Summary

Today’s businesses are part of a highly dynamic operations and supply chain that includes managers, various manufacturers, and distributors located worldwide. When a disruption or bottleneck happens in some portion of the stock chain, it is always challenging to establish the people to blame without a thorough review of supply chain control processes. It is challenging to attain targeted policies, revenue, and growth without first comprehending the issue’s root and cause. The method of analyzing a company’s operations from the managers’ appraisals to the business acquisition of raw materials from its merchants to the distribution of finished goods to consumers constitutes an operation and supply chain analysis.

Executive Summary

The current study aims to determine which management and supply chain elements can be enhanced or shortened to deliver the product to consumers more rapidly and efficiently. This study is founded on the impression that the more versatile a corporation can be, the sooner it can develop. The report is an operation and supply chain management audit of Unilever Group. It analyses the company’s operations, objectives, management system, and supply chain pathway that gives a clear structure of how the company has continually maintained its reputation in the world’s top companies over the years.

Unilever Group: The Big Picture

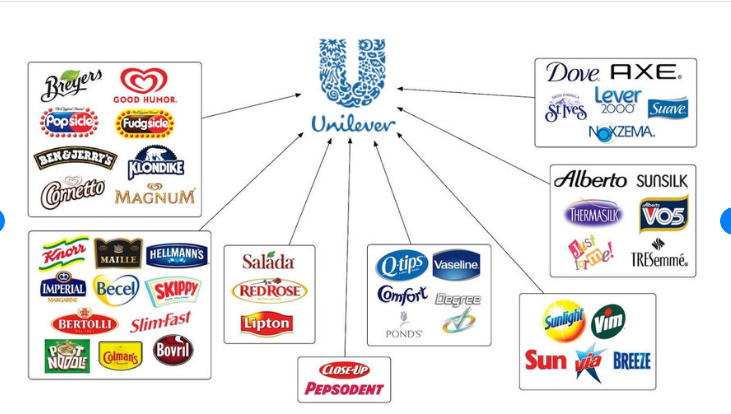

The company is a transnational corporation established in the U. K. and the Netherlands. It has continually been a company dealing in fast-moving consumer goods and sells its products in over 190 countries throughout its business operations. It is headquartered in London, England. In 1930, the Dutch margarine firm Margarine Unie combined with the British soap company Lever Brothers to create Unilever. Since they always fought for the same raw materials, oils, and fats to produce their products, they agreed to merge. Unilever’s new mission focuses on customers in the twenty-first century and a fresh corporate vision of building a better future every day.

Policy/Strategy Analysis

Strategic Direction of Unilever Group

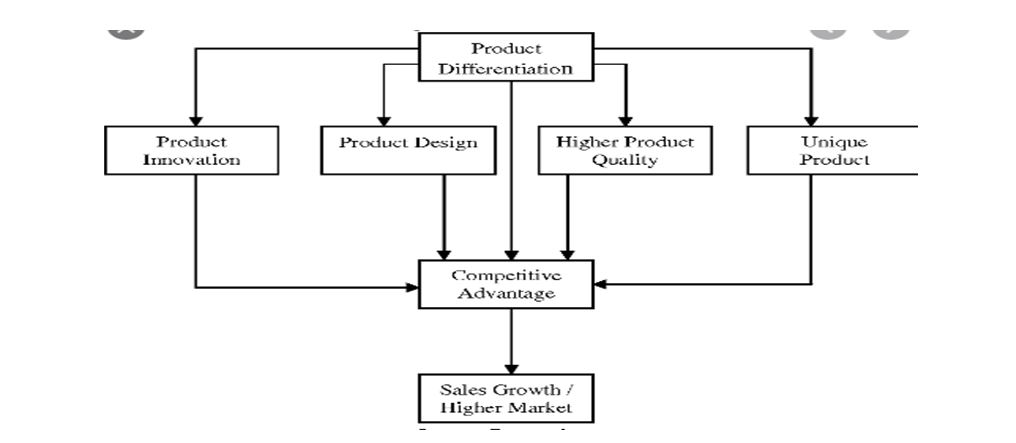

Without a doubt, the firm is such a well-known enterprise that it has proven its superiority over competitors and placed them on the road to glory. The organization has met almost all types of forecasting as functional targets set by Management. This report will concentrate on the forecasts and organizational targets, as well as their execution.

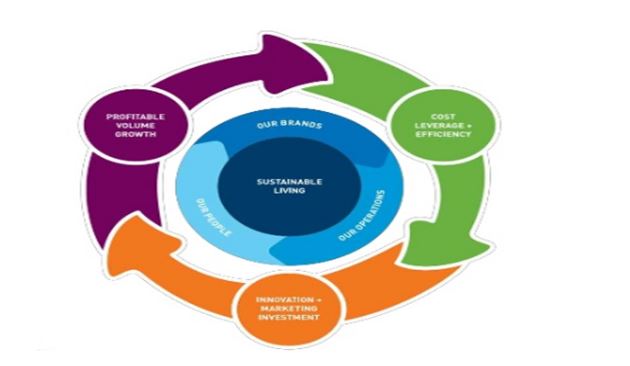

The corporation’s ambition is to create a sustainable lifestyle for all. They aspire to pursue a strategy for creating a better future systematically. They need to make their goods to be the people’s day-to-day companions. It is engrossed in the ecological challenges, in which they would avoid destroying the surroundings as a result of their operations. It is acutely aware of the importance of everyday matters in ensuring the smooth running of business operations. Moreover, it is attempting to make business more viable by discussing social problems. This is standard practice in their applied merchantable strategy.

The enterprise employs a wide range of skills in its development portfolio and strategic Management. It follows a future-fit business model to cover the maximum number of segments possible, thus delivering superior performance (Wilson and Beck, 2020). They must make their methodology a reality by partnering with the industry. They depend on the fact that by exploiting their presence in high-end markets with such a large number of brands, they can implement social responsibility and improvements in the people’s community (Chernobay, Yasinska, and Malibroda, 2020). Unilever believes that they are conscious of the world’s problems through its corporate social involvement (Chernobay, Yasinska and Malibroda, 2020; Mirvis and Googins, 2018). They are also ecstatic that they are paving the way for a more fair and unbiased mother earth for humanity.

