PV Module as an Asset in the Environmental Industry

Key issues to be addressed for this asset in the Risk management process

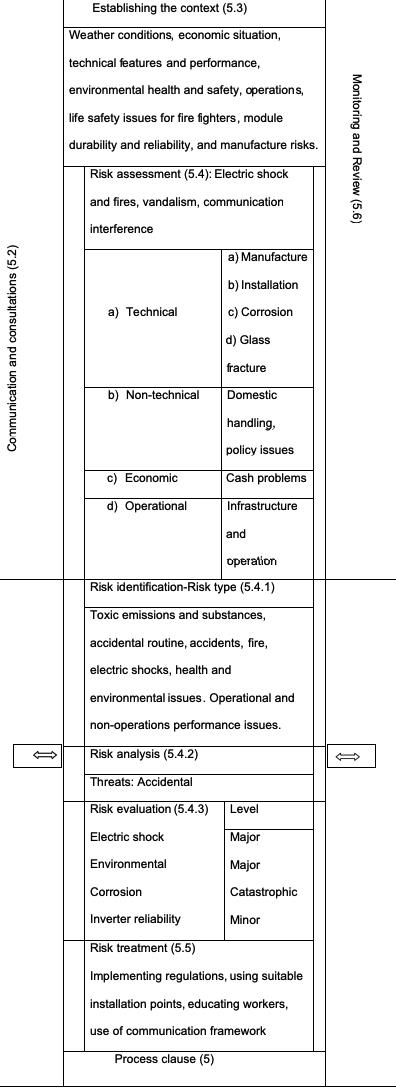

During the Photovoltaic Module (PV) life-cycle asset management, potential risks happen in each phase of the product lifecycle following the management approach of designing and operating the risk management process. According to Arnold (2014), it emerges that the risks associated with the PV module are classified into technical and project operational risks as well as non-technical development and operational risks. In designing and operating the risk management process, different issues arise following clause 5 of the ISO 31000 risk management system as shown in figure 1.

Hopkin (2014) notes that the clause consists of the key elements, which include establishing the context of the risks concerning Photovoltaic PV modules, conducting a risk assessment, identification, evaluation, and treatment as embodied in the ISO 31000 Risk Management System. Typically, clause 5 recommends that “the development and implementation of a framework whose purpose is to integrate the process of managing risk into the organization’s overall governance, strategy, and planning, management, reporting processes, policies, values and culture” (Purdy 2010 p.2). The key issues that arise when designing and operating the risk management process are inclusive of the following features:

Key issues

- Health and Safety Concerns

- Hazards due to installation

- Firefighting

- Outdoor weather exposure

- Chemicals in PV fuel cycle

Health and Safety Concerns

The issues that arise here are related to the potential hazards that workers of small and medium-sized get exposed to during the installation, decommissioning, and recycling of the PV modules. According to Purdy (2010), the risk assessment starts here as per sub-section 5.4 of clause 5 of the ISO 31000 risk management system when used to generate electricity and heat energy. It also includes the risks associated with the health and safety of workers involved in the manufacture of solar installations. A risk assessment shows that the potential hazards are due to the electrical shocks that often happen during the installation process because once the modules get exposed to sunlight, they immediately start to generate direct current (Mirzahosseini & Taheri 2012). Such a reaction increases the possibility of producing high voltage flashes that can damage the module which could lead to the risk of electrocution and severe burns.

A risk assessment shows that workers on duty are vulnerable to a combination of health and safety risks because of continuous exposure to PV burns, toxic metals and chemicals, musculoskeletal disorders, and issues associated with working at a height from the ground (Hopkin 2014). The work organization and psychological risks constitute the additional vulnerabilities that the workers get exposed to. Besides, Mirzahosseini and Taheri (2012) note that the issue of a different and diverse workforce with different skills, the use of subcontracted workers who might not have the requisite skills and knowledge on PV installation, decommissioning, and recycling are inclusive of the issues that arise in the risk management process (Hopkin 2014). It is also imperative to note that the disposal of recycled materials and other waste products resulting from the production or manufacturing of PV modules exposes the worker to health and safety risks as well as the probability of increasing the risk of the PV modules getting damaged due to leakages and the presence of some semi-conductor materials on the surface of the finished product.

