Abstract

The issue of preventive maintenance in relation to reliability can be interpreted as the practice of maintaining equipments or systems before they indicate any incidences of failure. Preventive maintenance is also akin to avoiding or mitigating repeated failure of machinery and equipment. This practice is aimed at improving the reliability of equipment and consequently reducing the costs that are associated with the replacement of parts and periodical system shutdowns. When preventive maintenance is up to par, it can also contribute towards higher sustenance of systems’ functionality. The only concession that applies to this last benefit is that maintenance has to be timely and professional. This project reviews the literature that is associated with preventive maintenance in accordance with MTTF and MTBF approaches. The reviewed literature addresses preventive maintenance using Maintenance Repair and Overhaul Performance indicated for Military Aircraft. Several aspects of preventive maintenance are covered throughout the paper, including analytic capability, accessibility, failure rates, and reliability.

Introduction of Literature

When it comes to the preventive maintenance of military aircraft, the goal is to guarantee a level of reliability that helps to keep the planes ready for deployment. Consequently, all forms of maintenance are aimed at being preventive and proactive. The genesis of Maintenance Repair and Overhaul Performance indicators can be traced back to the World War II period and the subsequent Cold War related tensions. Substantial resources had gone towards to improving and producing highly functional military craft. Some of these resources went towards coming up with outstanding designs, streamlining maintenance operations, and improving reliability.

These activities also incorporated the need for training highly effective maintenance teams with the view of safeguarding the initial investments. The purpose of this literature review is to identify a method of performance measurement that can quantify aircraft maintenance activities. Furthermore, the measurements should have the ability to correlate with effective managerial systems that apply to aircraft maintenance. The definition of reliability as outlined in this paper refers to the ability of a system to function correctly and complete the desired tasks in the course of a predetermined period and under certain conditions. The exploration of facts is in line with the activities that accompany the operations and maintencne of aircrafts. In addition, the significance of having a definite and recordable process that can be quantified is a key element in this review.

Nomenclature

MTTF = Mean time to failure

MTBF = Mean time between failures

λ (t)= Failure rate

ƒk = Failure density function of the kth

ƒR = Repair frequency

f(t) = Probability density function

L(t) = Total failure function of repairable.

C= Total cost

CR= Cost of repair

CM= cost of maintenance

Is = Serviceability Index

Tup = Aircraft Uptime

Ibd = Index for Breakdowns

Wi = Work accomplishment Index

Iec = Environmental condition Index

Cnew = As Good as News Index

Overview of Literature

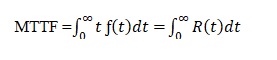

This literature review consists of two articles, which address the topic of preventive maintenance. The two articles encompass a similar approach as they access different aspects of aircraft maintenance such as maintainability, accessibility, and manufacturing capability within a certain system. For instance, the article on the impact of preventive maintenance on reliability addresses issues that touch on safety. The calculations that were used in the study were meant to offer support to the elements of time and cost. When these factors are brought together, they make up the MTTF and MTBF aspects of preventive maintenance. Below is one of the equations that are used to address these concepts, such as failure instances and costs of repair.

Equation (1)

The values of ƒ (t), L (t), λ (t), andƒR are then defined and applied.

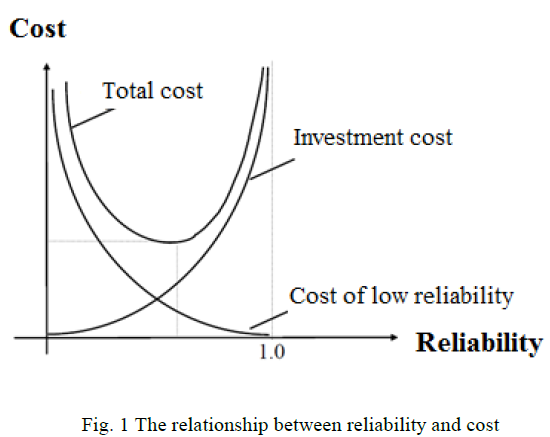

By applying this equation, the failures in any system are found to increase a system’s reliability by adding components that are more reliable. On the other hand, the cost-reliability factor was found to decrease after it reached a certain threshold.

