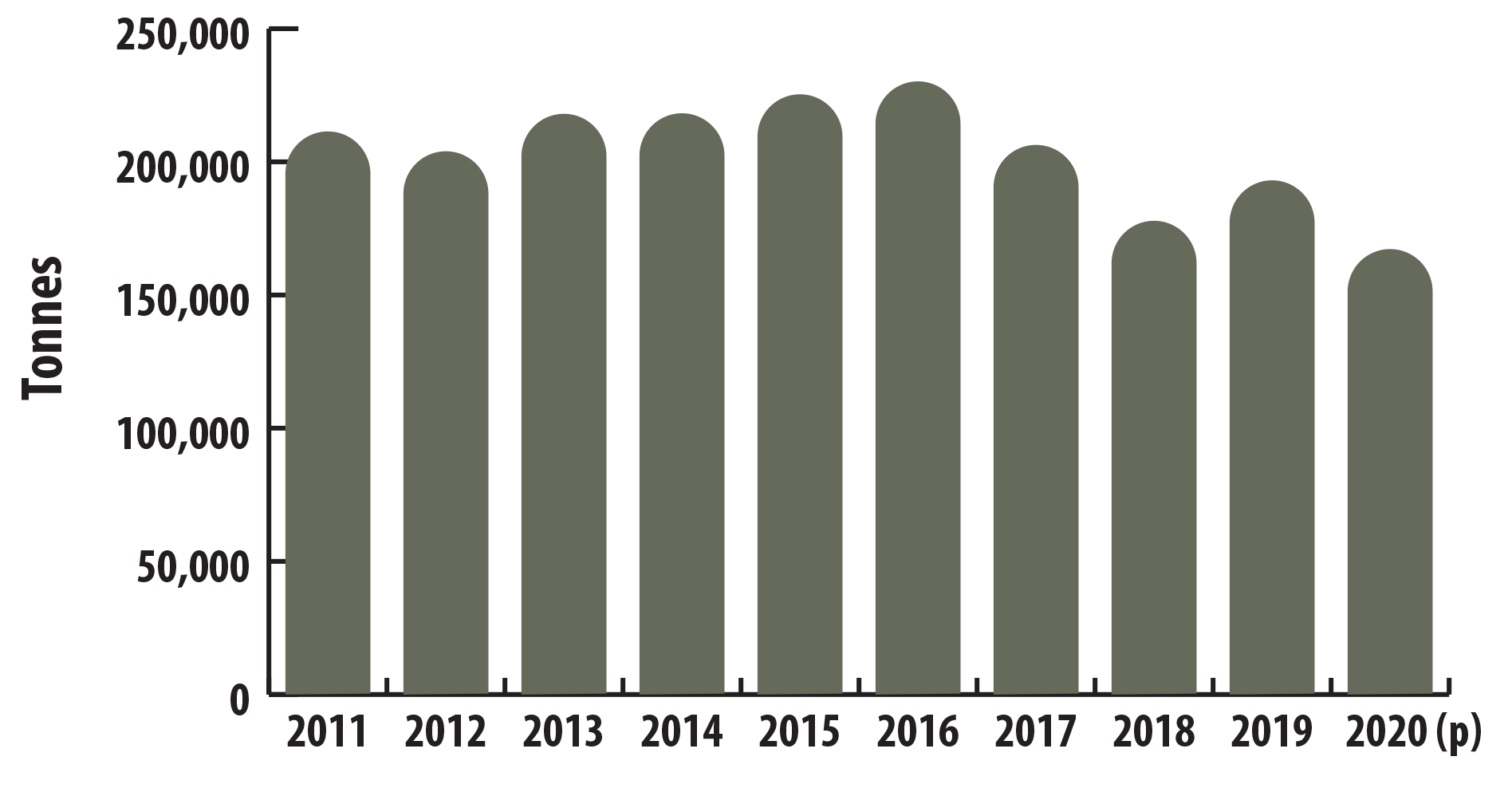

Material Scarcity

The primary responsibility of the procurement department is to ensure that materials needed for production are made available at the production plant. One of the challenges that the department may face is the scarcity of the raw materials needed for the production process (Iqbal, 2020). Canada is one of the leading producers of nickel, which is an important raw material for the production of industrial gas turbines. Figure 2.7 below shows that the production volume of this important material has been going down in the country since 2016. The scarcity may be caused by numerous challenges such as geopolitical wars such as the one which is currently happening between Russia and Ukraine. Such tensions create unique supply chain challenges for companies in the affected countries or their allies. The scarcity may also be caused by reduced availability of the needed products or a disproportionate increase in demand.

