Introduction

For any project to be implemented, resources are needed. These can be either services or materials required to accomplish the project. It is important to note that the type of resources and the source determine the extent of success in completing the project and subsequently satisfying the end user. The process of acquiring the resources is through the function of procurement which has become a core function in the operations of any organisation.

Procurement incorporates many aspects which call for critical thinking to guarantee both in the inbound and outbound logistics. According to Holm (2012), procurement plays a strategic role in helping businesses accomplish their operations and gain a competitive edge because it is integral in lowering the expenditures of a business and mitigating risks in a project. The following paper examines the function of procurement in a car manufacturing company by exploring sustainable procurement, procurement strategy, and risk supply management.

Project Risk and Procurement Management

In the modern times, procurement management is considered as a factor in the creation of value in an organisation. Efficiency in the procurement is established in terms of the price of the material or service, the quality and quantity affect the overall expenses. For instance, in the implementation of any project, there is the need to consider the risks and put in place measures that will ensure that throughout the procurement and supply chain, an organisation can cope with risks.

This leads to effective procurement that ensures that the organisation is robust in addressing possible risks. As such, efficient procurement ensures that there is timely delivery of materials to ensure continuity of a project. It is based on this understanding that Meehan and Bryde (2015, p. 983) state, “Procurement plays a key role in delivering sustainable outcomes through creating, developing, controlling and sustaining the links between organisations and their supply chains to avoid commitments that are only superficial and non-compulsory”.

Thus, organisations need to devise measures that ensure sustainability in the core areas of operations such as procurement in order to manage expenditures. It is based on this understanding that in the car manufacturing issues of sustainability, risk supply management, and procurement strategy are important as they influence the performance of the final product in the market.

Sustainable Procurement

Sustainable procurement entails practices that meet the current needs of the business without hurting the survival of future generations. Walker and Brammer (2012, p. 257) define sustainable procurement “as the pursuit of sustainable development objectives through the purchasing and supply process, incorporating social, environmental and economic aspects.” For instance, in the car manufacturing, there are different materials and services required some of which if not carefully regulated can have an adverse effect on the climate and at the same time influence the how the customers perceive the car.

It is important to note that perception is a fundamental component in the marketing of high-end goods, and thus poor reputation can affect the competitive edge of the product. Also, it is worth noting that the upstream supply chain processes can have a direct or indirect effect on the downstream logistics and are likely to affect the competitive advantage of the business. For example, today customers have become environmentally conscious and tend to buy from manufacturers who employ sustainable processes.

In the manufacturing industry, sustainable procurement involves practices, specifications, and applications of resource acquiring criteria that favour the protection of the environment, ensure the positive social progress, and support economic development. Therefore, there is a lot of emphasis on enhancing the quality of products and services by optimizing costs. In order to ensure sustainable procurement, it is important to assess the requirement of the company, the statutory requirements and the market influences. This enables the company to have a better idea of the products available on the market that meet the sustainability criteria.

In the case of the car manufacturer, most of its operations are guided by statutory requirements of environmental management that place certain obligations for suppliers of some products. Therefore, to ensure competitive edge, there is a need to go beyond the statutory regulations and implement internal purchasing practices that are sustainable; it is upon the procurement professionals to put in place measures that guide the practice.

Thus, sustainability has become a core function of business operations that serves for value addition and at the same time to meet the needs of the future generations. Sustainability has three key dimensions of environmental, economic and social considerations. The environmental aspect is concerned with how different processes are management in the procurement chain to ensure that the natural resources are utilised in the best way possible.

The key considerations in this sector include the management of wastes such as re-use, recycling, and disposal. It also involves the type of materials procured and their health and environmental implications.

For example, components to be procured for the car manufacturing should not be hazardous. Besides, most of the target customers for car manufactures are the corporate clients and international organisations that are concerned about the depletion of the ozone, global warming, and loss of biodiversity. As such they are inclined to shun buying from companies whose supply chain does not consider such factors. Purchasing products that are environmentally sustainable will reduce logical problems due to the high degree of compliance. Nowadays, there has been increased emphasis on compliance to set standards.

The car manufacturing industry is very competitive, and the buyers are very particular on the specifications they desire. Besides, they go beyond the specification to examine the best manufacturing practices and certifications such as ISO 14001. This is an international standard that focuses on the organisational protection of the environment and how it balances its operations with socioeconomic needs.

