Introduction

The term “operations management” refers to a broad and essential aspect of any corporation in which all procedures necessary to support the growth and development of the company are managed, administered, and regulated. Operation management consists of several steps: planning, managing, overseeing the manufacturing process, producing, and monitoring. Operations management improves service sector organizations because successful operations lead to contented consumers who benefit the business. Domino’s UK is an example of an organization that has effectively utilized operations management practices to its advantage. In this context, the current paper sheds light on the operation management process of a well-known pizza delivery company, Domino’s UK.

A Brief Description of the Operation, Facilities, and Processes

Domino’s UK’s food production system is built to function with various types of pizza production, such as vegetarian, fresh, handcrafted, bread-based, and non-vegetarian. The system is designed for mass manufacturing, producing around 125,000-150,000 pizzas per day; hence, monitoring the quality of the food production process is critical (Kumar et al., 2021). Aside from that, clients at various Domino’s restaurants frequently get the option to observe the pizza-making process.

Domino’s mass manufacturing strategy does not rely on a single supply chain center, and several pieces of equipment operate in each dough production house to meet client demand. Every mixing bowl can hold around 500 pounds of ingredient combination, and a bowl elevator is used to deposit the dough into the dividers (Kumar et al., 2021). This equipment is necessary for automated dough cutting and balling. This dough is delivered to every Domino’s location by enormous delivery trucks. The pizza base is then prepared and garnished to the client’s specifications.

Transformation Model

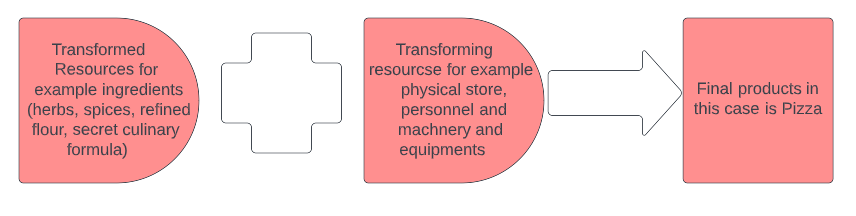

Operations produce commodities and services through the transformation process. Operations are processes that receive various input resources and convert them into outputs (Anand & Gray, 2017). The transformation process at Domino’s is meticulously planned and streamlined from the moment an order is placed until it is delivered to the customer. Operations are the processes that change the status of something to create output that consumers consume. The transformation model, which contains three production phases of products and services, explains the nature of activities.

Input

The operation input is divided into two broad categories: transformed and transforming resources. Raw materials, knowledge, and customers have transformed resources, whereas skilled personnel and machinery are transforming resources (Anand & Gray, 2017). The converted resources comprise raw resources that are further processed into value-added products through the transformation of resources. The input step at Domino’s contains both transformed and transforming materials.

Ingredients transformed include refined flour, vegetables, spices, herbs, a secret culinary formula, and client orders. Domino’s operations guarantee that transformed resources contribute to the overall value of the transformation procedure. Ingredients of the most excellent quality are selected, and a secret formula ensures that its goods taste the same worldwide.

Furthermore, client orders may be adjusted to their preferences, providing customization. On the other hand, stores, personnel, and equipment are examples of transforming resources (Anand & Gray, 2017). Domino’s employs specialized ovens to make high-quality pizzas.

Process

The process is the most critical stage of the transformation model, transforming low-value raw materials into value-added goods or services. This transformation is accomplished by a process involving transforming and transforming resources, ultimately generating an item or service that the client can access (Anand & Gray, 2017). As a result, Domino’s has a process dedicated to transforming raw materials into edible value-added food products.

The Process Design

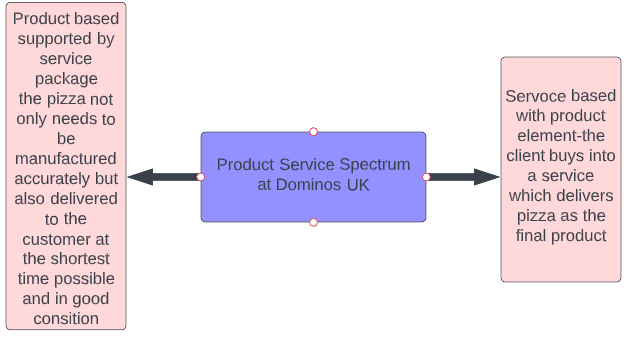

Product Service Spectrum

By considering the product-service spectrum, the company is distinctive in that it incorporates not only the product base but also the service base that is supported by both the service package and product element, respectively.