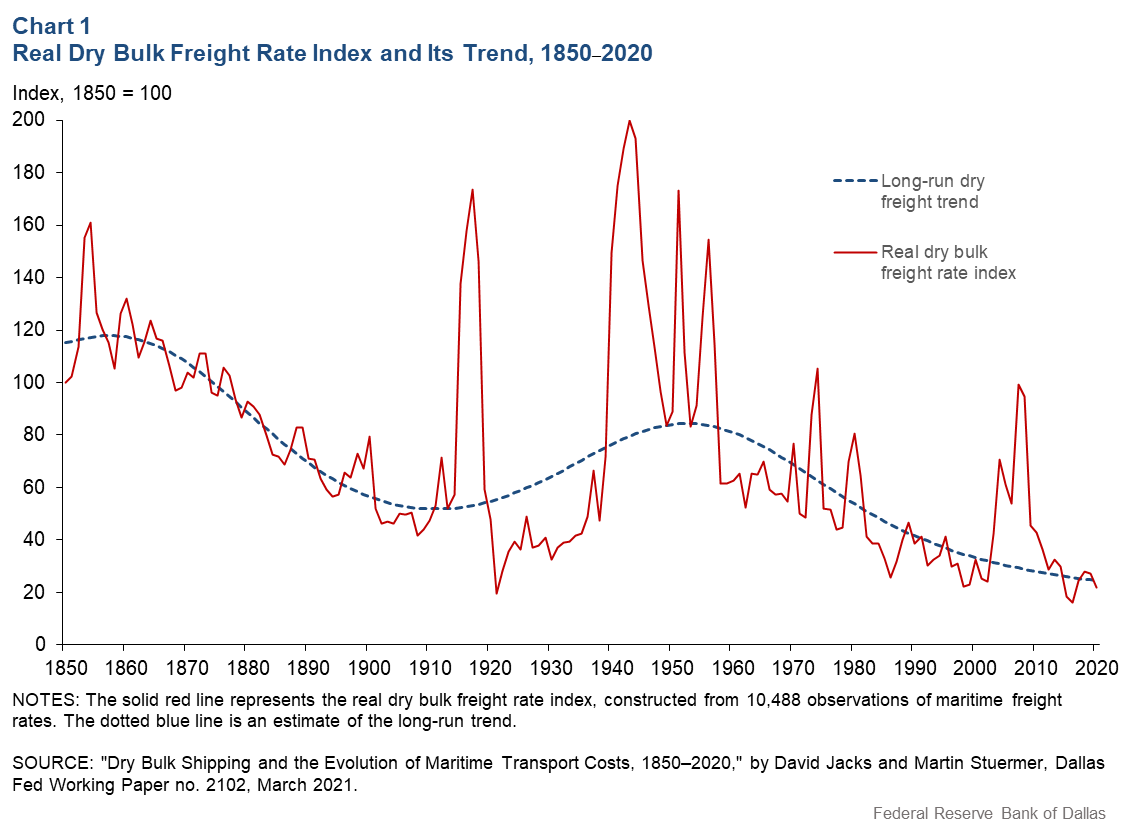

Fluctuating Cost of Freight

The cost of delivering raw materials to the production plants and finished products to customers defines the overall unit cost of production. A firm needs to have a stable freight cost to ensure that it can estimate the production cost to help in setting of price (Kumar, Raghunandan, and Sivaramakrishna, 2021). Figure 2.8 below shows the fluctuation cost of freight over the past several years. The problem is that the cost of freight keeps changing depending on various factors. Weather, security, and regional political security are some of the major factors that cause such fluctuations in the cost of freight. The firm may not directly control some of these external factors, as Lennon (2022) observes. However, it can streamline its internal environment to be in line with external forces, as Young (2021) advises. It makes it difficult for the firm to have a standard way of pricing its products.

Difficulty in Demand Forecasting

Supply chain management involves having an accurate prediction of demand in the market. Demand forecasting makes it possible for a firm to plan its production in a way that meets the expectations of customers (Lennon, 2022). However, Agarwal et al. (2016) observe that sometimes a firm may have access to misleading information, making it difficult to predict the demand. Inability to predict the demand may cause overproduction or underproduction. Overproduction would lead to massive losses because the firm will have to incur the cost of warehousing excess products (Kerzner, 2017b). Some of these products may be damaged while they are in the warehouse. On the other hand, underproduction may lead to customer dissatisfaction. They may consider moving to alternative companies that can assure them of regular delivery of products.

Port Congestion

Transporting some of the parts of industrial gas turbines requires precision handling because they are delicate. The congestion at ports may be a challenge in the handling of the turbines. Siemens-Energy uses the Port of Hamburg for exportation of the manufacture red industrial gas turbines (Siemens-Energy, 2022a). It is one of the busiest ports in Europe that is susceptible to the problem of congestion. To reduce congestion, the workers at the port may be careless (Ward, 2018). They can trade speed for efficiency, which may have devastating consequences. Problems may also arise when there are delays in processing at the ports because of delays. Such a delay in the processing of raw materials would mean that various activities will have to be delayed as the team waits for the arrival of needed items for production. The congestion can also lead to customer dissatisfaction when they are forced to wait for long before they can receive their products once payment has been made. The assembled industrial gas turbine is large and delicate when being transported, as shown in figure 2.9 below, which means it takes time to be loaded into a ship, which worsens the problem of congestion at the port.

Digital Transformation

The digital transformation promises to eliminate numerous challenges that are associated with analog data management. However, it is a disruptive change that requires a major shift from the traditional approach of managing information in an organization. The procurement department cannot afford to stop its operations to allow its employees time to learn the new system. It means that they have to learn while continuing their normal duties (Spalek, 2019). Some costly mistakes can be made, which may have a serious negative impact on the success of a project. The company reports that it has digitized most of its operations, which means that its management and workforce has had to face mentioned challenges (Siemens-Energy, 2022d). These challenges have to be addressed to ensure that the supply chain of industrial gas turbines is efficient.

