Introduction

Background

Industry 4.0, which refers to the fourth industrial revolution and also known as 4ILR, is a digital transformation in the field of manufacturing, production, and processing that emphasizes the need for the use of artificial intelligence (AI) when making decisions and undertaking specific actions. Information has become a critical factor that defines the success or failure of a given business (Yuanita, 2019, p. 15). As such, firms are under pressure to find the best ways of processing large data within the shortest period possible and use it to make critical decisions.

Traditionally, humans would be expected to process the data using simple machines and then make relevant decisions. However, that is changing with the emergence of concepts of Big Data and Machine Learning (ML). It is becoming increasingly possible to rely on machines to collect and process data, and then use it to make critical decisions and predictions more accurately than a human would (Tirkolaee, Sadeghi, Mooseloo, Vandchali, & Aeini, 2021, p. 13). As such, AI has gained popularity in the field of supply chain management (SCM). In this study, the researcher focuses on the benefits, opportunities, and challenges of embracing ML technologies in logistics to help SMEs boost their performance.

Research Problem

Micro, Small & Medium Enterprises (MSMEs) play a critical role in emerging and developing economies in terms of the creation of employment and the growth of gross domestic products (GDP). However, they face unfair competition from large multinational corporations that have the financial power, experience, and the right connections to facilitate their growth and embrace emerging technologies. Adopting industry 4.0 has been a major challenge for these small and medium enterprises because of the financial implications and expertise needed. Despite the challenge, Singh, Wiktorsson, and Hauge (2021) explain that industry 4.0 offers a unique opportunity for these firms to redefine their operations and compete favorably with the more established rivals (p. 67). Embracing AI in SCM makes it possible to reduce expenses on human resources, improve efficiency in operations, and enhance the quality of products that they deliver.

Research Objectives

This study aims to establish a practical and clear of the benefits, opportunities, and challenges of adopting machine learning technologies in logistics to help SMEs boost their performance. To achieve this primary goal, the researcher will focus on realizing the following objectives:

- To identify ML techniques frequently used in logistics in SMEs;

- To identify the benefits of ML in Logistics in SMEs;

- To identify the opportunities of implementing ML techniques in logistics in SMEs;

- To identify the challenges of implementing ML techniques in logistics in SMEs;

- To identify the relationship between ML adoption in logistics and MSMEs performance.

Research Questions

Artificial intelligence is a field that has continued to attract the attention of many scholars over the years. It is essential to specifically define the specific issues that need to be investigated in a given study. In this research, the following are the specific questions that the researcher seeks to answer:

- What are ML techniques frequently used in logistics in SMEs and what are the benefits and opportunities of adopting them?

- What are the challenges of adopting ML techniques in logistics in SMEs?

- What is the relationship between ML adoption in logistics and MSMEs performance?

Overview of the Current State of Research and Methodology

Artificial intelligence and its relevance in supply chain management is a field of study that has attracted massive attention from scholars over the years. According to Singh et al. (2021), scholars have been keen to understand how AI can help MSMEs to acquire materials they need for production more efficiently and cost-effectively (p. 69). However, a preliminary review of existing studies shows that this is a relatively new field as AI continues to evolve. In this project, the researcher will rely on secondary data sources to help achieve the aim and objectives identified above.

