Background

The preponderance of street lighting poles is made out of steel with a sprayed, metallic lacquered, or galvanized protective layer and come in a variety of types of construction and internal diameter. These are prone to corrosion, which can result in severe collapse, posing significant health and environmental risk to the community and institutions. The bulk of small constructions is made up of lighting columns. They are also prone to attachments, which, if not within the supporting design requirements, might cause the entire structure to be overloaded, resulting in early and disastrous collapse.

Objective

It is critical that scheduled frequent structural examinations and testing be performed as a component of the maintenance schedule. A regular testing and evaluation program will collect information regarding problems and will be able to track degradation over time. An examination, testing, and surveillance regime’s ultimate goal are to ensure that tangible resources are acceptable for use and fit for purpose, as well as to can provide data needed to support the performance management system.

The main problem of the work is the occurrence of corrosion in lampposts with the time uselessness of materials. The objectives of the work are to compare materials for the manufacture of poles, as well as to study the occurrence of corrosion and ways to prevent this process. The main limitations will be the cost and complexity of implementation. Since lampposts are used in almost all infrastructure facilities, a full-fledged replacement will take a long time and there will be high costs for updating facilities. The complexity of the implementation lies in the environment because the objects are located in different weather conditions and corrosion occurs individually everywhere.

Discussion

Steel Light Poles and Vibrations

Steel is a better choice for outdoor lighting poles than aluminum for a myriad of purposes, the most notable of which are different types of oscillations [3]. The first type and second form pulses are the two most typical forms of vibrations in light poles. These vibrations are caused by heavy winds striking light street poles, causing them to swing in the wind. These are generally minor tremors that are anticipated to accompany the pole’s placement and weather patterns.

Second-mode waves, also known as Aeolian vibrations, are a more destructive force. They are created by higher-velocity storms, which can cause significant internal damage to the pole’s midsection. Excessive exposure to Aeolian disturbances might result in fractures or broken fittings. Aluminum is considered to be more susceptible to Aeolian oscillations than steel, which is why the finest quality suitable voltage are made using steel poles.

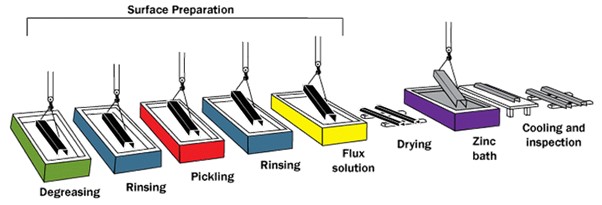

Galvanization

Before being exported, street light poles go through a procedure termed hot-dip corrosion protection, which covers the pole in a thick coating of zinc and other chemicals. Galvanization prevents the pole from corrosion, which is necessary if the pole is to last its whole existence [4]. However, not all galvanic corrosion procedures are the same. Some producers would utilize cold-dip galvanization to save money, which is less successful. Because of its upkeep lifetime, full recyclability, minimum environmental effect, and cost benefits for subsequent generations, galvanized steel may participate favorably in research and development projects [5].

The benefit, in this case, is that zinc converts to zinc carbonate and creates a chemical link with the steel. Cold-dip chrome plating is a more straightforward procedure in which the pole is coated with zinc-based paint [6]. This creates a mechanical link with the steel but is less successful than hot-dip galvanization since the zinc paint coating might wear off over time weather-related and friction [7]. Hot-dip galvanization, in addition to providing long-term anti-rust resistance, provides the photovoltaic outdoor lighting pole with a streamlined, modern appearance.

Durability

Galvanized steel is a challenging and long-lasting substance that can survive rough handling and construction, as well as a range of weather situations. Galvanized steel is powder metallurgy linked to steel, resulting in a rust and abrasion-resistant covering. These layers form spontaneously as a result of a chemical interaction between the irons in metal and the zinc in the boiling. Throughout this procedure, the coating layer has both uniforms covering, and the zinc grows orthogonal to the surface of the metal, leaving no weak places and total coverage. Both the inside and outside of the metal frame are coated. Hot-dip galvanized steel’s longevity in a wide variety of climates situations and in-soil locations has been shown by its usage in electrical transmission towers, which have been utilized for many generations across the world.

Powder Coating Light Poles

Powder coating is the last quality operation, which includes electrically charged blasting steel pillars with a large number of chemicals to give the pole a long-lasting surface. Other ways of putting a finishing to the photovoltaic street light pole emit contaminants known as Volatile Organic Compounds. A powdery finish is an ideal alternative since it is less costly and more ecologically friendly than other approaches. If customers want to be ecologically careful while buying solar lights, make sure the supplier employs a protective coating rather than more harmful techniques of pole cleaning.

