Summary

The industrial landscape of the 21st century is changing under the influence of various contemporary factors. Historically, humanity’s approach to most of its activities across different sectors has aligned with the development of societal, economic, and technological aspects. Today, the third component has taken a leading position, as progress dictates a paradigm shift in industrial development. This age is characterized by the intense digitalization of most processes that occur on two levels. First, existing aspects of business see an influx of new technology that preserves the processes while altering the way in which they are executed. Second, new, previously unseen variables are introduced, modifying the landscape of supply and distribution chain management profoundly.

Therefore, today’s industrial landscape is characterized by the profound influence and use of modern technological solutions. This tendency has acquired its specific name of Industry 4.0, reflecting the scale of transformation that can be described as the fourth industrial revolution. While the concept itself has become well-established in professional literature and practical experience, its specific elements remain in the state of further elaboration. This dissertation addresses supply chain management as an integral component of Industry 4.0 in its present condition. More specifically, it aims to determine the exact nature of how digital transformation of the operational environment affects supply chain management, as perceived by academic experts and practicing managers of the field. Chapter One introduces the scope of the research, along with its primary elements, objectives, and questions to address.

Research Statement

The primary purpose of the present research is to explore the nexus between advanced technological tools characteristic of Industry 4.0 and supply chain management as its integral component. This area of knowledge is essential for the effective development of industrial relations within the current paradigm shift of profound digital transformation that occurs on all levels, from individual small business to entire industries across national borders. The practical significance of the study is considerable, as the overall discussions surrounding Industry 4.0 appear too generalized to dictate a similar paradigm shift in supply chain management (SCM). Being an integral component of the overall industrial framework, SCM retains its particular priorities and regulations that deserve additional exploration in light of the Fourth Industrial Revolutions. Spoken differently, the aspects that are highlighted for Industry 4.0 do not necessarily reflect the current state of the subject matter for supply chain management. Technological solutions that are found highly efficient for product distribution may simply be irrelevant for SCM and vice versa. As such, the core principles of supply chain management dictate the direction and priorities of the present research.

In a way, this dissertation is approached as an origin point of more profound discussions that will provide a comprehensive framework upon which further research can be based. The design of the study reflects the key synergy of theoretical findings and practical application. It is channeled through the methodological combination that is used for it. The theoretical component is ensured by a rigorous examination of the contemporary body of academic literature. Considering the novelty of the subject, the research undertakes to synthesize the relevant information that is scattered across the current body of knowledge. Through the examination of key parts present in literature, the dissertation is to provide a uniform framework of reference that is evidence-based and informed by the leading experts’ opinions.

Next, the practical component ensures the applicability of the research to the actual environment of today’s supply chain management. The design implies that the theoretical discussions are equally valuable with the views of the managers engaged in modern SCM on a daily basis. The dissertation embeds the contribution of SCM experts into its synthesized framework, drawing comparisons between theoretical perceptions and actual situations on sites. This approach to research is expected to prove its efficiency through the synergy of theory and practice, transforming overall findings into a specific, useful paradigm that will reflect the current state of supply chain management in light of the Industry 4.0 development.

The interest toward the subject matter is justified by its extreme importance for the functioning of the globalized society. In the 21st century, markets have been growing, reaching unprecedented levels of scale and scope within the global economy. With the development of instant communication and rapid transportation, a variety of supply and distribution processes became facilitated. Thus, most businesses have grown accordingly, reaching nationwide or even international levels. In fact, it has never been as feasible to operate global supply and distribution networks across state borders and continents. In the current economic environment, most companies aspire to reach an international level, winning their shares of multiple segments of the globalized market. As a result, consumers benefit from better selection of products, while corporations see major contributions to the economic aspect of business.

However, such networks may be difficult to operate from the perspective of efficiency. On the one hand, modern technological solutions serve to improve communication, transportation, storage, and utilization of products. The overall conditions of the globalized market are easier, as many complex tasks are now being handled by technological tools with higher computing power, as well as analytics and prediction potential. On the other hand, the variety of these solutions expands along with the continuous digital progress. The mere reliance on advanced technology does not necessarily translate into a digital transformation. For this complex transition to occur, the solutions are to be used wisely and efficiently. This situation is only possible through the profound exploration of available options, analyzing them in light of specific industrial objectives faced by the particular element of the overall chain.

In this regard, the sphere of SCM appears to be lacking attention and coverage within the framework of Industry 4.0. The present discussion is generalized, and it does not focus on the details of what supply chain management needs to achieve in order to complete its digital transformation in a true sense. The present research aims to eliminate this gap in knowledge, addressing supply chain management as a specific element of the overall industrial revolution that is observed today on a global level.

Research Question and Objectives

As established within the contemporary body of literature, the efficient implementation of smart Industry 4.0 tools for supply chain management requires more profound knowledge of its attributes’ applicability in this context. Therefore, the projected research will address the following research question:

- What specific Industry 4.0 tools are applied in supply chain management?

To provide evidence-based answers to the specified research questions, the proposed study aims to accomplish several research objectives:

- Review the current body of knowledge to understand how Industry 4.0 and supply chain management interact;

- Synthesize a fundamental theoretical framework through the review of contemporary literature;

- Obtain practical knowledge of the Industry 4.0 tools implementation in supply chain management;

- Appraise the practical implementation of the Industry 4.0 tools in supply chain management in comparison to the theoretical framework of reference;

- Synthesize practice-oriented guidelines for the Industry 4.0 tools use in supply chain management;

- Outline the direction of further research within the specified area of knowledge.

Background of the issue

Industry 4.0 is a highly complex notion that serves to reflect the influx of innovative technology into the various spheres of human activity. Tjahjono et al. (2017) state that the term itself was coined to describe the dawn of the so-called Fourth Industrial Revolution. New solutions enable the formation of global networks that are assisted by the unparalleled computing capacity of the equipment (Ardito et al., 2019). In a way, Industry 4.0 is a unique nexus of human expertise and superior technology that complement each other, enabling smart production and supply management. In terms of the SCM, the impact of the new industrial reality is a concept that requires in-depth analysis. Tjahjono et al. (2017) note that the emphasis of modern supply chain management is laid on the transparency of all phases from the order placement to its ultimate completion. Theoretically, smart tools enabled by Industry 4.0 are to contribute to this objective through better assessment, communication, transportation, and evaluation opportunities.

On the other hand, the topic under review is highly complex and broad, which impedes the development of precise theoretical frameworks and practical guidelines. In its current understanding, it encompasses an array of industries and tools that enhance their operational efficiency. For example, the list provided by Hofmann et al. (2019) comprises IoT, Internet of Services, multi-agent CPS systems, big data, real-time algorithms, blockchain, and other solutions that can be implemented within the scope of Industry 4.0. At the same time, Shao et al. (2021) add that these principles are adequately developed for marketing and production operations today, whereas their application in supply chain management remains at the stage of “infancy” (para. 1). As such, rigorous research is required to advance the understanding of Industry 4.0 and its impact on the SCM. While the necessity of smart solutions is not questioned within the proposed research, the examination of specific tools and their contribution to supply chain management appears indispensable. Ultimately, the key problem within the field is the lack of complete understanding of which Industry 4.0 instruments are more efficient for the SCM.

