Business Idea

The business idea is to build a farm-sized dairy processing plant for cow and goat milk called Multifresh Dairy Product LLC (MDPLLC). Milk and milk products are a staple commodity on most people’s shopping lists. Therefore, the availability and accessibility of milk and milk products in the supply chain are necessary for governments and businesses such as retailers (Gao et al., 2021).

A dairy processing plant is a plant that deals with the processing of milk from the moment it is received from farmers up to the final product being ready for customer consumption (Das et al., 2022). The milk processing plant’s significant activity will include sourcing milk, capacity measurement, freshness testing, standardization, separation, homogenization, pasteurization, and finally, bottling and packaging.

Milk has its best attributes as a raw product to other commodities because it can process several other products. The products produced from the processing plant include whole milk, skim milk, milk powder, cheese and butter, and yogurt. In addition to the main milk-processing supply chain participants, all relevant parties will be included in a comprehensive map of the milk supply chain. They have those who supply the raw materials for packaging, transport companies, technological companies, and input suppliers for processing plants (Hashem et al., 2020).

To generate these goods, raw milk input suppliers, such as farmers and other intermediaries, will be required in an upstream supply chain. On the other hand, the output of items like milk can move on to customers, suppliers, and downstream consolidators, who procure and complement milk from the processing facility and deliver it to wholesalers, retailers, and caterers.

Scenarios Analysis, Competitors, and Value Proposition

Scenarios Analysis

Planning scenarios has been a recent development. People have attempted to make current situational judgments by researching the prospects for tomorrow throughout history. While creating a scenario, one must consider all potential change elements, how they interact, and which ones may become more significant over time (Koch et al., 2021). Destabilizing factors alter the environment of a particular product line, a component, or a local distribution network.

The first possibility, which does not amount to much, is known as “Dairy Evolution.” Nonetheless, it is a slow and steady continuation of the current situation and trends, with little noticeable shift (Koch et al., 2021). Therefore, the accompanying weak socio-environmental constraints and oppositions define it. Gradual changes to the environment and little advancement in technology increased global milk developments to cater to the growth in dairy deficit states, proceeded, moderate plant-based growth, centralization of traditional animal agriculture towards mega industrial agriculture, and biotransformation or lab-grown dairy casein persist niche products because they lack the consumer acceptance and scalability for mass markets (Berlese et al., 2019). Necessary parties still give dairies social legitimacy to operate.

Both indirect and direct subsidies are unaffected, meaning they continue or even grow to support employment (Famiglietti et al., 2019). The financial dangers of dairy farming and product processing are increasing due to global warming and concerns about animal welfare; the US dairy sector currently loses US$ 897 million annually due to heat discomfort in cattle (Berlese et al., 2019). Similarly, mega-industrial farming is enhanced with agricultural-level consolidation. In most regions of the world, a warming environment has made industrial dairy farming less profitable, undermining industry margins even with ongoing subsidies. Additionally, environmental penalties and food taxes based on animals are still exceptions.

The second scenario, “Green Dairy,” is representative of the shifts brought on by considerable socio-environmental objections and limits that require dairy farms and businesses to make massive increases in expenditures aimed at lowering their carbon footprint (Famiglietti et al., 2019). A slow pace of technical change characterizes it. Consumers will pay more for dairy products made from cows due to manufacturing cost hikes (Koch et al., 2021).

The establishment of animal-based food taxes, dramatic improvements to subsidy restrictions, and stronger animal welfare laws have all made it difficult for all but a few large-scale dairy products to stay viable. Robust plant-based growth is considered to have a more negligible environmental impact and increasing economic benefits over conventional dairy products (Berlese et al., 2019). As fermentation-based dairy products are neither cost-effective nor scalable on a large scale for the general market and encounter consumer opposition; as a result, they maintain a niche product.

Food taxes derived from animals, environmental penalties for dairy farms that pollute, and harsher laws for the prevention of cruelty to animals have become the norm (Famiglietti et al., 2019). Similarly, there is a rise in farm-level amalgamation, with only a few massive industrial farms able to weather the additional regulatory demands. Again, indirect and direct dairy subsidies are terminated, resulting in the survival of the most competitive dairy farms, an upsurge in momentary unemployment, and a move toward agribusiness (Berlese et al., 2019).

The socioeconomic license to conduct business for dairy production plants is also lost by important stakeholders like regulatory authorities and consumers due to a sharp rise in publicly disclosed animal welfare scandals, a greenhouse effect, and the agreement that animal-based agriculture is a significant cause of both of these (Famiglietti et al., 2019). Instead of supporting animal agriculture, governments are increasingly encouraging the private sector by incentivizing businesses to switch to plant-based agriculture (Koch et al., 2021). It is now required to include information about food items’ effects on the environment in connection to their nutritional worth.

