Introduction

Bio-Neutral Pty Ltd intends to design a bio-diesel production facility. The company requires that different sections of the production process be designed. These sections include the size and the number of the tanks used, the types of pumps and their ratings, and the number together with the models of electric pumps that will be used. This report analyses the electric heater to determine which model among the five that are available for selection can be best suited for implementation in the production process. The input power ratings of the heaters are given and using their efficiencies, their outputs will be calculated. A comparison of their costs will also be conducted.

During the mixing process, the electric heater element raises the temperature of the liquid from an ambient temperature of 25oC to 50oC within 1.75 hours. Heating is done as the liquid is circulated using a pump. Therefore the pump and the heater must run concurrently to ensure efficiency in the heating process. The pump should circulate 25% of the volume of the tank every minute.

Technical Analysis

The average density of the liquid being heated which is composed of oil, methanol, and sodium hydroxide is 911 kg/m3. The specific heat capacity of the liquid is 1.80 KJ/Kg/oC. These parameters together with the volume of the tank and the flow rate of the liquid play an important role in determining how the liquid will be heated. The specific heat capacity which is the amount of heat required to raise the temperature of one kilogram of a substance by one degree Celsius is also important in calculations in this section (Holman, 1990, p. 192). The table showing the types of heaters that are available together with their input powers and cost is shown below:

Table 1 – Electric heater specifications.

From the table above, the efficiencies of all the heaters are 1. This means that all the input power is transferred to the liquid. Hence the output power for all the heaters is the same as the input power. The relationship between the input power, efficiency, and output power is illustrated by the equation below (Hewitt, 2009, p. 226);

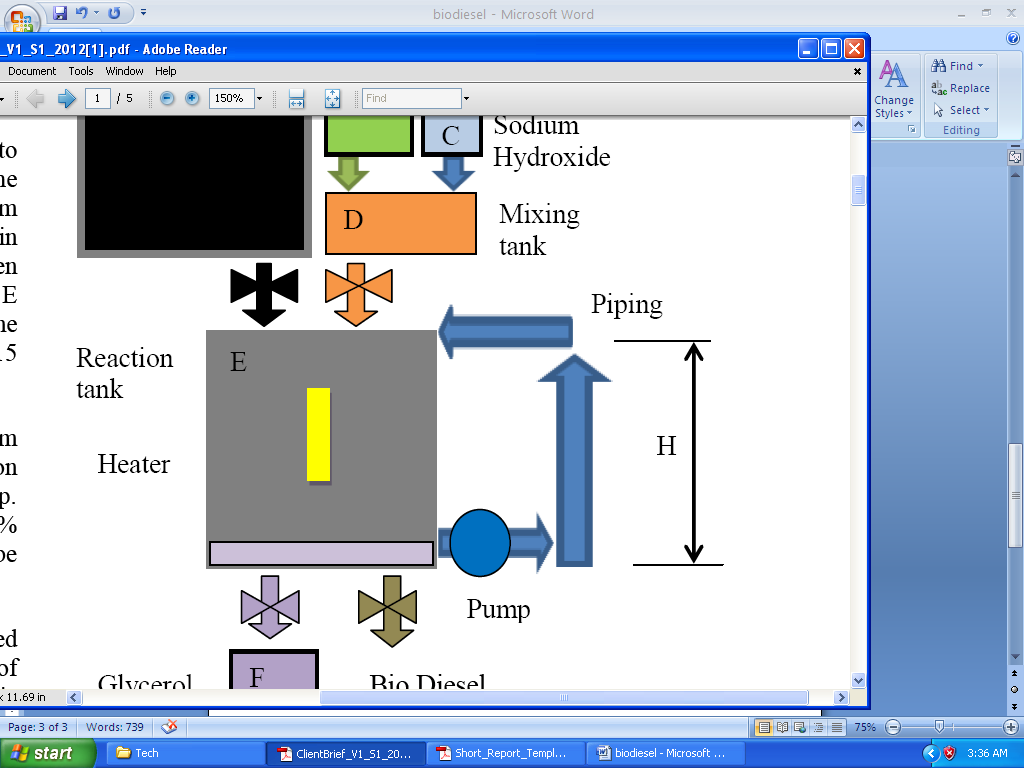

A diagram showing the heater section is shown below:

Each of the design sections depends on the operation of the other sections. For example, the heater section depends on the volume of the tank to determine the amount of heat that will be required to heat the liquid to the specified temperature within the specified time constraints. The pump also depends on the volume of the tank for its functionality.

Given that the company intends to produce 12000 liters of bio-diesel in 8 hours, it can be estimated that the amount of bio-diesel produced in 1.75 hours is given by;

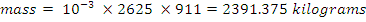

The density of the liquid mixture is 911kg/m3. Therefore the mass of this liquid can be determined from the expression below.

Therefore, the mass of the liquid becomes;

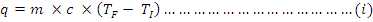

The specific heat capacity of a material can be obtained from the equation below (Petukov, 1970, p. 45);

Where q is the heat that is gained or lost, m is the mass of the material, TF is the final temperature of the material, and TI is the initial temperature of the material.

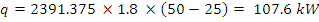

The heat required from the heater can then be calculated by substituting the known values in the equation above. The mass of the fluid is 2391.375 kilograms, the specific heat capacity is 1.80 KJ/Kg/oC, the final temperature is 50oC and the initial temperature is 25oC. Substituting these values in equation (i) above we have;

The value obtained above is the energy that would be required if the heater was heating the liquid while it was not flowing. The flow of the water means that the amount of the liquid passing over the heating element at any particular time will be reduced. The choice of the heating element is made to ensure that the temperature of the liquid is always achieved. From the available heater models, the heater model H80 is chosen. This model supplies the power of 80kW and this power is the one that is closest to the value that has been obtained. The pump will ensure the flow of water at a particular flow rate and this will ensure that the heater raises the temperature of a reduced volume and hence the mass of the liquid.

Conclusion

The analysis of the heat requirements for the production process indicates that the heater model H80 is the most appropriate. This is because its power output will be able to raise the temperature of the liquid within the time requirements of the production process. It is also evident that the interrelationship between different sections of the process means that the analysis of a particular section should be done with reference being made to the design requirements of other sections.

References

Hewitt, P. 2009, Conceptual Physics, Addison-Wesley, New York.

Holman, J. 1990, Heat transfer, McGraw Hill, New York.

Petukov, B. S. 2009, Advances in Heat Transfer, Academic Press , London.