Executive summary

The supply chain is an important element of the business community and is very vital and necessary for the smooth flow of goods from the manufacturer to the end consumer. It is as a consequence necessary that supply chain management managers incorporate planning and use appropriate strategies to make sure that raw materials, work in progress and finished goods reach where they are needed at the right time and in good quality (Lambert 144). Furthermore, they need to develop contingent strategies that will allow their distribution networks to obtain high degrees of flexibility.

If a supply chain fails to deliver goods and services where they are needed then this could affect the lively hoods of other industries and their consumers. Royal-Dutch Shell is a respected oil mining company with numerous oil rigs scattered around the world (Edward 14). The transportation of crude oil and other finished oil products is planned and executed by the company who work in collaboration with other supply chain members.

Shell is respected for its superior supply chain relationship management that enables its business partners to place their orders and queries using Electronic Data Interchanges, which have assisted in making the process of order taking and dispatch more simple and accurate. The use of EDI makes it possible to accurately conduct demand forecasts and queue processes which are to be conducted within the supply chain to operate efficiently (Worthington & Britton 212). Although the current systems have their challenges it also becomes appropriate to recommend changes that may further improve the supply chain activities within every level of the supply chain within the oil industry, especially for Shell.

Introduction

The movement of goods and services from the point of production to the point of consumption is part of the supply chain management process. In the absence of supply chain and logistic activities, it would become very difficult for goods to arrive for consumption at the right place time and condition. Hence a series and sequence of activities usually have to occur so that raw materials can be converted into useful finished goods that can be used to satisfy consumer needs.

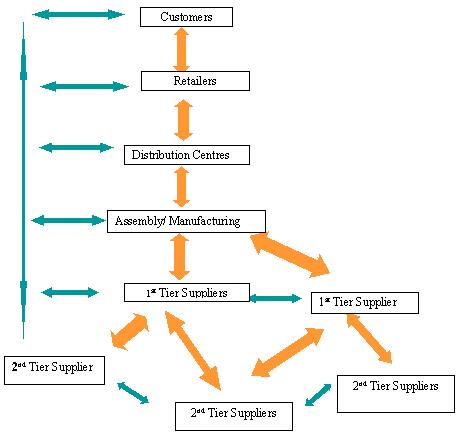

Supply chain activities are not activities of a single organization these activities often involve much different organization coming together to form a special relationship that will ensure the movement of raw materials, work in progress and finished goods strategically move from their points of origin to where they are needed efficiently ( Porter 44). Because different organizations usually come together to make the supply of goods and services a success it thus becomes necessary for planning and designing supply chain activities. Additionally, because each organization is an independently existing organization it becomes necessary to incorporate relationship management strategies to reduce inter-organizational conflicts (Wheelen & Hunger 314).

Thus supply chain activities can be described as a set of activities carried out by supply chain managers and procurement experts with an aim of designing, planning, controlling, continuously evaluating and monitoring supply chain activities to create value as goods and services move through the various interconnected business to reach the final destination of consumption (i.e. the consumer). Thus a good supply chain is a supply chain that is customer-driven; this is because customer-driven supply chains are supply chains that seek to optimize the addition of value to the goods and services which are delivered to the final consumer.

The oil industry is a good example of an industry that uses supply chain management activities to add value to crude oil and come up with a diversified range of products that can be used by various consumers in a wide range of industries. The level of investment and capital required to run activities in the oil industry is quite high and it thus becomes necessary for careful planning to be incorporated so that goods and services can flow from the oil rigs to gas refilling points in various towns around the world.

Royal Dutch Shell is one of the largest participants of the oil industry and thus after mining crude oil the company enters into agreements and numerous transactions are carried out to ensure that crude oil is transferred from various oil rigs to their destinations. It thus becomes important for the company to use supply chain management disciplines to design various networks within its supply chain to operate at an optimum level (Ford 322). Supply chain management enables organizations to accurately measure supply chain performance, conduct demand and forecasting in a supply chain, and ensure that aggregate planning in a supply chain takes place.