Theoretical Significance

From the theoretical perspective, the contribution of the present dissertation consists of synthesizing the dispersed information that is presented within the contemporary body of academic knowledge. First of all, supply chain management is an integral component of overall industrial activities that shape the global economy. Indeed, Industry 4.0 is a complex notion that includes a variety of elements that remain interrelated within its framework. For the proper functioning of industrial processes, supply and distribution links must function in a synchronized manner that also aligns with the strategic vision and operational execution in light of external and internal variables. However, this interrelation does not imply that the understanding of Industry 4.0’s principles suffices to arrange each of its elements in the correct manner. On the contrary, a deductive approach to theory is required in order to build a resilient economy, capable of yielding profits for all parties involved. By this deductive approach, the present research implies a transition for the whole to its elements in a theoretical sense.

At present, a large part of the academic body of literature concerns Industry 4.0 as the core notion. While this approach is justified by the novelty of the overall subject matter, a paradigm shift toward its specific elements is needed to advance the field and sustain the economic growth. As long as the discussion is limited to Industry 4.0, it remains too generalized to provide a meaningful framework of reference for the field of supply chain management. In other words, a major theoretical gap is observed, since this framework leaves serious blank points for SCM specialists. Having to apply the generalized perspective on Industry 4.0 to supply chain management leads to a variety of interpretations that create inconsistencies within the field. This research aims to eliminate the gap by providing a single framework that synthesizes such dispersed experiences into a universal paradigm upon which the sphere of SCM can rely for further development. As a result, the professional area will benefit from the clarity of its theoretical component, yielding major improvements and quicker rates of its contribution to economic growth.

Practical Significance

From a practical perspective, the history of academic research has seen numerous examples of inconsistencies between theory and practice. This idea is not limited to the matter at hand, or industrial management studies at all. In fact, the inconsistencies in question occur across a variety of spheres, from healthcare to military commandership, as instilled by normal psychological and social processes. First of all, the theory-practice gaps may occur because of the novelty of the subject. In most cases, theory is the first step toward a full understanding of a notion, which creates ground for the further practical implementation of the ideas. Theorists describe new processes that may appear sporadically within the industry, they attribute meaning and order to otherwise chaotic developments.

As long as the stage of theoretical description is not completed, the domain of practice has no framework of reference to rely on, and the inconsistencies persist. Second, even the developed theoretical paradigms take time to implement. In other words, a paradigm shift in theory happens before a similar transition in practice. Finally, the inconsistencies may be caused by such a notion as feasibility. Spoken differently, the processes and principles that appear logical or efficient on paper, may not necessarily be coherent with the practical experience.

In the case of SCM, people who actually work on these tasks within Industry 4.0’s framework on a daily basis may hold different opinions on the efficacy and usability of specific solutions, as compared to the theoretical perception. The design of the present research seeks to eliminate the gap by taking into consideration both perspectives on an equal basis. The developed theoretical framework is subjected to a cross-examination with the insights provided by professional experts in a successful attempt to find common ground between the two major domains of research. As a result, the final theoretical framework is adapted to the practical environment, providing guidelines that are not only research-backed but also tested in a practical environment. Thus, further researchers and experts can rest assured of its efficiency and applicability.

Benefits of the study

As can be inferred from the presented information, this research is expected to provide an array of benefits for the understanding of supply chain management in its modern form. The primary enabler advantages consist of an effective unity of theory and practice that drives the directly of this study. The research does not view these two key components as separate entities with their own laws and principles. Instead, theory and practice are viewed as inseparable facets of the same entity within the context of supply chain management. More specifically, the research produces a single, uniform framework of reference that is theoretically grounded in the contemporary body of academic literature, while being adjusted to the practical experiences of current experts engaged in SCM procedures. This way, both facets of unity work in a combined effort to help the sphere of SCM complete its digital transformation and enter the age of Industry 4.0.

In this regard, the principles of supply chain management are not opposed to their mother-concept of industrial activities. On the contrary, SCM is viewed as an integral component of Industry 4.0 that works in sync with its other elements, ensuring the sustained economic growth that benefits all parties involved in this exchange of goods services. However, the research adapts the postulates of Industry 4.0 to the specific tasks faced by supply chain managers in order to introduce the benefits of digital transformation into the framework of contemporary economic relations. In light of the novelty of the subject and the theoretical gap currently associated with it, the present research will make a meaningful contribution to the understanding of how supply chain management should develop in the age of the fourth industrial revolution.

Validation and limitation of the study

The validity of the research will be enabled by several points. First of all, the sample of the research, in both theory and practice, will serve to reflect a diversity of perspectives and mitigate the impact of researcher and participant bias. Second, the nexus of up-to-date knowledge and current practical insights will solidify the relevant nature of the project. Third, the study will be conducted in compliance with the principles of academic integrity and research ethics. All participants of the practical phase will be informed of the objectives and expected outcomes of the project, providing their informed consent. The interviewees will remain anonymous, as well, which will simultaneously contribute to the objectivity of responses and ethics of the project. In addition, all theoretical knowledge will be properly attributed to each source of information. As for the limitations of the envisaged study, the main one is related to its qualitative design. While it is justified by the early development stage of the body of knowledge, this project will serve as the foundation for the subsequent studies required to provide detailed practical guidelines.

Literature review

Introduction

In light of the novelty of the discussed concept, namely supply chain management in the age of Industry 4.0, a strong theoretical background is required prior to embarking on the practical investigation of the subject matter. A review of the literature has been completed as an integral component of the present dissertation, aiming to assert the theoretical foundation of the discussion. Furthermore, this format accounts for one of the key components of the overall methodology of the project. More specifically, this review reflects the theoretical aspect of the prior knowledge accumulated within the framework of the present research. Preliminary investigations have revealed that this knowledge lacks particular consistency, which is explained by the overall recency of the central issue. As established prior, the core of the discussion revolves around Industry 4.0, in general, providing an overarching overview of the concept. At the same time, Industry 4.0 contains an array of specific components, among which SCM is a prominent one. Each of these components adheres to its own rules, prioritizing different benefits of the digital transformation. As such, a deductive approach, in which the body of research proceeds from generalities to particularities is required.

The review of the literature provided within the scope of the present research aims to address this situation by synthesizing otherwise scattered information within the contemporary body of knowledge. More specifically, preliminary investigations have shown that modern works contain valuable information regarding the benefits and applicability of Industry 4.0 tools for supply chain management. However, this data lacks precision and systematization, remaining an element of the overall discussion rather than SCM-specific research. In this regard, the scope of the literature selection and examination procedures has been considerable, comprising a series of queries that address different components of the overall problem. This particular chapter serves to solidify the background of the discussion, providing key information and variables for the subsequent development of the topic. The findings are categorized in accordance with their thematic groups. When combined, these thematic groups create a full image of supply chain management in light of Industry 4.0 today. Based on them, an overall theoretical framework is to be developed and applied in Chapter 4.

Industry 4.0 as a concept

The identification of Industry 4.0 as a concept is necessary to establish the general context of the discussion. The work completed by Ghobakhloo (2020) explains the logic behind this term and its understanding. More specifically, the author elaborates on the numerical part of the notion, which implies the onset of the fourth industrial revolution. As per the title, an industrial revolution implies a major shift in the understanding and process of industrial relations in all their complexity. This shift can be conditioned by a series of factors, among which the emergence of new technological solutions is one of the most prominent aspects. Ghobakhloo (2020) notes that an industrial revolution is characterized by fundamental transformations and exponential development that introduce a new reality of the business environment. With new means of production, distribution, and communication becoming more prevalent, the landscape of the economy changes drastically. As a result, companies are required to accept the new reality and adapt to it, as failing to do so will entail dire consequences for the organizational performance. The present environment meets the aforementioned criteria, making Industry 4.0 a reasonable, well-grounded notion.