Changing Needs and Attitude of Consumers

The efficiency in supply chain management is achieved through doing something regularly and developing a pattern that helps in producing the best quality at the lowest cost possible. The challenge arises when the needs and expectations of customers change regularly (Zhang, Peng, Li, Johansson, and Xiao, 2019). Whenever there is a change in taste and preferences, the entire supply chain system has to be redefined. In the energy sector, a trend is emerging where consumers are moving towards green energy. Solar power, wind energy, and biogas are some of the options that are becoming increasingly popular (Sadler, 2020). These emerging trends may have a major impact on the supply chain as the manufacturer has to redefine its products to meet the new demands. Whenever there is a change, a firm will have to invest in the retraining of employees and purchase of the new materials needed for the new product.

Theoretical Background

Supply chain management is a field that has attracted many scholars interested in finding ways of enhancing the success of a major project by ensuring that the needed materials are made available at the right time. Various theories and concepts have been developed to help explain how to ensure that the process is a success. The following are the theories reviewed in this chapter because of their relevance in the research.

Total Quality Management

TQM is a tool that helps in facilitating continual detection and elimination of errors in manufacturing. It streamlines supply chain management, from the time of sourcing raw materials to the final stage of delivering finished products to customers (Rao, 2021). Its primary aim is to enhance customers’ experience by ensuring that their needs are met in the best way possible. At the same time, the tool help in lowering the cost of production to the lowest level possible. This customer-based tool enables a firm to understand and effectively respond to customers’ needs. As Wysocki (2019) observes, TQM requires emphasizes the need to maintain quality from the initial stage of procurement to the processing stage and finally the delivery of products to customers. This tool will be critical in ensuring that there is an effective sourcing for materials used in the manufacture of industrial gas turbines, efficiency in the processing, and timely delivery of the finished products (Didonet and Díaz, 2012). However, Badiru (2021) warns that when using this tool, the management should remain committed to making available the resources that the entire team needs to ensure that there is success.

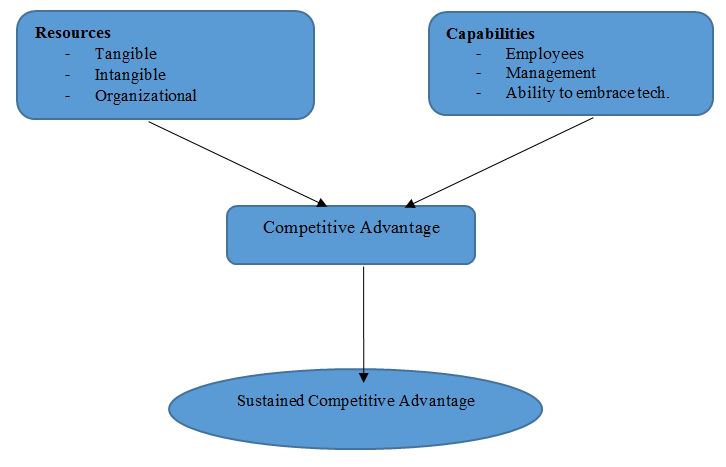

Resource-Based View

The theory seeks to find ways in which a firm can use its resources to achieve a sustainable competitive advantage in the market. As Prabhu (2020) observes, it involves using what a firm has to achieve what it desires. The firm uses its unique capabilities such as skilled employees, experienced management, and the ability to use emerging technologies to enhance its operations. Hellingrath and Lechtenberg (2019) reiterate that it also uses both tangible and intangible resources to achieve the same aim. These two factors create a competitive advantage for the firm. If they are maintained, they create a sustained competitive advantage, as shown in figure 2.10 below. The theory can be applied bManagement

How the Research Relates to Previous Studies and the Literature in General

Project management and supply chain management are topics that have attracted the attention of many scholars for the past several decades. This dissertation will be enriching the existing knowledge in the two fields, narrowing down the study to how the project management approach on supply chain management can help enhance operations at Siemens’s industrial gas turbine projects. Such projects are often costly and highly demanding, and it is necessary to find ways of ensuring that they are successful. The research will rely on previous literature to understand how the two concepts of project management and supply chain management have been used to eliminate waste and improve the success of such projects.

Gaps in Literature

The two fields of project management and supply chain management have received wide research. The review of the literature revealed that corporations, government agencies, and large non-profit entities have embraced the concept of project management when undertaking major projects (Davidson, 2019). This research narrowed down to investigate how project management approaches on supply chain management can affect operations and success of industrial gas turbine manufacturing and delivery to the market. Alfoqahaa (2018) argues that the significance of project management techniques in completing major projects is an area that is widely researched, but Chung (2021) believe that the link between project management approaches, the supply chain, and the success in the manufacturing of industrial gas turbines still needs further research. This is the area that the researcher considered worth conducting further research on to explain the relationship.

Summary

Industrial gas turbine production and sale is a delicate project that requires a firm to ensure that quality raw materials are delivered at the production plant in time, the processing is done effectively, and delivery is done using reliable means to meet the expectations of customers in the best way possible. As Wysocki (2019) advises, there should be an effective supply chain management system that helps in ensuring that the movement of parts is done efficiently. Doing so requires a firm to select appropriate project management approaches capable of meeting the set demands, as Davidson (2019) observed. The review has explained how various approaches are used and their relevance when handling specific activities. The chapter has identified an existing knowledge gap that needs further research. The review focused on answering research questions that were set in chapter 1 of this document. Findings from this chapter influenced the design of the questions used in collecting primary data. There was a need to address the gaps in the literature identified in this chapter.

