Executive Summary

In the 21st century, competition in all segments of the economy has increased drastically. Any organisation that does not adopt the best industry practices risks being phased out of the market. Organisations need to be in the front position in recognising their respective industry trends, adopting the best appropriate practices, and maintaining competitive advantage at all times. The fashion industry is one of the highly competitive industries. The need to retain the spirited advantage is very real. Despite being one of the oldest industries in human civilisation, the industry remains highly dynamic and aggressive. Any lag can cost an organisation its reputation and competitiveness. With this hint, this paper uses ABASCO Ltd as a case example of a company that operates in the fashion industry. The paper presents the status of the job market in this industry, a yearly hiring plan for ABASCO Ltd, and the most appropriate hiring, selection, and retention tactics that the company can put in place to remain competitive within the industry.

Introduction

The fashion industry is characterised by big and competitive apparel brand names such as Marks & Spencer, John Lewis, Calvin Klein, Zara, Nike, H&M, and Adidas, among many others. With such competition, small companies have a big challenge to overcome to break even in the industry. Such a playing ground leaves them with little margin for error or any other actions that may jeopardise their competitive advantage. It is with this realisation that ABASCO Ltd seeks to adopt the best practices, especially in the recruitment and retention of employees to help the company in sustaining its success in the industry. This report will discuss the employment market in the fashion industry, devise a 12-month recruitment plan, discuss the most appropriate recruitment and selection methods, and evaluate the potential retention strategies that ABASCO Ltd can execute to deal effectively with the challenges it is facing in its human resources. Further, the report will provide an implementation plan for the recommendations that this report will generate.

Fashion Industry Employment Market

The fashion industry is highly dynamic. With the emergence of globalisation and groundbreaking technologies, competition has increased tremendously. Despite being one of the oldest industries, the dynamism of the fashion industry has allowed it to adopt changes in the economy and technologies across time. This observation is even more evident with the industry’s adoption of e-commerce and other computer-related technologies. Some of the key highlights of competition and dynamism include short product life cycles, the abundance of product variety, unpredictable consumer demand, and complex supply chains, among others (National Statistics, 2014). As organisations seek to retain competitive advantage, the human resource segment plays a crucial role in this equation (Mello, 2002; Jones, 2014). Organisations need to attract and maintain the highest talent to beat the competition. Through human resources, organisations in the industry are guaranteed new fashion designs that can give them competitiveness and profits (Mondy & Gowan, 2005). However, with the short product life cycles that are characteristic of the industry, maintaining talent is not enough. However, attracting new talent all the time is a key aspect.

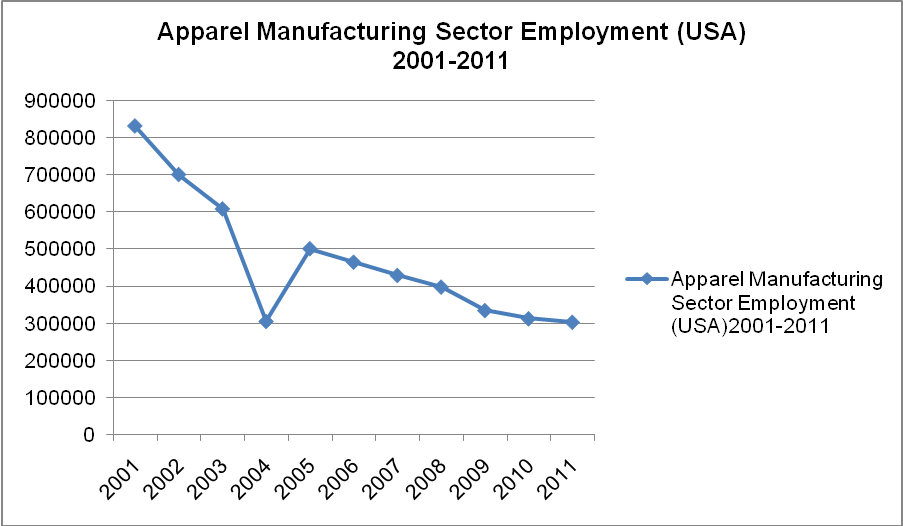

The £1.13trillion industry employs approximately 75 million people across the world and different segments of the industry. In the United Kingdom, the industry employs approximately 767,000 people. This figure is a decrease of 2.3% from 2009. On the other hand, in the United States, the industry supports approximately 3million people, although this figure has been reducing continuously (National Statistics, 2014). For instance, in the apparel-manufacturing sector in the United States, the industry employed approximately 1.8million people as compared to 303600 who were employed in 2011. The figure represents a reduction of 83% in the number of jobs that are provided in this segment (Statista, 2012). The graph below represents the trend in the number of jobs in the apparel manufacturing sector in the US from 2001 to 2011.

