Introduction

Tehindo is a leading producer and marketer of tea products. Goteh is currently presenting more sales and profits. Fteh is primarily marketed through modern chains and it remains less competitive. Supply chains for this product are complicated and unsustainable. The company is keen to make a final decision regarding this product. This paper revolves around this key problem at Tehindo.

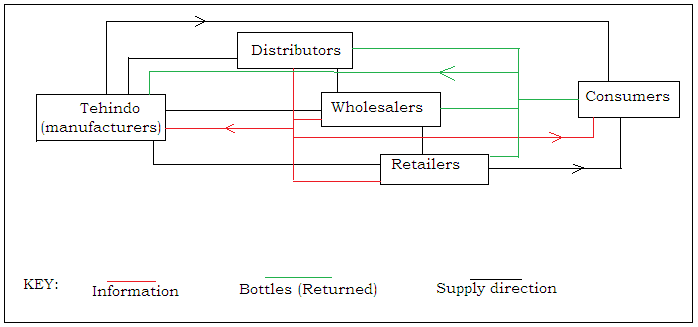

Flow: Information and Products

The presented diagram shows the flow of products from the company’s sales centers and manufacturers. Finished products can be marketed to consumers directly, wholesalers, retailers, or distributors. Similarly, bottles for RGB products will be received for refilling and support the supply chain. Information is shared and exchanged as shown using the red lines. These approaches are essential towards supporting the success and effectiveness of Tehindo’s products in the market.

Challenges: Managing Supply Chain

Tehindo uses RGB for its Goteh and Fteh products. This model requires that the company pursues both downstream and upstream supply chain processes. Companies and manufacturers should consider the demands recorded in the market. Fteh presents more challenges since the company has to identify the existing demands and coordinate every flavor. However, the situation is different Goteh since it remains a common product that is marketed across all traditional markets. Additionally, Fteh’s supply chain attracts additional partners, including commercial players and modern outlets.

Temporary Demand Causes

Tehindo has developed a model that requires wholesalers and retailers to exchange empties for filled bottled. This applies to orders made within the 2 weeks price change period. The organization communicates price changes to retailers and wholesalers to dictate their business practices. Tehindo requires its key wholesalers and retailers to exchange empties for filled bottled as a way of sustaining the supply chain process (Pujawan & Er, 2009). The approach is applicable to orders made within the 2 weeks price change period. Celebrations and holidays are known to dictate the recorded temporary demand. These issues explain why demand for Tehindo’s products tends to fluctuate.

Order Increases in Supply Chain

Wholesalers and modern outlets form a significant part of Tehindo’s business model. Supply chain processes are informed by the demands and predictions of these key partners. Throughout the year, orders in the supply chain will increase depending on the experienced factors. The first one is that wholesalers might order more when the company reports possible price increments. Such buying trends will be experienced during the two-week window period. The second one is when wholesalers anticipate more sales or demand from their respective customers.

Suggestions as the Supply Manager

Tehindo is presently operating in a competitive business environment. While the supply chains for the fruity tea variants remain unsustainable and complicated, desirable decisions are needed that can take the company to the next level. The involvement of all key partners is critical. The emerging number of stakeholders and modern outlets will require such fruity flavors (Pujawan & Er, 2009). These products are capable of transforming Tehindo’s profitability in the near future. The company needs to maintain such variants and consider the most appropriate ways to manage the supply chain process.

Continuation

The completed meeting revealed that the sales Tehindo made from Fteh were minimal. The company had a chance to identify new approaches to solve the recorded challenges and implement new supply chain procedures. The identification of the right manufacturers and distribution channels could support the entire process. Tehindo could also monitor most of the promotional initiatives different partners were undertaking and consider how positive outcomes could be recorded. Such measures will take Tehindo closer to its business goals.

Information Distortion

Information distortion is a challenging aspect that can affect the effectiveness of a supply chain process. The studied case has identified various sources of distortion. The key ones include the source and quality of information from supply chain networks, traditional market outlets, and promoters. The empowerment of manufacturers to support their supply chains makes it impossible for Tehindo to make the best decisions (Pujawan & Er, 2009). The current model has, therefore, led to additional challenges.