Competitors

Market leaders in the dairy industry will likely maintain their positions during the forecast period (Susanty et al., 2021). The dynamic nature of the market has been the primary force for expansion, while strategic mergers and acquisitions have bolstered business success. To begin with, children are the primary focus of health and wellness product development, but as time goes on, the importance of adult nutrition increases. The most successful businesses put their money into plant-based goods with a higher potential for health benefits and longer shelf life.

Nestlé and Danone hold top positions worldwide for dairy products and substitutes. Leading businesses expand their investment in plant-based substitutes. Likewise, the top 10 players were favorably affected by market momentum growth. Yili and Mengniu’s aggressive segment share has significantly grown. Leaders in the dairy industry sustain growth with well-balanced portfolios. In Western markets, top-ranked firms are challenged by private-label offers.

The market under study is cutthroat. This is because both indigenous and foreign players are present. Companies such as Lactalis Corporation, Nestlé SA Corporation, Fonterra Co-operative Group Limited, and Danone SA are a few of the market’s key participants. Most of these businesses actively engage in acquisition, product innovation, and mergers (Bhattacharyya et al., 2020). Also, the leading international corporations control substantial portions of the sector. These major players can maintain their preeminence over other local companies because of the abovementioned techniques.

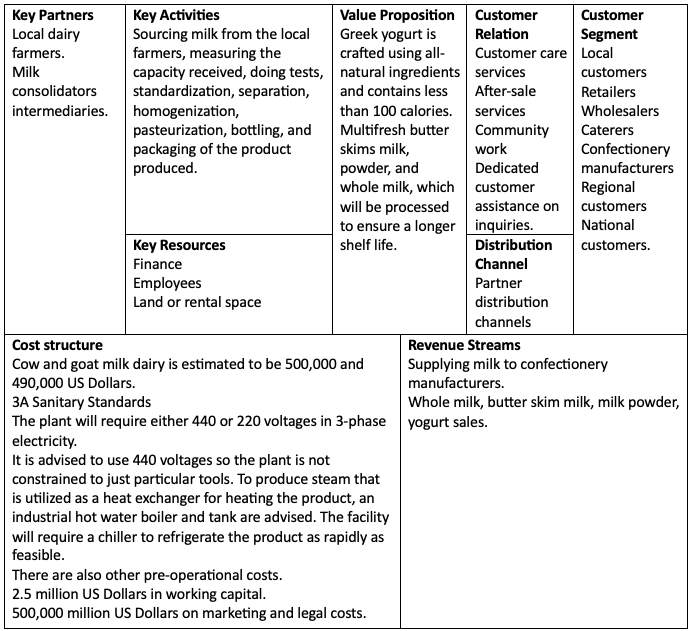

Value Proposition

Customers have not had a choice for products such as Greek yogurt, which is made with all-natural ingredients and contains no more than 100 calories. This is one sector that Multifresh Dairy Products aims to focus on. The product line that will go by Greek Multifresh will have 30 percent less cholesterol and 40 percent fewer fats. Like with other proposed products of Multifresh, this one will also come in a 16.5-ounce jar and can be used in place of regular sour cream for dips, sides, entrees, and desserts. It also works well in the kitchen because it doesn’t curdle when cooked. For the Multifresh butter, its new container will have an easy-open tabbed plastic covering that allows for quick accessibility to the butter. Other products will include Multifresh whole milk, which will have an extended shelf life to enable it to last for a long while in storage.

Customer Segments

The processing plant’s consumer segment comprises local, regional, and national customers. In a broader term, the local customers will be local retailers and consumers near the manufacturing plant. The regional customers will comprise customers considered to be located in the same state and region of 1000 miles. On the other hand, the national customers will incorporate any other customer in the United States.

The processing plant is targeting several customers. To begin with, in this value chain, the processing plant will be eyeing to open another vertical link that will act as a connector to confectionery manufacturers supplying milk products such as yogurt, butter, and milk powder as raw material for their needs. The world’s top candy producers and milk product co-packers are concentrated in the United States. These businesses are an excellent method for confectionery manufacturers to produce and package their goods, which require a supply of dairy ingredients like butter and milk powder. Their products range from chocolate and cocoa to candy bars.