The above reduction in the number of people employed in apparel is reflected in the whole industry. However, despite this high rate of reduction of jobs that are available in the sector, the industry has grown in terms of revenues that are generated annually. For instance, in 2014, the UK fashion industry generated £26billion to the economy as compared to £21 billion, representing an increase of 22% (National Statistics, 2014). Such findings, which are also reflected in other markets, indicate that the industry has increased its production and efficiency through the adoption of technology, which is increasingly replacing the cost-intensive human labour (Jones, 2014). In response to the adoption of more efficient production technologies, the industry has experienced numerous layoffs of employees to pave the way for more organisational efficiency through technology.

In comparison with other industries, production in the fashion industry has not grown as fast. The low rate of industry growth has had a strong bearing on what the industry can compensate its employees (IBIS, 2014). As compared to other manufacturing and retail segments of the economy, the fashion industry has the lowest average weekly wage of any manufacturing industry in the United Kingdom. As of 2014, the average weekly wage was £371 as compared to £574 for the manufacturing industry as a whole. With such low wages, coupled with the industry trend of layoff and reductions in the workforce, it is easy to explain the high rates of turnover in the industry (National Statistics, 2014).

Looking at the trends in the industry, ABASCO Ltd is facing challenges, which are common in other outlets. However, to remain relevant and competitive, the organisation needs to revisit its recruitment and retention strategies to ensure that staff members are not only well talented but also can remain in the organisation for a longer period. Currently, the high rate of employee turnover of 14% at the organisation’s St. Albans site is a reflection of a dire need for the organisation to reflect on its employee retention strategies. Also, the organisation needs to address its low wages that range from £18,000 to £40,000 for the lowest and highest-paid individuals.

According to Jones (2014), the fashion industry is highly dynamic, and that retaining talent is not enough. It is important to create a platform where the existing talent can grow and/or adapt to the emerging fashion trends, which can greatly ensure that the organisation remains relevant and profitable. Also, it is important to adopt the best recruitment and employee selection strategies that can allow the spotting of new talents, which are important in bringing fresh ideas in the organisation (Saunders, Millmore & Thornhill, 2007). Without the ability of an organisation to adapt to changes in the industry, it is easy to produce obsolete or slow-moving products that are not in demand, a nightmare that fashion industry players must avoid at all times (Robbins & Judge, 2013).

In the quest for attracting and maintaining employees in the long-term, organisations face numerous hurdles. For instance, the low wages that are offered in the industry are a great turnoff for potential employees who may be motivated to look for jobs in other better-paying sectors (Flanagan, 2014). For this reason, many employees see a job in the fashion industry as a transition job as they look for other places, which can partly explain the high rate of employee turnover at ABASCO Ltd. Consequently, the process of ensuring the recruitment and retention of employees at ABASCO Ltd requires great changes that must be adopted immediately.

Apparel Manufacturing Sector Employment (USA) 2001-2011

One of the easily recognisable problems that ABASCO Ltd is facing is the lack of a recruitment strategy and plan at the organisation. In a highly dynamic industry, it is important to put appropriate measures of ensuring that qualified and highly motivated employees are recruited. The process of recruiting the right talent for the right jobs has evolved greatly. It requires more than just academic qualifications for an organisation to fill its vacant positions (Jamieson & O’Mara, 1991). ABASCO Ltd must make critical decisions on what it wants in various positions, whom to target, how to staff the recruitment, and/or what message to convey to attract the right people (Holbeche, 2001). When not handled in the right way, ABASCO Ltd may end up with unqualified job applicants. It may fail to consider diversity. Further, by hiring the wrong people from the defective recruitment process, the organisation may end up experiencing high turnover and poor performance among another challenge (Fraser & Hunt, 2011). In this segment, important recommendations will be made on the methods that ABASCO Ltd should use to meet its workforce requirements. The report covers different widely researched recruitment topics such as:

- Reaching the targeted job applicants

- Identifying the right people to be recruited

- Timing of the recruitment exercise

- Designing and disseminating the recruitment message

- Evaluating past recruitment activities

- Managing the whole recruitment operation

Identifying the right people to be recruited

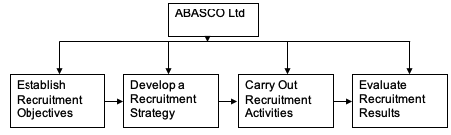

The proposed model of the recruitment process is an important tool that guides the steps through which ABASCO Ltd should carry its recruitment efforts. By carefully adhering to the steps that have been proposed, the organisation can achieve better outcomes for its recruitment efforts. The following diagram represents the various steps of the model, which will be discussed further.