Considering the importance of Industry 4.0 for the global economy, this concept is being increasingly recognized on a worldwide scale. According to Rojko, this notion has been adopted by the German government, making the new paradigm shift acknowledged and backed by the authorities. This approach reflects the general understanding of Industry 4.0, implying that scholars and governments’ perspectives align on this subject matter. As Rojko (2017) notes, Industry 4.0 as an initiative consists of a rapid and profound digitalization of the economy on a profound level that will encompass production, logistics, distribution, and customer relations. The development of the technological solutions used within industries creates new opportunities for the market players. Customization and personalization of experiences are some of the key attributes discussed within the framework of Industry 4.0. Companies no longer need to rely on a general image of the target audience. With new avenues of customer interaction and communication, bespoke experiences become the key descriptors of flexible, thriving companies of the 21st century. The organizations that can tame this technology to build meaningful links between them and their audiences are more likely to master the environment of Industry 4.0.

According to modern researchers, the tools of Industry 4.0 respond to the elevated technological needs of today’s economic activities. Vaidya et al. (2018) specify this idea by referring to the concepts of digitalization and “intelligentization” as the prioritized outcomes of the industrial development of the 21st century. In today’s environment, these two notions deserve additional exploration. In the case of digitalization, the situation is clearer, as the notion is widely spread in the economic discourse. It implies the introduction of new technological solutions that can be implemented to facilitate the processes that were otherwise longer or less convenient. However, this term is often confused with a related notion of technological transformation. Vaidya et al. (2018) note that the confusion is to be addressed and avoided. More specifically, digitalization is the process of adding technology to existing business processes. On the contrary, digital transformation is about the way business is done, in general. It is not limited to the modification and improvement of existing processes: it creates new ones.

Finally, the term intelligentization appears interesting for the subject matter. It highlights another key aspect of the subject matter: business processes are to be not only quick or technological, but also smart. Digitalization for the sake of digitalization is counter-productive and often detrimental to organizational performance. Instead, transformations need to be justified, pointed, and efficient in order to help the industry reach a new level that corresponds with the principles of 4.0. Thus, intelligent, reasonable solutions that actually make the work more efficient and productive.

The importance of Industry 4.0 as an actual industrial revolution was bound to attract increased attention of researchers and experts across the globe. One of such studies was completed by Oztemel and Gursev (2020) who explored the notion in all its varieties that are present in today’s economic environment. The authors acknowledge that the subject matter is not exactly recent per se. Indeed, technological advancement in the context of industrial performance has remained a topic of heated discussions since the dawn of the high-tech era in the late 20th century. Nevertheless, the degree of the new solutions’ influence on the economy struggled to pass the revolutionary threshold until recently.

Once the progress reached a truly global status with new tools being capable of instilling lasting and profound transformations, the fourth industrial revolution became a reality. However, the discussion by Oztemel and Gursev (2020) remains centered on the means of production as the backbone of the economy. This approach reflects the imperfection of contemporary Industry 4.0 research. While production is an essential component and a vital business process, it is impossible to consider it the definitive representation of Industry 4.0. Supply chain management, customer relations, and distribution networks are equally important, which is why the deductive exploration of the subject matter is essential for advancing the knowledge on it.

The aforementioned threshold between overall progress and an industrial revolution reflects the depth of the transformations that are associated with Industry 4.0. Most works within the contemporary body of knowledge are in accord regarding the comprehensive and profound impact of Industry 4.0 on the global community. Aside from the technological and economical benefits experienced by the market players, there are social and environmental effects, as well. For example, Bai et al. (2020) review this matter as an essential enabler of sustainable economic practices that are needed for the preservation of the future of humanity. This concept maintains an active presence in today’s discourse surrounding industrial activities.

Within this context, economic practices, including SCM, aside from being efficient, profitable, and technologically enhanced, also need to be mindful of the environment and the Earth’s resources. In this regard, Bai et al. (2020) consider economic sustainability as a key benchmark for compliance with the Industry 4.0 principles. This concept is applied and observed across different contexts, including – but not limited to – “automotive, electronics, food and beverage, and textile, apparel and footwear industries” (Bai et al., 2020, para. 1). With the use of Industry 4.0, complex hybrid solutions are introduced that bring a new level of sustainable efficiency into their industries. As a result, the four components that define Industry 4.0 can be formulated as follows: efficiency, technological superiority, profitability, sustainability.

Overall, the spread of Industry 4.0 solutions remains truly global, which aligns with its perception as the fourth industrial revolution. New technology is not only revolutionary, but comprehensive, improving people’s work and personal lives on various levels. The research completed by Javaid et al. (2020) is a case in point, as it describes the application of Industry 4.0 tools in the age of the COVID-19 pandemic. The outbreak of the novel coronavirus has paralyzed economic activities, meaning that industrial entities had a strong incentive to combat this emergency on a global scale. The tools that are normally associated with the transition toward Industry 4.0 have found their application in this difficult period serving social, healthcare, trade, and communication purposes.

The Internet of Things technology that normally helps industries track their performance across the supply chain or determine their customers’ preferences have been repurposed to track the infection spread and support containment protocols. Detection and diagnosis of COVID-19 have also been facilitated with the help of high-tech solutions (Javaid et al., 2020). Through these activities, industries and society have found a positive common ground for cooperation that contributes to the formation of mutual trust. In addition, the extraordinary contribution of Industry 4.0 to the global fight against COVID has solidified its position as the next logical step of industrial evolution.

As a result, the development of Industry 4.0 aligns with the expectations in terms of their comprehensiveness and globality. As formulated by Xu et al. (2018), these rapid advances mark the transition to a brand new generation of industrial activities in production, logistics, and distribution assisted by modern technology. Their work refers to governmental initiatives that support the recognition of Industry 4.0 as a new reality. More specifically, Germany’s future-oriented High-Tech Strategy 2020 Action Plan directly embeds Industry 4.0 as one of the overarching goals of the country’s strategic development. Furthermore, China, as one of the world’s leading economies, has laid a substantial emphasis on these next-generation principles. According to Xu et al. (2018), the country’s long-term plans revolve around its status of the world’s greatest workshop through a nexus of technology and expertise. Industry 4.0 is a major enabler of this plan, providing the nation with sufficient resources to attain said level. The policy includes such smart tools as the Internet of Things, blockchain, Enterprise Architecture, cloud computing, and industrial data integration. The existence of these strategic programs reflects the key status of Industry 4.0 advancements.

As the investigation of the contemporary body of literature shows, Industry 4.0 discourse is often limited to abstract suggestions and forecasts. This idea is developed by Dalenogare et al. (2018) who mention that the body of research confirms the status of Industry 4.0 as the next stage of the global industrial development. However, aside from the philosophical reasoning that surrounds the concept, the authors acknowledge the lack of precision and specific details regarding the input of the new solutions. In other words, “little is known about how industries see the potential contribution of the Industry 4.0 related technologies for industrial performance, especially in emerging countries” (Dalenogare et al., 2018, p. 384). This idea outlines the priorities of Industry 4.0-related research, which is expected not only to describe but to prescribe, as well. It does not suffice for modern companies to know that a digital transformation is occurring and they are expected to follow the lead. They should also understand why this is happening and why there is a necessity of said transformation.

For this purpose, researchers are encouraged to look beyond definitions and descriptions, analyzing the subject matter from a perspective of its profound processes. This approach is supported by Culot et al. (2020), whose study ventures “behind the definition of Industry 4.0” (p. 1). First of all, the authors of the article establish the fact that there is no common definition of the fourth industrial revolution that would be shared and approved on a global level. Spoken differently, the contemporary body of research fails to seize the essence of Industry 4.0 and formulate its principles concisely and in a uniform manner. Culot et al. (2020) refer to a range of concepts that are perceived as synonymous to the subject matter: digital transformation and smart manufacturing. The former case is questionable as an equivalent, as Industry 4.0 appears to be more specific, reflecting the intersection of digital transformation with industrial business processes. Simultaneously, smart manufacturing is an unjustified concretization of the main principle, as Industry 4.0 comprises more than just the production of goods.