It is based on the ability to go beyond statutory compliance and initiation of internal mechanism that ensure environmental responsibility. The ISO 14001 is a cycle that has continuous improvement based on planning, policy on environment, implementation, corrective actions, and review. Concerning the environmental dimension, Meehan and Bryde (2011) pointed out it puts an organisation at a competitive edge as it helps in financial savings.

On the other hand, the social dimension denotes how the company relates to the community. In most cases, it has been explained related t the corporate social responsibility. Sustainable procurement is a complex issue that puts into consideration the entire supply chain to determine the relationship of the suppliers with the immediate communities (Walker, Miemczyk, Johnsen, & Spencer 2012). It is the mandate of any business to ensure that their operations practices are in line with social requirements. Therefore, the management has the mandate to ensure that procurement department puts into consideration such environmental measures in order to get the desired competitive edge.

Efficient procurement drives an organisational sustainability and helps it to influence suppliers and buyers along the chain. This is achievable through an organisational policy framework that guides the purchase and procurement process to make sure that any procurement contract is guided by clear terms of an agreement. For example, in the procurement of energy and the raw materials, the manufacture should choose certified producers who have been approved to be compliant with sustainable environmental practices. For example, in the case of oil supplier, negotiations should centre on ensuring that company obtains its oils from trusted international dealers for supply of clean oils.

The current business environment necessitates the adoption of strategies that enhance efficiency and promotes competitiveness. A supply chain should incorporate environmental sustainability measures. In the contemporary society, environmental issues have become part of business operations. As a result, consumers are attracted to companies that are responsive to the environment. Environmentally conscious supply chain enhances the confidence of the customers and is crucial to gaining a competitive edge. Best supply chains act as enablers for businesses and help in achieving a competitive advantage (Kilubi 2016). Hence, there is a need to consider the components of environmental sustainability in the course of procurement.

The contracts should include the social responsibility of the parties to be involved in the contract. For a contract to be legally binding, one of the key elements is mutuality of obligation. This denotes that parties should agree on the terms. Based on the current emphasis on the environmental sustainability, contracts should include the environmental sustainability processes as part of the sub-elements in the mutuality of obligation. This will be critical in ensuring that there is value for all stakeholders. This is based on responsible procurement in which ethical, social and environmental factors are taken into consideration.

Procurement Strategy

Procurement strategy entails the procedure put in place by a company to ensure that it obtains the required supplies by considering several elements and factors that influence the value chain. For an effective procurement strategy, there is the need to consider projected risks, the available budget, specifications of the supplies and the stakeholders. Driedonks, Gevers, and van Weele (2014) noted that an effective procurement strategy should be comprehensive, include procurement contracts and measures to select competent suppliers. For the car manufacturer, the supplies are very specific and need to meet certain standards.

As a result, the procurement process is based on trusted suppliers who have a good track record with the company. This is based on the understanding that each service or product has a great implication on the downstream processes in the supply chain. Therefore, to gain the competitive edge, there is need to streamline the procurement process and ensure key processes are put into considerations.

Procurement is all about achieving a satisfactory product. For instance, an effective procurement in which some money is saved in the purchase process of car part and efficient equipment obtained will lead to a riffling effect in the whole manufacturing process, i.e. efficiency and working within time scales which in essence saves money. The management is thus required to ensure that the cost of procurement and the overall supply chain creates value and it is cost effective. One key important factor to consider in the procurement strategy is the input of stakeholders; it is important to implore the stakeholder concept.

The concept stipulates that without the stakeholders, a project cannot run or organisations will cease to exist. There are different categories of stakeholders. In the procurement process, the inputs of stakeholders determine the outcome of the project. For instance, there are stakeholders involved in the use of the product, examining the manufacturing processes, and those availing specifications for the material to be procured and the quantities. Therefore, it is important to consider all the key stakeholders in the car manufacturing as the first step in the procurement strategy. This will ensure efficient in operations which will not only save money but attain value in the process of procurement.

The other important factor that the car manufacturer is supposed to put into consideration as part of the procurement strategy is the need for detailed procurements contracts. Procurement management normally encompasses the relationship between the business and other organisations.

As a result, the strategy includes external players; hence, it is executed through relationships between the seller and the buyer. In the relationship, there are expectations for each party; hence, the need for a contract detailing what each party is supposed to attain from the relationship. Contracts play a great role in establishing a measure of certainty. In any business transaction, there is the need for the parties to understand the roles, responsibilities, and the benefits that are to be attained by each party.

