Introduction

Table 1: Project Scope Statement.

In the aviation industry, aircraft maintenance is integral in ensuring that an aircraft operates effectively. According to Stoop, de Kroes and Hale (2017), safety is an important issue in the effective performance of an organization in the aviation sector. Line maintenance is an aircraft maintenance area that involves regular checks such as lubrication, evaluation, and rectification of any defects (Reason and Hobbs, 2017). This maintenance aims to promote safety and eliminate accidents caused by human errors. For example, according to AAIB, the accident by British Airways B787 was caused by human error (Frances, 2019). Based on this, the airways require a new line maintenance for B787 to improve its safety and airworthiness. The project manager is tasked with planning and delivering of B787 maintenance project for British Airways.

Project Purpose

- The aim of this project is to plan, create, and implement a maintenance program for the existing B787 aircraft for British Airways.

- There is a need for ample space where the operation will take place within the airways to achieve this.

- The space will be equipped with maintenance tools ranging from B787 spare parts and equipment required for the process (Karami, 2017). In addition, skilled personnel with a good understanding of aircraft operations are necessary.

- EASA part 145 approval will be sought to ensure that the maintenance department is certified and can engage in the aircraft’s maintenance, inspection, and alteration.

- The stakeholders in relevant departments within the airways will be allowed to view, manage and update the project’s status.

- The quality department manager will be engaged in most areas, such as purchasing spare parts, hiring employees, training, developing a maintenance manual, and more (Classen, Werner, and Jung, 2017).

- The finance manager will be required in most of the stages where funds are required. The project manager will organize meetings and communicate regularly with various stakeholders within and outside the organization. For example, communication with key stakeholders on the project status will be done every Wednesday and Fridays through either virtual or physical meetings.

Work Breakdown Structure

Table 2: WORK BREAKDOWN STRUCTURE (Modified from source: Usmani, 2022).

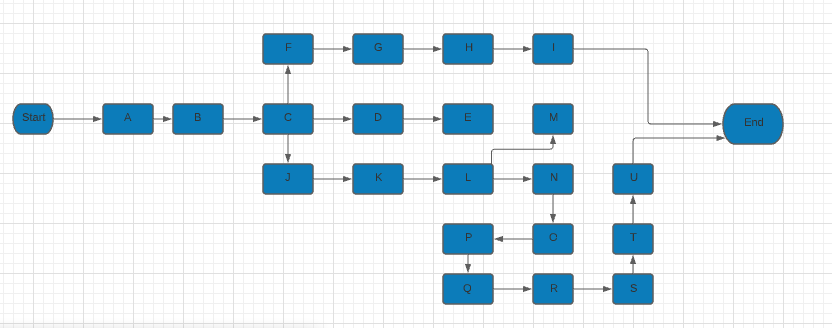

A Network Plan

Project Activity and Nodes

Table 3: PROJECT ACTIVITY AND NODES, a plan on how the project will handled (Modified from source: Usmani, 2022).

A Resource Plan

Table 4: A RESOURCE PLAN, indicate the tasks assigned to different people (Modified from source: Plan 2019).

The Four Main Risks

The project’s performance risk occurs when it fails to deliver results that fulfil its objectives. For example, a project can be completed on time and within the set budget but fails to achieve the desired outcome (Sanchez and Terlizzi, 2017). If the outcome causes the project’s cost and duration to increase, it is due to performance risk. For example, this project aims to plan and create an effective maintenance program for B787 aircraft (Naghizadeh et al., 2017). In addition, it is intended to promote safety and make the aircraft airworthy. The failure to achieve the anticipated safety, the project would be considered unsuccessful. The airways would have misused funds and time on a project that failed to accomplish its goals.

Poor communication among the project team and stakeholders may affect the project’s outcome. When one controls a project, one must adhere to a work ethic of efficient and time-based communication (Bandage et al., 2018). Organizing meetings with relevant stakeholders like project sponsors enables a project manager to update any modifications to the project, reassign tasks, and create a cohesive team. However, poor communication resulting from system failure or just ignoring the message may lead to data loss or misinformation and project disruption (Lundgren and McMakin, 2018). For example, ineffective communication between the project manager and finance team of the airways may hinder the project of operations, such as the purchase of spare parts. Therefore, inadequate communication is one of the risks that can affect the project.

The failure to comply with regulatory authorities is one of the risks that the project may experience. Compliance has always been an important aspect for organizations in the aviation industry (Cokorilo, 2020). There is a lot of pressure from regulatory authorities for airways to comply with the set safety standards and requirements. For example, it must obtain parts 145 and 147 approval for the project to be considered successful. If the maintenance project does meet the set standards, there is a high probability that it will not be approved. This means that the project manager will be required to identify the faults and solve them to approve the project. Apart from parts 145 and 147, a quality department is expected to approve the spare parts and materials to be used in maintenance.

