Introduction and Company Background

Though often underrated, the toy industry has been striving in the global economy environment surprisingly well, and Mattel, Inc. is a graphic example of the phenomenon under analysis. Founded in 1945 by Harold Mattson and Elliot Hardner (Mattel history 2015), the organisation has grown into a corporate giant, its products being available practically all over Europe. The organisation is primarily known for producing toys, the line of Barbie dolls being its most recognisable and by far the most successful brand.

The supply chain management (SCM) model, which the organisation uses in order to promote its product worldwide, has been viewed as the superior method for a while due to the innovative approach that it incorporates. Specifically, the “collaborative planning, forecasting, and replenishment (CPFR) programme” (O’Brien 2005, p. 282) deserves to be mentioned as one of the pillars of the company’s s SMC. Allowing levelling out the costs taken by retailers and suppliers and reducing the amount of inventory for the partners to work with (O’Brien 2005), the above-mentioned approach towards SMC helped the organisation create a very strong connection with the companies such as Wal-Mart (O’Brien 2005).

Despite the fact that Mattel still tops the list of the world’s most successful and profitable toy manufacturers, the company has not been doing quite well since recently, which can be attributed to certain flaws in its current approach towards SCM. According to the recent data published in the 2014 report issued by the organisation, Mattel’s annual sales dropped by 6% (Mattel reports fourth quarter and full year 2014 financial results 2014, par. 1). A closer look at the problems with Mattel’s SCM will reveal that the company suffers from a consistent lack in qualified staff (Chao 2015). Although the specified issue is only a minor concern at present, as the company has not redesigned its supply chain according to the new standards yet, “Finding really good people who’ve been there and done it before is a challenge” (Chao 2015, p. 282), as Mattel’s chief supply officer, Peter Gibbons, reports.

Although Mattel has been the beacon of high standards and a consistent quality in the toy industry for years, the recent issues with the SCM strategy may jeopardise the company’s success in the target market. A reconsideration of the current approach towards the distribution of roles and responsibilities for conducting the SCM processes, therefore, is highly required. The case in point can be viewed as a graphic example of different organisational processes, such as SCM and human resource management (HRM), being linked tightly to each other within the environment of a company (Christopher 2011).

Competitive Strategy

According to Porter’s Five Forces (Dobrivojević 2013), the organisation’s competitive strategy can be defined as rather well-balanced. It should be born in mind, though, that the power of suppliers is a rather broad concept in the toy industry, as the availability of substitutes needs to be evaluated on a case-by-case basis for each product separately. As a result, a range of organisations, such as Mattel, need to assess the power of suppliers for each brand product separately. That being said, the power of suppliers seems to be rather low in the case in point, as the organisation clearly has a range of substitutes available for producing its brand toys, which can be attributed to the deployment of the CERF strategy mentioned above: “CERF blurred the lines between supplier and customer” (Chao 2015, p. 282). Therefore, the power of suppliers can be deemed rather low in the specified scenario.

The power of downstream firms, which are positioned as buyers in the specified case, in its turn, can be viewed as rather high. Particularly, the purchasing power of Wal-mart, which is the key downstream company working with Mattel, deserves to be mentioned as the key stakeholder: “The greatest efficiencies will appear when the kind of trusting mutually beneficial relationship Mattel has with Wal-Mart is duplicated with the rest of the manufacturer’s retail outlet” (Chao 2015, p. 282).

Because of a rather impressive amount of toys produced presently on a global scale, the threat of substitution can be viewed as comparatively high. While Mattel has the Barbie as its brand product, it still has to face rather tough competition. For instance, once Bratz were introduced into the global market, a new and powerful competitor appeared in the target market. Despite having managed the competition rather efficiently, the company still faces a rather significant threat of substitution.

Finally, the threat of new entrants into the toy industry needs to be addressed. As it has been stressed above, toy industry is a rather competitive environment, mostly due to the fact that supplies for the products are quite cheap (About us 2015). Consequently, the threat of new entrants is also very high for Mattel. Being the corporate giant that it is, the organisation still needs to take notice of the emergent companies, such as Toynami, as well as keep an eye on the firms that have been in the industry for decades, such as Hasbro.