As a matter of fact, such concretizations are the primary cause of the knowledge gap that is identified within the scope of the present research. When the term Industry 4.0 is discussed, scholars and experts are prompted to consider manufacturing in all its forms and details. Nevertheless, modern industrial principles extend beyond the process of production, making supply and distribution chains equally important elements of the overall chain. Most definitions considered within this review agree upon the importance of vertical and horizontal integration of business processes as the key descriptor of Industry 4.0. Such ideas are expressed, for example, by Dalenogare et al. (2018) and Vaidya et al. (2018). Tang and Veelenturf (2019) distinguish logistics as an essential component of Industry 4.0 tools application in today’s business environment. They refer to these instruments, such as blockchain, drone technology, robotics, and AI, as the enablers of social and economic value that contribute to the adoption of Industry 4.0 principles. This discussion strengthens the position of supply chain management as an integral component of this transformation that is often disregarded in favor of manufacturing.

Digital Transformation

As established within the Industry 4.0 discussion, the subject matter is usually viewed in association with the concept of digital transformation. From one perspective, these two notions refer to a similar agenda that consists of introducing revolutionary high-tech solutions into business processes, making them efficient and economical. Industry 4.0 is all about advanced technology that has a comprehensive effect on the development of social, economic, and environmental values. Industry 4.0 creates a positive relationship between businesses and their environment, acknowledging the complexity of this interaction and contributing to the horizontal and vertical integration patterns through the application of advanced tools. Simultaneously, digital transformation creates a new business environment, in which digital solutions work toward better efficiency, convenience, and profitability of business activities. In a way, the two notions appear synonymous, referring to the revolutionary improvement of the entrepreneurial landscape. However, the degree of similarities is to be determined within this section.

In light of the prevalence of digital transformation discourse, it appears relevant to discuss this matter in terms of its definition, application, and intersection with the principles of Industry 4.0. The work provided by Crittenden et al. (2018) is devoted to this particular subject, which is presented as a definitive feature of today’s environment. The authors compare digitalization to a tsunami that swiftly covers most areas of human activity, introducing new solutions and rendering the existing paradigms obsolete. However, the velocity of this change often acts as a disruptive factor that prevents industries from fully appreciating its potential. Technology changes the way in which operations are completed and strategies are developed, but these transformations are often completed without a proper understanding of the mechanism. In this regard, digital transformation is not only about technology per se. As concluded by Crittenden et al. (2018), a true digital transformation occurs when new solutions are exposed to critical thinking, analysis, forecasting, and planning. Only through a thoughtful, informed implementation process, do digital solutions reveal their potential and instill meaningful, lasting transformations.

In fact, this discussion outlines the first core argument against the synonymity of digital transformation and Industry 4.0. For Crittenden et al. (2018), digital transformation is found everywhere, permeating most spheres of human activity. It is not limited to the work environment, production, or distribution. On the contrary, digitalization changes the way in which people not only work, but also live, think, and behave. It encompasses leisure and house chores, while becoming a major component of contemporary education. The same cannot be said about Industry 4.0, since it revolves exclusively around the patterns of economic relations, from product manufacturing to end consumer interaction through supply and distribution chains.

Of course, the global and comprehensive nature of digitalization makes its impact observable in the case of work and business environments. Balsmeier and Woerter (2019) provided an overview of digital transformation’s effect on this particular segment. These authors confirm that the rate of digitalization has attained the level of a “full swing”, introducing changes at an unprecedented pace. For production and distribution, this transformation usually consists of the extended process automation, which means that many tasks that require lower qualifications are now delegated to robots and computers. Spoken differently, this approach implies the use of artificial intelligence, robotics, blockchain technology, and other smart tools that are usually perceived as the descriptors of Industry 4.0.

Thus, there is a strong area of intersection between the two notions, which equally applies to supply chain management as an integral component of Industry 4.0. Interestingly, the impact of digitalization is not perceived as inherently positive by Balsmeier and Woerter (2019). They note that the replacement of lower-qualification labor by technology may cause a global job shortage, undermining the purpose of I.4.0 in terms of creating social value. This idea emphasizes the role of critical thinking and analysis, confirming that changes should not be introduced for the sake of a sense of progress. They need to be informed and based on actual consideration of its impact on the field. Hence, this analysis is what separates digital transformation from Industry 4.0.

At present, logic, analysis, and reasoning behind the introduction of digital solutions are not always guaranteed. This way, the social impact of the transformation is barely measured, leading to poorer outcomes in a broader, extra-industrial context. As a result, digital transformation faces reasonable concerns regarding its feasibility and impact, as described by Kwilinski et al. (2020). According to them, evidence suggests that digitalization of the European Union increases the risks of poverty and social exclusion in the region. Such an outcome is caused by the fact that many organizations and entire nations pursue digitalization without a full understanding of its essence. For some, the use of advanced tools per se suffices to create this sense of fulfillment. At the same time, when digitalization is executed correctly, it accounts for a lower risk of poverty and social inclusion, as all elements of the chain work in an integrated manner toward a common goal (Kwilinski et al., 2020). This idea aligns with the crucial role of critical thinking in digital transformation that is described earlier. Modern solutions are only efficient when applied with a full understanding of their potential and feasibility.

The presented evidence establishes digitalization as a broad concept that exists above the industrial context. It is not limited to manufacturing and supply chain management, but has a direct influence on it. Simultaneously, digitalization defines the way in which modern people work, live, and entertain themselves. Thus, it appears possible to conclude that digitalization is a broader concept the range of influence of which extends beyond the scope of Industry 4.0, as it defines the modern way of living above all. The firms that want to remain relevant in alignment with this context are prompted to pursue digitalization of their operations. This idea is expressed in the article by Bjorkdahl (2020), who concludes that “many firms are far from ready to benefit from digitalization and are mainly focused on achieving greater efficiency through digitalization rather than pursuing a growth agenda” (p. 17). Therefore, an imbalance is observed that can be formulated as the gap between Industry 4.0 and digitalization. These companies fail to appraise the differences between the two concepts, as well as the indispensable nature of careful, critical thinking-based assessment of digital initiatives.

Such inconsistencies create a situation, in which the benefits of digitalization remain unattainable due to the lack of understanding of this concept. Furthermore, Bloomberg (2018) insists that there is a fine line between digitization and digital transformation. In the contemporary body of research, the two concepts are often presented as synonymous, meaning the implementation of modern technology to assist with decision-making, production, and distribution with a higher level of efficiency. In his reasoning, Bloomberg (2018) relies on a straightforward understanding of digitalization as a term. For him, it is merely a transition from analog to digital operations. For example, the operations that were previously completed with calculators are now done with the help of computer algorithms. Digital transformation, on the other hand, is a more in-depth concept that becomes the ultimate result of an overall digitalization framework. In other words, a complex of digitization initiatives causes a paradigm shift within a firm or an industry which changes the way in which operations are completed profoundly. Digital transformation is a new level of industrial operations that not only augments current processes, but also creates new ones which were previously impossible.