Evolution of Artificial Intelligence

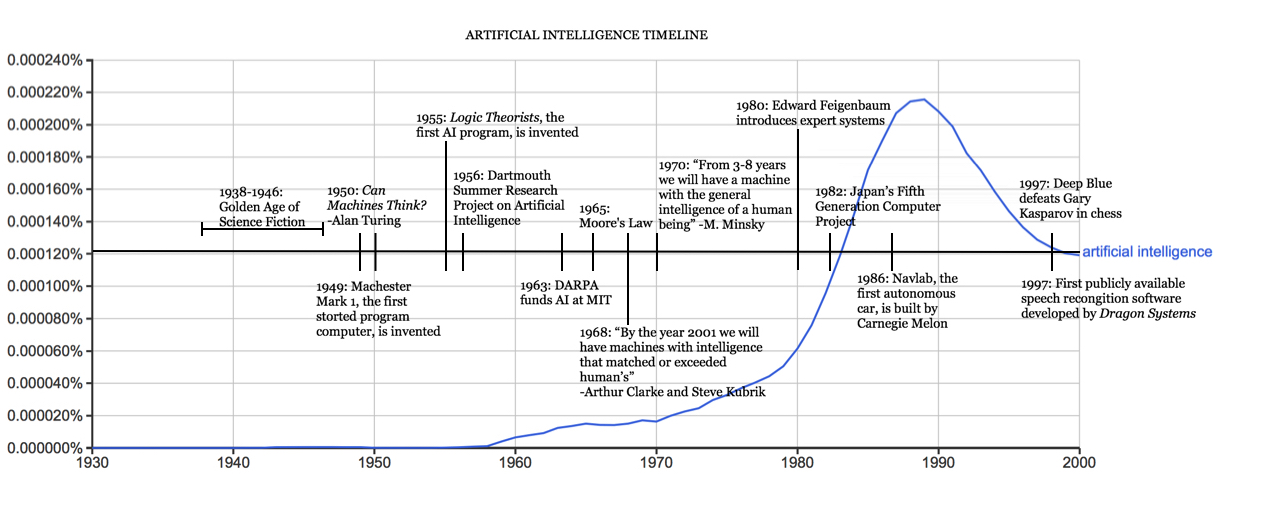

Artificial intelligence and machine learning have become increasingly relevant in the modern business environment. It is necessary to discuss the evolution of this technology and how it gained relevance in different fields (Rabayah, 2013, p. 8). The origin of AI can be traced back to Europe in the early 20th century, especially in the United Kingdom and Germany. Mathematicians, scientists, and philosophers have conceptualized the idea of having intelligent machines capable of solving human problems in the 1950s. Several scientists were able to develop a logical framework in 1950 referred to as Computing Machinery and Intelligence, which would later redefine the current use of AI in supply chain management (Pervaiz, 2020, p. 26). He explained how machines can be trained to be intelligent and ways in which their intelligence can be tested.

Stages of AI Growth

The pioneers in this industry faced numerous challenges that slowed the growth of this industry. One of the biggest challenges was the accessibility of the computers at this time. Sendler (2017) explains that leasing a computer in the 1early periods of its development was an expensive undertaking, which meant that only prestigious and financially empowered institutions could afford it (p. 87). He describes computers at that time as being primitive, only capable of executing commands but not storing them. Many institutions did not see the worth of investing in this technology, which means that these pioneers did not get the relevant support they needed to facilitate the growth of the industry. However, they were able to overcome these challenges and facilitated its gradual growth.

It became evident that the growth of AI needed experts to share ideas to help in improving its capabilities. The Dartmouth Summer Research Project on Artificial Intelligence (DSRPAI) of 1956, which was hosted by Marvin Minsky and John McCarthy was the first of its kind and catalyzed its growth. It brought together experts in AI and financiers from all over the world. The technology started developing as machines could not only execute but also store data and remember actions taken.

The Fifth Generation Computer Project (FGCP), which started in 1980 and lasted till 1990, saw major improvements in the technology as computer programs became enhanced. Personal computers had also become common, significantly reducing the cost of having computers (Matt, Modrák, & Zsifkovits, 2020, p. 310). By the late 1990s, machine learning had started gaining massive popularity around the world. The success of Deep Blue and Alpha Go in the gaming field demonstrated that AI had achieved a level of intelligence that matched or even surpassed that of humans. During the same period, the concept of big data also started gaining rapid popularity. Figure 2.1 below summarizes the evolution path of artificial intelligence.

