Executive Summary

Bananas rank as the top fruit produced globally and are far ahead of any other fruit produced. However, it is also the world’s most wasted fruit. Therefore, addressing this issue and working towards finding a solution for saving the amount of waste that takes place with bananas can be a starting point that offers a solution to all other products as well as assist in resolving the agricultural land scarcity and water shortages that are taking place with the climate change. This project will address the issue from a social responsibility perspective and provide financial benefits for growers, producers, marketers, and retailers by reducing waste. The exercise that needs to occur starts by evaluating all steps across the supply chain and finding ways to improve the conditions that lead to waste reduction.

Problem statement

It reduces losses incurred across the supply chain cycle in Bananas and preserves natural resources such as water, land, and energy wasted across the supply chain because of food wastage.

Background

For many decades, bananas have been considered the cheapest fruit available for consumers and a great source of nutrition. However, with the increase in diseases impacting the production of this fruit and the scarcity of resources available in the specific tropical countries where this fruit can grow, it is becoming more and more challenging to maintain a low cost of production. The crossroads ahead for banana growers and producers are decisive moments when decisions are made about continuing to grow this product, shifting the lands used for other products, or moving towards urbanization.

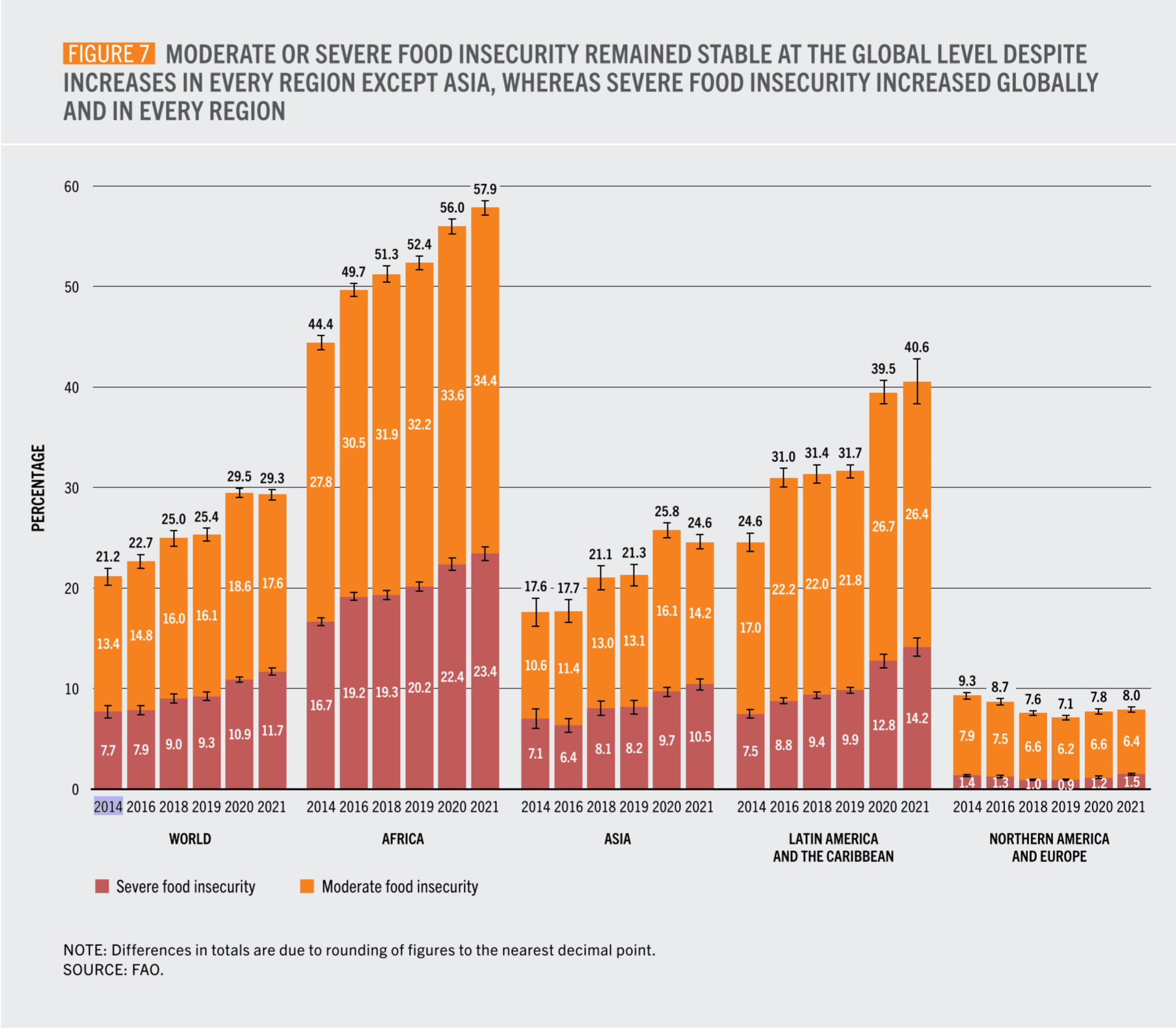

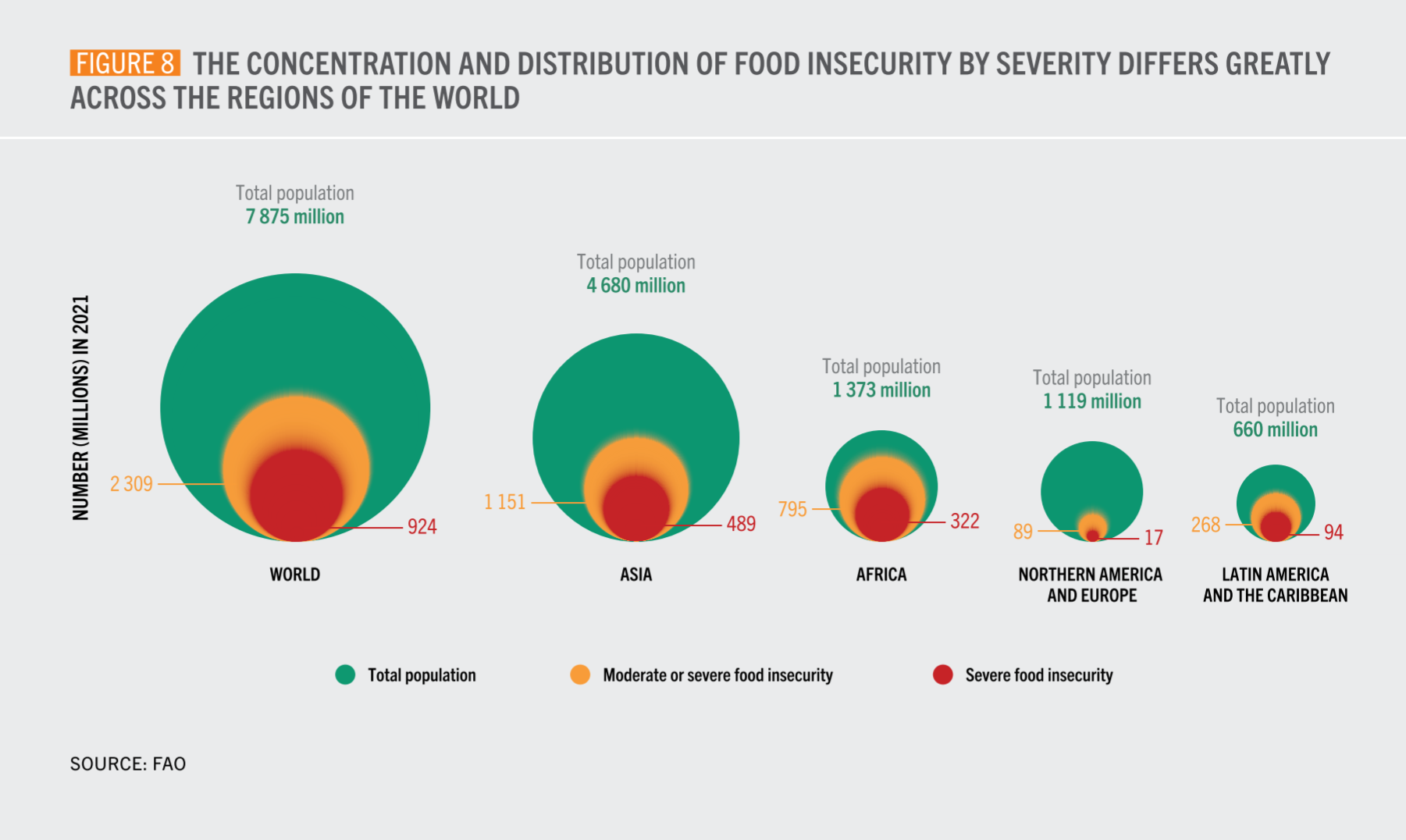

In recent years following the pandemic, which accelerated the risks, concerns have been growing about the security of foods and agricultural products in every country worldwide, including significant agriculture and farming lands. Looking at the trend of food insecurity worldwide from 2014 to 2020, the Charts clearly show a growing risk of food insecurity in every region. In 2014, world food insecurity was at 8.3%, and in 2020, it reached 11.9%. Africa, Latin America, and the Caribbean are the regions with the highest food security risks. One might assume that it’s a matter of the availability of food products, but in terms of continuity, there are sufficient food/agricultural products to feed everyone on the planet. (Statista, 2021)

The decline of agricultural land globally is confined to the availability of water resources or agrarian lands but also the availability of farmers themselves. This has been an inherent issue for many years, evolving and growing constantly. Simply put, farmers worldwide entice their children to leave the agriculture industry. The driving factor behind farmers’ use of this approach is their ever-shrinking profits. Farmers are at the bottom of the food chain in the produce industry.

Diminishing profits and the hard work they put into growing and producing various fruits and vegetables does not make them viable or sustainable enough to continue. This imbalance drives agriculture or farming families to move away from this sector. Farmers have been losing money for many years as pressure on prices increases, and the cost of production impacts the profits of small and medium-sized farmers. Farm debt in the US alone is at a staggering rate of $416 billion. (Semuels, A. 2019, November 27)

Expanding urban areas and diminishing rural areas are driving higher land prices as the population grows. This forces farmers to give up the land for higher sums of money or develop their lands into urban homes with higher profits. In almost a decade, farmlands in the United States shrunk by 11 million acres. This resulted from the expansion of the metropolitan areas and the commercial developments that took over farmlands. (Bozhinova, K. 2020, February 5).