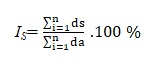

The article on “Maintenance, Repair, and Overhaul Performance Indicators for Military Aircraft” dwells on the calculation of maintenance performance using performance indicators (PMIs). These calculations are used to evaluate the efficiency of carrying out maintenance as an independent measure. This factor can also be used as a measure of group competency and the resulting operational availability index. The equation for calculating this serviceability index is laid out below.

Equation (2).

The efficiency of maintenance is measured using the ratios of the summing number of service-days for each aircraft. The insertion of the environmental factor in this equation is meant to account for differences in working conditions for different aircraft.

the effects of aircraft preventive maintenance on reliability:

The article’s analysis was concerned with finding out how various functionalities within an aircraft’s maintenance, such as the braking system and control system. The article also utilizes the Functional Failure Modes and Effects Analysis (FMEA) as well as a two-stage method of analysis. In the course of addressing the preventive maintenance schedule, the authors of this article adopt an approach that is considerate of both zonal and structural factors in its analysis. The calculations in this article seek to unravel the reliability analysis of the non-repairable components of aircraft. These are also the components that increase a system’s reliability owing to the connection between cost and reliability, as demonstrated below in Figure 1

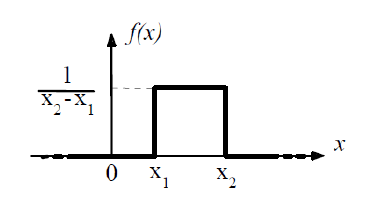

In the course of this article’s calculations, it becomes clear that randomness and normalcy of distribution are important significant variables in the subsequent reliability analysis. The sampled elements can also be applied to various forms of experiments through the utilization of Poisson or Chi2 distribution. The resulting outcome is a reliable solution to maintenance frequency. The f(x) function represents probability density, and it can only be applicable for the limited time of between zero and five years. Figure 2 demonstrates how the distribution function can be reliable in the course of calculating the reliability of a certain component in relation to maintenance.

The function of destitution is,

0, otherwise

The article also examines the maintenance data that spans a period of five years and in the context of three different case scenarios. Under regular preventive maintenance (TM=1 year), the correlating reliability is expected to be higher than 80%

Maintenance, repair, and overhaul pERformance indicators for military aircraft:

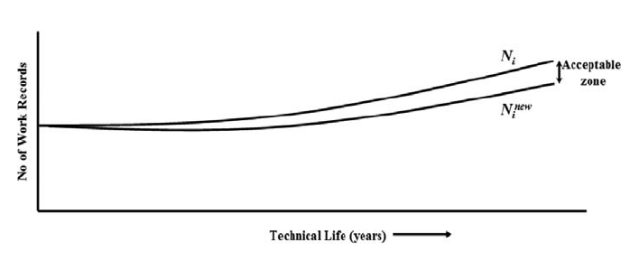

Maintenance PMIs of aircraft include tools for implementing maintenance performance systems. This process is implemented with the view of measuring the values of the entire maintenance process. Some of the improvements that relate to key indicators include carrying out repairs and overhauls of parts. This article presents an analysis of how factors such as work accomplishment, time, equipment breakdowns, and environmental conditions relate to PMIs. The authors of this article came up with a new standard of measuring repairs, maintenances, and overhauls. This system uses records from localized operations within an organization. Figure 3 shows the variations of the total number of maintenance-related activities in their technical capacity.

This article has successfully come up with a method of quantifying the probable duty accessibility of an aircraft. The planned maintenance of an aircraft can be optimized by the normal usage of the machine as well as the elements of the time-bound accomplishment of preventive maintenance. The measurement of performance, as discussed by this article, has become a useful tool to all levels of workers, including the aircraft maintenance staff and also the top level of management, in the overall purpose of maintaining high standards of safety.