The risk of getting adversely affected by hazardous material and related products increases due to the production of PV modules and related products. That is because the waste resulting from the activities, which accounts for 99% of the modules produced in the world has significantly increased the risk of exposure to occupational hazards (Mirzahosseini & Taheri 2012). Often, most of the risks associated with the health and safety of the workers are due to inhalation of semiconductor materials and the other chemicals used to manufacture the modules. According to Mints (2012), decommissioning and recycling is known to be the source of 0.5% of lead in the U.S.A, 2.5% polyvinyl fluoride substrate, 7.5% ethylene vinyl acetate encapsulation, and 20% aluminum related wastes.

There is a need to consider manual handling of the PV modules during the production, installation, and decommissioning period (Hopkin 2014). One of the proposed methods of addressing the problem is to use ergonomics of scale during the handling process, the use of vacuum tools, and the implementation of robotic systems to handle the lifting of PV modules.

Hazards Due to Installation

When installing the modules, it is possible to work from a height. Such working conditions subject the worker to the risk of slipping from glazed tiles (Mints 2012). Also, roofs with large pitches, damaged or brittle roofing, and fragile roofing are among the issues that an asset engineer needs to factor into the risk management process (Hopkin 2014). It is appropriate to carefully consider the long term safety during the installation. Among the issues that have been recommended include restricting access to the modules especially those parts that are susceptible to shock, integrating a fault protection system during the design and installation of the modules, and the use of appropriate D.C wiring methods. The other issues that have been proposed to address include using appropriate earthing via the circuit protective conductor and the use of Protective equipotential bonding.

Firefighting

Fire sometimes can be started by the sparks or electrical faults of some kind that occur, leading to the destructive effects of fire on the module and where it is installed. According to Hopkin (2014), the likely sources of dire that have been noted among installations of PV modules include fires originating from the modules, overheating junctions, conventional centerfire, residential fire, and any other malfunctioning of the PV modules. Some options have been suggested as appropriate for addressing the risk of fire.

Among the solutions that have been suggested include shutting down the flow of current. However, the approach has been deemed to be of little help because it is merely a way of interrupting the flow of current leaving out the voltages that are likely to be very high. Hopkin (2014) provides evidence which shows that installations use automatic DC breakers that disrupt the flow of D.C current that are located at the inverter cabinet. However, it has been demonstrated that such a disconnection does not prevent the occurrence and destructive effects of fire (Hopkin 2014). The risk of such a system causing fire has to be factored into the risk management process to ameliorate the level and effects of the risks.

On the other hand, it has been suggested that PV modules should be covered with foam sprayed directly on the surface of the PV module could prevent the spread of fire. Such an approach has been proved to be ineffective because the foam does not stick to the surface, but slides off the surface of the module.

Outdoor Weather Exposure

The risk of getting exposed and adversely affected by outdoor weather conditions besides the other effects due to environmental exposure is a significant source of risks. When designing the risk management process, it is imperative to consider various issues factors that happened due to the installation of the PV modules on the roofs and the environmental impact because of exposure to various forces (Hopkin 2014). Exposure and effects of direct ultraviolet light, high temperatures, mechanical load, thermal cycling, mechanical abrasion, moisture and humidity conditions, and atmospheric chemicals are some of the factors to consider during the risk management process (Lam 2014). Often, different methods have to be used to test the durability and ability of the PV module to withstand the effects of atmospheric elements that degenerate the efficiency of the module (Hopkin 2014). Among the methods that have been suggested include the DuPont Testing Protocols. The specific parameters to test include the behavior when subjected to heat, UV light, thermal cycling, and humidity freeze.