Methodology

The previous chapter has provided a detailed review of the literature. Collecting secondary data was essential in ensuring that the researcher captures what other scholars have found out in this field, and any possible contradictions (Bougie and Sekaran, 2020). The information has significantly influenced the research design to help address the identified knowledge gaps. For instance, Zwikael and Smyrk (2019) and (Earley, 2014) argue that a weak supply chain system can have a devastating impact on a manufacturing plant. However, the examples it provides to back this claim are unsatisfactory. Using a survey from Siemens-Energy, it will be possible to collect primary data that will help back this claim. Kerzner (2017a) and Badiru (2021) emphasizes the need to select a specific project management approach based on activities that one undertakes. However, the relevance of these approaches to supply chain management process in the industrial has turbine project is unclear.

Using qualitative research methods, it was possible to explain this relevance based on data collected from Siemens-Energy. It was also possible to explain how to use project management techniques to improve the supply chain process of industrial gas turbine projects. Supply chain path of the gas turbine parts, from assembling, manufacturing, installation, commissioning, and maintenance is explained by Meier (2020), but there is limited literature about how project management techniques can be used to improve it. A detailed qualitative research would help in addressing this gap.

In this chapter, the focus is to discuss how data from the primary sources were obtained, processed, and used to directly respond to the aim and objectives of the research. The chapter discusses the philosophical assumptions that were embraced in this dissertation. Research questions that guided the process of collecting data and the validity and reliability issues were discussed. The chapter then gives a detailed discussion of data selection and collection methods. The final section of the dissertation focuses on ethical concerns, bias, and limitations in the research.

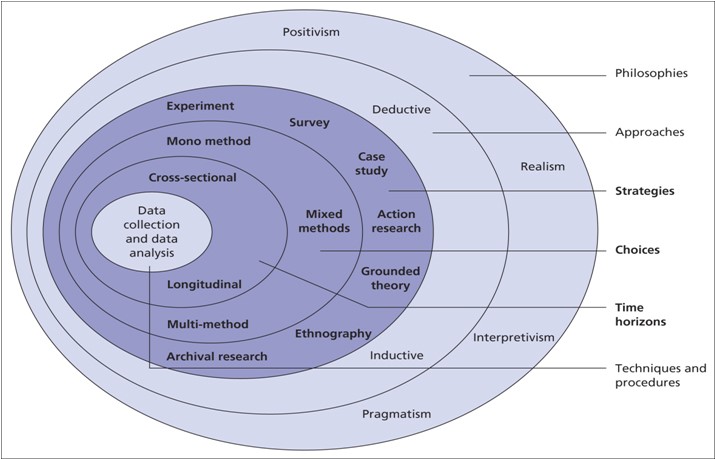

Philosophical Assumptions

Defining research philosophy is one of the first steps that a researcher should take when undertaking a given research. According to Bell, Bryman, and Harley (2018), at this stage, a researcher is expected to stipulate major beliefs and assumptions that will guide the process of collecting and processing primary data. The assumption defines the method that will be used to collect and process data (Saunders, Lewis, and Thornhill, 2019). One can use positivism, realism, pragmatism, or interpretivism, as shown in the research onion in figure 3.1 below, as the fundamental philosophy in the research. It is necessary to discuss each of these philosophies briefly before explaining why one of them was selected to define the principles and beliefs of the research.

Positivism

Positivism is one of the most commonly used research philosophies in social sciences. According to Aityan (2022), this philosophy holds the view that reliable and factual information can only be obtained through observation. A researcher is expected to avoid interfering with subjects to ensure that information obtained is trustworthy (Eden, Nielsen, and Verbeke, 2019). It holds the belief that if a researcher interferes with the subjects or in case that target group realizes that they are under investigation, they can change their behaviour, which means that the information gathered will not be an accurate reflection of the reality. When using this philosophy, its fundamental principle of processing collected data is through statistical methods. It means that one would be required to collect data that can be coded and analyzed mathematically (De and Kammerlander, 2020). This philosophy was considered inappropriate for the research because of its emphasis on quantitative methods of analysis. The researcher was interested in conducting qualitative research.

Realism

Some researchers, such as Aityan (2021) and Cooper (2018), believe that it may be necessary to realism as the underpinning philosophy in their study. It holds the assumption that reality exists independent of the human mind (Gupta and Gupta, 2012). In many cases, the ideas and views of individuals are informed by their cultural practices and stereotypical beliefs. Misinformation and miscommunication can also make an individual embrace a misleading view. As such, this philosophy holds the principle that scientific methods are the only way of developing knowledge (Young-Oliveira and Costa, 2021). In social sciences, this philosophy is less common because of the emphasis on the usage of scientific methods. It was inappropriate for this qualitative research.