In relation to the car manufacturing, the terms of engagement should relate to the materials and equipment required the quality, and the agreed price. In so doing, the specification should also include the grade of the equipment required. The terms should be based on the market standards. In addition, the specifications should be in line with legal requirements and the set out environmental standards. The aim of contract management is to ensure that there is better value. The better value is achieved by integration of various factors that include the reduction in the risks, right prices, agreed timescales, and reduction in the commercial risks.

On the other hand, the contract should deliver quality, comply with the laid down regulations, and should offer the required value in the survey process. For instance, the car manufacturing project requires specialized equipment and materials. This fact should not be overlooked in the design of the contract. There should be clear stipulations of the requirements which should be included in the contract. Therefore, contracts drawn by the manufacturer should include all the technical requirements to avoid procuring items that do not guarantee the anticipated efficiency during the assembling and the operations of the car.

The third factor for procurement strategy is to ensure that there are clear laid down procedures to get the right suppliers. In most cases, procurement for public organisations is done through competitive bidding. However, this may vary for high technical businesses where they need to deal with known suppliers who are effective. Effective suppliers play a critical role in ensuring that value is realized in the procurement and supply process.

For example, they are critical in ensuring that the terms of contracts are met without coercion and the completion of a project. Just like in other business operations, the positioning of suppliers is critical in achieving the competitive advantage. For the care manufacturer, to understand the supplier position, the key questions to ask include which supplier, where to focus effort, the type of relationship to cultivate during the supply process and the issues that might arise in the supply process. These questions are essential in the selection of the supplier and ensuring that the procurement strategy bores the needed benefits.

For value to be realised and avoid market turbulences that result due to poor selection of suppliers, the business needs to have a selection criterion based on clarification of the requirements and the sourcing options available and adoptions.

Also, the prequalification for suppliers should be based on financial stability, the technical abilities, experience in the field of the supply, track record of the suppliers, compliance with the various regulations and the environmental sustainability capabilities (Meehan & Bryde 2011). Therefore, by engaging the key suppliers from the design process, an organisation can solve supply chain predicaments and diminish wastes along the chain which will consequently lead to improved financial performance (Sobhani et al. 2013).

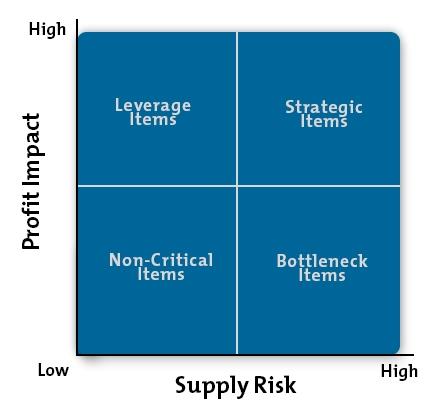

To ensure that supplier selection is enhanced, the Kraljic’s supplier model can be applied. The model helps in addressing risk management in the supply and helps buyers in selection the most effective supplier based on the product classification. The design of the model is meant to ensure there is the maximisation of caution in the selection of the supplier. This is achieved by making the buyers utilize their purchasing power.

This makes the selection of the supplier to be a strategic process rather than transactional activity. The model employs four steps that aid in the selection process. They include classification of the product, analysis of the market, strategic positioning, and action planning (Glockner, Pieters, & de Rooij 2015). Figure 1 is an outline of the model that focuses on the supply risk and profit impact. The application of the model ensures that the purchasers maximise the supply security.

In the car manufacturing, the quadrant that is more applicable is the ‘strategic items.’ This is because most of the materials required for the car manufacturing are specific in nature; hence, a limited number of suppliers who can provide the products. Therefore, strategic procurement operation gives an organisation a competitive edge by reducing wastes in the value chain by ensuring that the right supplier is engaged.

Supply Chain Risk Management

In the procurement and supply chain, risks will occur, and thus there is the need to put in place measures to manage them. The management of the risk starts before a business initiates the project with an idea of creating a system that is robust in dealing with risks. The risks can occur in the inbound logistics such as the supply risks or from the outbound logistics, i.e. the demand risks. It is important to note that a supply chain consists of many players who benefit mutually from each other. However, it is the mandate of a business to put in place measures to manage its suppliers to guarantee value for the business.