Technical Feasibility

Steel pillars and timber poles both function as a specific conduit of heat, energy, and noise, but steel pillars are instantly connected with a grounding nut and copper cable near the pole’s base, removing the possibility of electrocution. Steel can be produced for all sizes and design criteria because of its strength-to-weight ratio. Steel is considerably more fire-resistant than wood; therefore, steel transmission poles may be heated for construction purposes if necessary. Steel pillars, in reality, may be fabricated to replace timber poles in current infrastructure without the need to repeat lines or install new lamp posts. Steel coatings can deteriorate in the case of a fire, although they usually remain unaltered as long as the pole remains upright and the form is preserved.

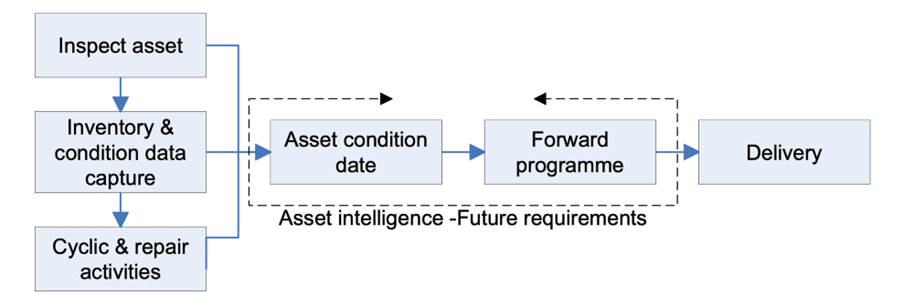

Pole Condition Assessment

Since a single-pole failure can be disastrous, governments, business owners, energy providers, and other persons in charge of public safety must frequently hire the services of certified inspectors and breakdown analyzers. There are services for capital structure determinants evaluation, integrity inspections, and corrosion risk assessment for decaying infrastructure, such as monopole antennas and high-mast lighting structures, as well as a broad range of other essential structures. Knowledge-Based Inspection is an examination status evaluation process used to determine corrosive hazards on implanted resources such as poles, trellis structures, grillage, and anchoring rods without the need for significant and costly excavations [8]. It can entail identifying structures at risk of rusting prior to on-site inspections, predicting corrosion behavior, determining life expectancy, and establishing a basis for future studies [9].

Street Lighting Lifecycle

For investment management considerations, street lighting is classified into many groups. The four essential components of a column, lantern, lamp, and power supply, have varied requirements, although the requirements of each lantern and light type are comparable. Measuring the degree to which desired levels of service are satisfied necessitates measures across four dimensions: security, accessibility, quality, and ease of maintenance. Over the next twenty years, the region will see significant new growth. This development will result in significant lengths of new motorways in new employment and housing districts, as well as road maintenance. The rise in the asset base will need extra maintenance expenditures and, in the long run, a greater demand for replacement.

Unlike contemporary lighting columns, which are fully coated and offer extra root protection, previous steel columns merely had an anodized or zinc perfusion pressure that was subsequently overpainted. The present painted columns will decay and become ugly in the beginning. Surface rust will then erode the parent metal, causing the framework to deteriorate. However, because the inside edges of the tube are not covered, these lighting columns corrode on the inside as well. As a result, the repainting will not significantly increase the life of these ungalvanized steel girders.

Minimization of Costs

Whole life costs encompass not only the direct expenses of construction, design, and supervising monitoring and examinations but also the ancillary expenses of poor management routines, such as user discomfort, environmental consequences, and third-party claims. The connections between these are not yet wholly quantified. This is an essential field for research and innovation, and national achievements will be utilized to drive policy choices. LED bulb advancement for street lighting operations will probably just become a viable option; these alternatives will be explored at the proper time [10].

Conclusions

It is evident that the incorrect pole might result in a short lifetime for solar light. Appropriate materials, the best production procedures, and the proper metal processing ensure that the sun concentrator pole outlasts all other elements, or the project will wind up. The first and most effective way is to hot-dip galvanize the pole. The hot-dip galvanized pole’s zinc coating is securely joined with the steel pole, the zinc coating does not flake off, and the anti-rust performance is outstanding. The surface of the light pole is then coated, the color may be chosen, and slightly elevated exterior plastics were included so that the light pole can be rust-proof for more than two decades.

High-temperature plastic blasting is a relatively new technique that has emerged in recent years. To produce the appropriate spray coating, the central operating concept is to spray nylon onto the surface of a previously prepared workpiece while it is heated and melted by the flame. Powder electromagnetic spraying entails negatively charged powder being equally deposited on the photovoltaic streetlight pole by electrostatic interaction and compressed air. This method helps improve the uniformity and flatness of the body of the lamp post pole. Of course, there are two techniques for electrically charged spraying: painting and spray polymer.