Pragmatism

In social sciences, pragmatism remains one of the most popular philosophies. According to Cooper (2018), the philosophy holds the view that a concept is relevant as long as it supports action. Pragmatists are flexible enough to acknowledge the fact that the world can be interpreted in different ways in a given research. It also explains that one specific view may not give an entire picture of a given issue as there can be multiple realities (Aityan, 2021). As such, one should not rigidly define a concept in a given way. They should be flexible enough to understand that the concept can be interpreted differently. This philosophy encourages the usage of mixed-method research (Stacey, 2019). The researcher is expected to use statistical methods to quantify the phenomenon and determine the existence of the relationship between variables. On the other hand, it also requires the usage of qualitative methods to provide a more detailed picture of an issue beyond statistics (Machado and Davim, 2020). Although this philosophy is relevant in this dissertation, the researcher did not use it because of its aspect that requires the usage of statistical methods of processing data.

Interpretivism

Interpretivism sometimes referred to as interpretive, is another common philosophy in social sciences. According to Raju and Prabhu (2011, p. 41), interpretivism holds the view that “access to reality, given or socially constructed, is only through social constructions such as language, consciousness, shared meanings, and instruments.” The philosophy sharply contradicts concepts and principles of positivism. It holds that the role of a researcher cannot be narrowly defined as that of data collection and analysis. Sometimes is necessary to do more than just collect and analyze data (Pochiraju and Seshadri, 2019). One may need to interact with the subject under investigating to have a detailed understanding of the phenomenon being investigated.

This philosophy was considered particularly important in investigating how to use project management techniques to improve supply chain processes of the industrial gas turbines at Siemens-Energy. This philosophy focuses on assessing specific phenomena to understand why they happen in a given way (Lee and Saunders, 2017). As such, it encourages the use of qualitative methods to analyse data. It holds the principle that qualitative methods allow a researcher to explain a given concept beyond statistical approaches (Mukherjee, 2020). It made it possible to investigate in detail the current supply chain system at the firm and the extent to which the company currently applies various techniques of project management. Principles of this philosophy allow a researcher to go beyond simple observation to allow the researcher to interact with participants to understand the phenomenon in detail.

Research Questions

It was necessary to develop research questions to help guide the process of collecting data. The following are the specific research questions that were formulated.

- How can Siemens-Energy use project management techniques to improve the supply chain process of industrial gas turbine projects?

- What is the supply chain path of the gas turbine part, from assembling, manufacturing, installation, commissioning, and maintenance?

- What are the challenges that Siemens-Energy can face in the project management approach on supply chain management of industrial gas turbines?

- What are the ways in which this company can overcome the identified challenges?

The first question focused on determining how the company can use project management techniques to improve the supply chain process of its industrial gas turbine project. It was the primary focus of the research as it sought to address the possible challenges that were identified in the current system. The second question focused on explaining the supply chain path of industrial gas turbine parts, from manufacturing, assembling, installation, commissioning, and maintenance. Answering this question made it possible to identify specific challenges and weaknesses of the supply chain and how they can be addressed. The third question focused on identifying specific challenges that Siemens-Energy can face in the project management approach on supply chain management of industrial gas turbines. The researcher acknowledged that some challenges may arise, and it is important to identify them and find ways of addressing them to eliminate or minimize their effect. The final question focused on findings ways in which the company can overcome the overall challenges in its effort to achieve efficiency in the supply chain of its industrial gas project. The researcher knew that the success of the company depended on its ability to overcome the problems.

Populations and sampling methods. The researcher identified a small sample of participants to help respond to this question. Instead of using all the employees in the SCM department of the firm, the researcher selected a small number of individuals to represent the entire population. The researcher used the non-probability sampling technique because it was necessary to collect data from individuals with relevant knowledge. Managers and those with experience of having worked in the supply chain department for years were selected. The researcher also included a few individuals who have successfully implemented major projects at the company. A sample size of 20 individuals, which included 10 managers and 10 project managers, was selected to take part in the investigation.

Deployment plans. The researcher contacted these participants directly through phone calls after getting the necessary approval from the management. The nature of this research was explained to them, including the role they were expected to play. The researcher then conducted a phone interview with each participant at their preferred time through WhatsApp or Facebook voice call.

Design of instruments. A simple questionnaire was developed to facilitate the collection of data to respond to this and other questions. For this specific question, the focus was to collect qualitative data. This method made it possible to process data in detail based on the response obtained from the participants.

Limitations. The main limitation when using this research design to collect data was that there was a concern that some of the participants may be biased in their response to the question. Those in management may sometimes present a more optimistic picture than is the case. However, the propensity of the risk was significantly low, which means that the integrity of the outcome was not compromised.

Validity and Reliability

The issue of validity and reliability of data collected and processed in a research is always critical when conducting research. De and Kammerlander (2020) explain that a report can be used by policy-makers, academicians, and other individuals who may find it useful. As such, the information that it presents should be as truthful and reliable as possible. Validity in the research was enhanced by using methods that accurately collect data that was needed from participants (Eriksson and Kovalainen, 2015). The researcher used open-ended questions to ensure that respondents explained their answers in detail. The reliability was enhanced by avoiding all forms of biases. The researcher did not allow personal opinion and beliefs to influence the process of collecting and processing data.