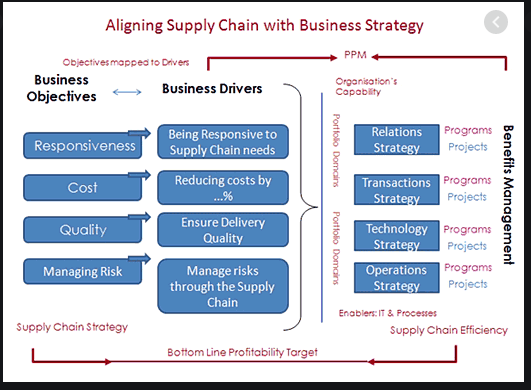

Unilever’s Operation and Supply Chain Management Strategy

The firm’s performance is focused on a well-defined global strategy, and efficient and reliable strategies that ensure it is carried out flawlessly. When it comes to the supply chain partner’s collaboration, It is a firm believer in collaboration and is among the first to implement new technologies. For instance, it uses RFID standard technology to monitor goods through the supply chain and applies data analytics to boost operations (Bottani et al., 2017; Usama and Ramish, 2020). It was also one of the first businesses to look at block-chain to track and control their incredibly complicated suppliers, such as Kroger, Walmart, Nestle, and Tyson Foods, joining.

In its search for sustainability, the company has introduced policy changes in its logistic strategies. They no longer outsource logistics and have now taken it in-house. In-sourcing 3PL services process is underway in the company to minimize emissions and prices. More than that, a stable, long-term supply chain necessitates complete alignment, with an assurance that all partners must be able and willing to commit to the same goals. Every year, Oxfam releases “Behind the Brands,” a report that evaluates the world’s top ten food producers’ sustainability policies, and since 2015, it has dominated the chart (Sacks et al., 2019). Unilever was also recently ranked first in the EV100, an initiative promoting world business commitment, and placed third on the Sustainability index’s Carbon Clear’s Taking Stock for sustainability reporting.

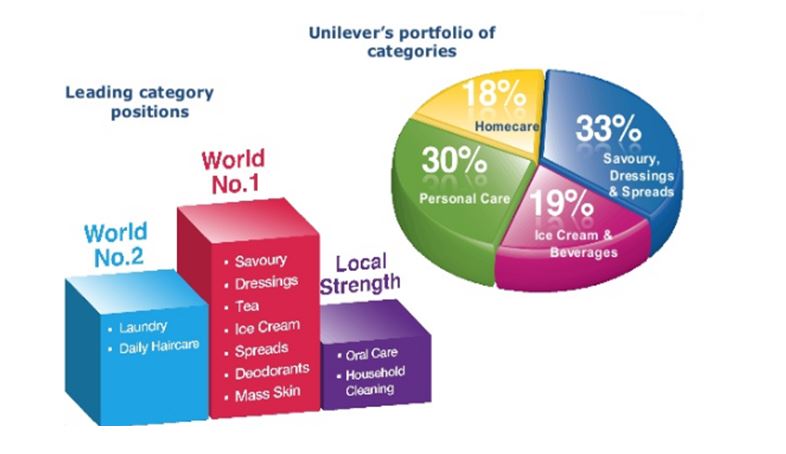

Table 1: Unilever’s Portfolio of Categories as a Percentage

Customer Service Strategy

Being one of the domain’s leading and healthiest businesses with a slew of famous varieties, Unilever acknowledged that its merchandise is used by people globally. The company first entered the overseas marketplace to compete internationally by leveling only a few extraneous bazaars, relying on the assets of its eight comprehensive brands: Dove, Sun silk, Clear, Pond’s, Vaseline, Magnum, Rexona, and Lux. The company extends its famous brand to several other countries and competes internationally after successfully launching its product in many markets.

Unilever and Astute Solutions recently announced the implementation of Astute Solutions, RealDialogTM knowledge management solution, and the RealDialogTM Agent Assist tool, advancing toward the goal of building a world-class consumer packaged goods contact center. It also offers a rare degree of insight into customers’ desires and needs, leading to significant business benefits (Chen, Chen, and Sun, 2021; Zhang et al., 2019). Millions of people in the U.S. and Canada depend on Unilever’s contact center members to help source its over 90 brands every day. It offers items in 14 different categories, including home, personal care, and food. Despite the organization’s large information repositories, these factors resulted in substantial customer engagement and knowledge management challenges. Contact center representatives were often unable to locate relevant product information to respond to customers’ queries promptly. These data were stored in systems that were difficult to access and maintain. RealDialog from Astute Solutions aims to solve this problem while also making access easier.

RealDialog is a conversational knowledge management solution that responds to a user’s question through a company’s website, intranet portal, contact center, email, talk, or another channel with a simple and precise response. It employs sophisticated linguistics methods and Natural Language Understanding (Chen, Chen, and Sun, 2021). It understands and responds to user feedback and questions in its natural language, including pronouns, slang, and company-specific words, with unparalleled ease and accuracy. When clarity is needed, it engages users in a human-like dialog to provide the most accurate and contextualized answers via a self-service solution.

Organization

Key Operations Management Roles and Responsibilities

Operation management is a corporate practice that aims to achieve the highest degree of ethical quality in administration. It is concerned with producing services and goods, which begin before production and end with consumption. All organizations create some combination of services and products, whether they are small or large, service or manufacturing, public or private, for-profit or not-for-profit (Prasad, 2020; van Hoek, 2020). Operations management, in basic terms, is the task of managing the resources that produce and distribute goods and services. Operations managers create policies and processes that help the company enhance its efficiency in strategic tasks and productivity decisions (Chernobay, 2020; Krepysheva, Sergievskaya, and Storchevoy, 2020). The operational success of Unilever is inextricably linked to its financial performance. To retain high efficiency, the company’s operations management must resolve issues in these strategic decision areas. Unilever has developed operations management methods to keep the business highly profitable as a leading consumer goods group. These premeditated resolutions include

- Goods and Services’ Design – This strategic decision area aims to create appropriate goods for the company. The organization’s operations management tackles product problems and concerns. Continuous innovation to fulfill customer needs is the secret to success.