Additionally, sales and operations planning can effectively occur only if planning and strategic management are made part of supply chain activities. Supply chain managers also get a chance to manage uncertainty in a supply chain and operate by exploiting economies of scale within the supply chain network. Thus in the absence of supply chain management activities, it would be less to impossible to determine the optimal level of product availability within various industries such as the oil industry, transportation decisions within the supply chain would be ultimately paralyzed or at least distorted making decision making weak or feeble.

Processes and strategies used in the Oil industry in supply chain activities

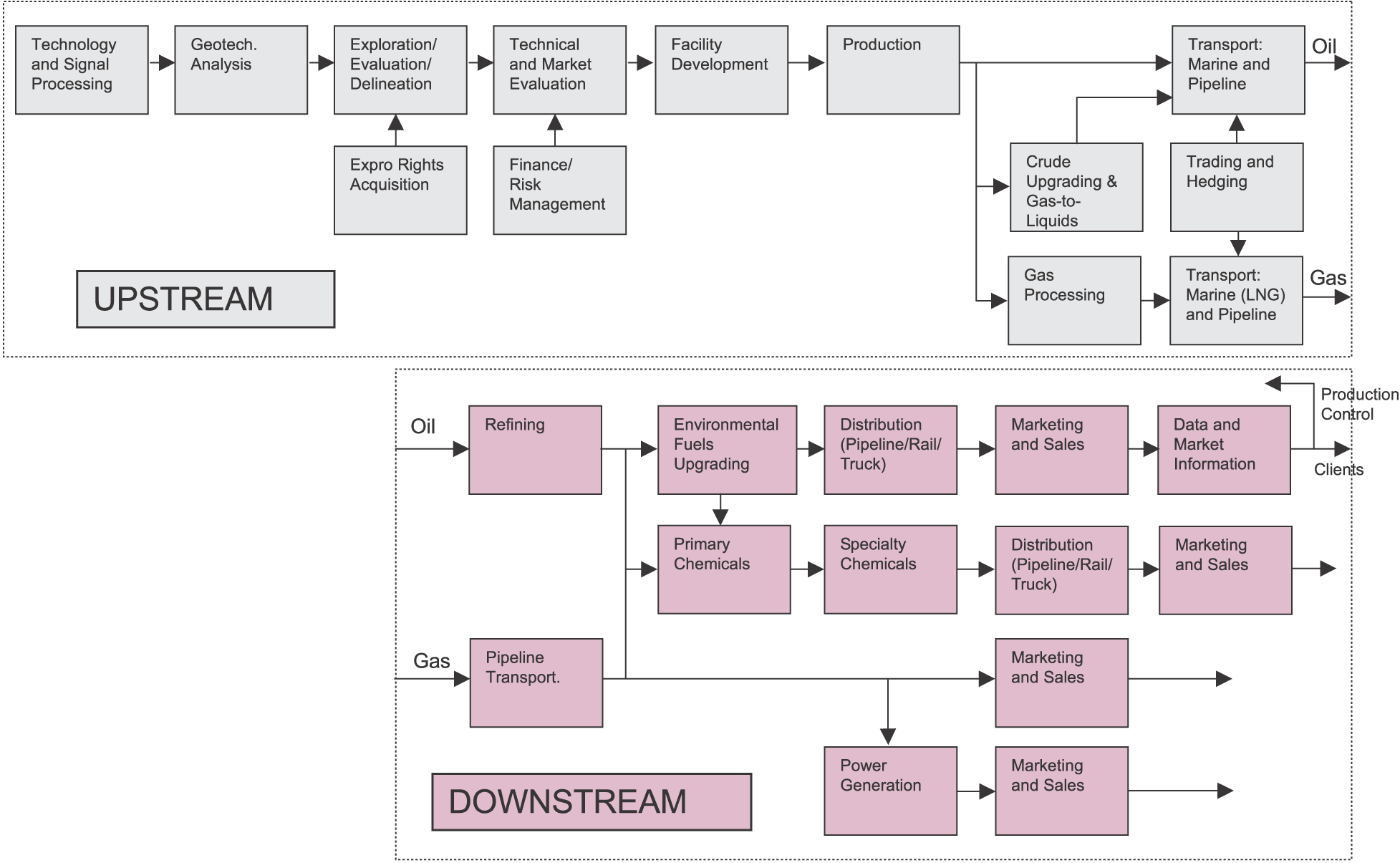

The oil industry is a unique business that has its supply chain divided into material supply, oil and gas exploration and development, storage, transportation, refining, product sales, and customer care activities. The Oil industry is a lucrative industry that has attracted major participants like Royal Dutch Shell, BP, Mobil-Exxon, and Chevron among many other participants. For the oil to move and be transformed from crude oil to finished products a lot of resources, and processes are usually carried out in the supply chain by individual companies or through collaborative efforts which often involve collaborating with the intent of achieving strategic supply chain and distribution goals ( Hartmut 132).

Due to the nature of, sophisticated machinery and technology required to make products such as engine oil, diesel, led and unleaded petroleum, tar, and many other products which are extracted from crude oil, it is difficult hard and expensive for other intermediaries individually to enter the production process due to a large amount of investment the industry requires.

Royal-Dutch shell is a company that has full integration abilities that allow the company to operate both upstream and downstream the supply chain but it also has its limits thus regularly entering into a contract with other companies to make sure Crude oil reaches certain destinations within the required time frame. Shell is a company that can produce and supplies other industries with crude oil to be refined or the refines crude oil itself as a company and markets it directly to the end consumer. The ability to integrate backward and forward within the supply chain enables the company to act as both a supplier of raw material and as a retailer of finished petroleum products in certain regions of the world.

When the oil is mined from onshore and off-shore rigs it is usually transported by various companies which own fleets which are part of the supply chain such as Oil shipping companies or pipelines which are part of the industries supply chain either belonging to Shell or to other business partners who are acquired through collaborative efforts.

