Introduction

The environmental impact forms the major pillars of concerns in dealing with food production and consumption strategies. A properly chosen environmental assessment tool influences the results obtained. To assess the environmental indicators, two categories of tools namely the product-based tools and the area-based tools may be used. LCA is a product-based tool that evaluates all the phases of a product’s life. This methodology deals with the flow of materials, outputs, and environmental impacts they have. LCA processes have been standardized (Dalgaard, Halberg, Hermansen, Mogensen 2008).

Life-cycle assessment (LCA) aims at analyzing the environmental impacts in the development of products. It takes a systems view where the product or a process assumes a whole component comprising of sub-units working towards the same goal.LCA undertakes environmental evaluation of products, raw or finished materials, and processes. Life-cycle assessment analyses environmental burdens throughout the process of developing a product from raw material acquisition, manufacturing process, distribution, use, and waste management (Joshi 2000). However, many of the LCA approaches face challenges of subjective boundary definition and goal determination, inflexibility and complexity, high cost, and time wastage.

This paper examines the Life Cycle Assessment basic components using the example product of tea manufacturing. It focuses on the raw materials extraction, manufacturing process, distribution, marketing, and use of tea products. The paper also discusses the advantages and the limitations of applying the LCA methodology in decision-making and environmental impact assessment.

Problem Statement

This paper uses LCA to study the impacts of the climatic changes on tea production from raw materials extraction, manufacturing process, distribution, marketing, and use of the final products. The paper also analyses the influences of emissions from the factory to the environment.

Life Cycle Assessment

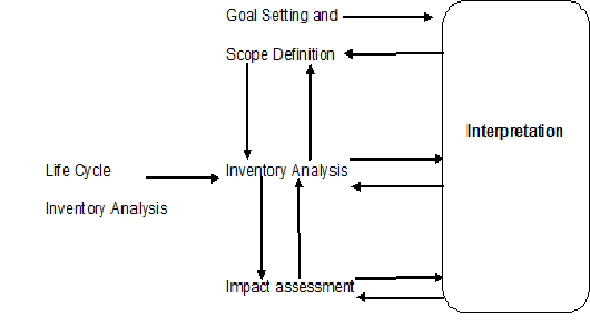

Life Cycle Assessment, which is abbreviated as LCA is a tool to assess the impacts caused by the environment and the resources used throughout the life cycle of the product. The life cycle starts from the acquisition of the raw materials, production process, use of the product, and finally its disposal. Due to its fast methodological development and use, LCA has an extensive reach (Ekvall, Finnveden, Guinée, Hauschild, Heijungs, Hellweg, Koehler, Pennington & Suh 2009). In 1969, The Coca-Cola Company moved from glass bottles and introduced plastic bottles. They studied the environmental impacts of its packaging forming today’s LCA methodology. The four phases of LCA include scope definition and goal setting, life cycle inventory analysis, impact assessment and results in interpretation (Trucost, 2011). International Organization for Standardization has defined a framework for LCA. The specifications of LCA developed by ISO include the stages of the cycle, the target, and the boundary limitations, and influence analysis of LCA (Broca 2008).

Life Cycle Assessment (LCA) is a tool developed to evaluate the products development processes as systems apply to the evaluation and analysis of environmental performance. It also applies to the determination of the opportunities available to improve the environmental efficiency of tea products development. Some LCA studies carried out in Thailand and other parts of the world evaluate the biopower and biofuel systems (Gheewala 2011).

LCA methodology has other variant methods such as the water footprint and the carbon footprint approaches. LCA methodology can be applied alone to assess the environmental impact of a certain product or processor used in combination with these variant approaches. Hoekstra in 2002 developed the concept of the water footprint approach. The introduction of this approach shows how a human being fits the freshwater resources. It studies the incorporation of water usage by a human being direct as a consumer or indirectly as a producer (Koehler, Pennington & Suh 2009). This variant approach applies to a wide field of study. The researcher may come up with the water footprint of a one-person, a society, a business, or the entire nation. In the field of product or process development, water footprint methodology implies the summation of the total volume of freshwater in litters or milliliters consumed during the product development. The total comes from the summation of the capacity of water used throughout the production chain (Aldaya, Ercin, Hodges, Jefferies, King, & Muñoz 2012).