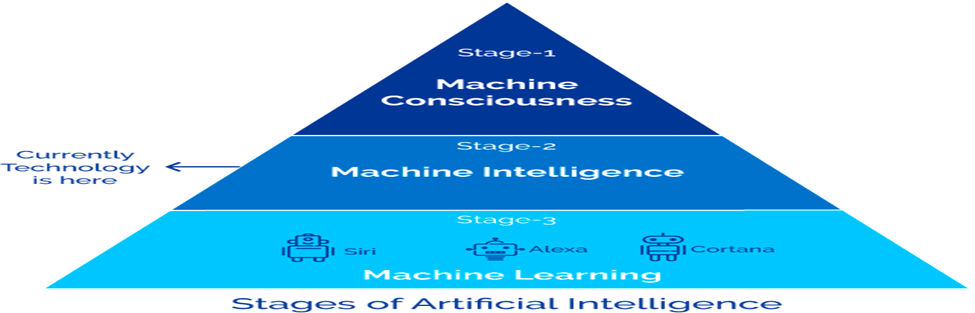

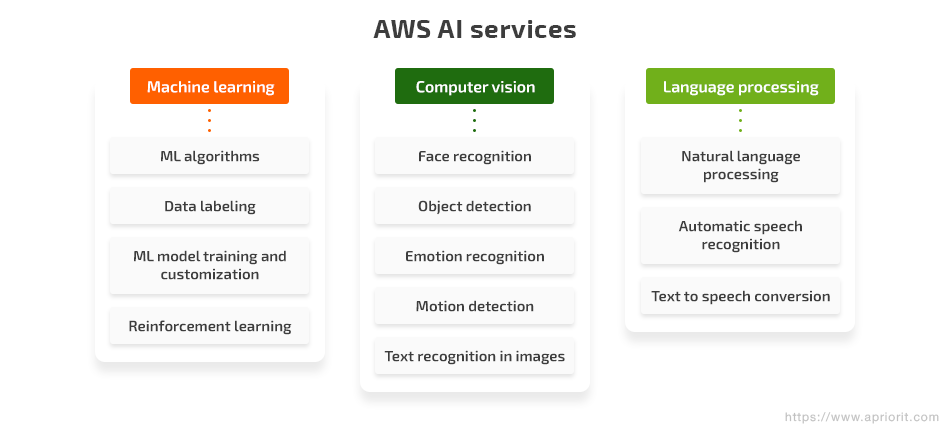

The growth of AI in the late 20th century and the 21st century can be summarized in three stages, as shown in figure 2.2 below. The first and critical stage was machine learning. Large technology companies such as Apple Inc., Microsoft, and Amazon.com created Siri, Cortana, and Alexa respectively. Small companies may not have such sophisticated tools but they have a role to play in the general development of the industry (Madanchian, Hussein, Noordin, & Taherdoost, 2015, p. 78). These were tools capable of communicating with humans and helping people to execute specific commands such as conducting online research and storing specific information, helping eliminate many challenges in the supply chain (Linh, Kumar, & Ruan, 2019, para. 117). These tools were also designed to become supper-collectors of data to help these firms to understand the emerging needs and expectations of customers. They were designed to learn based on information that they gathered independently.

The success of machine learning led to the second stage of machine intelligence. These machines were becoming increasingly independent as they could collect data and execute specific actions without any assistance from human beings. Earley (2014) explains that the current technology is at the level of machine intelligence (p. 59). Once the AI is trained on basic tasks, they can facilitate their further training as long as they can access accurate and reliable data. These machines are also capable of taking specific actions without any human input. The predictions and decisions that they make are sometimes superior to that of humans. This is so because they wholly rely on data instead of personal biases and cultural misconceptions, which enhances their competitiveness (Jovanovski, Seykova, Boshnyaku, & Fischer, 2019, p. 250). In the supply chain sector, this technology is proving to be crucial in supporting the decisions that a firm makes, based on data.

The next stage of AI, known as machine consciousness, is still futuristic. Currently, AI primarily bases its decisions on data, focusing on lowering costs while maximizing profitability (Devang, Chintan, Gunjan, & Krupa, 2019, p. 31). However, humanity goes beyond amassing wealth as these machines do. Compassion and the need to help those in distress make humans unique in their decision-making process. The fact that these machines lack consciousness may sometimes force managers to ignore the predictions, decisions, and simulations of AI. A firm may decide to invest in corporate social responsibility (CSR) to help the needy even if the plan developed by AI was different. The current progress in this field of technology is to facilitate the development of machine consciousness (Giudice, Scuotto, Garcia-Perez, & Petruzzelli, 2019, p. 310). AI should have human feelings and act in the interest of humanity.

