Introduction

Fermented diary products are considered to be “healthy products” that help improve digestive system function. These products have been known in different cultures and have been consumed all around the word comprising an important part of diet of many people in different times. Sour cream, yoghurt, kefir, cheese, white soft cheese and many others products are now easy available at supermarkets and are considered to be one of the most popular products.

According to Ramesh C. Chandan (2006 ), “the industrial production of fermented diary is relatively new production of present days. It has taken a significant position of consumer acceptance and growth through the world”. One of the most popular fermented dairy is yoghurt. The yoghurt market is growing rapidly. In this paper we are going to investigate the fermentation of yoghurt, the stages of its production (taking into consideration the fact that experimental yoghurt is different from the commercially prepared one. In addition, we are going to determine the pH and titratable acidity of milk and fermented milk.

Yoghurt Experimental

Yoghurt is a milk product manufactured through fermentation of milk. The manufacture of yoghurt dates back to many centuries ago. It is known and perceived as a healthy product which benefits are numerous. As Corine Guerin-Danean et all state in their article, ” Ingestion of fermented dairy products induces changes in the equilibrium and metabolism of the intestinal micro flora and may thus exert a healthful influence on the host” (p. 111).

Moreover, yogurt is a source of various minerals and vitamins. Thus, it goes without saying that yogurt is very useful for one’s health. According to a Persian legend, Abraham owed his longevity to yoghurt. In more recent times, Emperor Francis I of France was said to have been cured from a debilitating illness by consuming yoghurt made from goat’s milk (Robinson 2007). Fermentation improves the digestibility of milk in general. Milk lactose is partially broken down to lactic acid; therefore, lactose intolerant people can better tolerate yoghurt than fresh unfermented milk. During fermentation milk protein undergoes some structural changes. The fermentation culture is made up of ‘good’ bacteria, which has a health promoting action in the gut, with antimicrobial actions and thus are able to displace putrefactive micro-organisms.

Yoghurt is made from milk, mostly cow’s milk, but also goat or ewe (sheep’s) milk. Yoghurt is normally made thicker through the addition of extra milk powder or concentrated milk. The production of yogurt is based on strains Lactobacillus bulgaricus BGPKM1 and Streptococcus thermophilus BGTMS2. These are the basic ingredients of a “standard yogurt”. So, during the yogurt production, the milk is pasteurized at a higher temperature and longer time (85oC for 20 mins) if compared to normal pasteurized milk (75oC for 15sec), in order to make sure that all pathogens are killed and cannot grow during fermentation, as well as coagulate the whey protein to help form a firmer curd.

The heat treated milk is cooled to the fermentation temperature (42 – 44oC) and inoculated with either the standard yoghurt bacteria ie. Lactobacillus bulgaricus and Streptococcus thermophilus, or probiotic yoghurt bacteria, such as Lactobacillus acidophilus and Bifidobacterium sp. The bacterial culture ferments the lactose into lactic acid which reduces the pH, eventually reaching pH 4.5. The acidity coagulates the casein proteins, forming a gel which thickens the yoghurt consistency. The bacterial culture also creates fermentation of by-products contributing to the yoghurt flavor through the hydrolysis of the fats or proteins, plus it forms polysaccharides which contribute to the viscosity of yoghurt.

Yoghurt is available in a number of different forms:

- Set yoghurt – milk with added milk solids (milk powder or milk concentrate) is fermented in tub with a firm texture, known as the “natural” yoghurt. It is available at low fat, full fat (3.5%), or Greek with 10% fat.

- Stirred yoghurt – milk with added milk solids is fermented in a large vat, slightly cooled then fruit and thickeners are stirred through, packaged and chilled. It is available in non fat, low fat or full fat, in a wide range of flavors.

- Drinking yoghurt – fermented in large vat, lower solids, stirred, with fruit and flavors added.

Experimental Objectives

- To investigate the fermentation of yoghurt.

- To determine the pH and titratable acidity of milk and fermented milk.

Methodology

Yoghurt fermentation

Work in groups of about 2 persons

- Prepare fermented milk

- Measure 150 ml UHT skim milk into a beaker (pre-warmed to 45oC)

- Add 0.5 g of freeze dried yoghurt culture to milk, mix with a spoon. Yoghurt culture consists of Lactobacillus bulgaricus & Streptococcus thermophilus (delvo yog ty-17A).

- Cover with aluminium foil, place into warm water bath at 44oC and leave for 1 – 1.5 hr.

- Measure pH and titratable acidity of UHT skim milk, commercial yoghurt & fermented milk

- Observe consistency and aroma, before and after fermentation.

Titratable acidity

The titratable acidity is measured by the amount of a standard alkali needed to neutralize the acid in a food sample to the point of color change of an indicator. Phenolphthalein (endpoint pH 8.1) is the indicator generally used in the titration of food products.

Procedure

- Fill burette with 0.1M NaOH using a small funnel, have small beaker underneath to collect excess, ensure that there are no bubbles and that the burette runs easily.