The water footprint approach shows the total water capacity consumed by the source and output capacity by pollution. The two elements form a total water footprint. There are three types of water footprints namely the grey water footprint, the green water footprint, and the blue water footprint. The grey water footprint implies the component of pollution stated as the capacity of freshwater needed to bring together all the pollutants following the existing standards of water quality and quantity. The blue water footprint means the use of the underground and surface water described in assimilation with the supply chain process of the product. Water use in this case implies water loss through evaporation, which then returns to another ground surface or the water body. The green water footprint means water used from the rainwater absorbed by the soil in form of moisture (Jefferies et al. 2012).

Currently, there is a widespread concern over the change of climate, information need, and opportunities for consumers to lower their carbon footprint; Carbon footprint refers to the total amount of consumer responsibility for greenhouse gas emissions (Scott & Weber 2008).

Components of LCA Methodology

As defined by ISO 14040 in 1998, Life Cycle Assessment or Analysis constitutes the following four components. These components apply during the study of the process of products development (Campbell 2007).

Goal Setting and Scope Definition

This is the first phase in LCA. Before conducting any study, the researcher specifies the field of study where LCA has applied for example marketing, planning, or product development. The researcher also specifies the audience he is aiming at and the rationale for carrying out the study. The researchers specify the limitations or the boundary of the study in this phase. In this phase, the boundaries of a system specify the time it will take, capital resources needed, geographical area, and other impacts that may influence the process (Georgakellos 2002). Where it involves a comparison of two products, the functional unit specifies the comparisons.

Life Cycle Inventory Analysis (LCI)

This phase entails the process of data collection and organization and the calculation methods needed to determine the inputs and outputs of the system. The process of collecting data involves the identification and calculation of the needed inputs and outputs in each process and the sub-processes within a system. The inputs and outputs for most of the processes include energy, raw material, products, and waste. Emissions to the air, water, and soil form the outputs (Navigant 2012).

In creating a life cycle inventory, the sources of data include the data from measurements of lengths, widths, weights, and other quantifying metrics. The data can also be obtained from the previous studies related to the current product development procedure or from the constructed Life Cycle Inventory databases. The designer may also make estimations from the analysis data and warehouses. The essential data required includes the time and place of data retrieval and analysis (Vasquez-Campos 2010).

Life Cycle Impact Assessment (LCIA)

This is the most complex phase in the LCA by which the researcher relates the environmental releases established in the life cycle inventory stage and looks at their potential and actual human and ecological effects (Lemay 2011). Various tools of impact assessment have been developed. The latest life cycle impact assessment (LCIA) developed is the Eco-indicator 99. This tool came after Eco-indicator 95. This methodology evaluates the effects of emissions on human beings and ecosystems (Prek 2004).

Results Interpretation Phase

This phase evaluates the outcomes and picks the preferred product or the process. This phase gives the requirements and recommendations to interpret the results in LCA studies. However, it does not provide a description of the specific methodologies for the LCA and LCI studies (Thompson 2011).

Advantages and Applications of LCA

Despite the challenges in adopting the LCA methodology, LCA remains to be a valuable tool in the analysis of the environmental impact of a system. LCA helps in determining the extent to which a product or a process pollutes the environment. It shows the products or the process’s basic requirements for instance the resources and energy. It also identifies areas in the life cycle of a product or a process that reduce environmental pollution if followed (Levan 1995).

Many manufacturing companies apply LCA to identify areas that achieve a total reduction of environmental loads and emissions. They fix a method that is environmentally friendly into the existing design followed in processes and product development. The product process designers determine the energy and emissions at all the steps of product development all the way from raw material acquisition, processing, distribution and dispatch, utilization, and waste management (Levan 1995). Companies concentrate on the specific parts of the life cycle phases to reduce waste, utilize the energy, do away with dangerous materials, and preserve materials using LCA methodology.

Using the LCA methodology, researchers, companies, managers, and policymakers realize the potential benefits of a certain product and at the same time, they determine and minimize the potential risks in the development of the product (Vasquez-Campos 2010).

Example Product Studied Using LCA

In this study, the writer applies the process of developing tea products from the acquisition of the raw materials, manufacturing tea, distribution, and use to assess the environmental impact using the LCA methodology. The factory in this example forms a system.