Putting these factors together, water shortages, agricultural land availability, and lower farmer profits are the factors that pose a risk to food security globally. Food security is primarily linked to commodity crops such as wheat, corn, and soybeans. Prices of grain crops, which are considered commodities, are determined by the interaction of demand and supply functions. While demand plays a role, the primary factor in prices starts with supply linked with the inventory level or carryover from previous years, the imports in current years, and production, which is based on acreage and the yield of such crops each year.

Components of the demand side of grain crops include food products and industrial use. How grain crops are traded is based on futures on the commodity exchange market. Prices are set well in advance, usually based on predictions and geopolitical changes, including worldwide government policies and weather conditions. Such a method gives farmers a clear projection of what prices they will sell their crops at. If prices are down, which reflects lower demand, growers will reduce the amount and acreage they grow to avoid lower profits. Besides the price determination, it is also clear what the world requires regarding demand; there is no vagueness on the volumes needed to feed populations. (P. Westcott, L.Hoffman, 1999)

Objective Statement

To identify methods and areas which can help reduce banana wastage across the supply chain, starting from the farm level up to the consumer on supermarket shelves.

Methods

The agriculture sector will continue to fall under pressure in the coming years due to population growth and mismanagement of resources, which is food wastage. According to Morone (2019), food waste impacts the environment and is associated with land, water, and energy waste. Food waste takes place at various stages in the supply chain depending on the markets and whether it is a well-developed consumer market or an underdeveloped country with supply chain challenges. Bio Intelligence Service (2010) states that the largest food waste occurs at the consumer and household levels. According to a report on food waste by Statista (2021), 24% of food wastage occurs among Consumers at Home, 17% at restaurants, and 8% at retail.

Empirical Approach

To better understand the impact of food wastage on resources, it is essential to identify the amount of food wastage in tonnage and the consequent value or amount of land, water, and energy used or wasted in the process. Research shows that over 100 million tons of food were wasted in the US in 2018. The breakdown is primarily amongst the first four major categories, with industrially wasted food at 40 million tons, residential food waste at 25 million tons, restaurants at 17 million tons, and supermarkets at approximately 9 million tons. Another measurement point of food waste that needs to be put to good use is the quantity that goes into landfills, land applications, sewer and wastewater treatment, and controlled combustion, which is 67% of the total volume. Out of this wastage, bananas occupy a significant percentage. (Statista, FAO; IFAD; WHO, 2021)

To resolve this issue, a better planning process is required. The tool that can help predict demand is a regression model. Building the regression model for food wastage can be done by linking consumption or need, with consumer behavior, seasonality when it relates to consumption, and supply. On the other side, we can realize the benefit of the regression model by linking it to water reservation, cropland usage, landfill, and related factors used for wastage.