Recruitment Objectives

The first important step in the recruitment process is the establishment of recruitment objectives for the positions that the organisation seeks to fill. For instance, one of the objectives should relate to the number of open positions in the organisation at that given time. Further, the organisation must set an objective on the timeframe for filling such positions. In this case, the organisation must decide whether the positions will be filled urgently, on a rolling basis, or within any other agreed-upon timeframe. It is important to decide the characteristics of the candidates the organisation seeks (Hackman, 2005). In this case, the organisation must set the level of education, knowledge, skills and abilities, interests, values, diversity, job performance goals for new personnel, and the expected retention rate for the new hire.

In the setting of these objectives, the organisation needs to be well aware of the expectations of each position. It has to match the position accurately with the skills and qualifications that are desirable in the targeted candidates. Therefore, the process requires the input of the HR personnel, as well as line managers, who can shed more light on the requirements of each position in their respective areas of supervision. Further, in the setting of these objectives, the organisation must consider its brand name and therefore set its recruitment objectives to reflect its brand identity. According to Allen (2004), a brand is referred to how a company wishes its forthcoming and active workforce to distinguish it.

Brand identity requires deliberate efforts for an organisation to achieve it. For instance, ABASCO Ltd operates in a highly competitive sector. The industry’s big brand identities have set the bar too high. However, through describing the organisation in the recruitment literature, highlighting the brand in the organisation’s website, as well as treating prospective employees well during interviews, ABASCO Ltd can achieve a brand identity that can reflect well on its prospective employees, thus leading to better outcomes for the recruitment process.

Develop a Recruitment Strategy

After establishing the recruitment objectives, it is important to develop a good strategy through which the organisation will meet the objectives and consequently fill the available positions. The strategy is a specific action plan, which guides the organisation on systematic actions and timeframes for achieving each objective.

Carry Out Recruitment Activities

After creating a good recruitment strategy, it is important to actualise the objectives by carrying out agreed-upon recruitment activities. Such activities may include advertising through the organisation’s website, recruitment campaigns in universities, and advertising through credible recruitment agencies and any other method or activities that the organisation may agree upon (Bagshaw, 2004).

Evaluate Recruitment Results

Many organisations and decision-makers who are involved in the recruitment efforts are mainly concerned with the outcomes of the efforts. In this case, managers mostly measure the success or failure of the recruitment efforts in terms of whether they have been able to achieve the set objectives (Charlton, 2000; Jones, 2014). However, such an approach does not give the organisation time to review the effectiveness of the recruitment activities that the organisation has undergone (Armstrong, 2011). Managers cite different reasons for their lack of evaluation of recruitment results, including the large amounts of data collected in the process or other cases, lack of adequate data to carry out the evaluation.

Evaluation of recruitment results allows an organisation to review and, where necessary, make important changes to improve the effectiveness of the recruitment efforts. Also, it allows HR to determine and prove the importance of these recruitment activities to the organisation. For example, through evaluations, an organisation can determine the activities that yield the most recruits, the universities that yield most hires, employees who stay in the organisation for a longer time, and those who have the highest performance reviews. Such an evaluation can allow the organisation to drop some universities or recruitment activities while at the same time scaling up others.

12-Month Recruitment Campaign Plan

The following is the recruitment campaign plan that ABASCO Ltd will adopt for its recruitment activities.

Recruitment Policy

To develop and implement a long-term recruitment plan for ABASCO Ltd, which includes a recruitment schedule based on the historical trends in the supply and demand for all major disciplines in the fashion industry

Recruitment Goal

To recruit employees based on resignations, terminations, or growth of the organisation throughout the year

Recruitment Strategies

- To contact prospects as early possible to ensure competition in filling available positions

- To focus recruitment efforts on the fashion industry professionals who are completing their studies, as well as those who are already working in other fashion industry companies

- To ensure a continuous year-round recruitment schedule

Recruitment Structure

The recruitment cycle for ABASCO Ltd for____________ [Name of Training Institution/Programme] will begin on__________ [Date] of each year

The HR, in collaboration with other personnel in the respective departments, will coordinate the recruitment efforts

Recruitment objectives will be reviewed annually in February

Recruitment Activities

- Obtaining legal contracts for employees who will commence work at the organisation

- Follow up with interviewed candidates

- Quarterly meetings of the recruitment committee for reviewing action plans and development of implementation strategies

- Attending as many career fairs as possible

12-Month Recruitment Plan

The following recruitment plan highlights scheduled quarterly recruitment activities for ABASCO Ltd.