The unavailability of skilled and licensed employees to help with the maintenance program. The effectiveness of labors’ better training has a substantial effect on increased project production. The shortage of experienced professional laborers directly impacts the productivity of aviation projects (Banfield, Kay and Royles, 2018). In addition, there is a relationship between a lack of qualified staff and a downturn in project productivity. Projects with unskilled staff experience higher material and labor costs, project delays, inadequate scheduling, and a lack of quality to meet the project’s target. As a result, the project’s success depends mainly on a skilled labor force to help run the maintenance operations.

Risk Prioritization, Assessment and Control

The identified risk should be prioritized, analyzed, and controlled. The risk prioritization should be done to ensure that the project team majors on addressing the more important one. For example, as shown in the table below, the project team should consider mitigating the performance risk due to its likelihood and prioritization ranking. The risks should be assessed to determine their impact on the project’s performance. For example, the maintenance project might fail if there is a lack of trained and licensed employees to run the process. Based on the impact of these risks, they should be mitigated. There are various mitigation strategies that the project manager can use to counter the risks. Therefore, risk prioritization, analysis and control are crucial in managing risks.

Table 5: RISK ASSESSMENT AND CONTROL, risks that can affect the project (Modified source: Boom et al. 2021).

Measuring Risks Likelihood

Table 6: MEASURING RISKS LIKELIHOOD, how risks are rated (Modified source: Bohman 2020).

Measuring Risk Likelihood and Severity

Table 7: MEASURING RISK LIKELIHOOD AND SEVERITY, how risks are measured (Modified from source: Bohman 2020).

Project Controls

Project control is a function that is integral for achieving successful projects. The success of a project entails having the right team tools and making sure there is adequate time for project planning (Kerzner, 2018). One of the project controls to be managed during the project is a schedule. A project manager will ensure that all the tasks are completed within the set project. The other project control is budget management because it can determine the success or failure of the project (Kerzner, 2018). I will ensure that ensure the project operates within the set budget. In addition, the risks identified will be managed effectively prior to and during the project. Therefore, the identified controls are effective in completing the project.

Conclusion

The new line maintenance project is critical to ensuring that B878 functions efficiently. Line maintenance is a kind of aviation maintenance that entails routine checks such as lubrication, appraisal, and repair of any problems. The primary goal of this project is to increase safety and reduce accidents caused by human error in the airways. The project manager is tasked with planning and executing a B787 maintenance project for British Airways. The project will take about three months to be completed. The project starts with initiation and ends with closure and handover to the airways. To effectively achieve the project goals, aspects such as budget, risk, and schedule will be monitored closely. As a result, appropriate operations will ensure that the project’s objectives are met.

Reference list

Banfield, P., Kay, R. and Royles, D. (2018). Introduction to human resource management (3rd ed.). UK: Oxford University Press.

Bohman, C., PE. (2020). How to Use a Scoring System When Assessing Risks. Matrix Technologies Incorporated. Web.

Boom et al. (2021). Reducing the risk of non-sterility of aseptic handling in hospital pharmacies, part B: risk control. European Journal of Hospital Pharmacy, 28(6), pp.325-330. Web.

Cokorilo, O., (2020). ‘Urban air mobility: safety challenges’. Transportation research procedia, 45, pp. 21-29. Web.

Classen, A.B., Werner, C. and Jung, M. (2017). ‘Modern airport management–fostering individual door-to-door travel’. Transportation research procedia, 25, pp. 63-76. Web.

Dandage et al. (2018). ‘Analysis of interactions among barriers in project risk management’. Journal of Industrial Engineering International, 14(1), pp.153-169. Web.

Frances, D.A. (2019). Airline and Operator Legal Liability for Pilots and Their Selection Practical Issues and What Is Enough? 1. In Pilot Selection (pp. 121-142). US: CRC Press.

Karami, A. (2017). Corporate strategy: evidence from British Airways plc. In The Changing Patterns of Human Resource Management (pp. 46-64). UK: Routledge.

Kerzner, H. (2018). Project management best practices: Achieving global excellence. US: John Wiley & Sons.

Lundgren, R.E. and McMakin, A.H. (2018). Risk communication: A handbook for communicating environmental, safety, and health risks. US: John Wiley & Sons.

McFadden, M. and Worrells, D.S. (2012). ‘Global outsourcing of aircraft maintenance. Journal of Aviation Technology and Engineering’, 1(2), p.4.

Naghizadeh et al. (2017). ‘Managing integration in complex product systems: The experience of the IR-150 aircraft design program’. Technological forecasting and social change, 122, pp. 253-261. Web.

Plan, I.R. 2019. ‘Integrated resource plan’. Web.

Reason, J. and Hobbs, A. (2017). Managing maintenance error: a practical guide. US: CRC Press.

Sanchez, O.P. and Terlizzi, M.A. (2017). ‘Cost and time project management success factors for information systems development projects’. International Journal of Project Management, 35(8), pp. 1608-1626. Web.

Stoop, J., de Kroes, J. and Hale, A. (2017). ‘Safety science, a founding fathers’ retrospection’. Safety Science, 94, pp.103-115. Web.

Usmani, F. P. (2022). Project Network Diagram in Project Management: Definitions and Examples |. Fahad Usmani. Web.