- Weigh 10g milk or yoghurt sample (record weight), add 25ml distilled water in a small conical flask to dilute and help make endpoint easier to detect. (Adjust aliquot of sample depending on expected acidity).

- Add a few drops of phenolphthalein indicator to the mixed solution in the flask.

- Record level of burette (first reading). Titrate sample with 0.1 M NaOH to a permanent rose pink color, record final level of NaOH (second reading).

- Subtract first reading from second to calculate the NaOH used.

- Replicate the test 3 times to ensure that your results are accurate.

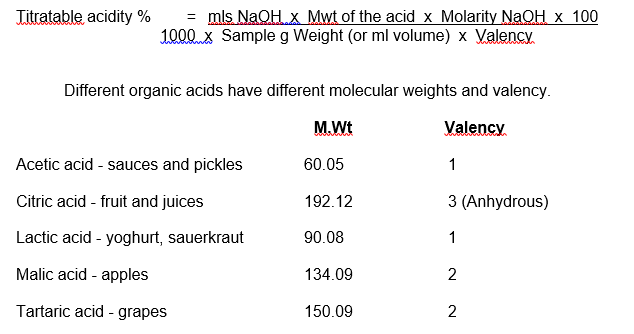

Calculation of titratable acidity

Results

Table 1. Titratable acidity.

Table 2. Titratable acidity and pH measurement.

Table 3. Consistency and Aroma assessment.

Equipment and consumable list for laboratory set-up

- UHT skim milk (No Name Brand)

- 150ml x 12 x 2 (control & test) = 4 L

- Yoghurt culture freeze dried – delvo yog ty-17A from DSM, Moorebank (DSM Lactobacillus bulgaricus and Streptococcus thermophilus)

- Commercial “traditional” skim yoghurt – direct set e.g. (Paul’s 500 g Natural) 50g per grp x 12 = 1 kg

- Distilled water wash bottles 1 per bench, plus at each pH meter.

- Standardised 0.1M NaOH (50ml x 12 = 0.6 L minimum; Plus at least 1L spare. )

- Phenolphthalein indicator, 1 per titration set-up. (12)

- Aluminum Foil

- Warm water baths at 44oC – enough to fit 12 x 200 ml beakers

- pH meters (and calibration buffers) – 4 or more

- Balances – 4 or more

- Titration Burettes – 12 set-ups – checked for operation

- 200 ml Beakers – 3 per set-up (36)

- 100 ml Beakers – 1 per set-up (12)

- small funnels – 1 per set-up (12)

- Conical flasks 100ml or 200ml – 3 per set-up (36)

- Disposable Plastic pipettes for sub culturing or measuring milk

- 10ml pipettes (TA%) – 1 box available

- 25ml measuring cylinders – 1 per set-up (12)

- Spoons for measuring yoghurt

- Micro-wipes, paper towels,

- Plastic wrap to cover beakers during fermentation.

Discussion

The results of this experiment show how yoghurt is manufactured. The difference between fresh milk and fermented milk is also apparent. In order to prepare yoghurt, a fresh milk should be fermented using a certain type of bacterium. The results that we presented in the table 2 show a difference in the titratable acidity and Ph between fresh milk, fermented milk, and commercial yoghurt. In addition, our experiment has proven that fermented milk is more acidic while commercial yoghurt has the highest titratable acidity. This can be attributed to the fact that bacterial growth is strictly regulated in industrial production of yoghurt these days. It should also be mentioned that the introduction of bacteria in fermented dairy production industries is also highly controlled.

The commercially prepared yoghurt has a strong aroma. It is achieved by adding either natural or artificial flavouring agents. The chemical and flavors are used in commercial production of yoghurt, and they do not alter the nutritional value of yoghurt but only enhance their palatability. Flavor and color of yoghurt influence the choice of consumers. This is why the commercial yoghurt comes in different colors and flavors in order to satisfy the preferences of modern consumers.

Conclusion

The commercially prepared yoghurt differs from the experimental yoghurt. Commercial yoghurt is made under a highly controlled environment. The chemicals that are used in the preserve commercially prepared yoghurt may affect the quality of the product. There is a need therefore for a complimentary research to establish the impact of chemical materials, which are added to commercial yoghurt, on consumers and their health.

References

Guerin-Danan, C, Chabanet, C, Pedone, Ch, Popot, F, Vaissade, P, Bouley, C, Szylit, O, & Andrieux, C 1998; “Milk fermented with yogurt cultures and Lactobacillus casei compared with yogurt and gelled milk: influence on intestinal microflora in healthy infants“, The American Journal of Clinical Nutrition. no. 67, pp. 111–7. Web.

Ramesh, C 2006, Manufacturing yogurt and fermented milks, John Wiley & Sons, New York. Web.

Robinson, RK 2007, “Fermented Milks: Yoghurt Types and Manufacture”, Encyclopedia of Dairy Sciences, pp. 1055-1058. Web.

Robinson R. K 2007, “Fermented Milks: Yoghurt, Role of Starter Cultures”, Encyclopedia of Dairy Sciences, pp. 1059-1063. Web.