The processing plant will sell indirectly to the customers through the retailers and the caterers. As they are the businesses closest to the end consumer, caterers and retailers are grouped jointly in this scenario. Retail stores and merchants will carry a range of milk-based items, including value-added dairy products from the processing plant. The retail sector comprises local stores, off-licenses, and big supermarket chains. In this context, caterers are businesses in the hospitality industry, such as cafes, eateries, and street food sellers, that procure fresh milk or milk-based items to meet the specific needs of the ultimate consumers.

Business Model Canvas

The Business Model Canvas (BMC) is a visual tool used in strategic management that helps businesses quickly and clearly define and communicate their ideas and concepts (Osterwalder et al., 2010; Sparviero, 2019). A one-page essay that logically organizes and discusses the main ideas behind a firm or its product before it is processed in a manufacturing facility (Daou et al., 2020). On the right side of the BMC, the customer takes center stage, whereas, on the left, the company is front and center. Converging internal and external factors form the value proposition, which is exchanged between the company and its consumers or clients.

Business Goals

The processing plant aims to achieve various sustainable development goals. It plans to conserve the local environment by engaging the community in environmental sustainability education and planting trees. The company will leverage ICT and mobile technologies to connect clients, merchants, input suppliers, and telecommunications firms within the dairy value chain, enhancing the quality of inputs and services provided to dairy producers. Additionally, it aims to provide affordable milk and dairy products at local, regional, and national levels while promoting excellence in sanitary practices across dairy farming, harvesting, transportation, and product distribution.

SDG’s Targets and Impact Areas

Provide cheap and affordable milk and milk products to local, regional, and national customers. The goal is to support the campaign of SDG2 zero hunger and SDG3 good health. In the reported activities to increase consumers’ attitudes of milk products as having high nutritional effectiveness and by adding dairy to federal diets, supported by food support programs targeted at various social and age groups, participation toward nutritional needs is partially conveyed (Vinuesa et al., 2020). The dairy farm contributes more to this SDG2 aim and, thus, to sustainability’s social and economic components.

Along with providing organizations with fresh perspectives on product creation and developing their marketing strategies, it would also assist dairy firms in better communicating the social worth of the dairy sector and changing how people view dairy (Fuso et al., 2019). Conserving the local environment by planting plants and engaging the neighboring communities in educational projects on environmental sustainability goals that target environmental conservation and SDG13 climate action. Dairy industry efforts have historically been heavily concentrated on reporting climate change initiatives since every industry is accountable for its effects on the environment. With the inclusion of levels like peace and collaboration, the UN objectives’ introduction highlights various concerns that fall under the sustainability heading and focuses more on the social component.

Enhancing the standards of excellence and sanitary best practices in the dairy farming, harvesting, and transportation industry’s goal targets SDG12 sustainable consumption and production (Fonseca et al., 2020). The company will also be concerned with activities promoting animal care, soil nutrients, biodiversity, and waste and raw materials management. This will also cover the consumption aspect by ensuring that the products produced are standard and fit for human consumption.

Using ICT and mobile technologies facilitates meetings between customers, merchants, input suppliers, and telecommunications companies along the dairy value chain goal, which targets SDG9 for innovation and infrastructure (Fonseca et al., 2020). Reporting actions that can promote economic growth and minimize environmental effects through technological advancement and innovation is required under the policies in which the dairy plant will be actively involved, ensuring that most of the transactions are digitized.

Increase the quality of the inputs and services available to dairy producers readily and enable local farmers to get the value for their farm produce goal targets SDG1 no poverty. The dairy processing factory supports similar social and economic challenges, such as alleviating poverty, social integration, and marketplace and social growth, especially in local communities (Fonseca et al., 2020). To provide one concrete example, the dairy processing industry is committed to sourcing regional milk, expanding the availability of dairy products created in the region, and restoring power to the farmers who produce them.

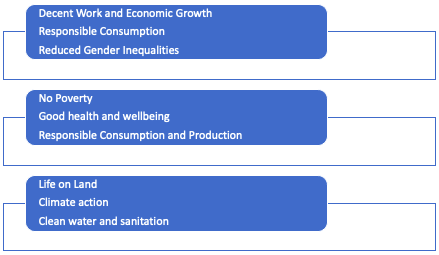

SDG’s Competitive Model

The following figure shows the SDG competitive design model Multifresh Daily Product LLC developed towards its sustainability and competitive edge. The model is interconnected into three sustainable layers.