Application of AI

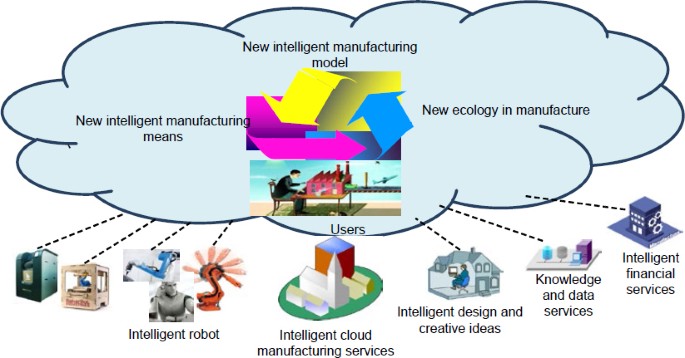

AI creators started spreading the application of AI from the gaming industry, where it had achieved massive success, to the business sector. It was evident that AI could help firms in making accurate decisions and predictions when it is fed with the right data (Chung, 2021, p. 55). One of the areas that it gained massive popularity was in the manufacturing sector. As market competition became stiff, firms were under pressure to find production strategies that would lower the cost while enhancing quality and productivity as a way of improving profitability. AI made it possible to develop simulations of the best manufacturing strategies. Robots also started taking active roles in the manufacturing plants as a way of lowering costs, reducing risks to humans at these plants, and increasing standardization and productivity. The success of AI in the manufacturing sector made business executives find ways of applying it in other sectors.

Marketing became another major area where AI technology gained popularity. Firms needed to accurately predict market demands, changing tastes and preferences, and ways of meeting clients’ needs in the best way possible. AI became a critical tool that facilitated predictions and decision-making based on data. Small and medium-sized enterprises are under immense pressure to find ways of improving their efficiency (Alfoqahaa, 2018, p. 12). AI offers them a perfect way of overcoming numerous operational challenges. It can monitor the money markets and help in making accurate investment decisions. It also became an essential financial planning tool for small, medium, and large corporations. Intelligent robots are also currently used in supply chain management, which is the primary focus of this paper. Other areas where AI is actively used include green manufacturing and other environmental-friendly initiatives. Figure 2.3 below identifies areas where AI has become a crucial tool that facilitates effective operations.

Technologies, Security, People/Workers and Society

The rapid growth of AI and its current application in various fields has been facilitated by the desire to achieve efficiency and lower costs. In AI, volume, velocity, and variety have been the primary factors that have enhanced growth. Data has become a critical factor that defines the ability of a firm to achieve success. However, firms find themselves in situations where they have to collect large amounts of data to help in the decision-making process. Irrespective of a firm’s size, it is essential to collect relevant data that can help inform decisions and predictions that a company makes. AI makes it possible to collect large amounts of data, process it based on its relevance, and use it to conduct simulations and predictions (Aarstad & Saidl, 2019, p. 39). The capacity of the AI to handle large volumes of data surpasses that of humans in a significant way.

The speed or velocity with which data is processed is another important factor that has made AI popular in the business world. When collecting data, it is common for one to have access to large amounts of information. Humans are limited in terms of the amount of data that they can process within a specific period. The problem with such limitations is that sometimes the information that is ignored is the most crucial for the firm’s growth (Kumar, 2019, para. 6). AI makes it possible to process such large amounts of data within a short period. It can speedily select the most relevant data, based on the issue that it has to address and then process the data to help solve the problem. Once processed, AI also makes it easy to share information with all the relevant stakeholders in real-time.

AI and ML enable a firm to have a variety of options when deciding on various issues. For instance, when a firm is interested in selecting an appropriate supplier, various factors such as price, quality, and reliability have to be considered. It is common to find a case where the decision is solely based on price or quality instead of the other equally important variables. Stakeholders may not feel comfortable when they are not aware of the decision-making process (Adixon, 2019, para. 9). AI takes into consideration all the other important factors through simulation. It then provides various alternatives, in terms of priority, that the firm can consider. It evaluates both pros and cons in the simulation before classifying the possible actions that a firm can take to achieve the intended goal.