Stage One: Goal Setting and Scope Definition of the LCA

The field of study where LCA methodology applies, in this case, is tea products development. The reason for carrying out this LCA study is to analyze the environmental impacts during the process of acquiring the raw materials, manufacturing process, final products distribution and marketing, its use, and finally disposal and wastes management. The target audience in this study entails the factory managers who make crucial decisions for the company. The geographical area in this study is limited to the factory as a system and the environment it is interacting with for example the suppliers, customers, shareholders, government, and other stakeholders. The scope definition in terms of the capital resources is limited to the amount of capital the factory invests in producing tea. In the scope, the study neglects the accidental and intentional pollution caused by the factory’s personnel within the factory.

The main goal of this study is to find out the effects of the surrounding climatic conditions in the raw materials acquisition, manufacturing process, distribution, and marketing of tea products, their use, and disposal. The goal extends to finding out how such environmental influences can be minimized for maximum profit-making. Another goal involves the determination of the effect of the environment surrounding the factory as a system towards the company’s profit, for instance, the government, customers, suppliers, and other company stakeholders.

Stage 2: Life Cycle Inventory Analysis (LCI)

To achieve the goals identified above, the researcher obtains the required data and all details of the data needed. The inputs relevant in the course of this study entail the tea leaves as the raw materials. This analysis determines the quality and quantity of tea leaves supplied to the factory at different climatic conditions. The analysis extends to the identification of the effects of climatic conditions affecting the manufacturing process, distribution, marketing, and use of the final products. Another input data analyzed entails the energy of the personnel working in the factory and the overall effects on the process. The output data collected entails the effects of the factory fumes and smoke on the surrounding climatic conditions.

The researcher followed the following procedure in collecting data for the LCI study. The first procedure is the inquiry from the suppliers, factory managers, customers, shareholders on the effects of the different climatic conditions on the inputs and outputs of the factory. Instruments used in the data collection include the focus group discussions, telephone, face-to-face interviews, and administering of questionnaires. At the same time, the researchers reviewed the previous works related to this study.

Life cycle inventory was prepared by organizing and storing the data collected from the field. Data is arranged according to the respondents, type of data, date and time collected, and the depth of data collected. They were then stored in locked cabinets.

Step Three: Impact Assessment

The research team led by the project officer analyzed the collected data to assess the impact of the climatic conditions in the raw materials acquisition, manufacturing process, distribution, marketing, and the use of the final product. The researchers never used any specific software for impact assessment but rather they analyzed the files based on the organization. One group assessed the interview results from the customers and the consumers of the final product to determine how the different climatic conditions affected the buying behavior. The second group analyzed the response from the suppliers of tea leaves to determine the impact of the climatic change on the quality and quantity of the tea leaves. The third group analyzed the impact of the smoke fumes emitted from the factory on the climatic conditions of the surrounding. The last group assessed the response from the managers and other factory personnel on the effects of the climatic change on the company’s profit.

Interpretation of the Results

The LCA practitioners scrutinized the results obtained to determine the goal achievement. The research team went ahead to interpret the results as analyzed in the previous stage. Results showed that consumers and customers of the final tea products do not like buying and using tea during hot and dry weather conditions because they do not use tea most of the time. Instead, they result in cold drinks. The second observation led to the conclusion that during the harsh weather conditions tea production drops tremendously. The two weather extremes include the cold and wet climates and the hot and dry climates. The third observation entails the effects of the smoke fumes emitted from the factory, it showed that the smoke causes acidic rains affecting the people, plants, and buildings around the factory. The last observation showed that the factory goes at a loss during the harsh weather and climatic conditions.

Limitations of Life Cycle Assessment

LCA does not analyze the risks associated with the uncertainty (Carmody and Trusty 2008). The study has also shown that LCA methodology is too expensive requiring a lot of money and time to implement. The complexity of the methodology adds to its limitations in application. This means that it is not easy to understand and interpret. LCA methodology application is relative and therefore not beneficial in referencing or comparing two products. It cannot help in determining the cost-benefit and practicability of two products (Hoff 2010). From the example product above, LCA does not gather for the uncertainties such as failure of the respondents to give accurate results. In addition, the study took a lot of money and time to come up with the results, as its interpretation needs a lot of expertise.