Conversion

The process includes tangible and intangible factors, with the client present at essential points throughout the production system. The introduction of the open kitchen technique has made the customer who waits for the takeaway a part of the whole experience, from ordering to.

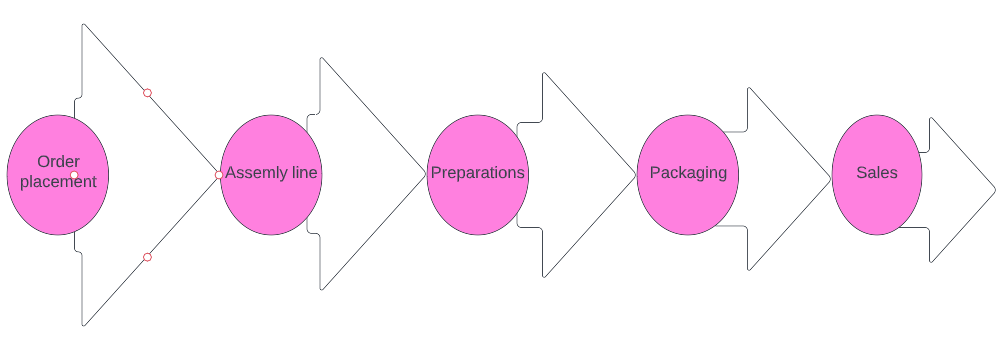

Production

The process is relatively efficient and organized, starting from placing orders through final delivery to the ultimate consumer. The steps involved in the production are as follows;

- The client places the order by phone, online, or in person at the restaurant.

- A staff member then receives the order and enters it into a proprietary system specially designed to streamline the order-taking process at Domino’s (PULSE).

- The order and the client specifications are shown on the assembly line’s screen.

- One of the staff members in the assembly line takes the order, prepares the dough, and applies the toppings and sauce appropriately.

- The next staff member in the assembly line then puts it into the oven.

- A third employee takes the pizza out of the oven after the designated baking period and packs it ready for delivery by either a delivery driver or given out to be picked up by a waiting client.

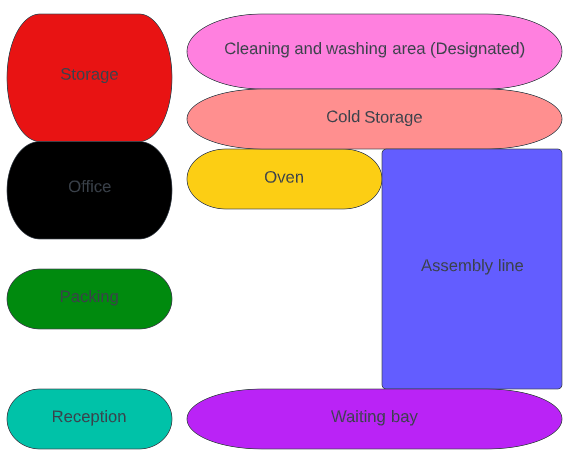

The figure below depicts further facets of Domino’s activities.

Output

Output is the last stage of the transformation model when the product or service is available for the client. Value is added to the product or service at this level. The output in the instance of Domino’s is the consumer’s requested product.

Domino’s earns money for the products it delivers to customers, which helps the company make a profit. As a worldwide brand, Domino’s ensures the quality and taste of the products and services it provides to customers. Domino’s offers free and on-time delivery to its customers worldwide. Domino’s transformation methodology is well-defined and beneficial for the firm, resulting in massive earnings.