This is because a failure by one business in the chain disrupts the entire chain and can lead to loss of revenue, loss of customer confidence, and inflated costs. According to Ghadge et al. (2013), the best way to manage risks is by putting in place measures that mitigate the risks before a project commences. This can be achieved through measures to manage inventory and strategies to ensure good supplier relations.

For example, risks can be mitigated by building ensuring that there are different forms of reserves, excluding suppliers who d not have the capacity to deliver and enhancing the responsiveness of suppliers through good procurement strategy.

This is because a failure in any of the factors leads to the inability to complete a project in the designated time, leads to dissatisfaction among the customers and has a high cost implication on the operations of the company. As a result, there is need to assess the possible sources of supply risk and put in place preventive measures. For instance, for the car manufacturer, the risk of supply can be mitigated by employing the 5-R model. This entails prior analysis to ensure right quality, right quantity, right time, right source, and right price of services and products that are to be procured.

The right quality designates the use of the standard specifications, efficiency and environmental considerations. The right time is a critical factor in the purchase process. Many disputes arise due to late suppliers. There is the need for consensus between the car manufacturer and the suppliers on timescales for delivery. This can be captured in the supply contract by stress testing to examine areas of potential weaknesses in advance.

On the other hand, right quantity entails an agreement with the supplier on the regular flow of the materials. The value of money is realised by ensuring that the right quantities are delivered to the organisation. Supply risks can also be avoided through stringent vetting to acquire suppliers from right sources. Car manufacturing involves many processes and has a high potential of having negative implications on the environment. Putting into considerations that many regulatory bodies monitor how companies balance their production processes with the ecosystem, risks can occur if regulatory bodies detect failure of compliance in the upstream supply chain.

Therefore, the products used by the car manufacturer should be from certified producers who have been approved to be compliant with sustainable environmental practices. Finally, the right price is concerned with ensuring that prices for quoted by suppliers are within the market levels. High prices can lead to increased cost of production and affect the competitive edge of the business. Right price should be based analysed based on capability and the type of the product.

Conclusion

The procurement function requires a great deal of ensuring synergies across the various departments in an organisation. To achieve the synergy, the management needs to have standard processes of buying with clear responsibilities and tools. The processes act as enablers to guide the purchasing. Also, the aspects of procurement should be based on ethical practices as well as the commercial viability. Therefore, for the case of the car manufacturer, there is the need to balance the sustainable requirements and the technical support. Thus, it is the duty of the concerned department to put in place guidelines to ensure that the suppliers abide by the laid down requirements to avoid wastes or external disruptions that may affect the competitiveness of the business.

References

Driedonks, B, Gevers, J & van Weele, A 2014, ‘Success factors for sourcing teams: how to foster sourcing team effectiveness’, European Management Journal, vol. 32, no. 2, pp. 288-304.

Ghadge, A, Dani, S, Chester, M & Kalawsky, R 2013, ‘A systems approach for modelling supply chain risks’, Supply Chain Management: An International Journal, vol. 18, no. 5, pp.523-538.

Glockner, H, Pieters, R & de Rooij, W 2015, ‘Importance of the Kraljic matrix as a strategic tool for modern purchasing’, LogForum, vol. 1, no.3, pp. 1-13.

Holm, P 2012, The dynamics of procurement management: a complexity approach, Copenhagen Business School, Frederiksberg.

Kilubi, I 2016, ‘The strategies of supply chain risk management; a synthesis and classification’, International Journal of Logistics Research and Applications, vol. 19, no. 6, pp.604-629.

Meehan, J & Bryde, D 2011, ‘Sustainable procurement practice’, Business Strategy and the Environment, vol. 20, no. 2, pp.94-106.

Meehan, J & Bryde, D 2015, ‘A field-level examination of the adoption of sustainable procurement in the social housing sector’, International Journal of Operations & Production Management, vol. 35, no. 7, pp.982-1004.

Sobhani, M, Malarvizhi, C, Al-Mamun, A & Jeyashree, S 2013, ‘Strategic procurement and financial performance of Iranian manufacturing companies’, Asian Social Science, vol.10, no.1, pp. 250-256.

Walker, H & Brammer, S 2012, ‘The relationship between sustainable procurement and e-procurement in the public sector’, International Journal of Production Economics, vol. 140, no. 1, pp.256-268.

Walker, H, Miemczyk, J, Johnsen, T & Spencer, R 2012, ‘Sustainable procurement: past, present and future’, Journal of Purchasing and Supply Management, vol. 18, no. 4, pp.201-206.