LCA as a tool analyses products and comes up with one of the many inputs and outputs when making crucial decisions. The use of LCA as a tool depends on the user and freedom to use it is a problem in spite of the standardization imposed by ISO. LCA user uses their judgments and knowledge to make inherent choices and determine the criteria that will positively affect the outcome.

LCA presents a subjective dimension meaning that outcomes always determine the weighing of the choices by the practitioner and the criteria chosen to affect the interpretation of the results. LCA is an important tool, but when applying it in the decision-making process, it is good to be aware of its challenges, limitations, and subjectivity. LCA helps in justifying the choice made but it does not give a decision in itself (European Bioplastics Inc. 2008). From the example product above, the study showed that the choices, criteria, and interpretation of the results depend on the LCA practitioner despite the ISO standardization. The LCA study evokes a lot of subjectivity in results interpretation and does not provide a final decision to the managers by itself.

Conclusion

LCA study is a cycle and can repeat itself if all the set goals are not achieved. Despite the standardization of LCA, it still poses some problems to the LCA practitioners. The tea factory managers used the LCA study to assess the impact of the environmental influence on their profits. LCA methodology has wide applications ranging from products development, marketing, and strategic planning. LCA methodology has variants including the water footprint and the carbon footprint approach.

References

Aldaya, M, Ercin, A, Hodges, J, Jefferies, D, King, V, Muñoz, I. 2012, Water footprint and life cycle assessment as approaches to assess potential impacts of products on water consumption, Elsevier, AE Enschede, Netherlands.

Broca, M 2008, A comparative analysis of the environmental impacts of ceramic plates and biodegradable plates (made of cornstarch) using the life cycle assessment tool, masters project, Teri University, New Delhi.

Campbell, A 2007, Life cycle inventory and life cycle assessment for windrow composting systems, The University of New South Wales, Sidney.

Carmody, J & Trusty, W 2008, “Life Cycle Assessment Tools”, InformeDesign, vol. 5, no. 3, pp. 2.

Ekvall, T, Finnveden, G, Guinée, J, Hauschild, M, Heijungs, R, Hellweg, S, Koehler, A, Pennington, D & Suh, S. 2009, Recent developments in life cycle assessment, Journal of Environmental Management, vol. 91, no. 1, pp. 1-21.

Dalgaard, R, Halberg, N, Hermansen, J, Mogensen, L. 2008, Life cycle assessment across the food supply chain, Wiley & Sons, Incorporated, New York.

Georgakellos, D 2002, Lca as a tool for environmental management: a life cycle inventory case study from the Greek market, University of Piraeus, Piraeus.

European Bioplastics Inc., 2008, Life cycle assessment of bioplastics, European Bioplastics e.V. Marienstr, Berlin.

Gheewala, S 2011, Life cycle assessment (lca) to evaluate environmental impacts of bioenergy projects, King Mongkut’s University of Technology Thonburi, Bangkok.

Hoff, J 2010, How green is green? Measuring sustainability with life cycle assessment (lca), Center for Environmental Innovation in Roofing, Boston.

Joshi, S 2000, Product environmental life-cycle assessment using input-output techniques, Michigan State University, East Lansing.

Lemay, L 2011, Life cycle assessment of concrete buildings: concrete sustainability report, Silver Spring, Maryland.

Levan, L 1995, Life cycle assessment: measuring environmental impact: USDA forest serv, Forest Prod. Lab., Madison.

Navigant, C 2012, Life-cycle assessment of energy and environmental impacts of led lighting products part i: review of the life-cycle energy consumption of incandescent, compact fluorescent and led lamps, US Department of Energy, Washington.

Prek, M 2004, Environmental impact and life cycle assessment of heating and air conditioning systems: a simplified case study, University of Ljubljana, Askerceva.

Scott, H & Weber, C 2008, Food miles and the relative climate affects of food choices in the United States, Environmental Science and Technology, vol. 42, no.10, pp. 3508-3513.

Thompson, L 2011, Life cycle assessment tools to measure environmental impacts: assessing their applicability to the home building industry, Partnership for Advancing Technology in Housing, Washington.

Trucost, D 2011, Measuring and valuing environmental impacts: network for business sustainability, University of Western Ontario, Ontario.

Vasquez-Campos, S 2010, Life cycle assessment of nm in polymer nanocomposites: nanopolytox approach, Leitat Technological Centre, Barcelona.