The export and import activities that succeed shipping are usually followed by the refining of the oil and coming up with highly differentiated product lines which include premium petrol, gasoline, diesel, jet fuel, and other products. Transportation of these finished product lines is made possible by either trucks or pipelines which are used to move the oil to terminals and depots where different retailers who are part of the industry can acquire finished oil products and sell them to their markets. Shell for that reason interacts with a lot of other companies during this process by acting as the highest level supplier by supplying raw materials to other companies.

But when Shell decides to integrate forward and backward at the same time that it can eliminate any other intermediaries and thus occupies all levels either as a manufacturer, distributor, and retailer. By doing so then the company can initiate a high level of competition within the industry and even if other suppliers refuse to stock their products then the company can reduce its inventory levels by selling its finished product on its behalf. Recent political happenings around the world, especially in the Arab states who are major oil exporters has made mining and transport of Oil hard, therefore, leading to inefficiencies within the supply chain and many regions of the world have been forced to pay more for this important commodity.

The challenge within the Oil industry Inventory does not exist as detached packages thus making it hard to use techniques such as bar codes, radio frequency hard to use on crude or refined products. Products like petrol, diesel, and kerosene are measured in kilolitres whereas products like natural gas are measured in cubic meters. Using supply chains management activities such as planning and control, product flow scheduling, information flow structuring, risk management, and control then participants within the Oil industry supply chain can manage to increase the efficiency of activities within the supply chain of the oil industry.

Oil is among the leading sources of energy in the world and therefore very crucial to the continuity of many businesses and human activities that require energy. Generators, automobiles, Aircraft, Assembly machines all require fuel to run; consequently, if delivery of this fuel is not done in time then many economies and livelihoods may end up being paralyzed (Hiles 32).

The market of oil products is vast ranging from large industries to common households, thus making it a very attractive industry because it has a guaranteed future and current market. Due to varying business environment conditions, the prices of crude is usually fluctuating daily depending on the dynamic business environment. Royal Dutch shell marketing techniques geared towards satisfying both retail and wholesale consumers and therefore the company acts both as a raw material supplier and a finished good supplier for various oil marketing companies located in various regions of the world, in some cases the company also owns refuelling points thus making it a respected retailer.

The fact that the company ha the ability to occupy almost every level of the supply chain reduces the number of risks that the company is faced within the course of doing business and increases their bargaining power as a supplier in the integrated supply chain model. Shell usually drills for oil and then supplies crude oil to other companies or enters into agreements that lease oil rigs to third parties (Hartmut 232).