Data

For the data collection process from the production aspect, we will identify the correlation between food production, water consumption, and cropland usage. The other data to be collected relates to the supply chain’s market end, which is the food wastage across the primary market segments of households, restaurants, and retail, then correlates that with landfills and other disposition methods. Data points to be collected as follows:

- Cropland used for Food Production.

- Water Usage in Agriculture.

- Food Wasted at each step across the supply chain.

- Land Fills and Similar Points of Food Dumping Methods.

Focusing on the US market for this capstone will create a benchmark that can be rolled out to other markets. Data collection will be from various sources depending on the data point required, which are as follows:

- Water and Land Usage for Food Production

- Source of data:

- Quest Resource Management Group US Census Bureau.

- US Department of Agriculture (USDA Economic Research Service) US Department of Commerce.

- Economic Research Service Environmental Protection Agency Food Insight IFIC.

- FAOSTAT.

- Market data on food wastage:

- Source of Data:

- US Department of Agriculture.

- Ipsos.

- World Food Program.

- Food Loss and Waste Database – FAOSTAT.

- RTS – Recycle Track Systems.

Outcome

With a smaller margin of error, this analysis expects to achieve a formula that can project demand per market that will minimize the need for oversupply and reduce food wastage. Such a reduction in food wastage will lead to several beneficial outcomes. The first is the better preservation and utilization of natural resources from the production side. With food wastage cost already being factored into the product’s price to consumers, this will help reduce the end product’s price. Reducing volumes or being more accurate with a market demand will conserve the need for logistics such as shipping and trucking, which will simultaneously ease the pressure on the system that exists at present times. Having more supply available in production will consequently result in product availability to countries and markets with an imbalance of food supply that could face food shortages in the coming years.

The limitations that might be faced in this analysis are identifying the food categories with further accuracy and linking them to the crop types required. Other limitations will come from converting certain crops into animal protein from which the end product is derived. The conversion from the finished product back to the origin might not be accurate since various aspects impact production depending on the location. In some cases, the conversion rates will vary. However, estimates can be based on industry standards used in this analysis.

Simultaneously, the production of crops will differ from one origin to another, and yields of wheat or corn might be different in the United States versus Brazil. We will also base this on average industry standards per crop type. The final limitation will be identifying the waste in landfills and other food waste disposal methods and converting them to the significant food segment. We will overcome this by estimating the food wastage per category based on the household and landfill retailer wastage, which might be captured and replicating this same breakdown.

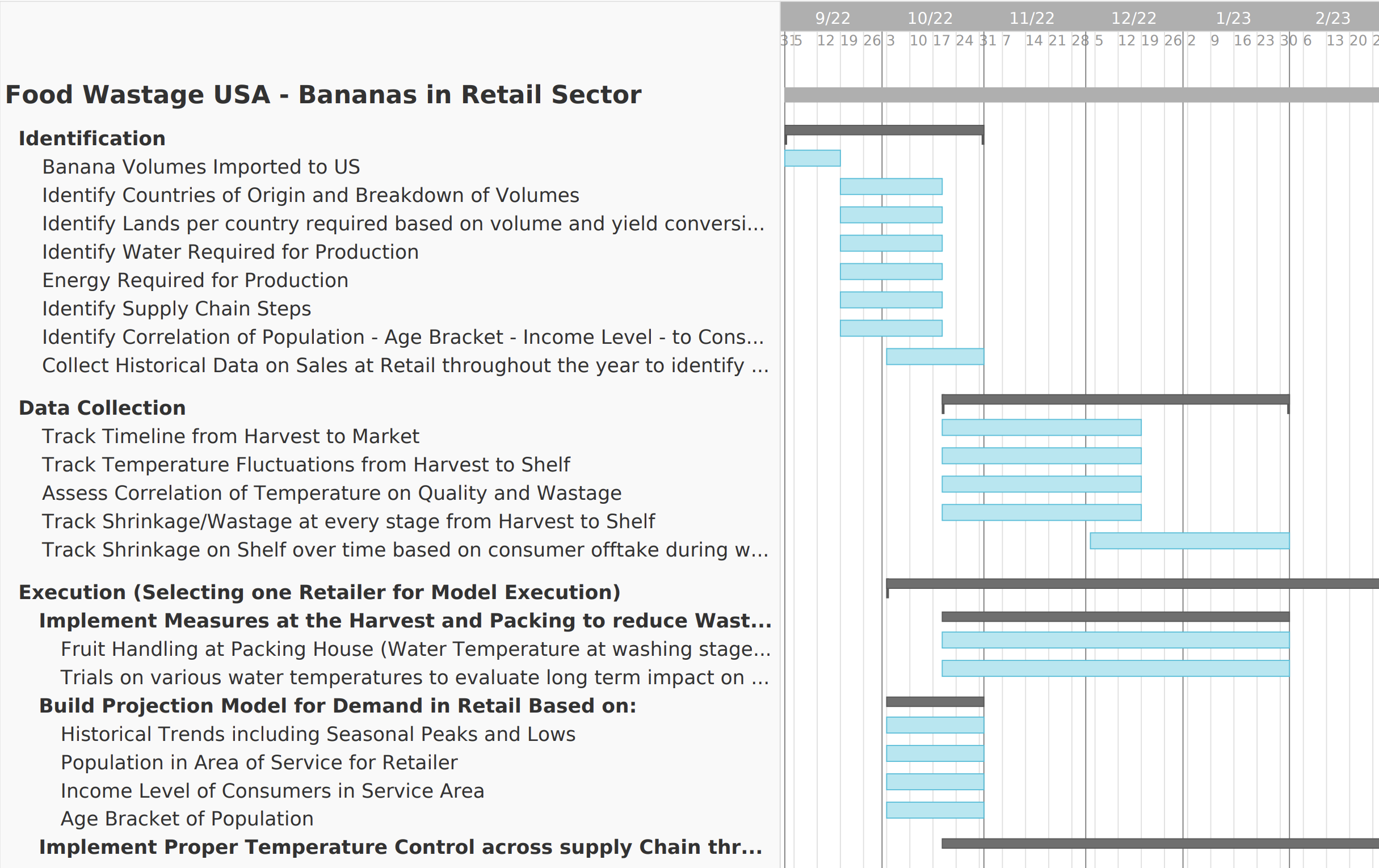

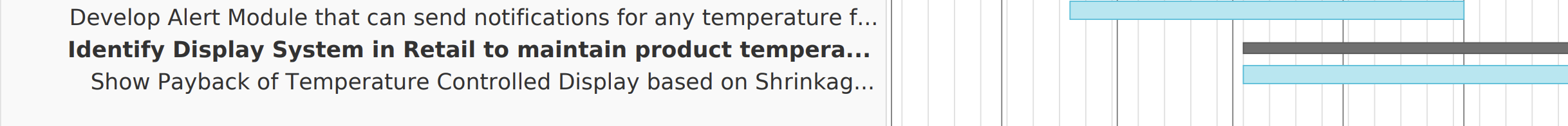

Timeline

Justification

With the world’s population growing and expected to reach almost 10 billion by the year 2050, this naturally requires more production of foods which will boost agriculture demand. The highly demanding intensive farming systems impact greenhouse emissions and water and soil resources. Water scarcity and agricultural land availability are challenging for the industry, and the need to retain resources has never been more essential than in our present time.