Analysis of the 4Vs Framework and Performance Objectives of the Operation

Volume

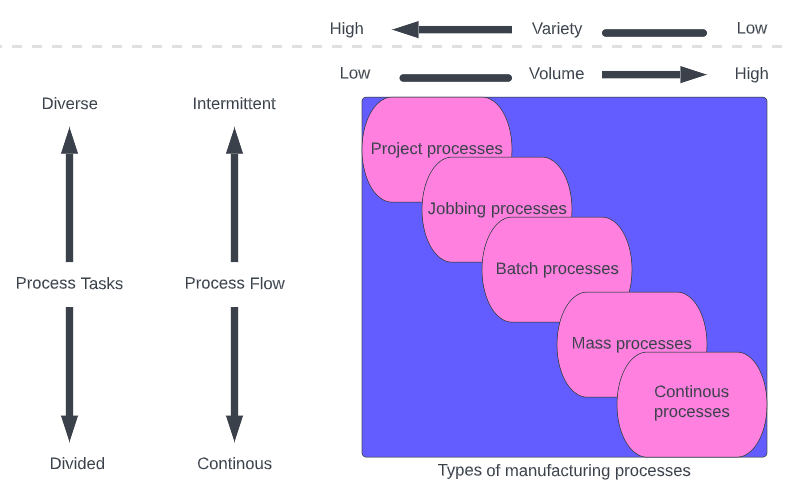

Based on the company’s operations, it can be claimed that Domino’s, as a medium-high-volume corporation, has well-known examples of low-cost, high-volume pizza. According to Clegg (2019), this volume is frequently seen as the key to understanding how the company is structured. For instance, Domino’s food production system features a ton of repeatable operations, such as dough preparation, garnishing, processing, and so forth, in addition to being well-systematized. The company specializes in the product since the process of creating it is highly repeatable. Domino’s employs skilled personnel who use sophisticated equipment to produce goods according to a predetermined standard method, enabling continuous operations.

Variety

At Domino’s, consumers may choose their toppings or add extra ingredients, making them more versatile. The type of pizza, whether vegetarian or non-vegetarian, handmade, thick and crispy, deep-pan, or traditional crust, determines the diversity of the food manufacturing process. Customers may order Veggie Supreme, Tremendous Beef, Original Cheese and Tomato, Texas BBQ, and Pepperoni Pizza as toppings. This indicates that the operating volume is considerable. Furthermore, Domino’s has revised operating tactics based on client input, which explains the wide range of products available in stores.

Variation

This component is related to the operation’s demand and changing features. Food production is closely linked to client product needs and the passage of time. For example, the preparation of deep pan and conventional crust pizza bases differs. Due to the presence of a single type of food, the pattern of variation is not diverse, implying that comparably steady operational needs might be created and performed in the company. The demand for Domino’s is minimal during the day, but it spikes at lunch and supper.

Visibility

Given the open kitchen structure that Domino’s has chosen, a customer opting for the takeaway format gets complete visibility of the production process. On the other hand, the operation also needs to meet the required level of transparency. For example, a consumer who selects home delivery has visibility once the merchandise arrives at their door. Clients may have specific, typical queries about the facilities’ hygiene standards, safe contact preparation, and disinfection safety practices without suitable and sufficient openness. Domino’s has adopted a distinct product or service mix, which is reflected in the company’s production line technique.

Given the importance of uniformity in preparing pizzas and other goods, Domino has opted to make it using an assembly line technique while retaining the flexibility of a batch flow process. In a Domino’s kitchen, the production process uses the homogeneity and efficiency of an assembly line approach while retaining the flexibility of a batch-type manufacturing process. It is worth mentioning that using an assembly line method enables Domino’s locations to handle higher quantities during peak hours.

Performance Objectives of the Operation

Quality

In today’s business, quality is the most critical performance goal that each organization must achieve. A high-quality product always meets its specifications. Domino’s adheres to food safety standards to ensure food manufacturing quality.

The product’s quality is adequate, and buyers are satisfied. Domino’s quality is consistent around the world. The product quality may need to improve since it is a quick food establishment. The educated personnel take good care of quality by using appropriate measures, such as wearing gloves and hats when cooking. Domino’s uses only fresh and high-quality ingredients.

Speed

It is determined by the number of consumers that visit a store. Food production is slowed during rush hour, although the system gets quicker during regular hours. Domino’s generally has a fast manufacturing rate, so consumers have a short wait time. Domino’s is affected by speed both within and externally. The internal effect of speed reduces costs, while the outward effect of speed provides clients with a speed advantage.

Dependability

Dependability is described as supplying goods and services to consumers on schedule. This makes the business reliable, and the consumer gains trust. Due to the rapid speed, it takes Domino’s extremely little time to deliver the order to the consumer.

As a result, Domino’s uses less time to deliver items to customers. Furthermore, all clients rely on the company’s pizza-making process, whilst the outlets rely on dough deliveries from supply hubs. Again, this is reliant on the availability and existence of raw resources.

Flexibility

Customers at Domino’s have the option of customizing their pizza toppings. In terms of delivery, Domino’s is highly adaptable. It offers the option of paying cash on delivery. Additionally, it is customer-friendly, with various sizes to pick from. The consumer has so much freedom that they may even pick the base for their pizza.

Costs

One of the primary operational goals is to reduce costs. Cost is the most critical level at which all businesses compete (Brown et al., 2018). Low prices draw in customers from all across the world.

Low-cost items are only achievable if production costs are low. All of the following criteria have an intrinsic impact on cost reduction. Domino’s manufactures on a vast scale, lowering the cost of the item. As a result, Domino’s features a low-cost menu that draws customers.