As can be inferred from the presented data, digital transformation and digital are two related concepts that exist on different levels. In most cases, digitalization is observed on the operational or tactical levels. In simpler terms, a company embeds technological solutions into an existing procedure, making it quicker and more efficient. While the benefits are evident, such an approach does not guarantee lasting results in global terms. Digital transformation unites a variety of digitization efforts, creating a new paradigm. Thus, it operates on a strategic level and even has the capacity to redefine the business model, along with the image of the industry, in general. Thus, digital transformation aligns more with the concept of Industry 4.0, but the synonymy of both is still questionable.

In light of these findings, digital transformation becomes the ultimate strategic goals of the firms that wish to remain relevant in the changeable business environment. Verhoef et al. (2019) state that this agenda puts an increased pressure on managers, as its completion requires profound changes for which many companies are simply not ready. In the age of Industry 4.0, these business models are no longer defined by the organizations’ internal objectives. Instead, the complex relations within industries are brought to light, encompassing manufacturers, suppliers, distributors, and consumers. Under such circumstances, each element of the paradigm needs to function in light of the system, in general. Supply chain management cannot function only based on its objectives of efficiency and profitability, as it is part of a broader framework and contributes to the overall impact of the industry in generating value. Verhoef et al. (2019) conclude that reaching a state of digital transformation is demanding in terms of the organization’s willingness to change its patterns and comply with the external conditions of Industry 4.0. Only by venturing beyond the normal limits can a company attain this level.

In fact, the information that is presented above illustrates a research gap in the field of digital transformation studies, as well. In many cases, the contemporary body of research fails to provide a definitive description of this process, which makes it difficult to draw comparison with Industry 4.0. An attempt to amend this gap has been made by Mergel et al. (2019) who sought an empirically grounded definition of digital transformation. The authors confirm that the inconsistencies remain present due to the lack of a systematic approach to the subject matter. More specifically, policy-makers and managers continue to interpret digital transformation in the way that aligns with their specific industries, goals, and strategies. As per the findings presented by Mergel et al. (2019), digital transformation is a state in which the industry changes its strategic and tactical business models to align with the changes in economic, political, cultural, and social environments, generating value in each domain. The unnecessary concretization of the concept undermines its integrity, creating a variety of approaches that are valid for one context while being subject to misinterpretation in the case of others.

Finally, contrary to the initial perception that is formed upon the examination of the term, digital transformation does not revolve exclusively around technology. This idea is developed by Tabrizi et al. (2019) who report that digital transformation is referred to as the primary concern and a matter of the highest priority by today’s corporate managers, shareholders, and decision-makers. Nevertheless, in spite of the increased attention to the matter at hand, 70% of digital initiatives fail to complete their objectives, which translates into almost $1 trillion in losses (Tabrizi et al., 2019). The authors provide a fitting explanation as to why even extremely high investments do not guarantee a positive outcome in this regard. According to Tabrizi et al. (2019), digital technology is a tool that offers a chance to complete this transformation by attaining a new level of efficiency. In other words, technology only accounts for the possibility of success but does not ensure it. For the efforts to become fruitful, technology should be combined with other factors, and investment is not the decisive one. In fact, the key to utilizing these technology-enabled opportunities lies in the correct mindset and considerate approach to digital transformation. Change does not occur spontaneously, and the entire company or industry should be ready to instill it.

Overall, digital transformation will be the ultimate outcome of the profound paradigm shift within the market, company structure, management mindset, strategic planning, and consumer behavior. In light of the provided literary data, the synonymity of Industry 4.0 and digital transformation cannot be confirmed. While the two concepts are closely related, they remain parts of a larger system rather than different names for the same process. In summary, the process begins with setting a digitalization agenda, which ultimately leads to a level of technological paradigm shift that can be called a digital transformation. Thus, digital transformation is a process, a paradigm shift needed to augment companies and industries to a state which is defined as Industry 4.0.

Supply Chain Management and Industry 4.0

Supply chain management functions on the basis of its specific principles, values, and priorities that are not necessarily similar to other industrial operations of the 21st century. In general, the review of contemporary sources suggests a strong inclination toward the transparency of modern SCM (Tjahjono et al, 2017). Supply chains integrate a range of steps and agents that need to interact efficiently. The aforementioned transparency is a key enabler of efficiency, as the ability to trace every link of the chain contributes to the timely identification of problems and their resolution. Tjahjono et al. (2017) mention that the principles of Industry 4.0 suggest that this process can be automated with the help of modern solutions. With the reliance on technological advancements, it is possible to ensure an autonomous, self-regulatory exchange of the vital data between the elements of the supply chain with limited human involvement. Of course, a certain degree of operator expertise remains indispensable, but the overall process becomes more efficient and transparent. The Internet of Things (IoT) is one of the tools that contributes to this transformation through detailed sensor data exchange between automated units.

This particular instrument is actively discussed within the contemporary body of literature in terms of its association with Industry 4.0 and SCM, in particular. For example, it becomes a central notion to the article by Ben-Daya et al. (2017), who explore the application of this revolutionary technology by supply chain management specialists in today’s practical environment. The array of benefits ensured by the IoT is difficult to overestimate, since it supplies managers with precise sensor data virtually in real time. This is particularly important today, as supply chains become globalized and more difficult to trace without automation procedures. In this regard, self-regulation is a tool of paramount importance that allows automation systems to detect any flaws or deviations within the supply chain and inform the responsible units before the entire process is compromised. Ben-Daya et al. (2017) concur with the views of IoT as an essential instrument of SCM, while highlighting a systemic research gap in this regard. In line with the issues identified earlier, most pieces of research focus on concrete cases, viewing the subject matter separately from the general framework.

A formation of such a framework will make a strong contribution to the development of SCM in the current environment. For Saberi et al. (2018), the main issue surrounding the current state of supply chain management consists of controlling the extended globalized network. Such networks become the new standard, as businesses aim at a global presence that transcends regional and state borders. Evidently, the ability of human-controlled supervision is limited for natural reasons, and the extension of supply chains makes them prone to errors. Industry 4.0 in SCM is a natural response to the situation, aiming to counteract this limitation through automation and efficiency. For example, the technology of blockchain is a promising digital ledger technology, which contributes to the traceability and reliability of the network. In spite of its potential, the research into blockchain’s application in supply chain management remains in its early stages. The main cause of this research gap is conditioned by the lack of practical evaluation data, which would shed light on the actual avenues of this technology’s use for tracing supply chain operations. In order to make further advancements, a comprehensive framework is needed.

Thus, all stages from the order placement to its completion are to be traceable to eliminate any stakeholder doubts and enable the resilience of the system. Furthermore, a modern supply chain needs to be versatile in terms of its value generation and compliance with the external standards. According to Tseng et al. (2019), another key element of modern SCM is related to its sustainability. In other words, not only should supply chains be efficient and beneficial, they are also expected to function in light of the environmental and societal needs of the global community. Today, there is a continuous dialogue between stakeholders and industries, the outcome of which depends on a variety of factors. Globalization of operations and supply chains is a bilateral process, meaning that it bears advantages for all parties involved.

As much as firms gain access to new, broader markets, their competitors profit from a similar situation. Ultimately, consumers have a better offer selection, and they serve as the ultimate judges of supply chain’s effectiveness. In this regard, sustainability perception is a valuable benchmark, upon which end consumers make their decisions. Koberg and Longoni (2017) concur with such ideas, emphasizing the integral nature of sustainability within the scope of SCM. This way, the principles of transparency and sustainability interact, forming the nexus of contemporary supply chain management.