Originally, street lighting was used to light the streets in order to promote a wide variety of human activities. They play an essential function in human behavior by providing light and can even have knowledge of health. They also contribute to the creation of a safe atmosphere. With the development of highly flexible LED lights, light may be dynamically regulated in a variety of ways to account for human perception and even give a set of communication properties [11].

These settings can be typically extracted based on the sensor input from walkers in the form of actual contributions ranging from basic appearance to more comprehensive data via intelligent portable electronics such as cellphones. New functions for public lighting may arise as a result of this interaction with people and street lighting. The proposed adaptive system has various potential uses for outdoor activities, but one key characteristic is how it adapts continuously to people’s appearances. It has a worldwide dark mode that consumes less power, reduces artificial light, and offers a personal lighting system that follows walkers around.

The programmable street light technology is far from ready for implementation, but the goal of the project was never to build a finished system. The invention is a proof of concept as well as an invitation to consider the future functions of the lighting system in the light of new technology. For the reasons stated above, interactive street lighting is intriguing and should be investigated. Furthermore, other concerns are required, such as examining its relationship to other aspects of society. New variables have become available due to the departure from the inflexible system and the introduction of interaction and communication components; all of these must be studied for involvement with oncoming vehicles.

Recommendations

Aluminum has a higher corrosion resistance than steel. As a result, aluminum lamp posts have the capability to last longer and cost less to maintain [11]. However, because aluminum is not the most durable material, these poles are not appropriate for applications in high-wind locations or with large loads. Steel poles are more durable and can support greater weights such as fixtures, frames, posters, and accessories. Steel poles, on the other hand, will rust with time, which suggests they will require more maintenance. A steel pole has an expected duration of many decades, depending on the exposure surroundings and how the pole is polished. Future research may focus on finding a versatile material that will meet all the required parameters but without timely corrosion.

It is essential to consider both the architectural needs and the aesthetic of their study area before selecting poles that suit both. If their proposed development is new, they may have a little more leeway in pole types, which may assist form the overall aesthetic of the area. The quantity of light necessary for both health and attractiveness should influence the elevation of their poles. The more intense and focused the lights at the ground surface, the longer their pole. Ample parking spaces, for example, often utilize 25-foot poles to give ample illumination, but sports field lighting typically begins at 40 feet to offer appropriate brightness without blinding spectators and participants. Lighting research is often done to determine the best installation height, luminaire placement, and pole mount for a particular region, but it will also be helpful to study the environments and their impact on existing facilities.

References

Acuity Brands. Poles and arms | commercial outdoor lighting. 2022.

Sabnavis, M., Jagasheth, U. H., Avachat, H., & Mishra, M. “Zinc Industry: the unsung metal of the economy.” CARE Ratings: Professional Risk Opinion, Report, October 31, 2018. 2018.

Greenshine New Energy. “About Solar Street Light Poles: The Foundation of a Street Light.” Greenshine New Energy, 2022.

Yadav, Satyendra. “Performance observation of hot-dip galvanization for steel sheets.” Materials Today: Proceedings 46. 2021: 6700-6703.

Dallin, G., Gagné, M., Goodwin, F. E., & Pole, S. “Duplex zinc coatings for corrosion protection of steel structures.” Proceedings of Conference: Transportation Research Board TRB 97th Annual Meeting. 2018.

Electric Energy Online. “STEEL POLES ARE STRONG, COST-EFFECTIVE OPTION FOR DISTRIBUTION SYSTEM.” Electric Energy Online, Electric Energy Online, 2022.

Matergenics Inc. “Pole Condition Assessment.” Matergenics Inc., Matergenics Inc., 2022.

Morcillo, M., Díaz, I., Cano, H., Chico, B., & De La Fuente, D. “Atmospheric corrosion of weathering steels. Overview for engineers. Part II: Testing, Inspection, maintenance.” Construction and Building Materials 222. 2019: 750-765.

[Dzombak, Rachel, Ebru Kasikaralar, and Heather E. Dillon. “Exploring cost and environmental implications of optimal technology management strategies in the street lighting industry.” Resources, Conservation & Recycling: X 6. 2020: 100022.

Sjöberg, Inga, Amanda Gidén Hember, and Carolina Wallerström. “Smart street lighting: The advantages of LED street lighting and a smart control system in Uppsala municipality.” 2017.

Rusnak, Cameron. Fatigue Behavior in Reinforced Electrical Access Holes in Aluminum Light Support Structures. Diss. The University of Akron, 2019.