Therefore, it can be assumed that Mattel is currently under a constant threat of being surpassed by the companies that incorporate the latest technologies into the design of their toys. Whereas Mattel manages to stay afloat, it needs a reconsideration of its image and a revamp of its approach towards raw materials usage, supplies, transportation and the related issues. The specified steps can be carried out

Agility

Typically viewed as one of the most fundamental characteristics of a viable organisation, which is capable of remaining afloat in the environment of global economy, agility is referred to as the “a business-wide capability that allows the firm to use market knowledge to exploit profitable opportunities when volatile conditions exist” (Gligor & Holcomb 2012, p. 442). In this sense, Mattel can be characterised as a very agile organisation judging by the fact that it adapts towards alterations in the business world. On the surface, the changes that Mattel does to the design of its supply chain are minor; for instance, the company’s vice president, Thomas Debrowski, announced in 2012 that the firm was going to “build our local market knowledge” (Tang 2014, par. 15).

Synchronisation

The planning cycle of Mattel, which constitutes a substantial part of the synchronisation process, can be considered fairly productive. The company does manage to correlate the previous actions with the following decisions, therefore, implementing the make-to-order principle. Mattel has learned its lesson well after the analysis of the lead toys scandal and now adopts a very responsible approach towards the choice of its suppliers, as well as the coordination of actions with the latter. At present, the firm only needs weekly synchronisations for managing the shipments process, according to the statement issued by Mattel’s supply chain manager (Cecere 2014).

With that in mind, one might suggest that Mattel should view the incorporation of a specific production planning parameter, such as the tactical renewal, as an option. According to recent studies, the specified approach helps synchronise the key processes carried out in the course of SCM in a manner as efficient and expeditious as possible: “Tactical renewal is a regular, routine process that aligns operational and tactical supply chain planning along the supply chain. Its core responsibility is to confirm and, if necessary, adjust tactical production planning parameters” (Packowski & Francas 2014, p. 3). Since Mattel will have to address the obvious issue of suppliers in order to improve its SCM design, the enhancement of the process with the help of the aforementioned tool may serve as the means for keeping the production pace at the required speed.

Risk Management

The risk management approach, which the organisation has adopted in order to reduce the financial losses, can be considered rather reasonable. According to the official statement of the organisation, Mattel views risks as an inevitable part of regular life; as a result, the process of managing them becomes considerably easier for not only the company leader, but also its managers and employees. Consequently, the process of decision making flows much faster in the specified setting.

An adequate choice of the existing insurance options is the tool that allows Mattel to coordinate risks efficiently and avoid drastic situations quite successfully: “The real power of this approach lies in its use as a framework to discuss and debate risks with the supply chain strategy team. Given that risk analysis has a large subjective component, reaching consensus is critical” (Dittman 2014, p. 15).

Unfortunately, the approach that Mattel has adopted to manage its supply chain does not incorporate a reasonable risk management strategy. More to the point, the lack of a proper risk management system has already triggered major losses for Mattel in 2007, when a line of toys was recalled due to the instances of lead poisoning and loose magnets (Barboza & Story, 2007). Apart from triggering the obvious problems with risk management, the specified issue serves as an indicator of an extremely poor choice of raw materials. In other words, the approach towards procurement, which is one of the basic elements of a supply chain management, leaves much to be desired in the setting of the Mattel Company. Naturally, the company has learned its lesson from the 2007 scandal, as it accepts raw materials from certified suppliers only (Bugalla & Narzaev 2014), but the procurement strategy has not been cemented into the company’s SCM design yet.

In order to address the specified issue, one might suggest the reconsideration of the corporate ethics at Mattel. Although the process of redesigning the approach towards supplies retrieval has already been launched, the organisation risks at failing once again as long as the current ethical premises are left intact. Therefore, it is advisable that the concept of corporate social responsibility (CSR) should be integrated into the SCM design at Mattel. Typically identified as “a programme of actions to reduce externalised costs or to avoid distributional conflicts” (Kotchen & Moon 2012, p. 1), CSR promotes a more adequate approach towards addressing ethical dilemmas, such as the choice between a cheaper raw material and the wellbeing of customers. In other words, the problem under analysis shows that the SCM process must be aligned with the company features such as corporate ethics and the leadership approach.