Chemicals in PV fuel cycle

According to the US Environmental Protection Agency (EPA), a chemical that constitutes the production and use of the PV modules should be regulated by the Clean Air Act Amendments of 1990. Besides, there should be guidelines to prevent the occurrence of accidents in case of the use of extremely hazardous chemicals. In addition to that, there should be a risk management plan that addresses the risk of exposure to the chemicals (Jeston & Nelis 2014). The risk of chemical happens in the process of acquiring raw materials, production of the PV modules, installation, heat and electricity generation, and disposal or recycling of the materials. In practice, it has been observed that 61% of the accidents reported in the industry have been due to hydrogen peroxide, one of the chemicals used in the production of PV cells.

Operating Performance Risk

It is important to ensure that the risk of operating the PV modules, which arises due to project development risks appropriately, factors the planning and construction functions. If properly addressed, the problems that arise due to the risks can be ameliorated properly (Lam 2014). The risks arise due to poor resource estimation leading to the potential shortfalls in the number of construction materials, poor component specification, system design issues, site characterization, and equipment damage (Hopkin 2014). Such risks can introduce failures due to potential damages, latent PV module defects, unexpected and forced outages, frequent unplanned maintenance, and off-taker infrastructure risks.

Non-Technical Development Risks

The most common risks in the category of non-technical development risks are policy regulations and macro-economic conditions. These situations include developer risks and construction risks.

Figure 1: Clause 5 31000 Risk management framework.

Risk Management Process Map According to Clause 5 of ISO31000

By clause 5 of ISO31000 standard, it can be noted in figure 2 that the risks have been mapped into six sections which include establishing the context (5.3), risk assessment (5.4), risk identification (5.4.1), risk analysis (5.4.2), risk evaluation (5.4.3), and risk treatment (5.5) (Jeston & Nelis 2014). Besides that, there are communication and consultations (5.2) and the monitoring and review (5.6) components of the risk management map. Each of the elements operates at a different level in the risk management framework, which has been mapped into the PV module clause 5 of the ISO31000 risk management component (Jeston & Nelis 2014).

The context of designing the risk management process begins with understanding the factors that impinge on the performance of the asset and the workers who install, service, recycle, and decommission the PV modules (Hopkin 2014). This is demonstrated in table 1 where environmental, technical, economic, and regulatory issues emerge as critical factors that have implications on the risk management process (Jeston & Nelis 2014). Once the context has been established, the phase of the risk assessment process sets in to determine the hazards, the risks associated with the hazards, and the best ways to address the risks. That is followed by the risk evaluation, which deals with the type of risks and the implications associated with each risk. At the risk evaluation level, the vulnerability of the risks in the asset management framework leads to serious effects on the technical functionalities of the PV modules in the entire asset lifecycle.

This is followed by the risk treatment process, where in theory, three approaches have been recommended to effectively address the risk phase. The key approaches that have been proposed include transferring the risks to a third party. However, the approach is inapplicable to a significant extent except by the use of insurance cover. The next approach is risk avoidance. Risk avoidance is inapplicable in this context because it entails avoiding using the asset for electricity and heat generation. Risk acceptance and mitigation plan provides the most appropriate approach to use, which has been recommended and discussed in the next section.

Recommend Changes to the Current Process

According to clause 5 of the 31000, the risks management framework consists of the key process elements of establishing the context in which the framework should be established. It is recommended that the managers and workers should be educated to be made aware of the risks that are related to solar power and energy generation besides using an assessment to determine whether the organization has adopted practical risk assessment and identification methods (Jeston & Nelis 2014). Training should form the backbone of the risk management framework to ensure that comprehensive risk assessment techniques are applied in the process.

It is imperative to include real-time or reliable communication mechanisms and networks to ensure that any incident of risk is communicated to the asset manager. Typically, the communication channels should be two way. Another element that should be integrated into the risk management framework is the risk evaluation process throughout the asset or PV module lifecycle (Jeston & Nelis 2014). It is imperative to note that a technique that factors practical approaches to risk assessment ad evaluation should be applied. The key elements that should be included in the risk assessment process are:

Detailed Recommendations

- An assessment of the existence or absence of the risk at the place of work

- Determining whether the risks have been eliminated or ameliorated at the workplace.

- Establish whether control measures to reduce the impact of the risks are in place.

- Determine the degree of impact the risks could have on the health and safety of the workers.

