Introduction

The simple explanation for the complicated supply chain is that over the past few years, customer expectations have changed significantly. Customers’ demands for openness and flexibility in the purchasing process have made creative fulfillment ideas necessary, particularly for businesses hoping to keep or expand their relationships with their present clients. Lead times have been decreased to satisfy consumer needs (Sharma et al., 2020b). Although this would have provided a competitive edge a few years ago, it is now a need in the current market. Customers want to be informed of the status of their orders and obtain the most precise delivery estimates within shorter delivery windows. They might not even want the quickest delivery, only accuracy within a suitable frame of time (Sharma et al., 2020a).

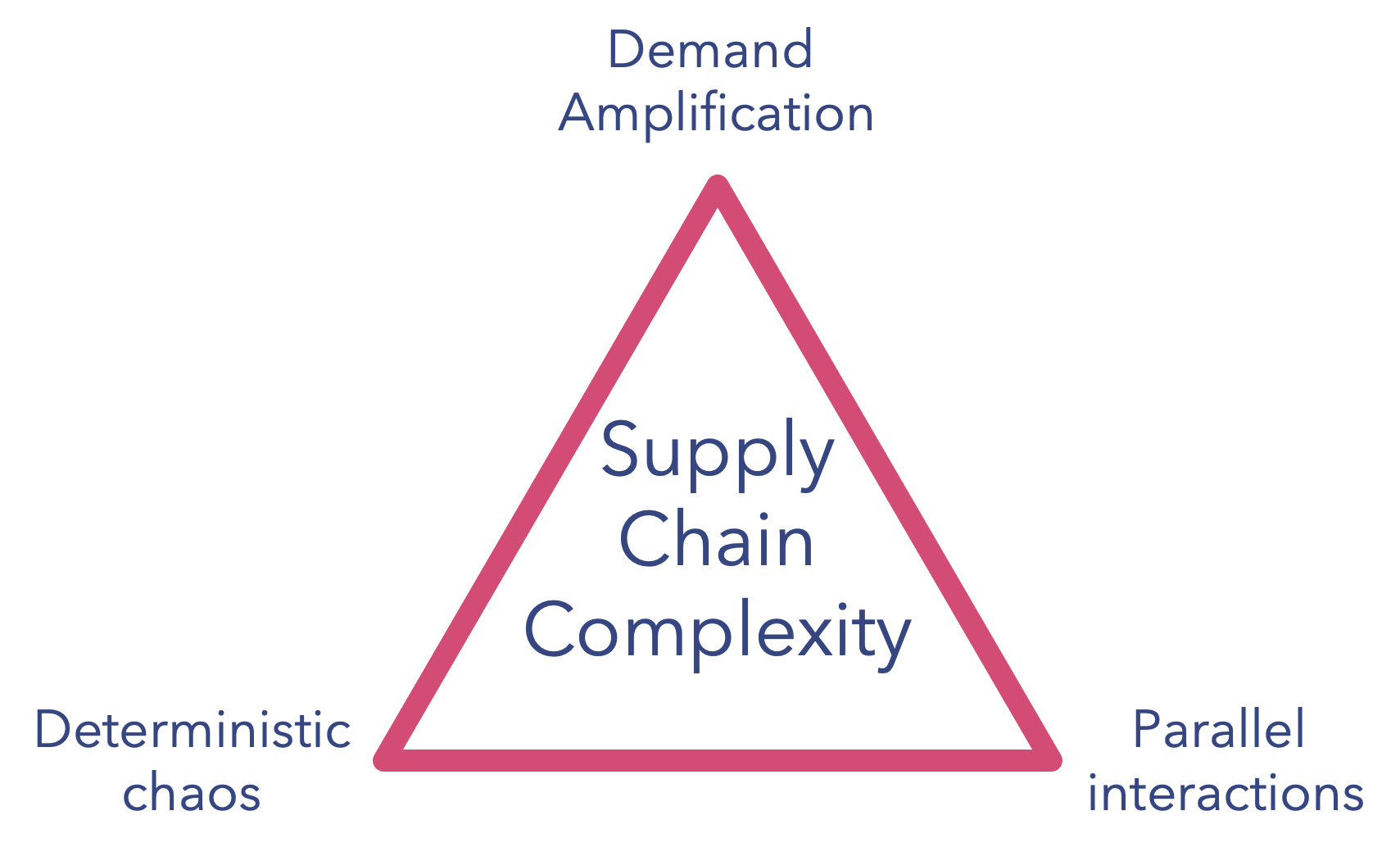

Supply Chain Complexity

A manufacturing process’s complexity may be influenced by a number of variables, some of the more common of which are listed above. The term “supply chain complexity” does not majorly relate to how sophisticated a distribution network is; rather, it describes how interconnected a system is and how changes to one part may have an impact on other parts. Consequently, the sophistication of the production chain is a framework with a variety of functions (Ahmed et al., 2022). A well-known illustration would be a global corporation with several manufacturing facilities that are all connected to numerous distribution hubs all over the world and provide service to thousands of locations (Rosado-Pinto and Loureiro, 2020).

A system grows more complex as the number of nodes and linkages increases. Many firms nowadays are more reliant on outside suppliers of goods and services as a result of outsourcing non-core operations (Azadegan et al., 2020). These third-party suppliers depend on a network of second-tier service providers, and so on. Procedures with several phases that are often carried out sequentially rather than in tandem exhibit complexity (Brammer et al., 2021). Because of this, businesses would experience issues with their distribution networks while operating internationally.