Thus when the volume of business from integrated supply chain activities falls below the target level, then the using forward integration activities the company can increase the sales of oil products by producing finished oil products and selling them directly in the market. A shortage of oil in regions where it is needed would spell disastrous and therefore it becomes important that the companies enter into collaborative efforts throughout the integrated supply chain model are used to ensure a smooth and efficient flow of Oil. Ships and Oil fleets are a common thing the world waters and they all operate on a given schedule, thus making it possible for oil to reach where it is most needed in the proper time and the right quality.

Various strategies are used to make sure that product lead times and scheduled supply chain management activities take place as planned and therefore this is why Shell may at some instances enter into an agreement with third parties and fourth parties with the aim optimizing inventory management, purchasing activities, transportation and movement of crude oil and other oil-related products, warehousing and storage. If any of these processes are done wrongly then the goals and objectives of the supply chain activities may end up being compromised.

Implications of current processes

The smooth flow of goods from point of origin to its various destinations is very important and hence Shell can receive its orders from all prospective clients through an Electronic Data Interchange (EDI) that the company has developed to efficiently manage customer relationships as part of their customer relationship program (Hiles 88). An electronic data interchange is a two-way communication system that connects interdependent businesses within the supply chain to receive information particular to orders and dispatch.

The introduction of electronic data interchange has enabled the company to employ various statistical models to assist the company carry out demand forecasts that are used in determining the intensity of mining activities throughout an operational cycle. Demand and Forecasting within the Oil Supply Chain enable Shell as a company to more accurately plan on how it is going to apply logistical techniques in collaboration with other supply chain participants to make sure that the crude oil reaches where it is needed at the right time and condition. Additionally Shells aims to maximize its sales and revenues from oil mining activities and therefore these demands forecasts can be used as means to which Aggregate Planning within the Supply Chain can be used by Sales departments as part of setting their quotas.

Current process structure in terms of information, inventory, transportation, and location

Once the orders are received through the special Electronic Data Interchange (EDI), it then becomes the responsibility of executives who are in charge of procurement and sales to come together and scrutinize the data and then quantify various orders and group them. Because Shell operates many oil rigs within various parts of the world then their customers are classified according to the various regions which they come from and then orders are dispatched from oil rigs which are nearest to the locations of Origin.

Customers who purchase oils such as oil cartels and national associations, therefore, go ahead to organize their transport by renting/hiring oil ship fleets and organize for insurance of the crude oil that they may have purchased. But in the case where a company like Royal-Dutch Shell wishes to integrate forward and sell the finished products of crude oil the company will, therefore, make its arrangement to transport the crude oil or finished oil products to the country where it owns refuelling stations.

The absence of EDI would make the entire business operation cycle time and lead time become longer. Technology is known to reduce workload and at the same time increase efficiency. Previously before these systems came into existence companies were forced to mail their orders in advance using postal services or email, methods that were not synchronized with the goals of supply chain management activities.

But with the introduction of EDI specific supply chain management relationships concerned with ordering and dispatched can be handled in real-time to achieve a high degree of accuracy and efficiency. Additionally, the bull whip-effect is a situation whereby order and demand forecasts become more and more inaccurate as information moves through the supply chain and therefore the introduction of an information system that incorporates an electronic data interchange can make it possible for an order to be dealt with a high degree of accuracy that would otherwise be somewhat individually achieved between Shell and its supply chain partners.

Process capabilities, attached to the current structure

COSTS

The current systems within the Oil industry supply chain make are costly especially when oil rigs are located in the seas, using ships as the main mode of transport is quite expensive and takes a long time for crude oil to be delivered. It is hence necessary for marketers of various oil companies to carefully plan their inventory levels and operate with buffer stocks that will allow them to smoothly operate for periods close to six months as they await fleets of oil ferrying ships to arrive in their destined markets.

Poor Network Design within the supply chain would, therefore, increase the lead time and therefore lead to undesirable consequences. Designing Global Supply Chain Networks is a very important part of international business management. A well-designed supply chain can reduce additional costs, operate with flexibility, and ensure that the quality of goods being delivered is high time schedules are adhered to. Designing supply chains can be achieved by the use of trial and error methods which may be gained after a tenthly period of operations and statistical planning to come up with the most appropriate supply chain routes and alternatives.