The population growth worldwide leads to further urbanization of land, which consequently reduces the availability of land for agriculture. Urbanization also increases water consumption, which naturally puts more pressure on the already challenged availability resulting from climate change. With growing incomes and urbanization, demand for livestock is continuously on the rise, and consequently, the need for crop products goes up to support the industry.

It is difficult to control the increasing demand for such agricultural products; however, one means of saving on resources comes through a more balanced demand plan and better control of food wastage, which is the primary objective. To address this, we need to reduce food wastage and develop a supply equilibrium that balances a more accurate demand, leading to better utilization of our natural resources.

Every phase or step in the supply chain that can end up saving part of the wastage that results in bananas will add value in terms of profit or benefit to stakeholders as well as benefit in water and land. Banana prices in the US have consistently ranged between $0.50 to $0.60 per pound on retail shelves or an average of $0.55 per pound. With shrinkage or waste levels at retail on bananas averaging 15% and a retail profit margin of 20%, retailers’ net per-pound price is $0.35 per pound. Looking at the historical trends, banana prices have always been stagnant at this level for more than ten years despite all inflationary costs. Retailers have mandated that bananas remain at this level. Over the years, this has become more and more challenging for growers, producers, shippers, and marketers.

Where retailers had a fixed high margin on bananas and disregarded any incentive to improve the returns for growers, it started pushing growers away to alternative agriculture and even walking away from agriculture, ultimately shifting their property to real estate projects. However, as a result of the past two years that started with the pandemic and is continuing as we are witnessing in the shipping industry, coupled with the inflationary costs impacting all aspects of the supply chain and agriculture costs, alarms started to go off that is jeopardizing the availability of the cheap fruit as called by retailers and is no longer going to be reasonable if returns to growers do not improve.

The solution and incentive to retailers and marketers for bananas are more necessary than ever. If prices are to be maintained on the shelves at the current level, then the solution will be to reduce the wastage throughout the supply chain, and that value that can be salvaged will be returned to the grower. Retailers will be able to maintain their prices, and growers will get the necessary return to continue with the business and have better well-being. As a result, there will be a benefit from an environmental perspective where water resources are not wasted, nor will demand the already scarce land be driven forward.

Steps in the Banana Supply Chain in the US

Field

The supply chain for bananas is complex and varied. Starting from the farm level in Central America, getting bananas to retail shelves in US supermarkets involves multiple steps. On the field, farmers are responsible for harvesting and grading the fruit. For example, improved mechanization can reduce losses caused by manual picking on banana farms. At the same time, better sorting and grading processes can help to guarantee that only premium-quality bananas are chosen for export (Alzate Acevedo et al., 2021). Much of the wasteful practices start on the farm level with poor agricultural and post-harvest practices and inefficient transportation processes, leading to an overall increase in wastage across the supply chain.

Packing House

Once packed, they are transported to the packing house for further sorting, cooling, and packaging. At this stage, a quality assessment is conducted to determine which fruits should be used for export and which should be donated or sold in the domestic market. After quality control, bananas are transported to cold storage facilities (or ripening rooms), where they receive a treatment of ethylene gas to obtain the desired color and sweetness for optimal market presentation. The bananas are then loaded and transported to their final destination in the US.

Storage

The storage facilities are located close to the farms where the fruits have been harvested and generally have a storage capacity of up to 15-20 days. The produce is usually refrigerated, quality checked, and sorted into different grades according to size and appearance. Cold storage facilities should have modern technologies to maintain optimum temperatures and humidity (Abraham et al., 2022). The cold storage facilities maintain the quality of bananas until they reach their destination markets.

Container Loading

Upon loading in the container, the bananas are shipped to the destination and sorted based on size, color, and taste. This process occurs in a container loading platform as the workers inspect each box of bananas and decide if they can be sold (Alzate Acevedo et al., 2021). If rejected, the package will be moved for breaking down and further processing for animal feed or other industrial uses. In addition to sorting, the ripeness, and other conditions are also examined. This is an essential factor as if the bananas are too ripe, they will not be able to withstand long trips, and the ship itself may compromise the quality of the produce.

Handling Points Port to Port

Trucking

The trucking of bananas is the key step in the supply chain process from farm to retail shelves. Trucks are used to transport and deliver bananas from Central American countries, where they are farmed and harvested, to supermarkets in different states across the United States. This trucking aspect of the banana supply chain process is highly regulated. Any delays due to traffic or road conditions can result in a shorter shelf life of the bananas, leading to higher wastage.

Truckers must follow several steps to ensure timely and efficient delivery of bananas across the supply chain, including proper packaging, temperature regulation, and handling protocols during loading, unloading, and transit. Packaging is essential before loading bananas on trucks, as appropriate packaging helps reduce bruising and damage during transportation. Temperature regulation is another vital step, as bananas need a specific temperature to keep them fresh during travel time. Incorrect loading of trucks can cause unnecessary damage and lead to more wastage, so truck operators must use best practices while loading and unloading bananas on their trucks.

Container Yard

The container yard is an essential aspect of the supply chain regarding reducing banana wastage. As part of a typical supply chain process, bananas are transported from farms in Central America to container yards and then onto retail shelves. The container yard is where the bananas are checked for quality, sorted, and packaged before they are distributed to retailers. At this stage, one of the leading causes of banana wastage is poor quality control, which can lead to a large amount of wastage and even rejections (Abraham et al., 2022). To reduce this waste, the container yard must be managed efficiently and strictly adhere to quality standards. This means the container yard should have adequate resources, processes, and personnel to ensure that only high-quality bananas make it to the retail shelves.

Loading on Vessel

In the supply chain process, loading on the vessel is often referred to as loading banana cargo onto ships for transport to its destination. Packing on the boat is an integral part of the supply chain process. It is a critical step in transporting bananas from Central America to retail shelves in supermarkets in the United States. The loading process must be done correctly, as improper loading can lead to damaged bananas and wasted products. Once the bananas are loaded onto the vessel, a team of workers will inspect and verify that the cargo has been loaded correctly.