Data Selection and Collection

It was essential to collect and analyse data to help respond to specific research questions. In this dissertation, the researcher relied on both primary and secondary data sources. Secondary data was collected from books, journal articles, and reliable online sources. They formed the basis of the literature review conducted in the previous chapter. It made it possible to develop background information and to address knowledge gaps, which were then probed in the primary data collection and analysis. The information from these sources was also used to support arguments in other chapters of the report. On the other hand, primary data was collected from sampled participants, as mentioned in the section above. The sampled individuals are all employees of Siemens-Energy, working in various departments, which were of interest to this research.

The researcher contacted the management of this company and explained the significance of this research. The goals and objectives of the research were explained, including the role that the firm’s employees were expected to play. A formal consent form was sent to the management that had to be signed to confirm that the approval was granted. It was only after getting the approval that the researcher contacted the employees in the various selected departments. The researcher was interested in collecting data through face-to-face interviews. Eden, Nielsen, and Verbeke (2019) explain that such interviews are often effective when collecting data using unstructured questions. Unfortunately, various challenges made it impossible to collect data using this strategy. The researcher had to rely on phone interviews to facilitate the data collection.

The process involves preparing the respondents for phone interviews by selecting appropriate times when the phone calls should be made. Each respondent was called at the time they had chosen. Each phone interview lasted about 15 minutes. Data collected were transcribed in ways that responded effectively to the research question. It then facilitated a qualitative analysis of the report in line with the research philosophy that had been selected for the research.

Practical challenges

When collecting primary data, there were some practical challenges that the researcher had to overcome (Smith, 2020). One of the challenges was the inability to physically interact with the participants. The geographical challenge and COVID-19 concerns made it impossible to collect data using face-to-face interviews. The researcher was able to overcome this challenge by collecting data through phone interviews. It was also noted that some of the participants who had previously agreed to take part in data collection were not available when it was time to conduct the interview. The researcher had to replace them to ensure that data saturation was achieved.

Ethics and Bias

There was a need for a consideration of the relevant ethical issues and any bias that may be inherent within the study or the subsequent analysis with thought given to validity, reliability, and generalisability. The researcher was keen on avoiding personal bias when selecting participants in this research. When using judgmental sampling, care was taken to ensure that all the participants were selected based on their ability to authoritatively answer the specific questions based on their knowledge and experience as Easterby-Smith et al. (2021) suggest. Factors such as gender, race, religious affiliations, or any other demographical classification were not prioritized when selecting the participants. The researcher designed research questions to be as objective as possible to limit cases of biased answers. There was a deliberate effort to avoid placing the blame of the current weaknesses of the company on specific individuals or departments. Instead, the researcher focused on identifying the problem and finding the best solutions.

The researcher made an effort to observe ethical concerns when collecting data and compiling the report. Before contacting respondents, the researcher obtained consent from the management of the firm, as Eisend and Kuss (2019) recommend. The researcher then explained the significance of the research to participants and the role that they were expected to play. They were reminded that participating in the research was voluntary and that anyone who considered it necessary to withdraw had the liberty to do so. Bell, Bryman, and Harley (2019) emphasize the need to protect the identity of participants when collecting primary data. Instead of using their actual names, the researcher assigned participants specific codes to help in their identification. As an academic project, the researcher avoided plagiarism, which is considered academic malpractice.

Limitations

When developing an academic report, a researcher may likely face some limitations that may define the context under which the document should be used. Discussing the limitations makes it possible for those using the document to determine its relevance in specific contexts (Sekaran and Bougie, 2016). The main limitation that was observed is that the primary data was collected from a specific company, narrowing it down to a specific context. The researcher was interested in the industrial gas turbine sector of Siemens-Energy. As such, the application of the information presented in this document should take the same into account.

The challenges and benefits that this company enjoys in this particular segment of the economy may be different from what a firm in a different sector is facing. The researcher was interested in interviewing some of the top managers who were capable of providing information on specific issues. However, the limited time and COVID-19 concerns made it difficult to achieve these specific goals. It is important to note that despite these limitations, the researcher was able to collect the relevant data, conduct an analysis and interpretation, and respond adequately to the research questions.

Analysis and Discussion

The previous chapter discussed the method that was used to collect data from primary sources. It explained how the gaps in the existing literature will be addressed to expand knowledge in this field. In this chapter, the researcher presents findings that were made from the information gathered from the primary sources. According to Lee and Saunders (2017), it is crucial for a researcher to collect primary data in case there are major inconsistencies or gaps in the existing literature. It helps to address the knowledge gaps by specifically focusing on gathering data that respond to the gap. As was explained in the previous chapter, a sample size of 20 individuals, which included 10 managers and 10 project managers, was selected to take part in the investigation.

Data Analysis

The researcher collected primary data from a sample of 10 individuals who are currently working for Siemens-Energy. Care was taken when selecting the participants to ensure that those who are selected had the capacity to provide informed opinion on the issue being investigated based on their knowledge and experience within the firm. Data was analyzed thematically to respond to each of the questions that were presented in this study. Thematic analysis was considered an effective way of providing deep insight into how the use of project management techniques can improve the supply chain process of the industrial gas turbines project at Siemens-Energy.

How can Siemens-Energy use project management techniques to improve the supply chain process of industrial gas turbine projects?

The first question focused on explaining how Siemens-Energy use project management techniques to improve supply chain process of industrial gas turbines. It had been established that the firm has been using PM techniques. The sampled individuals were expected to help in understanding how it helps to improve the SC process. Table 4.1 below shows themes that emerged based on the response that was obtained from these individuals.