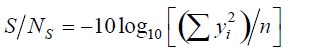

In an efficient method of gauging fault diagnosis, ɳfd time is used as a reliable utility value. Therefore, the sums of snags in a certain timeframe are related to the diminishing time and improvement in the signaling of noise, with the view of achieving accuracy.

Where,

S/NS signal to noise for shorter the better time.

yi Time is taken for the correct rectification.

ɳfd Max(S/NS).

These articles were chosen depending on various factors, including their relevance to practical maintenance practices. For individuals with experience as preventive maintenance technicians, the articles provide them with a wide range of practical applications.

Another rationale for choosing these articles was the fact that working in this field provided a chance for implementing maintainability and reliability. The analytic tools in both articles could also be reliable measures of preventive performance. The two articles were focused on the need for excellence in the course of maintenance, systems reliability, and persuasion of efficiency.

Discussion

These articles have relevant contributions to the topic of reliability that results from timely replacements. Therefore, the conditions that contribute towards the results are worth noting. There is also a risk that the values of deficient reliability can be calculated as a minimum cost for the purpose of ensuring high levels of dependability in a certain aircraft.

Contributions of the effects of aircraft preventive maintenance on reliability:

The review of this topic contributes to the technical contributions of values that are achieved as a result of applying preventive maintenance. This preventive maintenance is not used in relation to MTTF, and it involves frequent distribution values, information on homogeneity, and other calculation efficiencies. Furthermore, there are significant aspects of preventive maintenance that exist in relation to reliability conditions. These basic concepts are explained through simple applications, which are related to preventive aircraft maintenance

CONTRIBUTIONS of Maintenance, repair, and overhaul preformance indicators for military aircraft:

There are significant contributions in relation to an aircraft’s preparedness and reliability. These contributions add to the purpose of maintaining a functional and reliable serviceability index. A reliable index takes into account the levels of work accomplishment, breakdown logs, and overall effectiveness. All these factors are aimed at providing high levels of efficiency and reliability. Therefore, aircraft companies can be able to gauge how maintenance contributes towards their overall business goals.

Discussion of Dificiency and Potential Improvements

The two articles have shortcomings in their assessment of maintenance performance in the context of various working conditions and skill levels. These articles are not able to decipher the accurate impact of work accomplishment and skills in their quest to understand the system’s reliability.

Deficiencies the effects of aircraft preventive maintenance on reliability:

This article addresses technical deficiencies as the result of having preventive-maintenance on reliability. On the other hand, the values of MTTF are directly related to the number of system failures in reference to repair costs and working tasks. Therefore, improvements can be related to changes in reliability, preventive maintenance, and scheduling within a Tm value of 1 year. This approach reveals that the critical juncture in an aircraft maintenance regime lies in the maintenance intervals of between 0.2 and 0.25.

Deficiencies of Maintenance, repair, and overhaul pERformance indicators for military aircraft:

The apparent technical deficiencies in this article include the fact that the top management is in charge of outlining performance. An effective model of ensuring above-average performances includes non-management-oriented variables such as environmental conditions. It was up to the MPIs to make up for these types of ratio deficits by including other preventive maintenance factors.

Summary

These two articles are effective in their bid to outline the importance of preventive maintenance. The application of preventive maintenance in regards to MTTF is also well executed in the two articles. For instance, it is apparent that downtime in the flight departments could result in both short-term and long-term financial implications. Maintenance of aircraft involves regular testing and monitoring of equipment. Therefore, it is important for military aircraft operators to create efficiency by minimizing downtime through their ability to make an accurate diagnosis of problems and maintaining high levels of reliability.

References

Kiyak, E. “The Effects of Aircraft Preventive Maintenance on Reliability.” International Journal of Applied Mathematics and Informatics 6.1 (2012): 9-16.

Raju, V. R. S., O. P. Gandhi, and S. G.Deshmukh. “Maintenance, Repair, and Overhaul Performance Indicators for Military Aircraft.” Defense Science Journal 62.2 (2012).