Consequently further in-efficiencies can prove more costly and therefore affect the goals and objectives of those participating within the Oil industry simply because there is a ceiling limit upon which businesses can absorb costs before they start facing losses. It thus becomes necessary to strategically plan supply chain activities and other logistic components to avoid incurring any incremental costs. According to Wisner 304, this is why logistics and supply chain engineers use complex mathematical models such as ” mean time between failures (MTBF), mean time to failure (MTTF), mean time to repair (MTTR), failure mode and effects analysis (FMEA), statistical distributions, queuing theory to plan activities that take place throughout the supply chain”.

The costs that are accumulated during shipment and channeling oil thorough pipelines make it necessary that additional costs are transferred from refiners and marketers to the end consumer. The flammable nature of oil products, it is thus necessary to use specialized mechanisms to move these products from one region to another.

Flexibility

Royal Dutch shell operates many oil rigs within various onshore and offshore locations; this fact hence makes the supply chain activities more flexible. In case if one rig experiences difficulties that will delay the distribution of oil other rigs that are nearer to that oil rig will, therefore, act as substitutes which can supply clients who are nearest to that oil rig. Flexible supply channels present consumers with numerous alternatives and therefore when an occurrence interrupts the supply of crude oil from one avenue other existing contingent sources can be used to ensure that there is continuity in the supply of crude oil to whichever consumer who needs the oil (Edwards 98).

Therefore, it is hard to experience shortages if a supplying company is said to have flexible supply chains because if option one fails then through strategic planning the company uses other means to make sure supply chain activities are not disrupted. Thus this is why shell assists all its clients to acquire good transport and insurance facilities when transporting crude oil in the high seas, especially in a situation where a client is small enough to have the negotiation capabilities to negotiate on his/her behalf (Heide 64).

Time

The nature of crude oil and exploration of oil in the high seas usually makes it quite a challenge to move crude oil across the world’s waters to the respective counties on dry land. Ships are known to be a very slow thus making the business cycle of the oil industry to become quite long. In some cases, it may take close to 6-9 months to transport oil to certain parts of the world but this can further be delayed with piracy activities in certain parts of the world.

The further the country is from an oil rig belonging to Shell then the longer the lead-time, it, therefore, makes it necessary for this countries to order very large volumes that are above their consumption rates and consequently store the surplus as safety or buffer stock to avoid crude oil or other oil-related product stock-outs. Due to the long time frame that is usually taken to deliver crude oil from where mining activities occur it, therefore, becomes very important to use supply chain design disciplines that incorporate mathematical and statistical models to ensure that delivery occurs by following the optimal route (Hartmut 165).

This is done usually through increasing global operations, which involve more and more global coordination and strategic supply chain management planning to achieve global optimum performance. Thus logistical operations like order tracking using globally positioned satellites can be incorporated within the supply chain so that ships and other modes of transporting crude oil can be easily located using real-time time techniques when in transit and during storage. Such a move will help companies meet supply chain expectations by carefully designing the steady and timely flow products at any level of the industries supply value chain.

Quality

The quality of crude oil delivered from Shell usually remains un-altered because ships usually carry what they are given and thus do not attempt to alter the crude oil until they reach their respective destinations. While in other businesses delicate products need extra care and may end up being compromised in the process of delivery this is highly unlikely because crude oil is a product that requires a lot of heat and various catalysts for it to change form. The conditions and surroundings of ships are often customized and thus make it suitable to carry crude oil without affecting the quality of oil (Wisner 99).

Companies which have been either successful or unsuccessful in using the practice

Major Oil mining corporations like Chevron, Mobil Exxon, and Royal Dutch Shell and British Petroleum have successfully used the above logistic practices to effectively move oil throughout the world successfully. The main reason why these companies have successfully managed this is simply that they can raise resources and they operate on a very large scale which enables them to enjoy economies of scale as far as storage and transportation are concerned (Edward 88).