Modern manufacturing processes are supported by the exchange of information across all organizations and divisions that make up the entire end-to-end system. There is a tremendous amount of data flowing in all dimensions, but it is not necessarily accurate and can be distorted (Sharma et al., 2022b). The majority of businesses have traditionally been divided into functions and divisions, and these organizations’ sequence diagrams contain a variety of features and a hierarchical structure (Cardoni et al., 2020). The logistics system may become more complicated as a result of the vendor base’s growth because more interactions require regulatory oversight and costlier overall transactions (Eden and Nielsen, 2020).

Solutions to Supply Chain Complexity

In the past, a lot of companies had a just-in-time supply strategy, whereby they stored what they urgently needed and depended on logistics to deliver additional goods quickly (Koberg and Longoni, 2019). Increased on-shoring and near-shoring capabilities have been requested due to the disruptions these modifications have caused (Hofmann et al., 2020). Supply operations have been negatively hampered by logistical difficulties (Fransen et al., 2022).

There have been several concerns about carrier box shortages, port delays, and price increases in key areas. Product agreements are complicated by shipping delays, and this makes it difficult for enterprises to obtain the materials they need to construct items (Canton, 2021). Distribution networks have been severely damaged by high unemployment rates and economic crises, which have resulted in delays, price increases, and a variety of logistical challenges (Fernández-Miguel et al., 2022).

Evaluation of the Recommendations

The term “appropriateness” refers to how well a suggestion’s objectives match those of its intended audience as well as national, international, and partner and sponsor initiatives. Strengthening domestic capabilities through on-shoring and near-shoring would be the solution and meet the demands of the nation (Giuseppina and Michele, 2018). The level to which the solution’s goals were met or are projected to be met in light of its significance is referred to as usefulness. Multinational corporations place a premium on improving domestic manufacturing skills since doing so would reduce the expenses associated with outsourcing output (Ghauri et al., 2021).

The efficiency requirement refers to how contributions and resources, such as cash, information, and time, are converted into results. The sustainability factor relates to the growth benefits that result from the application of a solution (Xu et al., 2020).

References

Ahmed, et al. (2022) ‘Knowledge sharing in the supply chain networks: a perspective of supply chain complexity drivers’, Logistics, 6(3), p.1-20.

Azadegan, et al. (2020) ‘Supply chain disruptions and business continuity: an empirical assessment’, Decision Sciences, 51(1), pp.38-73.

Brammer, S., Nardella, G. and Surdu, I. (2021) ‘Defining and deterring corporate social irresponsibility: embracing the institutional complexity of international business’, Multinational Business Review, 29(3), pp.301-320.

Canton, H. (2021) ‘United Nations Conference on Trade and Development – UNCTAD’, In The Europa Directory of International Organizations 2021 (pp. 172-176). Routledge.

Cardoni, et al. (2020) ‘Measuring the impact of organizational complexity, planning and control on strategic alliances’ performance’, Measuring Business Excellence, 24(4), pp.531-551.

Eden, L. and Nielsen, B.B. (2020) ‘Research methods in international business: the challenge of complexity’, Journal of International Business Studies, 51(9), pp.1609-1620.

Fernández-Miguel, et al. (2022)’ Disruption in resource-intensive supply chains: reshoring and nearshoring as strategies to enable them to become more resilient and sustainable’, Sustainability, 14(17), p.1-13.

Fransen, et al. (2022) ‘The emergence of urban community resilience initiatives during the COVID-19 pandemic: an international exploratory study’, The European Journal of Development Research, 34(1), pp.432-454.

Ghauri, P., Strange, R. and Cooke, F.L. (2021) ‘Research on international business: the new realities’, International Business Review, 30(2), p.1-11.

Giuseppina, T. and Michele, S. (2018) ‘Re-Shoring and resilience in Italy during and after the Crisis’, American Journal of Industrial and Business Management, 8(5), p.1-25.

Hofmann, E., Brunner, J.H. and Holschbach, E. (2020) ‘Research in business service purchasing: current status and directions for the future’, Management Review Quarterly, 70(3), pp.421-460.

Koberg, E. and Longoni, A. (2019) ‘A systematic review of sustainable supply chain management in global supply chains’, Journal of Cleaner Production, 207, pp.1084-1098.

Rosado-Pinto, F. and Loureiro, S.M.C. (2020) ‘The growing complexity of customer engagement: a systematic review’, EuroMed Journal of Business, 15(2), pp.167-203.

Sharma, et al. (2020a) ‘Managing uncertainty during a global pandemic: an international business perspective’, Journal of business research, 116, pp.188-192.

Sharma, et al. (2022b) ‘Complexity in a multinational enterprise’s global supply chain and its international business performance: a bane or a boon? Journal of International Business Studies, 53, pp.1-29.

Sodhi, M.S. and Tang, C.S. (2021) ‘Supply chain management for extreme conditions: research opportunities’, Journal of Supply Chain Management, 57(1), pp.7-16.

Xu, et al. (2020) ‘Impacts of COVID-19 on global supply chains: facts and perspectives’, IEEE Engineering Management Review, 48(3), pp.153-166.