The following table is a summary of the recruitment process for ABASCO Ltd.

Selection Methods

It is important to note that for an organisation to achieve its goals and/or employ the right people, the right skills and motivation are an obligation. When an organisation recruits the wrong people, it is doomed to fail. The situation must be avoided all the time. To achieve this goal of recruiting the right employees, it is important to ensure that the selection methods of employees that are used in the organisation are good. Such selection methods must reconcile the needs of the employees and employers (Human, 2003). Many organisations strive to meet the dual goal of attracting the most productive employees and providing the best organisational environment for the employees since they (employees) seek employment from organisations that meet their demands. Consequently, the selection methods that organisations employ in recruiting the best employees are very important. They should not leave any margin for error.

Selection methods that an organisation utilises must adhere to four important characteristics, namely, validity, impartiality, the scope of usage, and cost. In terms of validity, the selection methods must be accurate in ensuring that the identified test scores correlate with the expected performance expectations. In terms of impartiality, the selection method must be fair. It should not discriminate people based on their sex, religion or other factors that are not part of the job description (Hackman, 2005). In terms of the scope of usage, an organisation must determine how many job tasks the method can be applied. Lastly, the cost of the method is important. It should factor in the organisation’s resources and financial capability. Below is a description of the various selection methods that ABASCO Ltd should adopt on a need basis to ensure that the right people are recruited for the right job.

Preliminary Screening

With the level of publicity that the internet has allowed, it is a guarantee that any advertised position is likely to attract hundreds or even thousands of applications. The preliminary screening involves cutting down the number of applicants based on their qualifications as required by the specific role (Bagshaw, 2004). In his case, the organisation can shortlist a manageable number of people who it can now contact for formal interviews among other selection criteria.

Telephone Interview

After shortlisting the prospective candidates, the first important step is to perform telephone interviews. Telephone interviews are very important since they allow an organisation to determine whether the candidates are still interested in the position (Armstrong, 2011). Further, it is an important method for small organisations since it saves money and time by avoiding face-to-face interviews immediately after the preliminary screening. Telephone interviews allow the organisation to further shortlist the candidates who can articulate their qualifications and skills as required by the organisation’s staffing needs.

Selection Tests

Selection tests are important in reducing the number of interested candidates to a manageable number. These tests are important since they allow an organisation to come up with a list of candidates who have the right skills, aptitudes, and other characteristics that are necessary for the job (Human, 2003). As a kind gesture, all candidates must be informed early in advance of the tests for preparation. These selection tests include psychometric testing, aptitude tests, in-tray exercises, and presentations. For ABASCO Ltd, these tests are important in helping the organisation identify the best talents.

Panel Interview

For ABASCO Ltd, it is highly recommended to have panel interviews. Panel interviews allow candidates’ qualification to be reviewed by a wider number of people. It gives a better impartial outlook for each candidate and consequently his or her appropriateness for a given position. ABASCO Ltd is a company, which operates in a highly dynamic industry that requires talent and special aptitudes for its candidates to ensure a competitive advantage (Bagshaw, 2004). A panel interview has two main purposes, namely, collecting information on the qualification of the candidate and determining how he or she fits the requirements of the job. Such information is important since it allows panel members to check the skills, experience, and the general background characteristics that are important in determining the most suitable candidate. The second purpose of the interview is to give the candidates more information relating to the applied position and clarify on issues that the candidate may not have understood well. The third objective is to give the candidates a positive view of the organisation and to ensure that they feel they were given a fair hearing, which is good for the organisation’s brand.

The panel’s composition must be composed of people who have knowledge and experience in the various roles that are being sought. It is also important to ensure that the panel members are of a higher rank than what is being sought. For fair and impartial hearing, the organisation should strive to ensure that both genders are represented in the panel with at least one female at all times (Holbeche, 2001). Another important aspect relates to the interview questions during the panel interview. The interview questions must be developed based on the person’s specification of the job. In the end, the panel interview should act as the final selection method where the possible candidates and prospect employees are identified and/or offered a job subject to their agreement of the rules of the contract.