Table 4.1: Using PM Techniques to Improve SC Process

Thematic analysis above shows that Siemens-Energy can use project management techniques to improve the supply chain process of industrial gas turbine projects. By using PM techniques, the firm can create order in supply chain processes, eliminate waste, save time, enhance responsibilities of various stakeholders, and improve coordination in the entire system. All these factors helps in ensuring that supply chain process of the industrial gas turbines at the company is a success.

What is the supply chain path of the gas turbine part, from assembling, manufacturing, installation, commissioning, and maintenance?

In the review of the literature, the researcher was able to discuss the supply chain path of industrial gas turbine parts of different companies. It was necessary to understand the supply chain path of these turbine parts, from assembling, manufacturing, and installation to commissioning and maintenance at Siemens-Energy. Figure 4.1 below shows a model of Siemens-Energy gas turbine that is ready for installation. The researcher asked the participants to explain this process, especially the stages involved.

Participant 1 explained that “the raw material used in manufacturing the gas turbine blades is nickel. Other materials include aluminum and yttrium. The procurement department at Siemens-Energy imports nickel from Indonesia and the Philippines. The firm imports aluminum from China and India, while yttrium Burma. The logistics department then has to ensure that they are delivered to the production plant in Germany.”

This statement shows that Siemens-Energy has to import these products from different countries because most of them are not available locally in Germany where production takes place. The success of this firm, therefore, depends on having a highly efficient supply chain system that ensures that materials are made available at the right time and in the right quantity. To achieve such a goal, Clegg, Skyttermoen, and Vaagaasar (2020) advise that there should be an effective communication among different departments to ensure that there is smooth flow of materials and work.

Participant 6 noted, “Manufacturing activities at Siemens-Energy takes place at its main plants in Berlin, Germany and Charlotte, North Carolina. The 60 Hz model are exclusively produced in Charlotte, while the 50 Hz model of turbines are produced in Berlin. All the manufacturing activities are completed at these sites, and the turbines leave the plant when it is ready for installation.”

Once the raw materials are made available at these two plants in Germany and the United States, the next step in the path is the manufacturing process of different parts. These parts include the compressor, combustion engine, the turbine, rotors, auxiliary parts, and the casings (Gülen, 2019). A detailed image of these parts are shown in figure 2.2 in chapter two. The production unit of the company relies on the sales and marketing unit to understand the demand for the product and the type that customers need.

Participant 9 stated, “Assembling and installation of the turbines often take place at the plant where the customer needs the turbine. Once the purchase is made, the turbines will be delivered as parts because their large size and delicate nature makes it inappropriate to be transported when they are assembled.”

One of the later stages of the supply chain path of the industrial gas turbines is the assembling and installation. As the participant above explained, Siemens-Energy has the responsibility of ensuring that this product is assembled and installed at a location identified by a client. The firm has a team of highly skilled engineers and technicians who are responsible for this task. They have to assemble the parts, install the system and text if it is functioning as was intended. The client will then have the chance of testing the system to determine if it is functioning as was intended. When the test is passed, the final stage is the commissioning of the system. Once it is commissioned, it is a sign that the client is satisfied with the product. When a client has a team of experts who can be responsible for the maintenance of the system, then the supply chain path for the industrial gas turbine for Siemens-Energy ends at this stage.

Participant 18 observed, “Sometimes a client may need Siemens-Energy to be responsible for the maintenance of the gas turbines once they are installed. Once the request is made, this firm creates a schedule where its technicians and engineers will conduct regular supervision and maintenance of the system.”

At this final stage, the focus is to monitor the running of the system, identify major issues that may arise, and take corrective measures when necessary. The goal of the maintenance team is to ensure that there is a smooth flow of operations and that cases of breakdown are as minimal as possible. The crew responsible for the maintenance is paid by Siemens-Energy. However, the client pays Siemens-Energy for the additional cost of maintenance.

What are the challenges that Siemens-Energy can face in the project management approach on supply chain management of industrial gas turbines?

This question specifically focused on identifying challenges that Siemens-Energy faces in its supply chain management of the industrial gas turbines when using project management techniques. These techniques have obvious benefits, as noted in the first question. They create order and define how specific activities need to be undertaken in a specific project. However, it is necessary to acknowledge the fact that sometimes they may pose some challenges, especially when they are rigidly implemented without crating room for adjustments and innovation. This question was presented to the participants and their response was analyzed thematically, as shown in table 4.2 below.

Table 4.2: Challenges Associated with the PM Techniques in SC Processes

The table above identifies major challenges that Siemens-Energy can face when using PM strategies in its supply chain processes of the industrial gas turbines. Cost inflation, pilferage, and limited knowledge are some of the major concerns. The data analyzed also showed that limited innovation and resistance to change are the other major issues that have to be addressed. These challenges may hinder the ability of this company to effectively use these techniques to enhance the success of its supply chain processes.

What are the ways in which this company can overcome the identified challenges?

The analysis above identified various challenges in supply chain management of Siemens-Energy’s when using project management techniques. It is essential to find a way of addressing these challenges to ensure that the company can have an efficient supply chain system in its industrial gas turbines’ project. As Iqbal (2020), one of the first steps of addressing a problem is identifying the underlying issues, which are noted in the section above. The next step is to find a way of addressing each problem effectively. Table 4.3 below identifies the possible solutions that the participants proposed based on their knowledge and experience working at Siemens-Energy.