- Establish the level of exposure of dangerous chemicals to workers and occupants where the PV modules are installed.

- Assess the availability of mechanical ventilation throughout the fabrication.

- Evaluate the framework for the availability of an emergency plan.

- Ensure that the asset management framework has factored the datasheet for the PV module, which contains several technical instructions.

The section is an important component of the risk management process in the engineering asset management practice because it provides the datum line on which the risk management process begins (Mints 2012). However, it is worth noting that the approach can be improved by first exploring different environments where the PV modules are manufactured, installed, and used as well as decommissioned and sometimes recycled. Such an approach could enable the company to develop a risk management framework that factors every aspect that deals with the health and safety, installation, fires, and exposure to the environment once the modules have been installed for use to generate electricity and heat (Mints 2012).

The aspect that deals with the health and safety of the workers and the operational safety of the PV modules once they have been installed should be factored into the risk management framework. Examples include establishing the context in which the technological basis on which the PV modules are manufactured and operated. The technological basis includes the technical aspects of the asset lifecycle, which includes production, installation, use, decommissioning, and recycling as mentioned before.

Health and safety

Typically, the health and safety hazards could include exposure to heat due to hot water and electric shocks, which constitutes the aspects of risks to factor into the risk framework. The technical aspects related to the establishment of the risk management framework include the technology and use of silicon, the semiconducting material underlying the raw materials, and manufacturing processes of the solar cells that convert radiation into electrical or heat energy (Mints 2012). That is also concerning the cadmium telluride (CdTe) materials and the flow of current across the layers that make the semi-conductor materials.

In the installation, maintenance, decommissioning, and recycling process, the risk management framework constitutes the important aspects of the psychosocial risks as well as the work organization (Kelly, Male & Graham 2014). These should include making available information on the electrical installation of electrical systems and the hazards and risks associated with the process. Also, it includes establishing the availability of properly skilled workers to work on the installation and wiring of the modules as well as those who are trained in safe handling procedures (Mints 2012). The other recommended approach is to educate all the workers on the risks such as work-related stress and tight schedules. It is important to ensure that the communication channels are efficient and reliable.

Insurance is the last line of defense that should be factored into the risk management framework because it enables the company to transfer the risks by using it as a risk mitigation technique. The approach is appropriate to address the risks associated with the economic and manufacturing process.

Managerial issues

In conclusion, to accommodate the issues arising due to the pertinent issues related to the health and safety concerns, hazards due to installation, firefighting, and outdoor weather exposure, it is important to factor risk assessment at different levels of asset management (Mints 2012). These include an assessment at the business level that could potentially impact the business objectives. Asset portfolio risk assessment includes identifying the risks associated with the asset lifecycle, which includes production, installation, and maintenance, decommissioning, and recycling of the PV modules. Besides, an inventory category and the methods in place to address the risks that happen due to maintenance issues.

Reference List

Arnold, G., 2014. Corporate financial management, Pearson Higher Ed, New York.

Hopkin, P., 2014. Fundamentals of risk management: understanding, evaluating and implementing effective risk management, Kogan Page Publishers, New York

Jeston, J. &Nelis, J., 2014. Business process management, Routledge, London SW1P 1WG.

Kelly, J., Male, S. and Graham, D., 2014. Value management of construction projects, John Wiley & Sons, New York.

Lam, J., 2014. Enterprise risk management: from incentives to controls, John Wiley & Sons, New York.

Mints, P, 2012, ‘The history and future of incentives and the photovoltaic industry and how demand is driven’, Progress in photovoltaics: research and applications, vol. 6, no. 20, pp.711-716.

Mirzahosseini, AH, Taheri, T, 2012, ‘Environmental, technical and financial feasibility study of solar power plants by RETScreen, according to the targeting of energy subsidies in Iran’, Renewable and Sustainable Energy Reviews, vol. 5, no. 16, pp. 2806-2811.

Purdy, G 2010, ‘ISO 31000: 2009—setting a new standard for risk management’, Risk Analysis, vol. 6, no. 30, pp.881-886.