Domino’s Store Layout

Domino’s has a process-dominated retail structure in which similar operations are grouped as the product travels between stations. The integrated floor concept of Domino’s locations simplifies the movement of items and staff between stations, allowing capacity to be managed during peak hours and minimizing bottlenecks (Cost, Flexibility). The shop layout accommodates the typical peak-hour movement of goods and customers (Speed, Dependability).

The storage area is designed to hold ingredients for three days. The plan’s architecture maximizes the available space and equipment, enhancing team members’ skills and productivity while enabling them to adjust to varying output levels (Quality). In addition, Domino’s ensures adherence to health and safety regulations to provide safe working environments for its staff. The consistency of interior surface materials throughout all UK sites fosters a welcoming environment for staff and clients while enhancing the brand’s reputation (Quality).

Flow Process Critical Evaluation and Recommendations

The Process

Among the most common challenges encountered on the company’s manufacturing line is that the line needs to be balanced by nature. This is so since the time required for each operation varies, and because the process is not automated, individual team members’ efficiency results in an unequal workflow. These factors will likely result in inconsistencies and bottlenecks in the manufacturing line, especially during peak hours. Another significant concern is the need for a GPS-based guidance system for drivers. Hence, efficient on-time delivery primarily depends on individual drivers’ geographical knowledge to ensure delivery time.

Proposed Improvements and Challenges

Automation of the assembly lines is required to eliminate the inefficiencies brought on by the manual movement of goods along the line. Furthermore, having mobile phones with Bluetooth headsets and navigation systems would speed up delivery times and increase efficiency overall. However, implementing the above-proposed improvements comes with challenges, particularly for the managers and the staff at Domino’s. At Domino’s, one of the manager’s primary functions is to offer employees training. Every staff member must be conversant with the recognized methods of producing items and operating the equipment (Hales, 2019).

Automating the assembly line will involve replacing or upgrading the current manual line with state-of-the-art equipment. These machines come with modern technologies that may be unfamiliar to workers. Furthermore, drivers with GPS-guided vehicles must be updated with the technology. The manager will ensure that every employee has adequate knowledge and skill to operate this equipment. This will call for immediate training of the employees to ensure its effectiveness, which takes time, and time is money.

In addition, replacing the automation line will also involve a complete system shutdown to realize its effectiveness. This process tends to affect the company’s performance objectives, particularly dependability, flexibility, and cost. To the managers at Domino’s, the main challenges will be to ensure that the implementation of the system does not jeopardize the dependability and flexibility of the company while, at the same time, it is cost-effective. This is important since public image, trust, and perception are critical to a successful business. On the other hand, the staff will be required to adapt to the technology as soon as possible.

Conclusion

In conclusion, Domino’s UK is one of the businesses that has successfully and efficiently adopted adequate operations management methods. The business operation process at Domino’s includes input, transformation, and output activities critical to the company’s ability to deliver successful products and services to consumers: volume, diversity, volatility in demand, and visibility significantly impact Domino’s organizational operations. As a medium-high-volume firm, Domino’s provides well-known instances of low-cost, high-volume pizza production in a range of toppings to pick from based on the 4Vs framework.

The fluctuation in demand varies depending on the time, when there is visibility owing to using an open kitchen. Furthermore, the 4 V’s will assist the organization in meeting its performance targets related to cost, speed, quality, reliability, and flexibility. Based on the five performance criteria, it can be stated that Domino’s offers high speed, reliability, operational flexibility, and good quality while keeping costs low, owing to mass manufacturing. Although the company’s process layout is well-structured, modifications are needed to increase its efficacy.

Reference List

Anand, G. and Gray, J.V., 2017. Strategy and organization research in operations management. Journal of Operations Management, 53, pp.1-8.

Brown, S., Bessant, J. and Jia, F., 2018. Strategic operations management. Routledge.

Clegg, B., 2019. Improving systemic success factors in a university to achieve more effective and efficient operations: Using the PrOH modeling methodology. Business Process Management Journal.

Hales, C.P., 2019. What do managers do? A critical review of the evidence. Managerial Work, pp.263-290.

Kumar, N., Singh, P., Shan, L.P., Kee, D.M.H., Mei, L.T., Ying, N.W. and Zhi, O.Y., 2021. A case study on Domino’s business survival strategy during the Covid-19 pandemic. International Journal of Tourism and hospitality in Asia Pacific (IJTHAP), 4(2), pp.28-41.