- Quality Management – Operations managers deal with meeting consumers’ product quality standards in this strategic decision field. To meet product quality criteria, Unilever’s strategy includes integrating quality standards into operating processes.

- Capacity and course design – In this tactical assessment part, procedures in the administration aim to guarantee adequate capital and establish processes to withstand development. Unilever uses robotics and automation in the bulk of its manufacturing processes.

- Stock Management – The objectives of this premeditated assessment in the field of tasks management are optimal inventory and portfolio assembling and allotment. The firm is apprehensive about preserving a sufficient account of buyer products to react to market fluctuations.

- Maintenance – In this part, actions directors strive for a high business course for the Company’s efficiency and stability. When demand spikes unexpectedly, the corporation retains joblessness processes to certify progressions capability.

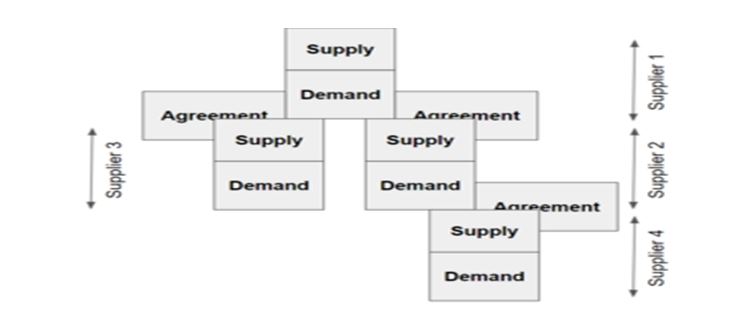

Key Supply Chain Control Duties and Responsibilities

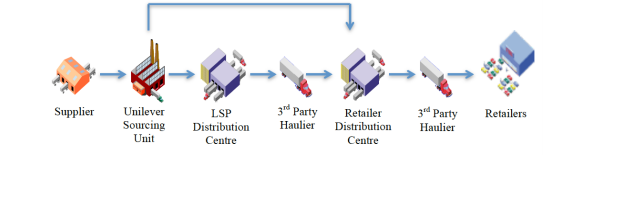

Supply chain supervision denotes the running and the undertaking of goods and amenities, and it incorporates all developments that convert raw materials into finished goods. It entails reshuffling an enterprise’s supply-side setups to advance buyer approval and accomplish a competitive edge in the manufacturing sector (Pant and Ramanchandran, 2017; Edman, 2016). The supply chain is a critical catalyst at the heart of the company. From sourcing raw materials to producing and shipping the finished product, the group plays a central role in fetching the products to customers (Laursen and Andersen, 2016; Moya et al., 2020). The supply-chain prototype’s principal role is to offer the Group’s companies a collective comprehension of the supply-reach chain and sub-processes. The model establishes a shared language for the various Business Groups, allowing synergies to be identified and implemented (Wati, 2020). Assessing supply-chain efficiency and designing and aligning KPIs are two of Unilever’s most significant supply-chain model applications. The primary roles of the supply manager include:

Selling and Distribution – Unilever’s products are principally advertised to chains, distributors, cooperatives, and self-regulating grocery accounts and foodservice merchants and institutes through its sales workforce and independent dealers, mediators, and brokers.

E-procurement – Unilever implements NPI planned tracing and e-procurement helps to achieve one main shared strategic drive: World-class Supply Chain and Simplification. The six drives for executing world-class supply supervision are as follows; device executive buying, hasten and influence simplification, drive evidence and dimension, enable e-procurement globally, professionalize NPI sourcing, attract, cultivate and preserve world-class purchasers.

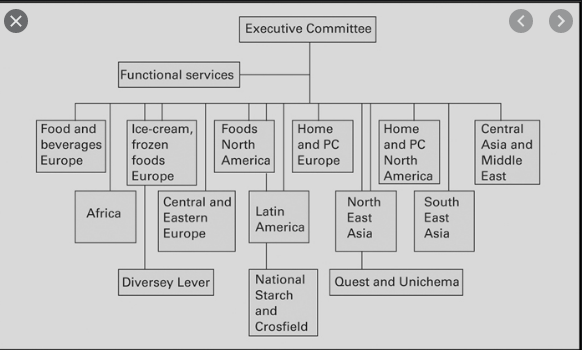

Unilever’s Nature of the Supply Chain Structure or Network

Aligning the business plan helps the company take advantage of cross-enterprise opportunities that save money and time. Conventional supply chain philosophy must be abandoned in favor of a modern understanding and parallel emphasis on both market and supply strategies. As Unilever U.S. has learned over the years when designing and implementing its Supply Chain 2010 plan, it also needs a rational approach and a considerable amount of hard work. Towards an Acceptable Supply Chain Model, the organization is a truly multinational business, with net revenues of $50 billion in 2006 across the Americas, Europe, Asia, and Africa, with 179,000 employees in 150 countries (Unilever, 2020). The portfolio includes well-known trademarked brand names in categories such as spreads and dressings, beverages (Lipton teas), sauces (Ragu), ice cream (Good Humor and Breyers), and frozen food (Bertolli dinners), and more (Dove, Suave, and Axe). As product lines were bought and sold, portfolio priorities changed, assets were rationalized, innovations were adopted, and customers were increasingly provided with differentiated services, these challenges evolved.