However, the transition toward the specified principles is a long endeavor that requires profound transformation within the field of SCM. Wieland (2020) argues that the transformational capacity of the supply chain management system is the key instrument of the field’s development. In other words, SCM models of the 21st century require a strong presence of adaptation to the specific needs and standards of the time. Regardless of the success of older methods in the past, they cannot retain their efficacy in the long term within the new environment. According to Wieland (2020), this path includes the more profound implementation of digital solutions that enhance the operational efficiency of the systems. Nevertheless, the arsenal of these solutions is extremely broad, which requires the in-depth analysis of specific tools’ applicability for particular tasks faced by the SCM. Thus, it is vital to examine the intersection of Industry 4.0 with supply chain management and its objectives.

Within the framework of efficient 21st-century SCM, the principles and tools of Industry 4.0 have become a subject of intense interest for experts and researchers. Shao et al. (2021) affirm the reliance of modern supply chain management on smart tools. According to them, Industry 4.0 contributes to the formation of stable multi-stage frameworks that adhere to the principles of transparency of sustainability. For Shao et al. (2021), SCM 4.0 is the next logical step of smart factory development, which, however, is still in the early stages. Moreover, the existing body of knowledge focuses on the benefits of Industry 4.0 tools for SCM, in general. First of all, there is a certain lack of information regarding the use of specific solutions for supply chain management. Second, little or no attention is paid to the challenges associated with the Industry 4.0 impact on SCM.

Certain experts make attempts to review specific smart instruments within the scope of supply chain management. Ben-Daya et al. (2017) view the Internet of Things (IoT) as the key enabler of Industry 4.0 principles in the contemporary environment. In the context of SCM, it contributes to the efficiency of production and transportation, strengthening the connection between its multiple stages. Data obtained through the application of IoT can be used for the detailed analysis of all procedures that provide insight related to the possible improvements. Smart supply chains are, first of all, efficient, meaning that all room for improvement is actively utilized to benefit all parties involved. Managers can take advantage of the immense amount of data and variability ensured by the IoT. This way, their strategies become informed and practice-oriented, utilizing relevant information to optimize their entire supply chains.

Another prominent solution is represented by the increasing use of blockchain technology across various settings. Its application within the sphere of SCM becomes the central idea of the research conducted by Saberi et al. (2018). According to them, the globalization of supply chains makes it more challenging to supervise their functioning across all stages. As a result, the principles of transparency and traceability are compromised as it becomes physically impossible to control all details of the supply chain. The use of blockchain wields high potential in terms of compensating for these drawbacks of the global network formation. As per Esmaeilian et al. (2020), this technology is a new approach to data storage and transmission that is likely to improve the degree of control exercised by managers over their supply chains. Nevertheless, the research surrounding blockchain use in SCM remains in an early phase. Furthermore, companies face an array of inter-organizational, intra-organizational, technical, and external impediments on the path to its implementation (Saberi et al., 2018). Thus, a further examination of this topic will make a positive contribution to the overall project.

Methodology

Introduction

The methodology consists of two stages. The first stage was an extended review of the literature with the aim to determine the current state of research and derive the main theoretical framework behind the study. The next step was to be more practice-oriented in order to draw a comparison between theory and actual knowledge possessed by supply chain managers. I conducted interviews with SCM specialists from different companies and regions to examine their perspectives on Industry 4.0 tools in today’s supply chain management. As the body of knowledge in this area is in an early stage of development, the qualitative model of research appeared viable. This approach to the study reflects the necessity of a stronger foundation upon which further, specialized knowledge was obtained.

Based on the introductory facts, research objectives, and literature findings presented earlier, the present thesis relies on its methodological approach to advance the understanding of supply chain management in light of Industry 4.0. The choice of the study model was dictated by the novelty of the subject matter combined with its extreme level of underrepresentation in the contemporary body of research. The main objective of the thesis is to determine the specific tools that are used in modern supply chain management in light of the Industry 4.0 development. Moreover, the theoretical component of the study was to ensure that there is a fundamental framework to support the choice of the instruments. It was theorized that some of these tools are being used intuitively by SCM specialists. In other words, they represent another instance of concretization, in which supply chain managers focus on the tactical and operational goals faced by their specific companies at a given moment. The nexus of theory and practice provided within the framework of the present research attempts to build a bridge between the two hemispheres of SCM. Thus, practical experiences are to be supported with theoretical findings from the contemporary body of literature.

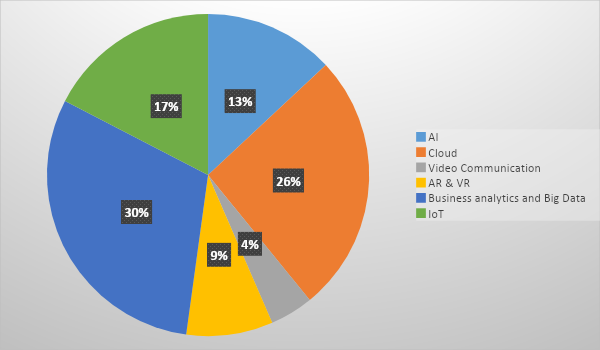

The data obtained in the course of the literature review will be categorized in specific categories. It is required to maintain a gradual approach to the knowledge acquisition, moving from broader aspects to the specialized ones. As such the research funnel will start with an overview of Industry 4.0 and SCM principles, leading into their intersection and concluding with the examination of specific tools and their applicability. Then, the information will be synthesized into a single theoretical framework that will guide the analysis of the interview data. Each of the discussions will be held in a broad narrative form that will allow the participants to explore the subject at length. Each interview will be transcribed and coded for the further examination, which will consist of distinguishing the key notions and patterns. The analysis applied to this data will result in a set of specific tools and their descriptions as per the supply chain management. The measurement will be ensured through evaluating the prevalence of specific tools and concepts in the responses.

This chapter describes the methodology used for this project, while emphasizing its justification and elaborating on the completed research procedures. The methodology is qualitative, considering the novelty of the subject and the need for a better description of it. The research procedures are completed in two stages: a review of the literature and a series of expert interviews.

Methodology description

The present thesis describes an actual phenomenon that does not exhibit a sufficient degree of representation and coverage within the current body of knowledge. More specifically, the primary objective is to describe the influence of Industry 4.0 on supply chain management, while outlining the primary digital tools that are used in this sphere from both theoretical and practical perspective. In the first case, the idea is to ensure a better understanding of the mechanisms behind the modern principles of SCM: what is important for SCM and how the sphere needs to perform in order to meet the requirements of the time. Industry 4.0 on its own is a relatively new phenomenon that still remains a subject of rigorous studies aiming to understand its principles in all their complexity. Its intersection with supply chain management is largely an uncharted territory, in which experts and professionals tend to navigate by intuition or prior experience. At present, SCM 4.0 does not have a solid theoretical framework that could guide managers in the new age of the field that is heavily influenced by the emergence of new technology.

Overall, the project implies a two-step model of research, in which theoretical findings are complemented by practical experiences. First of all, the study relies on a qualitative method, as conditioned by the context of it. According to Mills and Birks (2014), qualitative models are designed specifically to address such issues, improving the understanding of the research problem through better descriptions of the phenomenon. At this stage, the knowledge of SCM’s functioning in the age of Industry 4.0 is insufficient, lacking details and systematization. Thus, quantifiable data is not attainable at present, as the current level of this phenomenon’s understanding does not enable a solid framework within which these calculations can be held valid and precise. On the contrary, qualitative research is the correct approach to this matter, as it will systemize the existing data scattered across the body of literature, synthesizing a uniform model of SCM in the age of Industry 4.0.