Smaller Oil companies like DNO international, Grupa Lotos, Perenco, Tullow Oil, Pakistan Petroleum, DONG Energy, and Encana have faced restraints and hurdles that have made it hard for the companies to operate in large-scale like Chevron, Mobil Exxon, and Royal Dutch Shell and British Petroleum simply because they lack the capacity and funds to operate under such a supply chain framework. The nature of risks and resources required make it hard for them to expand their activities to a fully global scale like Royal Dutch Shell.

Existing problems and weaknesses in the current process and additional capabilities that the process needs to develop

The current processes don’t lack its shortcomings ships carrying crude oil in the high seas are often attacked by malicious crews who are pirates. Piracy attacks have a very impact on the final delivery and smooth movement of Crude oil and finished oil products throughout the supply chain. Additionally, these means that oil marketers and oil companies are forced to incur extra costs, time delays, and inefficiencies which are in turn faced by the final customers who reside in various nations of the world. When ships are high jacked than the oil tankers will not reach their destinations in the required time and thus many of these regions will be forced to exhaust their safety stock thus bringing economies and international business to a standstill. Hence insecurity within the supply chain of companies operating in the oil industry such as Royal-Dutch Shell poses a big threat to the smooth existence and functioning of the oil industry.

Events arising from terrorism and piracy have pushed up the price of crude oil per barrel simply because the number of risks involved in doing business has also gone up. Insurance companies and other financiers are becoming wary of partnering with other companies within the oil supply chain because the kind of risk simply involved with transporting sand moving oil through the supply chain has made it hard for companies to realize substantial returns from their investments along the oil industry supply chain (Hartmut 144). The industry participants are thus required to come up with appropriate mechanisms that will guarantee the safety of oil products in transit so that customers of the shell can safely transport crude oil without fearing that their fleets of oil ship will be high jacked and they will be required to pay ransom for them to be released.

The existence of various oil cartels that have significant control over the operations of the oil industry has also affected activities within the supply chain making it hard for end consumers to enjoy oil products at more affordable prices. Oil cartels mostly those who act as intermediaries sometimes hoard crude oil so that they can manipulate prices to their selfish interests. Oil prices are known to be quite volatile and even sometimes change on an hourly and daily basis but many existing cartels go ahead and purchase thousands of barrels and hoard them so that prices can artificially be pushed up to increase their profit margins.

When this occurs then a shock wave is sent throughout the supply chain and these effects are transferred to other members of the supply chain, therefore, inconveniencing their goals and targets. When these costs are absorbed by other collaborative members of the supply chain they are finally passed down to the end consumer. Therefore when Shell finishes its mining activities and sells oil to various organizations and associations it loses further control over what happens on the crude oil and hence end-consumers face the heat by having incremental costs transferred to them.

Restructuring processes to improve on current weaknesses and add additional capabilities

The current weaknesses reduce the level of efficiency within the supply chain, it is therefore very important to reduce the number of risks that usually exist in a supply chain to ensure a continuous flow of products. The absence of risks within the supply chain will thus reduce the lead time (the period it takes for a placed order to be delivered) and therefore reduce the length which is usually taken to complete business processes. Inefficiencies within the supply chain of the oil industry will always result in increased costs which are to be included in the costs that are computed in the global supply chain. By using strategic planning in supply chain management then organizations can successfully manage to reduce risks through carefully queuing and using mathematical models such as simulation to design the overall supply chain activities.

The existence of insecurity within the oil supply chain makes it harder for businesses to flow smoothly it thus increases costs, introduces inflexibility, and time delays. It is thus the duty of participants within the oil industry like Shell, BP, Chevron, Exxon Mobil, and shipping companies to come together and come up with a permanent solution that will counter-terrorism within the industry. Alternatively, the companies can for a security unit with the help of world superpowers and the United Nations that will successfully patrol waters and escort oil shipments through dangerous waters. Alternatively, security intelligence can be used in collaboration with host countries to counterterrorism activities before they occur. (Michael & Jude 142)

The problem and hindrances that have been introduced into the oil supply chain as a result of oil cartels colluding to distort the supply of oil to various nations of the world can be further prevented by introducing new laws that will prohibit the control that cartels have over the supply chain activities of the oil industry. If an association of oil mining companies is present then this body should identify these cartels and find means by which they can reduce the negative impact that arises out of cartel activities. If the following implementations are carried out then the flexibility of the oil supply chain will improve and the movement of oil and other related products will be improved. Furthermore, extra costs incurred throughout the global supply chain will be reduced thus empowering the end consumer (Jaber 142).