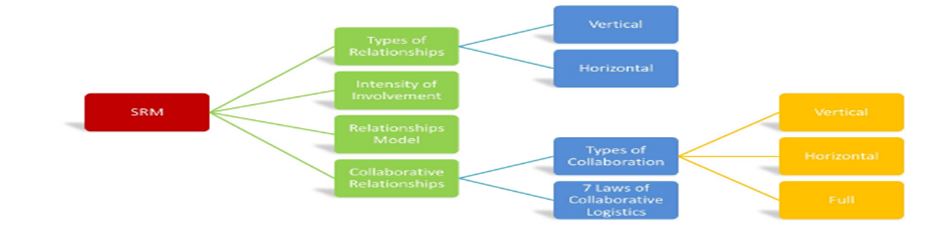

The Nature of Relationships with Supply Chain Partners

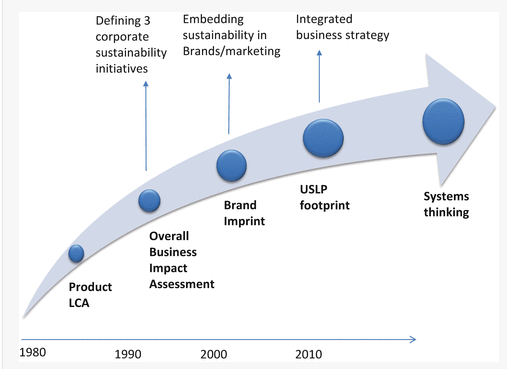

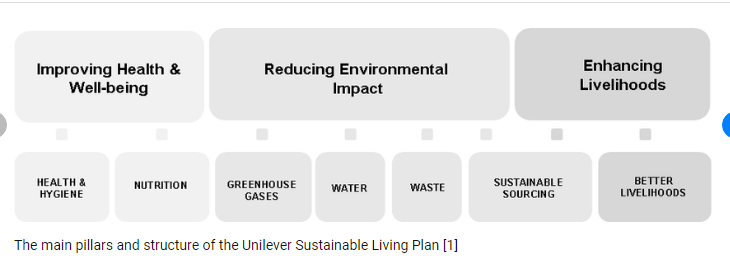

Unilever has set a lofty goal of doubling its business while halving its product’s environmental impact. The company is making substantial progress in both fields, as shown by the latest update on the Unilever Sustainable Living Plan and financial results. However, to achieve goals, the company collaborates with strategic suppliers that foster innovation and long-term investment in the supply chain. It launched The Unilever Sustainable Living Plan in 2010, a corporate strategy to build a long-term sustainable business and seek new ways to work that do not take from society and the environment (Ionescu-Somers and Brassey, 2019; Lawrence, Rasche and Kenny, 2019). It aims to accomplish many goals that seem to be at odds with one another at first glance. The organization wants to double its revenue while lowering its total environmental impact (including manufacturing, customer use, and disposal) and raising its positive social impact. Unilever recognizes that being the customer of choice for suppliers is vital to receiving preferential access to services, ideas, and technologies through partnerships (Dentoni, Bitzer, and Schouten, 2018). It also represents a mindset change for procurement practitioners from a transactional to a Business Relationship Manager approach to procurement.

Processes

Business Process Models and Their Development

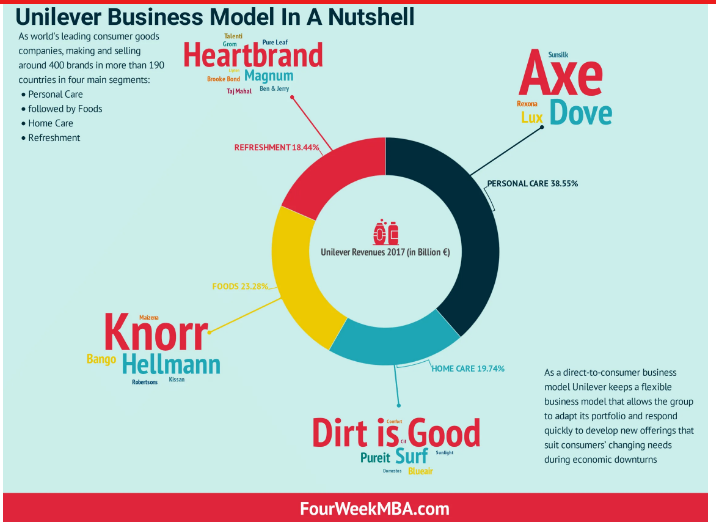

The corporation is the domain’s second-largest advertiser, with sales consisting of personal maintenance goods, home management and care, foodstuff, and nourishment.

The business has succeeded in establishing a global value chain. This worthiness of its operations is established on a direct-to-consumer commercial theory, which necessitates a comprehensive knowledge of customers and the products they choose to connect with. As a result, it employs large-scale marketing strategies to forge a bond between customers and brands (Escamilla et al., 2020). Aside from its appealed value chain, its success is undeniably focused on its capacity to rapidly respond to changing economic conditions, buying or supporting products that will trade well throughout tough times. Constructing R&D for product creation to integrate with advertising activities is critical (Chirumalla, Oghazi, and Parida, 2018). The average organization collects customer information for product growth. Unilever invested over 900 million euros in research and development in 2017.

Furthermore, the organization can ensure its brands’ are adequately delivered by collaborating with manufacturers worldwide and using a vast supply chain from its products and brands. Based on customer insights, the supply chain deliverables are converted into finished goods and produced worldwide (Erhun et al., 2020). Distribution and direct access to customers through a network of over 400 warehouses and 25 million retail outlets.

Consumer insights are crucial ingredients in this value chain used in their R&D strategy, leading to productivity growth. The corporation has a direct-to-consumer business prototype that generated over $50 billion in revenue in 2017 (Lee, 2020). Also, the organization uses a comprehensive promotional approach to hold its products in front of customers’ minds.

Managing Operations and Supply Chain Processes

The company affects people’s lives in various ways, with 400 brands covering 14 categories of personal care, home, and nutritional items. Lux, Domestos, Knorr, Lipton, Flora, and Hellmann’s are selected of the best-acknowledged labels. Unilever is committed to helping customers grow more out of the existing portfolio of products. It conducts comprehensive market exploration to warrant that its products continue to meet its clienteles’ evolving preferences, lifestyles, and aspirations worldwide. Unilever Bestfoods and HPC have an exceedingly energetic supply chain and industrialized business line due to their broad product portfolio.