Suggestions

The best solution to address the recorded information distortion at Tehindo is for the supply chain players to collect data from all sources. All key partners should be part of the process. The collected data will be essential to support decision-making processes. The company can encourage all supermarkets and retailers to provide timely insights regarding the challenges in supply chain and support the company’s business model. This approach will minimize the recorded gaps and take the organization closer to its business goals.

Vertical Integration and Outsourcing

Vertical integration is a term that refers to the ownership and management of the supply chain process. The organization will dictate the location of distributors and warehouses. Tehindo controls the supply chain processes and allows manufacturers to meet the demands recorded in the selected region. Such approaches are essential and capable of delivering timely results. Outsourcing measures are considered to ensure that timely results are recorded (Vural, 2015). The leaders identify opportunities and the demand for its tea products and flavors to develop the most appropriate supply chain process.

Advantages

The implementation of a vertical integration model for supply chain continues to make it possible for Tehindo to remain profitable. The outsourcing processes allow the organization to produce and deliver tea products to suppliers, wholesalers, and retailers. The organization is also able to acquire empty bottles and support the effectiveness of the supply (Anca, 2019). Such attributes have led to increased efficiencies, reduced operational costs, and sustainability. The leaders find it easier to identify possible challenges and engage in actions that can deliver timely results.

Disadvantages

The adopted supply chain model and relationship with suppliers and manufacturers delivers a number of benefits. However, the framework presents various disadvantages that might affect the recorded profits. First, the company finds it hard to compete directly with the players in the sector. Second, the vertical integration contributes to the problem of information distortion. The professionals find it hard to make informed decisions and deliver timely outcomes. The company’s managers should consider these issues and implement powerful strategies to streamline the supply chain process.

Identification

Tehindo is presenting performing optimally in the selected industry. The supply chains are bringing together players from different regions to serve and meet the demands of the targeted customers. Currently, the management of supply chains and the desire the meet the orders made for some of the variants are affecting performance (Soleimani, 2018). Such issues explain why the leaders should be on the frontline to identify and implement an evidence-based solution that can help the company achieve its business aims.

Alternative Solutions

Several alternative solutions are available for Tehindo that might work synergistically to support the formulation of sustainable supply chains. Currently, the organization is recorded better gains from the sector. The professionals should begin by collecting information from the right sources and liaise with all key partners to streamline operations. The approach will result in a superior supply chain framework that resonates with the demands of all the targeted customers.

Recommendations and Justifications

The most appropriate recommendation is for Tehindo to maintain its line of fruity tea. This initiative will prepare the organization for future profitability. The stakeholders will consider better ways to transform the supply chain, solve existing problems, and make proper decisions based on all the available data. Such measures will make it possible for Tehindo to maintain its current position, attract more possible clients, and eventually become profitable.

Conclusion

Tehindo currently requires proper decisions regarding the issues surrounding Fteh tea. While the product is less competitive, the organization can identify additional measures that will deliver positive outcomes. The professionals involved will need to address the existing gaps and transform the supply chain process accordingly. The use of timely data will ensure that timely results are recorded.

References

Anca, V. (2019). Logistics and supply chain management: An overview. Studies in Business and Economics, 14(2), 209-215. Web.

Pujawan, N., & Er, M. (2009). Managing chain complexity in a tea manufacturing company. Operations and Supply Chain Management: An International Journal, 2(3), 167-171. Web.

Soleimani, S. (2018). A perfect triangle with: Artificial intelligence, supply chain management, and financial technology. Archives of Business Research, 6(11), 84-94. Web.

Varsei, M. (2016). Sustainable supply chain management: A brief literature review. The Journal of Developing Areas, 50(6), 411-419. Web.

Vural, C. A. (2015). Sustainable demand chain management: An alternative perspective for sustainability in the supply chain. Procedia – Social and Behavioral Sciences, 207, 262-273. Web.