Timeframe

The nature of costs and complexity that is expected to accompany changes within the Oil industry is quite tremendous and therefore a larger time frame of up to 5 years will be required so that Shell and other participants within the oil industry can come together and set up mechanisms that will be required to effect changes. Because the nature of relationships within the industry is similar to those suggested in the systems theory, collaborative efforts will be required to make the recommendations turn into reality.

Measuring performance within the supply chain

The measurement of performance within the oil industry supply chain can be achieved by the use of key performance indicators and the balanced scorecard approach. The balanced scorecard approach is a measurement and evaluation technique that compares desired performance and actual performance by using key performance metrics such as financial indicators, customer indicators, and internal business indicators to measure actual performance within the supply chain. By taking a look at inventory turns, cycle times, quality, lead-times then it is possible for Shell and other members within its supply network to assess their performance and prompt retaliatory action.

If other members within the supply chain complain about the quality of the crude oil then the Royal-Dutch shell can carry out measures to improve on quality. If the costs and flexibility of the supply chain are also adversely deviating from the planned and actual performance f the supply chain then the organization will be required to re-align its supply chain management strategy. Evaluation and measurement are an important and integral part of the supply chain without it then a high level of efficiency will be hard to achieve because it is through evaluation that the mistakes of the current system can be identified and then the necessary resources put aside to correct the mistakes.

Conclusion

Supply chains are vital to the existence of businesses, because they facilitate the flow of raw materials, work in progress and finished goods within the organization and intra-organizationally. Since business executives are aware of this, they, therefore, formulate and implement supply chain management strategies that ultimately increase their level of efficiency at which raw materials, work in progress and finished goods move from one level of the industries supply value chain to another level.

This is therefore why companies like Royal-Dutch Shell focus much of their efforts in making sure that crude oil and other oil-related products move smoothly and efficiently through the global supply chain. Supply chain and procurement executives carefully design, plan, control, continuously evaluate and monitor supply chain activities to create value as goods and services move through the various levels of the supply chain and through the interconnected business organizations which exist as interdependent systems to reach the final destination of consumption in the right time and quality.

References

Edward, Jones. Royal Dutch Shell: The Power and Policy of Big Oil Super–major, 4 edn. New York: Springer, 2010. Print.

Ford, David. “Understanding Business Markets: Interaction, Relationships and Processes.” Industrial Marketing Management Vol. 5 (1990): 319-32. Print.

Ford, David. “Buyer/seller relationships in international industrial markets”, European.” Journal of Marketing, Vol. 14 No. 5 (1980): 339-54. Print.

Hartmut, Stadtler. Supply chain management and advanced planning: Concepts, models, software, and case studies. New York: FastBook Publishing, 2008. Print.

Heide, Jan. “Interorganizational governance in marketing channels.” Journal of Marketing Vol. 58 (1994): 71-85. Print.

Hiles, Andrew. The Definitive Handbook of Business Continuity Management. New Jersey: John Wiley and Sons, 2010. Print.

Jaber, Mohamad. Inventory Management: Non classical views. Florida: CRC Press, 2009. Print.

Lambert, Douglas. Supply chain management: processes, partnerships, performance. New York: Supply Chain Management Inst., 2008. Print.

Michael, Allison & Jude, Kaye. Simplified strategic planning: a no-nonsense guide for busy people who want results fast. Worcester, MA: Chandler House Press, 2005. Print.

Porter, Michael. The competitive Advantage of Nations. Northampton, MA: The Free Press, 1990. Print.

Wheelen, Thomas & Hunger, David. Strategic management and business policy. New Jersey: Prentice Hall, 2002. Print.

Wisner, Joel et al. Principles of Supply Chain Management. New York: Cengage Learning, 2008. Print.

Worthington, Ian & Britton, Chris. Business environment, 6th edition. Melbourne: Pearson Education, 2009. Print.