To satisfy the consumer demand of millions of people who continually choose a Unilever product every day, the company ensures a steady supply of its products to retail outlets worldwide. It has consistently maintained effective delivery but also maintain a high product quality level. From sourcing to trading and dissemination, the company’s catalogs underpin a variety of leading business processes. It implemented a CA Databank Management model to simplify the databases simplifying repetitive administration activities and reducing downtime (Maheshwari, 2019). Its North America has been able to minimize operational costs and increase reliability by snowballing database enactment and usage, ensuring supply chain stability and value industrial processes and good manufacturing practices (GMP).

Unilever executed the CA Database Management model to help improve data management performance across the organization, allowing it to streamline monotonous management activities while still increasing application availability significantly (Chen et al., 2020). Based on the Fast Unload items, the answer achieves the responses by permitting Unilever to swiftly and competently remove and establish evidence from its databases. Unilever was particularly pleased with the solution’s failure prediction function (Kubota, Horita, and Tasaki, 2020). By allowing database managers to unpack and regroup data while mission-critical requests remain online, the solution reduces downtime.

Means of Process Improvement

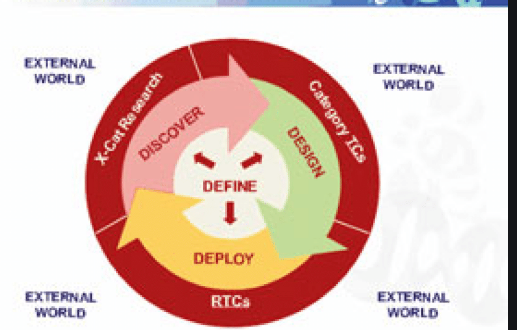

Over the years, it has been dealing in goods found in the homes of more than 2.5 billion people in over 190 countries around the world. Unilever brands have been a part of people’s daily lives for over 90 years, with hundreds of different items (Dorsch and Flachsland, 2017); Locatelli et al., 2020). With such a large global footprint, quality assurance is a top priority for the entire organization. As illustrated in the ROD process improvement below.

When customers demand high-quality goods, it’s critical that product packaging lives up to the brand pledge. Quality assurance that lives up to its reputation has continually instigated insight and creativity at the core of Unilever Dubai’s operations (Hammond, 2019). They need to deliver brands and goods that match or exceed their consumers’ highest expectations, allowing for long-term growth across the board (Kalkanci and Plambeck, 2020). Focusing on personal care items like shampoos and lotions, any quality management problems must be identified and resolved quickly to ensure that products stay consistent with the Unilever brand.

A team of analysts in the quality control department is in charge of conducting all checks and identifying any inconsistencies that may make their way onto labels and packaging. Any defects must be promptly reported to the department manager to ensure that only high-quality goods leave the manufacturing facility (Berghout, 2020). The quality department found it difficult to maintain 100 percent accuracy during the proofing phase of manual proofreading because the human error was inevitable. Global-Vision serves as a monitoring unit, allowing the department to navigate inspections with ease and ensure that no mistakes leave their lab. The cost and time savings are crucial, with over 200 labels to inspect every week.

Information

Information Infrastructure

With more than the various employees and staff across the world because of its several branches and chains, and with the availability of a technical workforce and the current digital presence to be proud of, the success of Unilever Group depends on its solid online portfolio and robust technological infrastructure, which delivers top-of-the-range IT products. Information Technology has shifted the model to a customer-centric approach from a centralized investment based on financial data and technology platforms from TBM to align Information technology capabilities with productivity plan and Unilever’s growth. This has enabled the company to improve accurate chargeback models, emphasize costs of IT, better match spending with industry benchmarks, and reduce the program numbers as it supports by half (George et al., 2020; Shawkat, Habib, and Khan, 2019; Uribe-Macías, Vargas-Moreno, and Merchán-Paredes, 2018). Unilever aims to expand and become more competitive by eliminating legacy systems, which will allow it to concentrate on critical platforms.

Managing Unilever’s technology infrastructure to support such a vastly dispersed organization is a challenge, as it is for many businesses that use Apptio and technology business management (TBM) to get IT spending under control. (Janudin, 2020). Since the organization does business in so many places worldwide, it organizes itself by organizing countries into “clusters,” or countries. Unilever’s technology, data, and service function manages technology costs centrally, distributed to clusters using a turnover-based algorithm.

To re-architect its business model so that every country and feature could be correctly billed for their technology use, it developed an IT-based model. The company adopted technology with a platform-based approach to delivering shared services, rather than the previous, project-based way of doing business. Platforms are a single set of internationally standard technologies covering a company’s digital products and information systems while still serving a vital business function, such as sales (Kazi et al., 2020). By putting platforms at the core of their strategy, IT can quickly develop and execute business strategies while lowering the total cost of ownership (TCO), reducing complexity, increasing scalability, and speeding up innovation and digitalization.

To achieve such a positive swing between mapped and unmapped costs, every organization must collect accurate IT spending data. By improving its configuration management database’s accuracy, Unilever has solved many of the problems (Venkatesh et al., 2020). With all of this cost data, Unilever can better monitor the total number of technology projects in the queue and those projects’ market value. In the pre-Apptio era, this was not possible. Unilever used to spend almost half of its IT budget on 650 projects a year before TBM. They now invest half of the total on even fewer programs.

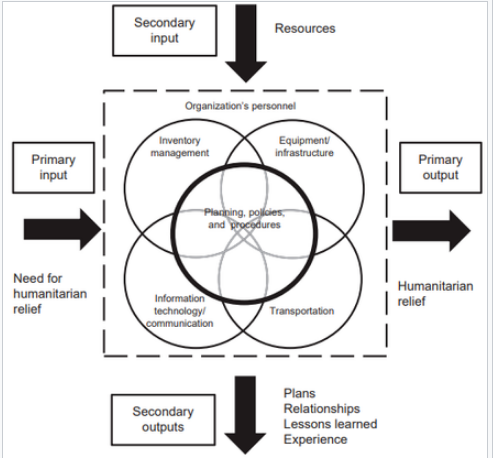

The Effectiveness of Information System for Operation and Supply Chain Planning and Decision Making

The physical and informational assets needed to operate a supply chain are referred to as supply chain infrastructure. This includes the systems through which an organization produces and distributes its goods and the fixed and mobile equipment installed within those structures, the transportation fleet that transports products across the manufacturing and distribution network, and the information technology necessary to prepare, and conduct track supply chain activities.