Table 4.3. Managing the Challenges Associated with the PM Techniques in SC Processes

The management of Siemens-Energy needs to understand how it can address the specific challenges associated with the use of project management techniques in its supply chain process of industrial gas turbines. Table 4.3 above shows the major ways in which this firm can overcome the various challenges based on the information obtained from the participants. The management will need to understand how to apply each of the proposed solution to the specific challenges to ensure that its supply chain processes of the industrial gas turbines are as successful as possible.

Discussion

Siemens-Energy is one of the leading manufacturers of industrial gas turbines in the global market. Although the firm has been successful in making available quality products to its customers around the world, it faces numerous challenges that pose existential threat to its operations (Bond-Barnard, Fletcher, and Steyn, 2018). In this research, the focus was to discuss how to use of project management techniques to improve the supply chain processes of the industrial gas turbine project. It is necessary to discuss findings made from both primary and secondary sources at this stage of the report.

Using Supply PM Techniques to Improve Supply Chain Process

The supply chain process in the industrial gas turbine projects is highly complex and it is common for the employees involved to encounter numerous challenges. Some of these challenges have serious cost implications, while others may cause major delays in the completion of the project. According to Adebayo, Eniowo and Ogunjobi (2018), the use of PM techniques can help in eliminating these challenges or significantly reducing the impact that they have on the overall success of the project. As shown in the analysis above, one way in which PM techniques improves SC processes is by creation of order. Primary data shows that using techniques such as agile or lean project management helps in defining step-by-step processes that should be followed when undertaking specific activities in a given project (Wren, 2017). It helps to eliminate some of the errors that often occur when undertaking mega projects.

The analysis of primary data reaffirmed that using PM techniques helps in waste elimination as a way of improving supply chain process of the industrial gas turbine project. The respondents explained that a technique such as lean project management helps in identifying sources of waste and effectively eliminating them to ensure that the project is less costly. Dohe and Pike (2018) reiterate the claim, noting that using lean project management is one of the best ways of ensuring that a project does not exceed the initial cost. It helps to identify various factors, including inflation, which may affect significantly increase the overall cost of the project. It then proposes ways in which the management can avoid or manage such undesirable forces. Reducing the overall cost in the supply chain involves identifying suppliers who can deliver the best quality products at the lowest cost possible (Emere, Musonda, and Okoro, 2019). Such strategies are defined in various project management techniques, and if they are implemented effectively, Siemens-Energy can lower the unit cost of its industrial gas turbines.

The analysis of primary data has shown that using PM techniques also helps in saving time when undertaking specific supply chain activities in mega projects. The respondents explained that using a specific project management technique such as waterfall streamlines activities. Butera (2020) agrees with the assertion, explaining that waterfall project management outlines specific steps that should be taken when undertaking various tasks to ensure that activities are streamlined. Time is also saved when duplication of tasks is eliminated, as one of the respondents noted. According to Kamble and Vanakudari (2018), these techniques helps in ensuring that specific tasks are assigned to specific individuals. As such, it eliminates cases of redundancy, which not only saves time but also the overall cost of the project.

Enhanced responsibility is another major benefit that is associated with the use of PM techniques. When using a PM technique such as waterfall, each employee is assigned specific roles, as one of the respondent explained. Once these roles are assigned, every employee will be held personally accountable for the progress made in the completion of the activity. Hasan and Islam (2019) explain that people tend to be highly responsible when they know that their actions will be evaluated to determine if their performance meets the expectations. It eliminates laziness and blame games that may negatively affect the completion of specific supply chain activities in the industrial gas turbine project at Siemens-Energy.

Improved coordination was another major benefit of using PM techniques in supply chain management of the industrial gas turbines at this company. One of the respondents explained individuals’ roles are clearly defined when using a technique such as agile project management. It means that when one needs a piece of information, it is easy to identify the department or an employee who should be contacted. According to Levy (2018), PM techniques also create platforms for communication among various stakeholders. It makes it easy to address issues that may arise in the process of undertaking various activities in the project.

Challenges of Using PM Techniques in Supply Chain Management

When using PM techniques on the supply chain management, it is common to encounter various challenges. Cost inflation is one of the challenges that one may encounter when these techniques are rigidly applied. One of the participant explained that when the management rigidly insists on following a given PM technique, an employee may use a new strategy that uses less resources and then steal the additional resources that would have been consumed if a traditional technique were used. They only need to ensure that the task is completed as per the specification, which then allows them to misuse or misappropriate the additional resources (Madhavarao, 2018). As such, a manager needs to ensure that such strategies are applied with care to avoid the possibility of mismanagement of resources. Managing pilferage helps to eliminate inflation of cost and delays in completing a given project.

Limited knowledge was identified as a major concern that affects the use of PM techniques in supply chain management. According to Klein and Müller (2021), PM techniques have obvious benefits to a firm, especially when undertaking complex projects. However, one can only implement the project if they understand its principles and how it should be applied. One of the participants noted that sometimes it is essential to take the employees through some form of training to ensure that they have the capacity to correctly apply the technique. The challenge is that the process of training these employees takes time and resources, which a firm may be unwilling to spend.