The Supply Chain Process in the US upon Arrival

When the bananas arrive from Central American countries in the US, they are unloaded onto docks and brought in for inspection. The shipments undergo quarantine and customs procedures to ensure that all the necessary paperwork is in order and that only safe and healthy bananas are released into the domestic market. Once they pass inspection, they are shipped to a distribution center and sent to supermarkets or other retailers throughout the United States.

Port Unloading

The bananas are carefully handled at the port to ensure they are not damaged during transport. The unloading process is crucial as it helps minimize potential damage while transferring them from ship to shore. Once the bananas have been loaded onto trucks or containers, they can be transported to distribution centers or other retailers.

Container Yard

Upon arrival at the container yard, the bananas are stored in large containers until they can be further sorted and transported. This process is usually done in a temperature-controlled environment to preserve the quality of the fruit during transport. The containers are monitored to ensure proper airflow and ventilation to protect the product from spoilage or damage.

Stripping at Port

The bananas are stripped of leaves or stem at the port to ensure they are in optimal condition for further transport and retail. This process helps to reduce the risk of bacteria or fungi spreading between containers or affecting the quality of the fruit. The stripped bananas are then sorted and stacked into large crates labeled with their destination and the type of banana.

Loading to Distribution Centers

The bananas are stripped, sorted, loaded into crates, and shipped to distribution centers nationwide. At the distribution centers, the crates are unloaded and checked to ensure that the quality of the fruit is suitable for further transport and retail. The distribution center staff then sorts the bananas based on the type and size of each banana. The sorted bananas are then loaded onto trucks or containers that will take them to their final destination.

Movement Between Storage and Ripening

The bananas that have been sorted, loaded onto trucks or containers, and shipped to their final destination are then moved between storage and ripening. During the ripening process, the bananas are monitored to ensure that their flavor and texture are optimal for retail. The bananas can be shipped to retailers nationwide after the ripening process.

Ripening Process

The ripening process is essential in ensuring the bananas have an optimal flavor and texture for retail. This process involves controlling the ripening room’s temperature, humidity, and ventilation levels to ensure the bananas are ripe and ready for customers. The ripening process also aims to prevent any potential spoilage or wastage as the bananas are monitored and handled with care throughout the process.

Loading to Client

The bananas ripened and checked for quality are transported in trucks or containers and delivered to their final destination. At the client’s premises, the bananas are unloaded and checked for any defects or damage that may have occurred during transport. The bananas are then sorted and loaded onto shelves or displays for customers to purchase.

Trucking

Trucking is an essential part of the banana supply chain as it helps to transport the bananas from farms to retail stores. The trucks are carefully monitored to protect the bananas from any potential damage or spoilage during transport. The trucks are also equipped with temperature-controlled units to ensure that the temperature of the fruit is optimal throughout the journey.

Offloading at Client Distribution Center

When the bananas arrive at the client’s distribution center, they are unloaded and checked for defects or damage. The bananas are then sorted and placed into crates or displays ready for transportation to retail stores. This method helps minimize potential waste by continuously monitoring the bananas throughout their journey.

Storage or Cross Docking at Client

The bananas are sorted and sent to the client’s premises, and then stored or cross-docked. Cross docking is a technique that quickly moves goods from one site to another without intermediate storage. This procedure allows reduced waste as the bananas are handled with care and are not subject to any further delays in transport.

Loading to the Stores

Once the bananas have been stored or cross-docked, they are loaded onto trucks and shipped to their final destination. At the store, the bananas are unloaded and placed onto shelves or displays ready for customers to purchase. This operation is necessary to lessen potential wastage as the bananas are carefully monitored and handled throughout the journey.

Offloading and Storage

The bananas unloaded at the store are then stored in appropriate conditions to ensure optimal quality. This process enables the reduction of wastage as the bananas are scrutinized and stored in the right conditions to ensure they retain their flavor and texture for customers.

Unboxing and Display

The bananas stored at the store are then unboxed and arranged on shelves or displays, making them available for customers. This move helps diminish potential wastage as the bananas are observed and handled carefully. The production of bananas is also vital in ensuring customers can identify the best quality fruit.

The Alternatives to Each Step

Reduction in Handling

There are several alternatives to reduce the handling of bananas from farm to port and during storage. Quality of infrastructure such as roads, bridges, ports, warehouses, and cold storage used for shipping and storing bananas must be well maintained. Appropriate packaging materials should protect the banana during its journey (Richter, 2022). Educating consumers on selecting the best banana can also help reduce waste. Predictive analytics through artificial intelligence (AI) is useful for predicting when specific bananas will be ripe so retailers don’t buy too many. Lastly, improving the labeling process helps to ensure accurate information regarding expiration dates and other product information is available on every container or package to reduce the overstocking of inventory in supermarkets.

Reduction in Temperature Disruption

Temperature disruptions can be reduced by introducing effective temperature management solutions throughout the supply chain. This includes refrigerated transportation, ensuring proper ventilation and airflow, and optimizing warehouse humidity control. These steps will help lower the environmental conditions contributing to spoilage and wastage, reducing temperature disruptions.

Reduction in Transit End-to-End

Reducing transit end-to-end can be achieved through several measures. Better information management systems and tracking processes should be implemented to quickly and efficiently identify and respond to potential issues (Reynolds et al., 2019). Quality control from the farm level to retail shelves is also essential for reducing wastage due to spoilage or other factors. Further efficiency can be achieved in the production and harvesting processes, minimizing any wastage due to over-production or incorrect packing. Lastly, consumer engagement and education can help reduce wastage on retail shelves.

Demand Planning Store Level

Planning at the store level requires better forecasting measures that are accurate and timely to adjust orders accordingly. This will help retailers avoid overstocking bananas or any other product, which leads to spoilage and, eventually, wastage. In addition, better shelf management practices like displaying the bananas according to their ripeness and keeping them at a sufficient temperature level so that they do not spoil quickly or are exposed to too much heat, which will cause them to rot.

Testing Each Alternative

Trial Runs

Trial runs help to identify areas in the supply chain that may need improvement or change. This entails checking for quality assurance of banana boxes before picking them up on the farm and ensuring proper control over temperature during transport, which would identify issues in steps one and two of the process. After the trial run, data should be collected from each step and analyzed to see the potential effects and cost savings of implementing a change.

Temperature Logger Evaluation

This analysis should be done in all areas, including storage facilities, vehicles, and the packaging used for the banana. Temperature loggers measure and control temperature during storage, transport, or any other handling step in the supply chain process. By testing alternative techniques against each other with a temperature logger analysis, it is possible to determine which one will reduce waste the most. This will ultimately lead to fewer resources being used and save money for everyone involved in the supply chain, from farm to retail.