The diagram below represents the norm that evaluates the cross-functional information framework has continually constructed and how they have added significant value to Unilever company’s supply efficiency.

Transaction Processing Systems can help assess the degree of service in places like supermarkets and biometric devices. For science, design, and procurement, the cognition degree of determination is required (Meiryani, Isa, and Candra, 2020; Meiryani, Deniswara, and Dewi, 2020; Amanah, Dhiana, and Fathoni, 2018). The Knowledge Work System will contribute to determining cognition levels. The use of a management information system or a decision support system will help you assess your managerial level. As well as trying to implement a more digital and centralized platform for transformation and innovation, Unilever has changed the way it approaches other areas, too, such as legal practices and recruitment.

All Brands Great and Small

As a result of Unilever Group’s digital crossing based on its various brands, there have been such problems as replication, intersection, and a lack of share buying experimentation. Previously, Unilever intended to take a platform-based approach to IT, yet at the same time sought to customize standard tools where possible, without hindering the ability of different brands to grow and revolutionize. Two of the leading obstacles for Unilever’s revolution were the number of technologies accessible in the market and the segmented methodology to embrace new tools without rational know-how about the group as a whole. In this regard, the company employed a virtual reality system to gauge the type of employees they were recruiting.

Further Information on Unilever IT

The firm targets to embrace disappointments and setbacks to accommodate and adopt an online technology test for strategic Management of its various brands. This is made possible by learning the IoTs, and customers’ attitudes towards the changes, and making it more agile. The Company is also overseeing the implementation of opportunities for new startups to work with, rather than endeavoring to the device all facilities and platforms in-house. As such, the corporation is applying the use of a virtual reality system (VRS) to recruit and interview such potential marketers as graduates, thus lowering the recruitment process in the long run, from at least six months to about half a month (Samarasinghe, Baghaei and Stemmet, 2020). Based on these IT changes, the innovations help the firm close what Unilever Indugula terms the adoption gap, which is the variation between how fast a technology operates and the form of the technological changes the consumers use in its adoption scaling in the business operations.

Performance

Means of Operations and Supply Chain Performance Measurement

Performance in a company can be evaluated from different theoretical perspectives. For instance, according to Hourneaux et al. (2018), the top line of performance is underpinned by profit, the people, and the plant. This process is indicated on the chain of communication a company uses based on the Balanced Scorecard, evaluating the social, ecological, and monetary situation. In this case, performance assessment is gauged on how well an organization attains its vision and mission statements.

The shift in Unilever’s Supply Chain function, a behemoth of more than 100,000 workers in 190 countries, involving sourcing raw materials to ensure goods make it to store shelves is a clear example of the layered impact of Unilever’s diversity-focused initiatives. Women, on the other hand, have traditionally been underrepresented in the field, especially in Management. When Marc Engel was hired as Chief Supply Chain Officer in 2016, he prioritized diversity and adapted Unilever’s global D&I plan to help the role progress faster. Although this challenge was particularly challenging in Hot Spots, women face significant cultural barriers; it was not impossible.

Unilever Indonesia has been on a positive trend in business profits and efficient operations by embracing the Balanced Scorecard model (BSc). Each of the knits is the complete scorecard and uses Individualized Key Performance Measures (KPIs). A simple sample from one of the Group’s MCO, Unilever Indonesia, is a proud affiliate of the multinational consumer goods giant Unilever (Johnsen et al., 2020). Financially, until 2004, Unilever Indonesia was able to sustain double-digit growth for six years in a row. All Unilever operating programs begin with a business plan. This complies with the Balanced Scorecard (BSc) system’s basic principles, which Unilever Indonesia has been using since 2000 (Llivisaca et al., 2020). The BSc method was initially introduced with the aid of a consultant.

Critical Aspects of Performance over Time

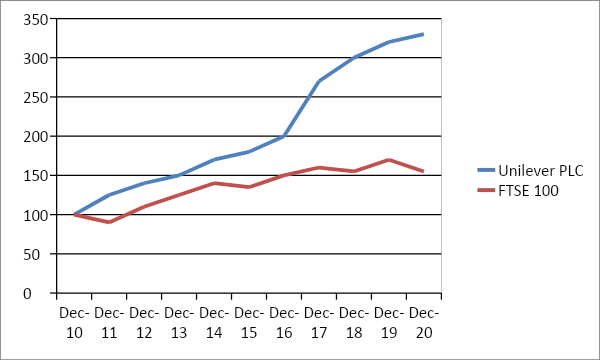

Unilever’s success is partly due to its leaders’ ability to cultivate a culture of performance and quality. To control the business and boost efficiency, the firm’s executives, for example, employ market-based and results-based approaches. Market-oriented Management adjusts management strategies based on market data (Datta and Difee, 2020). Results-based Management, on the other hand, focuses on achieving desired business outcomes. These strategies aid human resource efficiency and organizational success (Gouda and Saranga, 2018). As a result, Unilever’s leadership and management styles contribute to its corporate culture, as shown in the past centuries in the diagram below.

The graph (see Figure 20) below includes growth in the value of a theoretical £100 asset over ten years’ FTSE 100 comparison based on month-trading-day typical values.

The table (see Table 1) shows Unilever’s performance against the FTSE 100 Index, which is the most pertinent index in the UK where the principal listing is indicated. Unilever is a constituent of this index.

Table 2: Value of Theoretical Dollar Value Holding

Unilever’s leadership-based methods ensure that corporate culture is implemented correctly, particularly during mergers and acquisitions. Integrity is critical in mergers and acquisitions, where effective corporate merging necessitates human resource integration (Behnke and Jenssen, 2020). Unilever, for example, uses results-based Management to enforce the organizational culture in its operations. As such, the company’s leadership warrants that the corporate culture of success and quality remains consistent even after mergers and acquisitions. Therefore, all the previous achievements are not lost upon partnerships and merger formation.