Retention Strategies

With the cutthroat competition in the fashion industry, ABASCO Ltd needs to find ways of ensuring that the organisation’s employee is there in the long run, to ensure best returns for investors, as well ensuring consistency. High employee turnover can lead to low productivity, which can greatly affect the organisation’s competitiveness (Robbins & Judge, 2013). Therefore, an organisation needs to put in place employee retention strategies to address its current employee retention problems.

Firstly, the most important retention strategy starts in the recruitment and selection process. During this stage, the organisation must strive to hire the best people. Hiring the best workers makes them (employees) feel at ease in their positions and less stressed. The situation translates into job longevity and a feeling of security. When an organisation hires underperforming employees, they are likely to be put under pressure by the management. Besides, their inability to fit in the job context can lead to high turnover in the organisation (Human, 2003).

Secondly, ABASCO Ltd needs to offer competitive benefits packages that are in line with employee needs. When employees feel that they are not adequately compensated, they are likely to have low performance and/or seek other better opportunities. For example, offering wellbeing cover, sequestration benefits, and life indemnity is an important step of maintaining the workforce. Further, offering small perquisites such as free bagels on Fridays and other rewards might seem small. However, they are very important in retaining employees (Saunders, Millmore & Thornhill, 2007). For instance, the fashion industry is known for its low compensation rates as compared to other industries. Therefore, ABASCO Ltd needs to review its compensation packages to offer its qualified and highly motivated employees what fits their needs.

Thirdly, providing some employee development opportunities such as training and education leaves is a very important process of employee retention (Mello, 2002). Also, the organisation can motivate its employees through contests and incentives. Lastly, the organisation must closely follow up on employee welfare through ‘stay’ questionnaires, exit questions, and other feedback methods that can allow the organisation to adjust accordingly to guarantee a good working environment for the employees (Jamieson & O’Mara, 1991).

Conclusion

The fashion industry is highly dynamic and competitive. To remain competitive, human resource plays an important role in ensuring that employees comprise the right people for their respective positions. Therefore, it is important to ensure that recruitment, selection, and employee retention methods are the best. Such processes must ensure that the human resource goals of the organisations are met. The recruitment and selection methods that have been discussed in this report are critical. Their adoption by ABASCO Ltd is highly recommended. The recruitment campaign plan is very important since it will guide the organisation in streamlining its recruitment efforts. Further, the retention methods are very critical in ensuring that once the best candidates are recruited, they can stay in the organisation for a longer period to guarantee competitiveness and return on investment.

Reference List

Allen, R. (2004). The Need for Diversity in Corporate Training: One Size Doesn’t Really Fit. Industrial and Commercial Training, 26(10), 15-17.

Armstrong, M. (2011). Armstrong’s handbook of strategic human resource management London: Kogan Page.

Bagshaw, M. (2004). Is diversity divisive? A positive training approach. Industrial and Commercial Training, 36(4), 153-157.

Charlton, G. (2000). Human Habits of Highly Effective Organisations. Western Cape: Van Schaik.

Flanagan, J. (2014). Virtual Reality and retail: Fashion’s E-Commerce. Web.

Fraser, J., & Hunt, E. (2011). Faculty diversity and search committee training: Learning from a critical incident. Journal of Diversity in Higher Education, 4(3), 185-198.

Hackman, J. (2005). The design of work teams: Handbook of organisational behaviour. Englewood Cliffs, N.J: Prentice-Hall.

Holbeche, L. (2001). Aligning human resources and business strategy. Oxford: Butterworth-Heinemann.

Human, L. (2003). Contemporary Conversations: Understanding and Managing Diversity in the Modern Word. Coree, Senegal: Coree Institute.

IBIS. (2014). Clothing Retailing in the UK: Market Research Report. Web.

Jamieson, D., & O’Mara, J. (1991). Managing Workforce 2000. San Francisco, CA: Jossey Bass.

Jones, K. (2014). What’s on Trend this season for the fashion industry? Big Data. Web.

Mello, A. (2002). Strategic human resource management. Australia: South-Western College Pub.

Mondy, W., & Gowan, M. (2005). Human resource management. Upper Saddle River, NJ: Pearson Prentice Hall.

National Statistics. (2014). Textile Industry Average wage Lowest within UK Manufacturing.

Robbins, P., & Judge, A. (2013). Organisational behaviour. Upper Saddle River, NJ: Prentice Hall.

Saunders, M., Millmore, M., & Thornhill, M. (2007). Strategic Human Resource Management: Contemporary Issues, New York, NY: Prentice Hall.

Statista. (2012). Number of Employees in the U.S. Apparel Manufacturing Industry in 2010 and 2011. Web.