The selection of the correct sample is an integral component of success, which is understood as the sufficient completion of research procedures in light of meeting the research objectives. In order to identify the optimal sample for each phase of the project, it was vital to understand the current state of research, as well as the goals of the study. For example, if the subject matter is currently underdeveloped within the contemporary body of literature, it may be problematic to identify a large number of relevant resources. Accumulating articles and books for the sake of expanding the sample was not perceived as a reasonable approach in this regard. By doing so, the author of the present research risked digressing and moving further away from the subject matter. A similar approach was taken in regard to the expert interview phase of the project. The sample was to become sufficiently broad to incorporate a variety of backgrounds and opinions. However, it was necessary to preserve a sufficient amount of time for each discussion and its analysis.

During phase one, a selection of 47 academic knowledge sources was retrieved and subjected to rigorous research. The inclusion criteria comprised authoritative publishers’ books, peer-reviewed articles, and expert reports published within the past 5 years. The specified time limit was necessary to ensure that the knowledge was up-to-date and reflects the current state of research into supply chain management.

As for the practical aspect, there is a strong need for a balanced sample. The number of participants was to be large enough to provide a diversity of models, counteracting the impact of research bias. At the same time, it should not be too high to ensure the adequate amount of time dedicated to each discussion. As such, the final number depended on the availability of respondents from the initial sample of 15 SCM experts that represent various industries and geographical locations. Ultimately, 8 experts were able to complete the scheduled procedures in their entirety. These were the people who are directly involved in the decision-making and functioning of supply chains. All interviews were to be conducted remotely to enhance the coverage of the study, while complying with the current pandemic restrictions.

Systematic Review

A review of the literature is a fundamental aspect of any research project. Its purposes are evident, as studies cannot be completed separately from the current body of knowledge. Contemporary literature reflects the state of the knowledge and progress within a specific area of studies, namely SCM in the age of Industry 4.0. However, in many cases, literature reviews serve to outline the background of the issue, becoming a starting point for the actual research project. In this case, the role of this review is purely informative, but it is possible only when the state of the knowledge is sufficiently developed to provide a comprehensive description of the issue’s basis. The same cannot be said about the matter at hand, since preliminary investigations revealed serious research gaps in this regard. As such, a literature review of this particular project becomes integral to the process and an indispensable procedure within the two-step model. More specifically, it serves to consolidate the existing knowledge that is currently scattered across multiple sources.

Indeed, modern literature fails to provide a uniform framework for SCM in the age of Industry 4.0. The sources that have been examined tend to address particular instances of digital transformation for supply chain management. In other words, there is currently a paradox in the literature. From one perspective, a considerable degree of concretization is observed in regard to the subject matter. Researchers discuss specific technologies in terms of their application for particular projects industries, disregarding the larger context. As a result, the data lacks transferability and recreation potential, which prevents a uniform framework from being formed. On the other hand, another portion of the academic discussion remains highly generalized. Spoken differently, sources discuss higher, abstract notions of Industry 4.0 technology’s influence on and interaction with supply chain management. Only general data is provided, reflecting the necessity of digital transformation and further progress toward Industry 4.0. At this point, a time has come to elaborate on the specific tools’ applicability and usefulness for SCM experts.

By consolidating the body of literature, the present project serves this exact purpose. As there is no uniform framework currently observed in literature, this study undertakes an attempt to synthesize the scarce and dispersed data into a single nexus of theory and practice. This review of the literature cannot remain a mere background part of the study that informs its continuation. On the contrary, it is vital to take more steps toward the systematization of the data through thematic analysis of the writing. In order to complete this task, the researcher has categorized these dispersed findings into specific groups. The first one outlines the very concept of Industry 4.0 and its principles as a new phenomenon that is currently being studied. Second, Industry 4.0 is compared with another prominent notion of digital transformation that is often present in the academic discourse. The purpose of it is to determine whether these two terms are, indeed, synonymous in any way, while describing the exact relationship between digitalization, digital transformation, and Industry 4.0. Third, supply chain management in its current state is examined, namely from the perspective of Industry 4.0 and its principles. Finally, the process culminates with the description of Industry 4.0 tools’ perception by modern authors described as a part of the findings.

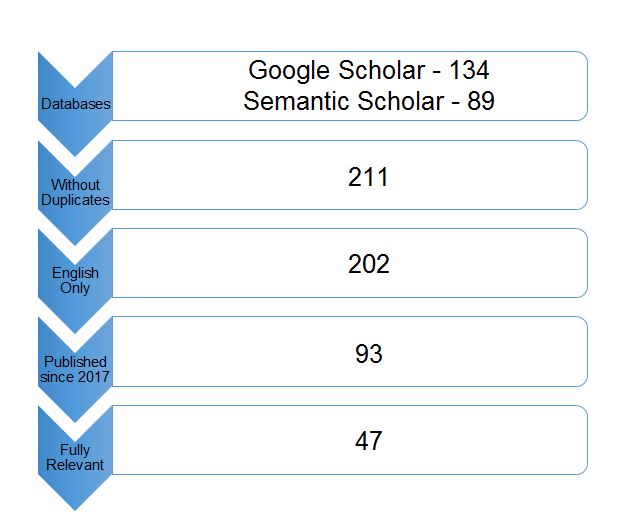

In the case of systematic reviews, preference was given to academic articles related to the subject matter to a sufficient degree. Initially, three primary databases were selected, which are Google Scholar, Semantic Scholar, and Oxford. These databases are universally recognized as containing a variety of pieces of academic knowledge that are relevant, reliable, and peer-reviewed. Upon a subsequent examination, the range of databases was reduced to two (Google Scholar and Semantic Scholar), since they were found to contain a large number of matching entries. Thus, the search was continued in these two libraries, following the algorithm of the study. As the subject matter is underdeveloped, a decision was made to search for its elements rather than for the sources that cover the whole topic, as the latter was deemed barely possible. For this purpose, the project relied on a set of key words with increasing relevance: “Industry 4.0”. “Industry 4.0 principles”, “Industry 4.0 and digitalization”, “digital transformation”, “digital transformation and digitalization”, “digitalization of SCM”, “supply chain management”, “supply chain management and Industry 4.0”.

Following these patterns, an initial set of 211 articles was selected that was further subjected to the secondary selection process, described in Table 1. This phase relied on specific inclusion and exclusion criteria with the intent to filter the entries that did not meet the purposes of the assignment. Criterion One said that the articles were to be written in English, representing the international knowledge on the subject. Upon this filter, 9 articles that were written in other languages but had titles in English for search index purposes were eliminated. Second, the next inclusion criteria revolved around the date of the publication. This project addresses supply chain management in its current state and in light of recent advances. Thus, it was decided to consider exclusively recent sources that were published within the past 5 years. At this stage, a list of 109 references was excluded from the total selection for not being sufficiently up-to-date.

Table 1. Literature review source selection funnel

Finally, the study selection process entered the stage of another filter, which was by relevance. The author of the thesis reviewed each work in detail, eliminating those that did not contribute to the actual project objectives. For example, some articles had only a small percentage of relevant information, mostly being devoted to irrelevant subjects. Others reiterated the same pieces of data as previously included articles, thus rendering themselves redundant. The third and fourth filters eliminated another 46 articles, making a total number of studies processed through the prism of the literature review 47 recently published, peer-reviewed academic sources of knowledge.