Action Plan

Today’s trending organizational aspect is the supply chain administration policy that has shed light on various organizations’ operational systems. Unilever is a multinational consumer goods corporation (Seyedghorban et al., 2020, p.117). The sustainability philosophy is built on three pillars: environmental, social, and economic growth, as shown in the diagram below.

Adopting environmentally friendly business practices has a range of benefits (Unilever, 2021). It requires the company to be more accountable to its market and the consumers with whom it communicates. Organizations with a track record of local and global sustainability can generate revenue through investments (due to a positive public image), employee productivity, and a more considerable 1ong-term public following. Sustainability isn’t just about the environment; it’s also about jobs, business practices, supply chains, and other aspects.

Unilever has thrived for over a century on a model focused on mass manufacturing, distribution, and marketing. In retrospect, this model and goal to improve customers’ lives and well-being seemed clear (Van et al., 2020). Today’s world is diverse and fragmented, and customers are well-informed about brand preferences and have more shopping options. However, the same digitalization that disrupted the conventional FMCG industry is expected to play a vital role in the corporate behemoth’s transformation. Direct interaction between customers and makers is becoming possible because of technological advancements and more distributed and shared manufacturing and precision marketing.

Unilever is developing new alliances to address the demands of the hyper-segmented market. It is a belief that there is a need to step away from a linear supply chain and toward a supply circle, with Unilever at the center as a digital hub (Akalin, Huang, and Willems, 2016). Demand generation, demand fulfillment, and creativity replace traditional functional silos such as sales, research and development, marketing, and supply chain need to be implemented. Future supply chains will need to be much more flexible and sensitive (Dogru and Keskin, 2020). Unilever is working with Kinaxis to rewire the planning modules to create a more agile, responsive, and future-fit supply chain, helping them adapt to market shifts in real-time and get their goods to their buyer’s customers in the right countries at the correct times.

Reference List

Akalin, G., Huang, Z. and Willems, J. (2016) ‘Is supply chain management replacing operations management in the business core curriculum?’, Operations and Supply Chain Management: An International Journal, 9(2), pp. 119-130.

Amanah, N., Dhiana, P. and Fathoni, A. (2018) ‘The influence of dividend policy, debt policy, profitability on company values that impact good corporate governance, Journal of Management, 4(4), pp. 1-27.

Behnke, K., and Janssen, M.F.W.H.A. (2020) ‘Boundary conditions for traceability in food supply chains using blockchain technology, International Journal of Information Management, 52, p.101969.

Berghout, E. (2020) ‘COVID and opportunities for information systems management research,’ Information Systems Management, 37(4), pp. 357-360

Bottani, E. et al. (2017) ‘Monitoring on-shelf availability, out-of-stock, and product freshness through RFID in the fresh food supply chain,’ International Journal of RF Technologies, 8(1), 33-55.

Chen, L., Yao, S. and Zhu, K. (2020) ‘Responsible sourcing under supplier-auditor collusion,’ Manufacturing & Service Operations Management, 22(6), pp. 1234-1250.

Chen, W., Chen, X. and Sun, X. (2021) ‘Emotional dialog generation via multiple classifiers based on a generative adversarial network,’ Virtual Reality & Intelligent Hardware, 3(1), 18-32.

Cheng, Y. (2021, February) ‘Analysis on the opportunities and challenges of Unilever’s differentiated competition by Using SWOT and PEST,’ In 6th International Conference on Economics, Management, Law and Education (EMLE 2020) (pp. 280-284). Atlantis Press.

Chernobay, L., Yasinska, T. and Malibroda, S. (2020) ‘Applied aspect of corporate social responsibility impact company competitive (Unilever example),’ Entrepreneurship, 8(1), pp. 32-44.

Chirumalla, K., Oghazi, P. and Parida, V. (2018) ‘Social media engagement strategy: investigation of marketing and R&D interfaces in the manufacturing industry,’ Industrial Marketing Management, 74, 138-149.

Datta, P. and Diffee, E.N. (2020) ‘Measuring sustainability performance: a green supply chain index,’ Transportation Journal, 59(1), pp. 73-96.

Dentoni, D., Bitzer, V. and Schouten, G. (2018) ‘Harnessing wicked problems in multi-stakeholder partnerships,’ Journal of Business Ethics, 150(2), pp. 333-356.

Dogru, A.K., and Keskin, B.B. (2020) ‘AI in operations management: applications, challenges and opportunities, Journal of Data, Information and Management, pp.1-8.

Dorsch, M. J., and Flachsland, C. (2017) ‘A polycentric approach to global climate governance,’ Global Environmental Politics, 17(2), pp. 45-64.

Edman, J. (2016) ‘Reconciling the advantages and liabilities of foreignness: towards an identity-based framework,’ Journal of International Business Studies, 47(6), pp. 674-694.

Erhun, F., Kraft, T. and Wijnsma, S. (2020) ‘Sustainable triple: a supply chains,’ Production and Operations Management.

Escamilla, R., Fransoo, J.C. and Tang, C.S. (2020) ‘Improving agility, adaptability, alignment, accessibility, and affordability in Nano store supply chains,’ Production and Operations Management.

George, J.J., Yan, J. and Leidner, D.E. (2020) ‘Data philanthropy: corporate responsibility with strategic value?’, Information Systems Management, 37(3), pp. 186-197.

Gouda, S.K. and Saranga, H. (2018) ‘Sustainable supply chains for supply chain sustainability: impact of sustainability efforts on supply chain risk,’ International Journal of Production Research, 56(17), pp. 5820-5835.

Hammond, R. (2019) Friction/reward: be your customer’s first choice. Pearson UK.

Hourneaux Jr, F., Gabriel, M. and Gallardo-Vázquez, D. (2018) ‘Triple bottom line and sustainable performance measurement in industrial companies’, Revista de Gestão, 25(4), pp. 413- 429.