This technology is also meant to make the work of people, especially employees, easier than it was in the past. Some of the physically and mentally demanding tasks can now be done using machines. Robots have become effective in handling physically demanding tasks. On the other hand, sophisticated computers can now handle complex data processing and help in making accurate decisions. According to Amblee (2018), AI is emerging as a tool that will help protect modern society from natural forces such as global warming and climate change (para. 11). Fed with the right data, they can facilitate smart manufacturing and transportation in ways that have negligible impact on the environment. It can be possible to reverse some of the damages that have been made to the environment. Scientists believe that AI is set to make society a better place.

Artificial Intelligence in Supply Chain Management

Artificial intelligence has become a critical tool in supply chain management. According to Anyoha (2017), news about having driverless trucks was welcome news to many trucking companies in the United States (para. 7). Although the idea is yet to be actualized, its development is in advanced stages and there is a consensus that most cars on the road will not need drivers. For major trucking companies around the world, such a technology will have an immense impact in cutting the cost of hiring numerous drivers, paying their medical allowance, and having to deal with workers’ unions. AI goes beyond the promised creation of driverless trucks (Kersten, Blecker, & Ringle, 2019, p. 18). Numerous benefits are already available for firms that have chosen to use the new technology. It is necessary to discuss how AI and ML have gained relevance in SCM and how they are applied to help cut operational costs, improve efficiency, and enhance profitability.

Data and Optimization across the Value Chain

The concept of data optimization has gained massive relevance in the recent past as firms embrace big data. Data optimization refers to a process that uses sophisticated data management tools to have access to, organize, and process data from various sources at high speeds and in a comprehensive manner (Wright & Recht, p. 45). The processed data is then used to make critical decisions within an organization. The primary goal of data optimization is to facilitate a performance that is capable of meeting customers’ expectations (Dash, McMurtrey, Rebman, & Kar, 2019, p. 43). It makes it possible to provide real-time service to clients by understanding their emerging needs.