Climate Action, Life on Land, and Clean Water and Sanitation

This section holds the root of the company’s entire activities. For the plant to be operational and running, factors such as life on land, clean water and sanitation, and climate action must be considered. Therefore, the firm will be aware of such issues as the carbon footprint associated with its activities and how to reduce its carbon footprint. Factors of spillovers and waste management from the plant will be handled and covered with clean water and sanitation. The company will ensure that it uses and provides clean water to its workers and the community. Life on land matters a lot. These describe the conditions in which the factory will subject organisms living on the ground, ranging from birds and microorganisms to employees. Therefore, chemicals used in the industry will be used with care to avoid hazards to life on land.

No Poverty, Zero Hunger, and Good Health and Well-being.

At the center of the ladder, there is no poverty, people enjoy high levels of health and happiness, and no one goes hungry. Making a profit and, perhaps, employing some of the locals is at the top of the list for any firm. This dairy processing company is committed to buying local milk, increasing the availability of locally produced dairy products to consumers, and restoring farmers’ bargaining power in the dairy industry. Farmers will benefit from this since it will increase demand for their goods. The processing facility will do the same to ensure its goods are accessible and cheap to the local community.

Decent Work and Economic Growth, Responsible Consumption, and Reduced Gender Inequalities

Providing decent jobs and economic development, encouraging ethical consumerism, and decreasing gender inequality are top of the list. The local workforce will be used, and the goods will be sold at local establishments. The firm will handle spills and garbage properly by limiting production and consumption that contribute to pollution. Some of the trash is planned to be transported to composite manure plants in the area. Finally, if they achieve the minimal criterion for open positions, the corporation will keep the gender restriction in place and guarantee that underrepresented genders are fairly represented in the industry.

References

Berlese, M., Corazzin, M., & Bovolenta, S. (2019). Environmental sustainability assessment of buffalo mozzarella cheese production chain: A scenario analysis. Journal of Cleaner Production, 238. Web.

Bhattacharyya, J., Krishna, M. B., & Premi, P. (2020). Amul Dairy (GCMMF): Expanding in the USA, leveraging the e-commerce advantage. International Journal of Management and Enterprise Development, 19(2), 149-163. Web.

Daou, A., Mallat, C., Chammas, G., Cerantola, N., Kayed, S., & Saliba, N. A. (2020). The Ecocanvas as a business model canvas for a circular economy. Journal of Cleaner Production, 258. Web.

Das, I., Panchal, D., & Tyagi, M. (2022). A novel PFMEA-Doubly TOPSIS approach-based decision support system for risk analysis in milk process industry. International Journal of Quality & Reliability Management, 39(1), 1-29. Web.

Famiglietti, J., Guerci, M., Proserpio, C., Ravaglia, P., & Motta, M. (2019). Development and testing of the product environmental footprint milk tool: a comprehensive LCA tool for dairy products. Science of the Total Environment, 648, 1614-1626. Web.

Fonseca, L. M., Domingues, J. P., & Dima, A. M. (2020). Mapping the sustainable development goals relationships. Sustainability, 12(8). Web.

Fuso Nerini, F., Sovacool, B., Hughes, N., Cozzi, L., Cosgrave, E., Howells, M.,… & Milligan, B. (2019). Connecting climate action with other Sustainable Development Goals. Nature Sustainability, 2(8), 674-680. Web.

Gao, J., Li, X., Zhang, G., Sadiq, F. A., Simal‐Gandara, J., Xiao, J., & Sang, Y. (2021). Probiotics in the dairy industry—Advances and opportunities. Comprehensive Reviews in Food Science and Food Safety, 20(4), 3937-3982. Web.

Hashem, N. M., González-Bulnes, A., & Rodriguez-Morales, A. J. (2020). Animal welfare and livestock supply chain sustainability under the COVID-19 outbreak: An overview. Frontiers in Veterinary Science, 7. Web.

Koch, C., Johansson, M., Kalling, T., & Kärreman, M. (2021). The future of the dairy industry–2030 scenario analysis. IIM Industry Report Series, 22.

Osterwalder, A., Pigneur, Y., & Clark, T. (2010). Business model generation: A handbook for visionaries, game changers, and Challengers. Wiley.

Sparviero, S. (2019). The case for a socially oriented business model canvas: The social enterprise model canvas. Journal of social entrepreneurship, 10(2), 232-251. Web.

Susanty, A., Puspitasari, N. B., Prastawa, H., & Renaldi, S. V. (2021). Exploring the best policy scenario plan for the dairy supply chain: a DEMATEL approach. Journal of Modelling in Management, 16(1), 240-266. Web.

Vinuesa, R., Azizpour, H., Leite, I., Balaam, M., Dignum, V., Domisch, S.,… & Fuso Nerini, F. (2020). The role of artificial intelligence in achieving the Sustainable Development Goals. Nature communications, 11(1), 233. Web.