Ionescu-Somers, A.M. and Brassey, J. (2019) Unilever’s super-stretch goal for 2020. In Managing Sustainable Business (pp. 623-635). Springer, Dordrecht.

Janudin, J. et al. (2020) ‘The effect of return on equity to stock prices at Pt. Unilever Indonesia’, HUMANIS (Humanities, Management and Science Proceedings), 1(1), pp. 1-8.

Johnsen, L., Sadrieh, A. and Voigt, G. (2020) ‘Short‐term versus long‐term contracting: Empirical assessment of the ratchet effect in supply chain interaction,’ Production and Operations Management, 1(1), pp. 1-21.

Kalkanci, B. and Plambeck, E.L. (2020) ‘Reveal the supplier list? A trade-off in capacity vs. responsibility’, Manufacturing & Service Operations Management, 22(6), pp.1251-1267.

Kazi, A.G. et al. (2020) ‘The impact of product line extension on parent brand image: the case of Unilever Hyderabad, Pakistan,’ Journal of Public Value and Administrative Insight, 3(2), pp.11-19.

Krepysheva, A.M., Sergievskaya, A.A. and Storchevoy, M.A. (2020) ‘Definition and measurement of risk in compliance management, Strategic Decisions, and Risk Management, 11(2), pp. 150-159.

Unilever. Annual Report and Accounts 2020. Web.

Kubota, R., Horita, M. and Tasaki, T. (2020) ‘Integration of community-based waste bank programs with the municipal solid-waste-management policy in Makassar, Indonesia’, Journal of Material Cycles and Waste Management, pp.1-10.

Laursen, L.N. and Andersen, P.H. (2016) ‘Supplier involvement in NPD: a quasi-experiment at Unilever’, Industrial Marketing Management, 58, pp. 162-171.

Lawrence, J., Rasche, A., and Kenny, K. (2019) Sustainability as Opportunity: Unilever’s sustainable living plan. In Managing Sustainable Business (pp. 435-455). Springer, Dordrecht.

Lee, H.L. (2020) ‘Supply Chains with a Conscience,’ Production and Operations Management, 30(3), 815-820.

Llivisaca, J. et al. (2020) ‘Key performance indicators for the supply chain in small and medium-sized enterprises based on balance scorecard,’ Test Engineering and Management, 83, pp. 25933-25945.

Locatelli, B. et al. (2020) ‘Climate change policy networks: connecting adaptation and mitigation in multiplex networks in Peru,’ Climate Policy, 20(3), pp. 354-372.

Maheshwari, A. (2019) Digital transformation: building intelligent enterprises. John Wiley & Sons.

Meiryani, DLW, Deniswara, K. and Dewi, K. (2020) ‘Accounting information systems evaluation of medicines management, Systematic Reviews in Pharmacy, 11 (8), pp. 83-87.

Meiryani, Y. S., Isa, S. M. and Candra, V. L. (2020) ‘The effect of system user support on accounting information systems,’ Systematic Reviews in Pharmacy, 11(8), pp. 76-82.

Mirvis, P. and Googins, B. (2018) ‘Engaging employees as social innovators,’ California Management Review, 60(4), pp. 25-50.

Moya, C. A. et al. (2020) ‘Characterization of best practices for customer/supplier collaboration in co-innovation projects,’ Journal of Technology Management & Innovation, 15(4), pp. 5-18.

Pant, A. and Ramachandran, J. (2017) ‘Navigating identity duality in multinational subsidiaries: a paradox lens on identity claims at Hindustan Unilever 1959–2015’, Journal of International Business Studies, 48(6), pp. 664-692.

Prasad, L.M. (2020). Principles and practice of Management. Sultan Chand & Sons.

Sacks, G. et al. (2019) ‘BIA‐Obesity (Business Impact Assessment—Obesity and population‐level nutrition): a tool and process to assess food company policies and commitments related to obesity prevention and population nutrition at the national level,’ Obesity Reviews, 20, 78-89.

Samarasinghe, D. A. S., Baghaei, N. and Stemmet, L. (2020) Persuasive virtual reality: promoting earth buildings in New Zealand. In International Conference on Persuasive Technology (pp. 208-220). Springer, Cham.

Seyedghorban, Z. et al. (2020) ‘Supply chain digitalization: past, present, and future,’ Production Planning & Control, 31(2-3), pp.96-114.

Shawkat, T., Habib, S. and Khan, S. A. (2019) ‘Socially responsible identity: linking corporate social responsibility, strategic implementation, and quality performance,’ Pakistan Business Review, 20(3), pp. 612-625.

Uribe-Macías, M. E., Vargas-Moreno, Ó. A. and Merchán-Paredes, L. (2018) ‘Corporate social responsibility and sustainability, enabling criteria in projects management,’ Entramado, 14(1), pp. 52-63.

Usama, M. and Ramish, A. (2020) ‘Towards a sustainable reverse logistics framework/typologies based on Radio Frequency Identification (RFID),’ Operations and Supply Chain Management: An International Journal, 13(3), pp. 222-232.

Van Hoek, R. (2020) ‘Where we are heading and the research that can help us get there–executive perspectives on the anniversary of the Journal of purchasing and supply management, Journal of Purchasing and Supply Management, 26(3), p. 100621.

Venkatesh, V.G. et al. (2020) ‘System architecture for blockchain-based transparency of supply chain social sustainability, Robotics, and Computer-Integrated Manufacturing, 63, p. 101896.

Wati, V.D.E. (2020) ‘Application of good corporate governance in Pt.Unilever Indonesia. Dynasty, International Journal of Economics, Finance & Accounting, 1(3), pp.482-490.

Wilson, S.A., and Beck, M. (2020) ‘Why multinationals should consider geographic complexity first,’ MIT Sloan Management Review, 61(2), pp.1-6.

Zhang, Z. et al. (2019, May) Neural multimodal belief tracker with adaptive attention for dialogue systems. In The World Wide Web Conference (pp. 2401-2412).