Analysis of data collected from temperature loggers should also be performed to identify areas where improvement can be made within the supply chain process. This analysis will allow for a more tailored approach toward reducing waste at each stage. The data collected by the temperature loggers can provide valuable insights into the various conditions that cause waste and will help identify the key improvement areas.

Inspection Comparison

This process involves comparing various stages of production and ensuring that only quality products make it to supermarket shelves. This could be through the grading processes that need to be introduced, which ensure that standards are maintained so only suitable products can be used for further processing and distribution. Furthermore, proper storage facilities must be in place to store the product in optimal conditions to minimize losses.

Evaluation of Quality Improvement on Each Step

This is one of the first steps that need to be taken. This includes assessing and identifying key issues, such as traceability, worker safety, and productivity, which can help reduce spoilage and wastage. Additionally, evaluating storage conditions across all supply chain stages, from farm harvesting to final retail delivery, can positively affect reducing banana waste. The selection and harvesting of bananas must be made carefully to ensure that only those for sale are picked. This means they should not be selected too early or late, as this can lead to the over-ripening or rotting of bananas on their way to the retailers.

Trials and New Mapping Acceptance

Once the supply chain has been evaluated, the next step is to conclude trials in significant production, marketing, and receiving areas. Completing problems with all stakeholders provides a basis for tackling the issue and mapping out a strategy that works for everyone involved. The goal is to create acceptance among stakeholders such as producers, marketers, importers, retailers, and consumers for a new mapping of the banana supply chain. This will help develop an effective action plan to reduce waste across the entire chain from the farm level to the supermarket shelves consumer.

Establishing a Demand Planning System

A demand planning system involves retailers, marketers, and growers working together to identify demand patterns and predict what volume needs to be produced each season or month to reduce waste at all levels during production, transport, and retail sales. As a part of this system, it is essential that all stakeholders can share data and use appropriate technologies, such as artificial intelligence and machine learning, to analyze the available data. This can help make accurate predictions about demand, production, and wastage.

Soft Launch

Communication with Selected Customer

The project’s soft launch can be executed by engaging with a select group of customers to understand how they currently manage banana waste and where they perceive that improvements can be made. This initial step will help us gain more insight into what retailers and consumers think about their current situation, their ideas for improvement, and any potential solutions for reducing further waste. This helps to understand better how the project can be developed to meet customer needs and desires, as well as any issues from the perspective of environmental and social responsibility.

During the soft launch, the team will reach out to a specific group of customers, including retailers and consumers, who play a direct role in the banana supply chain. This targeted approach will help gather comprehensive insights from various perspectives and stakeholders. It will incorporate different communication methods, such as surveys, interviews, focus groups, or direct feedback sessions. This allows us to understand how these customers currently handle banana waste and identify areas where we can make improvements. By initiating this initial conversation, our goal is to build a solid foundation for future collaboration and development.

Identifying Improvement Opportunities

Engaging with these selected customers also provides an opportunity to gather their ideas and suggestions for improving banana waste management. These customers may have valuable information on the potential solutions, probable practices, and inventive techniques that could assist in reducing banana wastage. Their opinions will also shape the direction of this project by ensuring the goals are met. These interactions will provide informed suggestions that could be implemented to help reduce wastage.

Understanding Current Practices

Through these interactions, the aim is to gather information about how customers are currently managing banana waste. As part of this assessment, it is vital to delve into the operations of a company to explore its established systems, uncover the trials they may be experiencing, and acknowledge any efficient endeavors they have taken with waste reduction. From this analysis, the efficiency of the procedures can be pinpointed, and specific areas in which enhancements can be introduced can be identified.

Considering Environmental and Social Responsibility

Throughout the soft launch phase, it is also essential to prioritize environmental and social responsibility. This will be done by exploring how current waste management practices impact the environment and assessing any potential social implications. To create sustainable and socially responsible solutions that are in line with the wider aim of waste reduction and environmental conservation, these factors should be taken into consideration. The soft launch plays a crucial role by building strong customer relationships, obtaining valuable feedback, and detecting areas for improvement. By effectively communicating with the selected customers, the team can lay the groundwork for a successful and impactful initiative aimed at reducing banana wastage in the United States.

Issue SOP for the Supply Chain

Establishing Standard Operating Procedures and implementing them across the supply chain can reduce waste and increase profitability through improved efficiency and cost reduction. This SOP should include a strong culture of leadership with clear roles and responsibilities, employee training, quality assurance measures, inspections, transportation practices, packing standards adapted to the local conditions, and a detailed traceability system. By implementing these standardized procedures, all stakeholders involved in the banana supply chain can work together towards the common goal of reducing waste and improving efficiency.

A key aspect of the SOP is fostering strong leadership throughout the supply chain. This involves clearly defining the roles and responsibilities of each participant, including farmers, distributors, retailers, and consumers. Effective leadership ensures that everyone understands their role in waste reduction and actively contributes to implementing the SOP. Another important factor to consider is employee training. Effective SOP requires proper employee training to facilitate waste reduction techniques such as appropriate storage measures and proper handling according to the requirements of the SOP standards.

Another factor is quality assurance measures. Incorporating quality assurance measures into the SOP is essential for reducing banana wastage. These measures include regular inspections and quality checks to identify and address potential issues that could lead to waste. By ensuring that only high-quality bananas are selected for distribution and sale, overall wastage can be significantly reduced. The SOP should also consider local conditions and environmental factors when establishing packing standards. Different regions may have varying requirements for packaging materials, ventilation, and protection against pests. By adopting the packing standards to suit local conditions, the likelihood of banana wastage due to improper packing can be minimized.

Implementing a detailed traceability system is crucial for waste reduction in the banana supply chain. This system enables tracking and monitoring of bananas throughout their journey, from the farm to the consumer (Engelseth et al., 2018). It allows for swift identification and recall of potentially contaminated or damaged batches, reducing the chances of wastage and ensuring food safety. Issuing and implementing the SOP can provide a comprehensive framework for waste reduction practices. This includes establishing a culture of strong leadership, providing employee training, implementing quality assurance measures, optimizing transportation practices, adapting packing standards, and implementing a detailed traceability system. Through these measures, the project aims to increase efficiency, reduce waste, and improve profitability in the banana supply chain.

The Trial Phase

Production Steps

The first step in the exercise is to evaluate all production steps for reducing waste and improving efficiency. This should include, but not be limited to, soil management on farms, harvesting techniques, banana quality evaluation protocols, transport from farm to stores (including packaging), shelf-life extension measures, and customer education campaigns related to banana consumption habits. These steps must be broken down, evaluated in detail, and assessed for potential waste reduction.

A comprehensive evaluation of all the production steps involved in the banana supply chain is mandatory. This evaluation goes beyond a surface-level examination, delving deep into the intricacies of each stage. This can be done by assessing the practices employed in soil management on farms, taking into account sustainable farming techniques, optimal fertilization methods, and effective disease control measures. Also, by focusing on soil management, this will help to enhance the overall health and productivity of banana plants, leading to reduced waste.