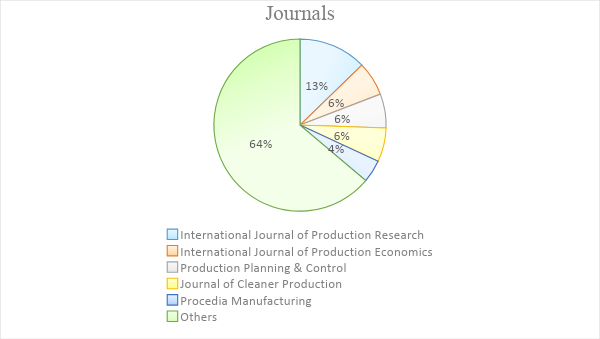

The process of the systematic review commenced with the selection procedure. In the course of the exclusion-inclusion analysis, each source was examined several times, providing a concrete understanding of the themes and contents. However, when the sample was finalized, another round of rigorous article study began, during which the author conducted thematic analysis of each source. Next, the range of key themes and notions was synthesized, allowing for the final categorization of the review. Overall, the project’s procedures determined four core themes, into which the literature was categorized. First, there were studies that illustrated the essence and principles of Industry 4.0 with its varying definitions and perceptions. Second, the concept of digital transformation was described with the help of relevant sources. Based on this analysis, the differences between digital transformation, digitalization, and Industry 4.0 were presented. Next, the core of the literature review culminated with the intersection of supply chain management and Industry 4.0 tools. This information informed the further process of the study, and its fourth theoretical category, comprising the synthesized theoretical framework, is presented along with the findings.

Expert Interviews

Having completed the literary analysis of the contemporary body of knowledge, the study proceeds to its second stage, which is a series of expert interviews. This particular procedure serves to ensure the practical orientation of the study by incorporating the experience of active supply chain management specialists into its framework. The idea is to hold an open and honest discussion with the people who actually interact with the subject matter in their daily professional activities. Prior to the beginning of the present study, it was theorized that active specialists might become an invaluable source of information regarding the subject. Furthermore, it appears highly interesting to investigate their perspectives in order to outline the practical approach to modern supply chain management. It is not a surprise that there are often inconsistencies between theory and practice, especially in the case of recent phenomena. Thus, it is vital to understand whether the same can be said about supply chain management. If theory and practice continue to develop separately or with limited codependence, the field may enter a state of chaos.

In this regard, the experts’ insight is expected to prove useful in forming a unity with theoretical findings. This format implies a series of qualitative interviews with SCM specialists that are currently engaged in this field and have enough experience to appraise the progression toward Industry 4.0. As the selected methodology of the present project is deemed qualitative, no quantifiable data is obtained from the discussions. Instead, a sequence of open-ended questions is provided to stimulate an active, transparent discussion without artificial constraints, being one of the reasons why a questionnaire survey was not selected. In the course of each interview, the speaker has had an opportunity to express their thoughts in regard to the subject matter. First, a narrative script was provided to guide the interviewee across the key points of discussion. Next, based on the collected information and voiced thoughts, a more open discussion was proposed to complement what was previously said. Each interview is transcribed in a written form, preserving the original thoughts of each speaker.

Then, having completed this step, the researcher conducted a thematic analysis of the scripts. It consisted of carefully investigating the contents of each interview narrative, highlighting recurring themes, key notions, and essential opinions. Based on these findings, a consolidated framework is proposed, in which the researcher identifies the most common perceptions, as well as rare views on the subject matter. In the end, the results of this analysis are compared with the theoretical framework that is produced by the literature review in order to find commonalities and inconsistencies between theory and practice of SCM in the age of Industry 4.0.

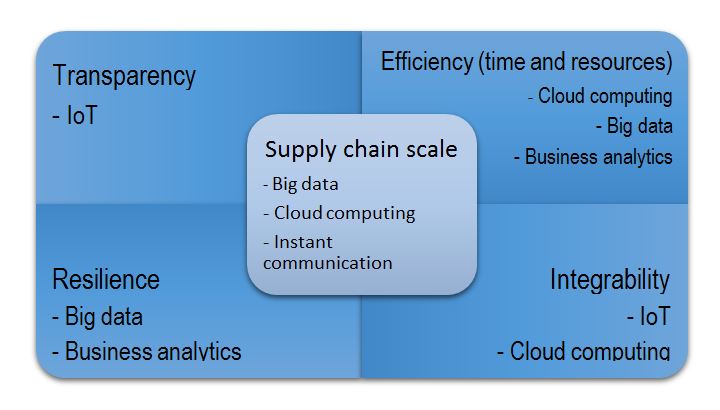

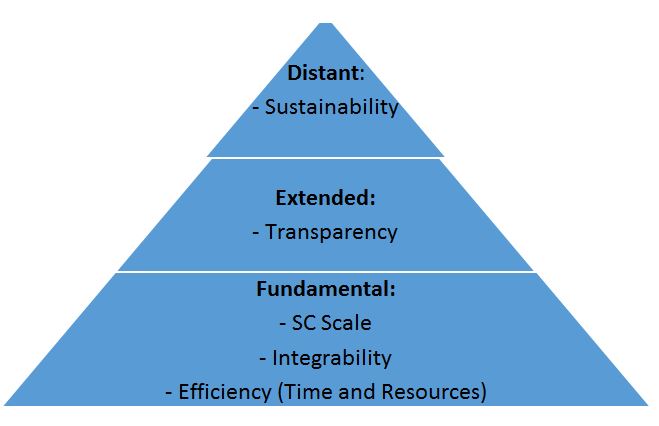

For the thematic analysis, the structure consisted of preparing a synthesized list of themes that derive from the examination of literature. More specifically, this stage implied a certain degree of inductive reasoning. Based on the scarce data obtained from the literary sources, four key principles of SCM 4.0 were formulated. They served as the basis of the theoretical framework, which served as an instrument of thematic analysis. This list of principles was expected to be the lens, through which each expert’s narrative was examined in the transcribed form.

The subsequent stage is the deductive one, consisting of preparing possible variations of phrasing, through which a certain principle can be expressed. It is natural that interviewees can refer to the same principles in different ways in an impromptu conversation. For example, the principle of supply chain sustainability can be expressed through the words and phrases such as “green”, “environmentally aware”, “waste reduction”. The key was to categorize the core thoughts of each expert as per the identified literature framework. For this purpose, it was essential to be able to look beyond the surface of the text and understand the profound ideas and concepts beneath the words.

For the practical component of the present study, the selection process was determined individually in light of the project’s goals and the overall research question. As described previously, the main idea was to ensure a diversity of opinions, covering different perspectives of experts, each one possessing their own experiences with Industry 4.0 tools. At the same time, there was a serious risk of expanding the sample beyond reasonable limits, thus lacking the time and attention devoted to each specific expert. This project implied the organization of one-on-one interviews with active SCM specialists. Thus, the time devoted to each interview needed to be enough to cover the subject matter fully. In addition, pre- and post-interview procedures were taken into consideration. In light of all these requirements, it was decided to limit the initial sample to 15 experts.

The selection process included the criteria that revolved around the professional expertise of the participants and not their personalities. There were no limitations in terms of the experts’ nationality, ethnicity, place of residence, religion, race, or personal views. Furthermore, age was not a decisive factor, as the study acknowledges the possibility of being a renowned professional at any age. Listed below are the inclusion criteria in light of which the sample was initially selected:

The participants of the project are to:

- Hold a bachelor’s degree or higher

- Be currently occupied in the sphere of supply chain management

- Have at least 5 years of relevant experience

- Have at least 1 year of managerial experience in supply chain management

- Be available for a remote online interview

The candidates for the interview were identified with Mutual connections, open sources, namely the website LinkedIn. Using this platform’s search engine, the author of the project selected a list of potential interviewees to be recruited for this stage of the research. Each one received a detailed message regarding the purposes, procedures, and expected outcomes of the project. Several candidates requested an executive summary of the project to become more familiar with it. Out of 43 experts initially contacted, 7 candidates respectfully declined an invitation to participate. Next, the remaining 25 experts stopped replying to the interviewer’s messages, eventually disappearing.