Supply chain organisational structure

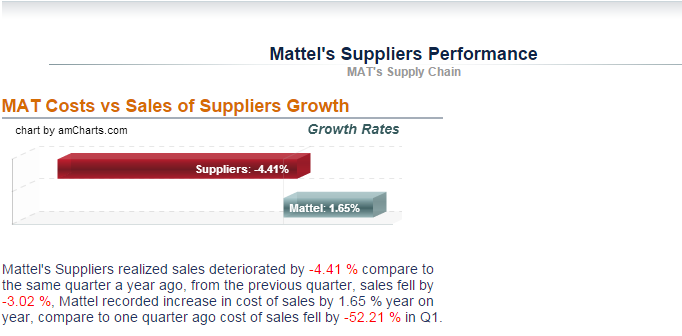

The organisation of the SCM structure also displays that Mattel could use better tools for coordinating its SCM with the rest of the organisational processes, such as regular audits for checking the quality of the end product and the raw materials, implementation of corporate ethics principles is required. Therefore, the current SCM strategy shows that there is a close connection between the leadership approach, the ethical standards and the actual performance within the SCM framework. Unfortunately, Mattel is still recovering from the drastic effects of the 2007 scandal, and the current suppliers that the firm cooperates with deliver unsatisfactory performance. According to the latest data, the growth of suppliers returned very poor results, the sales of the organisations involved dropping by 4.41% (Mattel’s suppliers performance 2014, par. 1). As the chart below shows (Fig. 1), Mattel, however, has been doing comparatively well in its production process.

Much to the dismay of the organisation, the economic landscape of 2015 has not created many favourable premises for the development of a proper supply chain management system. Particularly, the company has been lacking proficient staff consistently over the past year. As a result, the development of a proper supply chain has been stalled (Chao, 2015). Therefore, the supply chain organisation structure could use a major redesign.

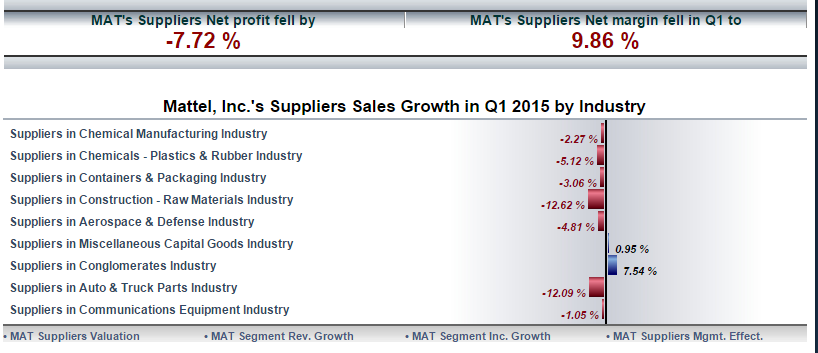

As the chart provided above shows, the consistent failure of the suppliers has prompted a different approach towards the SCM process within the organisation. Apart from the company’s key suppliers suffering from a streak of losses, Mattel itself has been having a rather rough year so far; according to the data provided in the chart, the company’s annual revenues have dropped by 9.86% and are continuing to decline despite the alterations to the current SCR approach.

Based on the information regarding the drastic state of the company’s suppliers, one may suggest changing the company’s approach towards choosing the raw materials and the organisations providing it. Particularly, more expensive options need to be considered. Although Mattel has been rather wise in its choice of cheap resources for retrieving raw materials, the current rates of the organisation’s key suppliers make it very obvious that the firm should consider the partners such as

Global supply chain management

The transfer to the global economy area was a necessary step for Mattel, as it allowed the company to expand into new markets and explore new opportunities in attracting customers from all over the world. However, the creation of the global supply chain management was fraught with a range of difficulties that stemmed from the problems in the overall SCM design of the company. At present, Mattel’s global SCM approach can be defined as aiming for expansion into new markets. Specifically, the Asian market (China in particular) needs to be brought up as one of the target areas that Mattel views as a priority at present.

Indeed, a closer look at the situation that Mattel has found itself in will show that the company has been suffering from the lack of expertise in the choice of international partners for its SCM. Specifically Mattel does not seem to be able to evaluate the feasibility of specific business relationships as it chases the solutions that will lead to the smallest losses possible. True, the reduction of losses is an essential step in creating a viable SCM strategy; however, even when facing the need to isolate the cheapest options, the company must consider quality along with pricing issues. Therefore, in order to update its SCM correspondingly and improve the quality of the products released, Mattel, inc. will need to create new ties with other suppliers.