Harvesting Techniques

Another crucial aspect to evaluate during the trial phase is the harvesting techniques employed in banana production. It is important to carefully consider factors such as the timing of harvest, ensuring proper handling to minimize damage, and techniques for differentiating between mature and unripe bananas. The goal is to optimize harvesting practices, ensuring that bananas are picked at the ideal time and handled with care, thus reducing the likelihood of premature spoilage and waste. Implementing effective quality evaluation protocols throughout is essential to minimize waste. These protocols help identify bananas that may not meet the desired quality standards, enabling appropriate actions such as diverting them for immediate consumption or processing. By consistently evaluating quality, we can minimize the distribution of subpar bananas, thus reducing waste.

Shipping Measures

Shipping measures should be optimized to reduce waste. Temperature, oxygen, and humidity levels must be carefully controlled to maximize bananas’ shelf life and quality. Routes, packaging length, and temperature control systems should be optimized for minimal spoilage or loss during transit. Sorting technology during harvesting can separate good bananas from rotten ones (Jones et al., 2021). Moreover, proper storage is essential in keeping bananas in top condition over extended periods. Transportation plays a pivotal role in preserving the freshness and quality of bananas. During the trial phase, the transportation process should be meticulously examined, including packaging methods, temperature control measures, and handling procedures. Through optimization in these areas, there will be minimal damage and spoilage, and the shelf life of bananas, ultimately reducing waste during transit.

Receiving and Throughput in Philadelphia Port

This process from origin to arrival at Philadelphia port can be very long and complex, with some ships potentially taking weeks before completing their voyage. To reduce wastage, the port must invest in efficient refrigeration systems that maintain reliable temperatures throughout the voyage. Additionally, better warehousing and management of bananas is recommended, as timely deliveries and accurate inventory tracking can help minimize losses due to spoilage or overstock. Once the bananas have arrived in Philadelphia, they are distributed to various retailers and supermarkets around the US.

Shelf-Life Extension Measures

Extending the shelf life of bananas is crucial for reducing wastage in stores and households. Therefore, the trial phase places significant emphasis on evaluating and implementing measures to prolong shelf life. This can involve implementing proper storage techniques, utilizing appropriate ripening and preservation methods, and exploring innovative packaging solutions. By increasing the longevity of bananas, we decrease the likelihood of them going to waste before being consumed.

Process Changes at the Client End

For the banana waste reduction process to be successful, changes must be made at the client’s end. This involves differentiating products by freshness and providing client feedback on production processes regarding product quality, packaging, and handling to reduce wastage. These measures can help ensure that the product meets customer demands, thus improving sales and reducing wastage.

In addition, the trial phase should incorporate the development and implementation of customer education campaigns focused on banana consumption habits. These campaigns aim to raise awareness among consumers about proper banana storage, handling, and usage. By educating customers on how to best enjoy bananas and avoid unnecessary waste, we promote responsible consumption and reduce wastage at the consumer level.

Reassessment of a Soft Launch

Identification of Required Changes

The first step at the farm level is to reassess any measures taken for a soft launch and identify the required changes. For example, they are determining whether the method of growing bananas (organic or non-organic) impacts wastage at harvest time and assessing current packaging methods, which can reduce damage and spoilage caused during transportation. By creating a better understanding of the existing processes and making improvements where necessary, farmers have an opportunity to reduce wastage at harvest time.

Revisitation Process

In the case of a soft launch, it is important to revisit the process and roll-out plan to ensure that the right procedures have been in place. The goal should be to identify areas that can be improved to reduce wastage and optimize performance across all links in the supply chain. By revisiting the process, it is possible to identify and rectify any potential issues before anything major develops.

Roll out Implementation

Training on New Standard Operating Procedure

Many steps that can be taken to reduce banana waste require a thorough understanding of the current process and how it might need to change to reduce waste. Therefore, it is vital for everyone involved in the supply chain – from growers and producers to marketers and retailers – to receive extensive training on the updated standard operating procedure necessary to reduce banana waste. This training should cover all aspects of the new process, from proper storage and handling techniques to implementing new technologies and applications.

Production

Producers are responsible for producing the actual bananas on supermarket shelves. Therefore, they should be held to a high standard to ensure that the bananas they produce are not wasted. This could mean introducing new technologies and practices, such as automated packaging and sorting systems, which can reduce waste at the production level. Producers should also work with suppliers and retailers to ensure the bananas are properly stored to ensure minimum wastage.

Costa Rica

Costa Rica is one of the countries in Central America that supplies bananas to the United States. As such, they are an integral part of the supply chain in terms of banana waste reduction. Costa Rica has been taking several steps to reduce banana waste, including instituting a ban on plastic bags for banana packaging, increasing environmental regulations related to banana production and transportation, and instituting water-saving practices on farms. Costa Rica also works with retailers in the United States to ensure that their export bananas are handled properly to reduce waste.

Guatemala

In Guatemala, there is a need to upgrade the efforts to reduce banana waste. This involves implementing regulations, providing incentives, and making technology investments to support producers. Retailers abroad should also work on improving their storage practices. Taking proactive measures like better regulations, incentives, and technology investments can foster a more sustainable and environmentally friendly banana industry in Guatemala.

Achieving this goal requires collaboration between producers, retailers, and regulatory bodies. These initiatives will have a positive environmental impact and foster a more sustainable banana industry in the long run. Solving Guatemala’s banana waste issue requires these proactive steps while also encouraging retailers to improve their practices.

Ecuador

Ecuador is the world’s largest exporter of bananas, so it must do its part to reduce banana waste. Ecuador has been taking some steps to reduce banana waste, such as introducing traceability systems that can help identify the origin of bananas in the supply chain, introducing better packaging and labeling to increase shelf life, and investing in new technologies such as automated sorting systems (Jones et al., 2021). The US can implement some of these strategies from Ecuador to ensure that their efforts to reduce banana waste are successful.

Shipping

Shipping is a crucial part of the banana supply chain, and it poses unique challenges in waste reduction. To minimize waste during transit, we need to ensure that shipping containers are properly maintained and monitored. This way, it is possible to prevent bananas from getting damaged or spoiled due to unfavorable conditions. Shippers can also play their part by using more fuel-efficient vessels and investing in renewable energy sources, reducing their carbon footprint and contributing to waste reduction.

Port Operations

Port operations are another important part of the supply chain in reducing banana waste. Ports should invest in proper infrastructure and equipment that can help reduce banana waste, such as automated sorting systems and proper storage facilities. Additionally, ports should ensure they comply with all relevant regulations and standards for banana transport and storage.