As far as the current options regarding suppliers are concerned, Mattel might view Apple, Inc. and BigFishGames as an alternative to the organisations, the services of which it is using presently (e.g., THQ). Providing an array of services regarding games development and promotion, the above-mentioned companies also provide quality based on the reviews of their numerous customers and the corresponding audit results (Parker, Cox & Thompson 2014). Thus, the essential dent in the overall admissible approach towards SCM can finally be addressed by Mattel successfully.

Conclusion

Mattel, Inc. has gone a long way since the time of its foundation. The company has evolved fast enough to take its niche in the global market and even land at the top of the charts of the world’s largest and most profitable organisations. However, because of the recent inconsistencies in the choice of suppliers for its SCM strategy, the company has seen a large drop in its annual income; more importantly, the flaws in the current SCM design do not allow Mattel to evolve further and explore new opportunities. Therefore, the firm will have to re-evaluate its approach towards costs management and choose more adequate suppliers, even if the given step will trigger an increase in Mattel’s expenses list.

An analysis of the organisation has shown that the SCM approach cannot possibly exist on its own, isolated from the rest of the organisational processes; quite on the contrary, the SCM approach is linked directly to the issues such as the corporate ethics, company values, principles of decision-making and the leadership strategy. Aiming at reaching the top of the global toy industry, Mattel’s leaders seem to have left the principles of environmentally friendly approach and customer satisfaction out of their focus, which has resulted in a streak of failures over the past few years.

Although Mattel is trying to redesign its current operations so that it could integrate into the global economy once again and retain its customers, the firm clearly needs to revisit its ethical principles, quality standards, the processes of decision-making and the company’s financial strategy; consequently, the identification of the potential suppliers should be viewed as the way of providing the target audience with the product of the finest quality instead of the endeavours at selling a comparatively cheap product for a moderately high price. Once Mattel gets its priorities straight, the organisation will inevitably regain its position as the producer of not only entertaining, but also high quality products. As a result, Mattel will both regain its past customers and attract new ones.

Reference List

About us 2015. Web.

Barboza, D & Story, L 2007, ‘Mattel issues new recall of toys made in China,’ The New York Times.

Bugalla, J & Narzaev, K 2014, ‘Five ways to manage supplier risks,’ CFO.

Cecere, L 2014, ‘Which metrics Matter? Interview with Philippe Lambotte,’ Supply Chain Shaman. Web.

Chao, 2015, Mattel Reports fourth quarter and full year 2014 financial results. Web.

Christopher, M 2011, Logistic and supply chain management, Financial Times Series, Upper Saddle River, NJ. Web.

Dittman, J P 2014, Game-changing trends in supply chain. Web.

Dobrivojević, G 2013, ‘Analysis of the competitive environment of tourist destinations aiming at attracting FDI by applying Porter’s Five Forces Model,’ British Journal of Economics, Management & Trade, vol. 3, no. 4, pp. 359-371. Web.

Gligor, D M & Holcomb, M C 2012, ‘Understanding the role of logistics capabilities in achieving supply chain agility: a systematic literature review,’ Supply Chain Management: An International Journal, vol. 17, no. 4, pp. 438–453. Web.

Kotchen, M & Moon, J J 2012, ‘Corporate Social Responsibility for Irresponsibility,’ The B.E. Journal of Economic Analysis & Policy, vol. 12, no. 1, pp. 1–21. Web.

Mattel reports fourth quarter and full year 2014 financial results 2014.

Mattel’s suppliers performance 2014.

O’Brien, J 2005, ‘Real world: case 5. Wal-Mart and Mattel: supply chain management best practices,’ in J A O’Brien & G M Marakas (ed.), Management information systems, 10th edn, McGraw-Hill Education, New York City, p. 282. Web.

Packowski, J & Francas, D 2014, ‘Lean SCM. Part 4: Organizational design for world-class performance management,’ Indian Journal of Pharmaceutical Sciences, vol. 76, no. 6, pp. 878–882. Web.

Parker, R, Cox, S & Thompson, P 2014, How technological change affects power relations in global markets: remote developers in the console and mobile games industry.

Tang, C 2014, ‘Mattel’s Executive Vice President Thomas Debrowski shares his insights about “global supply chain in the toy industry,’ The UCLA Anderson.