Vessel Cold Chain Monitoring

Monitoring the cold chain on vessels is crucial for reducing banana waste. For example, monitoring systems can track vessel temperature and humidity levels, which can help ensure that the bananas are not exposed to excessive heat or cold and don’t spoil in transit.

Operations in Market

The market operations are where the supply chain’s final step begins. Retailers should have proper storage and handling systems to ensure the bananas are properly stored and handled. Additionally, retailers should also take steps to educate the public about proper banana storage and consumption to reduce waste. Finally, retailers should also work with suppliers to ensure they only source bananas from farms and shippers committed to reducing wastage.

Discharge

Reducing banana waste also requires proper discharge systems. Any banana waste must be disposed of safely and responsibly to ensure it does not end up in waterways or other ecosystems. Investing in waste-to-energy technologies that can help convert banana waste into useful products, such as animal feed or compost, is also important. Reusing banana peels as compost fertilizer is another viable discharge system.

Cross Docking

Cross-docking is another essential part of reducing banana waste. Cross-docking involves transferring goods from one container to another without additional handling or storage. This helps to reduce spoilage, as the goods are moved from one container to another without any delays. This also ensures minimal handling of the bananas, which can accelerate their ripening before they arrive at their destination.

Trucking

Trucking is another important part of reducing banana waste. Trucks should be properly maintained and monitored to ensure the bananas are not exposed to extreme temperatures or conditions. Truck drivers should also be properly trained and equipped with the necessary tools and equipment to ensure the bananas are handled and stored properly during transport.

Distribution and Ripening Centers

Cross-docking, trucking, and distribution are also key aspects of the supply chain related to reducing banana waste. Cross-docking and trucking can help reduce the risk of spoilage due to long-distance transportation. At the same time, distribution and ripening centers can ensure that bananas reach their destination promptly and in the best condition. These operations should also allocate resources to advanced infrastructure and equipment that aid in minimizing banana waste.

Customer Demand Planning

System Implementation

To reduce banana waste across the supply chain, investing in systems and processes that can help streamline operations is important. This includes investing in digital systems that track, monitor, and analyze banana production, shipping, and storage data. Investing in predictive analytics and artificial intelligence systems that can provide insights into customer demand and help with decision-making is also important.

User Training

To ensure that all systems and processes are properly implemented, it is important to invest in user training. This includes providing users with the necessary information and resources to properly use the systems and ongoing support and guidance when needed. User training can help ensure that all stakeholders in the supply chain know their roles and how to reduce banana waste.

Monthly Review

Analysis of Trend Improvement

The data should be evaluated to determine average waste reduction across production, harvesting, packaging, and transportation steps to identify opportunities for greater efficiency and waste reduction. Current practices should then be compared against industry standards to identify areas needing more aggressive action (Hikal et al., 2022). Furthermore, new techniques or technologies to minimize banana waste throughout the entire supply chain should also be implemented. A monthly review of trend improvement can ensure efforts are constantly monitored and adjusted for maximum efficiency (Al-Dairi et al., 2023). Ultimately, this leads to greater sustainability and cost efficiency for all involved parties.

Comparison with Similar Time Previous Year

Tracking and measuring success is an invaluable way to assess progress. Recognizing working areas that need adjustment or further exploration will help reduce waste in banana production from Central America to supermarkets in the US (Jones et al., 2021). Track and record waste at each stage of the supply chain for a clear understanding of wastage, improved practices, and more bananas on shelves with less waste.

Audit Critical Points to Ensure Compliance

Auditing is critical to guarantee processes are compliant and that no issues arise along the supply chain. This includes verifying food safety and environmental regulations, particularly water, land use, and pollution. Audits can identify inefficiencies and potential improvements such as harvesting, transport (including temperature control), storage at ripening facilities, and packaging/shelf-life management – where unnecessary waste can accumulate quickly. Audits quickly identify compliance issues leading to wastage so corrective action can be taken promptly.

References

Abraham, B. M., Saleh, B. K., & Zelelew, D. Z. (2022). Effect of post-harvest handling and ripening methods on quality and shelf-life of banana. American Journal of Plant Sciences, 13(02), 175–192. Web.

Al-Dairi, M., Pathare, P. B., Al-Yahyai, R., Jayasuriya, H., & Al-Attabi, Z. (2023). Post-harvest quality, technologies, and strategies to reduce losses along the supply chain of Banana: A Review. Trends in Food Science & Technology, 134, 177–191. Web.

Alzate Acevedo, S., Díaz Carrillo, Á. J., Flórez-López, E., & Grande-Tovar, C. D. (2021). Recovery of banana waste-loss from production and processing: A contribution to a circular economy. Molecules, 26(17), 5282. Web.

Bozhinova, K. (2020). U.S. farmland is rapidly decreasing. Giving Compass. Web.

Buzby, J., Bentley, J., Padera, B., Campuzano, J., & Ammon, C. (n.d.). Updated supermarket shrink – USDA. Web.

Engelseth, P., Molka-Danielsen, J., & White, B. E. (2018). On data and connectivity in complete supply chains. Business Process Management Journal, 25(5), 1145–1163. Web.

Gunders, D. (2021). Op-ed: 5 billion bananas get thrown away each year – how reducing food waste can help solve the climate crisis. Chicago Tribune. Web.

Hikal, W. M., Said-Al Ahl, H. A., Bratovcic, A., Tkachenko, K. G., Sharifi-Rad, J., Kačániová, M., Elhourri, M., & Atanassova, M. (2022). Banana peels: A waste treasure for human being. Evidence-Based Complementary and Alternative Medicine, 1–9. Web.

Jocelyn, V., & Biagi, L. (n.d.). Bananas in North America. Statista. Web.

Jones, S. L., Gibson, K. E., & Ricke, S. C. (2021). Critical factors and emerging opportunities in food waste utilization and treatment technologies. Frontiers in Sustainable Food Systems, 5. Web.

P.Westcott, L. Hoffman. (1999). USDA: Price Determination for Corn and Wheat. Web.

Reynolds, C., Goucher, L., Quested, T., Bromley, S., Gillick, S., Wells, V. K., Evans, D., Koh, L., Carlsson Kanyama, A., Katzeff, C., Svenfelt, Å., & Jackson, P. (2019). Review: Consumption-stage food waste reduction interventions – what works and how to design better interventions. Food Policy, 83, 7–27. Web.

Richter, S. (2022). Food waste reduction– ecological coating for bananas. International Journal for Rural Development. Web.

Semuels, A. (2019). American farmers are in crisis. Here’s why. Time. Web.

Statista, FAO; IFAD; WHO, 2021, World Food Programme; UNICEF.