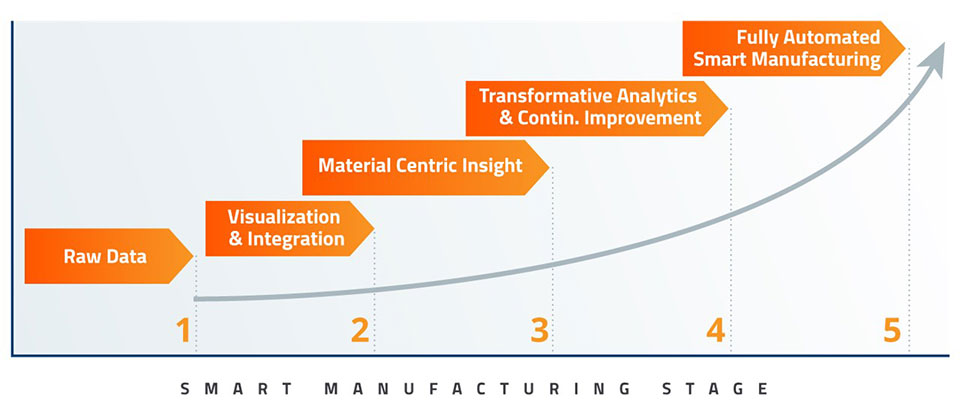

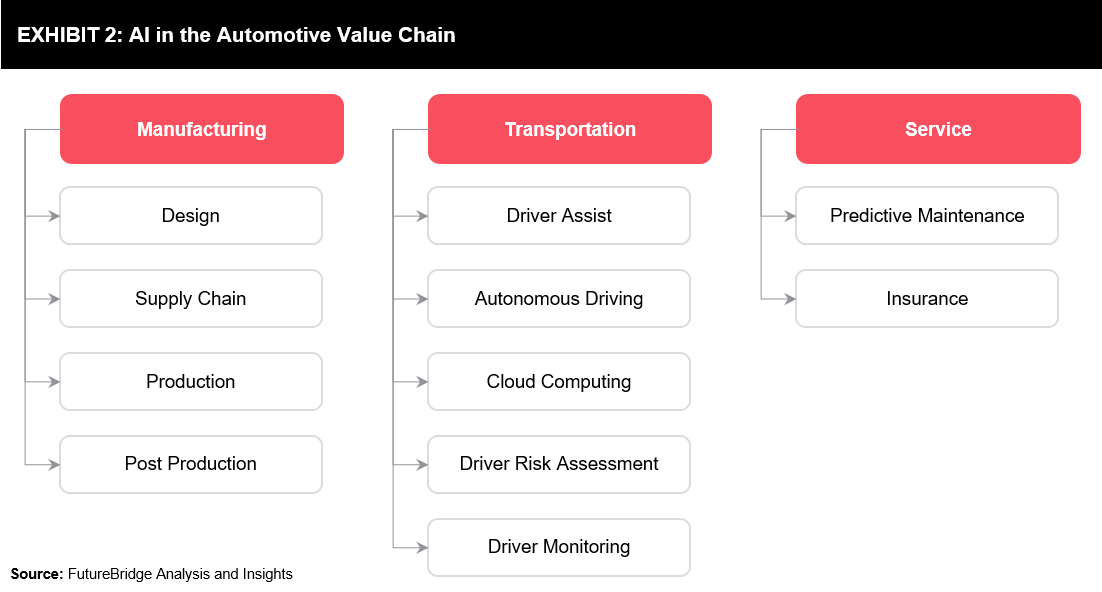

In supply chain management, data optimization has become essential in ensuring that smart manufacturing is achieved irrespective of the size of a firm. Didonet and Díaz (2012, p. 101) observe that successful companies have come to appreciate the significance of big data and its application in making predictions and decisions. Smart manufacturing requires effective communication and coordination in the entire supply chain, from the stage of raw material acquisition to the stage when the product is delivered to clients. As shown in figure 3.1 below, there are five stages that are involved in smart manufacturing when AI and ML are applied. The initial stage involves collection of raw data. At this stage, the focus is to gather relevant information about different suppliers to understand those that offer superior value.

The second stage is the visualization and integration of data. A firm starts to develop a database that can help it in making critical decisions. The third stage of material-centric insight involves the systematic use of the collected data to assess the suppliers’ worth to the firm (Belhadi, Mani, Kamble, Khan, & Verma, 2021, p. 4). Continued reliance on data facilitates transformative analytics and continuous improvement. At this stage, a firm will be moving from traditional approaches of manufacturing to one that integrates the use of machines in making predictions and decisions. Once the data is available, a firm can trust computers to process it and use it to accurately address specific challenges that affect the operations of a company. When these four stages are completed successfully, the company can move to the final stage of having fully automated smart manufacturing. At this stage, computers will be responsible for providing simulations about the best ways of operation that can yield the best output for the company.

AI and ML have made it possible for firms to achieve fully automated smart manufacturing. Traditionally, firms had to make manufacturing decisions based on human predictions (Toorajipour, Sohrabpour, Nazarpour, Oghazi, Fischl, 2021, p. 506). The problem with such predictions was that in most of the cases it was based on outdated data and personal biases that led to consistent inaccuracies. It was always impossible to produce the exact number of products needed by clients. The products were either in excess or less than what the market needed. Smart manufacturing helps in eliminating such challenges. Real-time data makes it possible for a firm to understand the current demand in the market.

The information will then be used to facilitate the delivery of the exact amount of raw materials needed, which will then be fully utilized to develop products. The produce will then be delivered to the market within the right time. Smart manufacturing helps in eliminating wastes caused by overproduction and delays that result from underproduction. It also helps in ensuring that the right quality of products is made available to customers at the right time. AI and ML make it possible for smart manufacturing to be realized in an organization.

ML Techniques Frequently Used in Logistics in MSMEs

Machine learning has achieved popularity in various business settings because of its unique capabilities. For small and medium enterprises, this technology offers a wide range of services that can be used to enhance activities in the logistics sector. Figure 3.2 below identifies specific ML techniques that can be used in logistics. Face recognition has become a powerful tool that firms use to facilitate the identification of persons. In the logistics sector, one of the challenges that SMEs face is cases where unauthorized individuals have access to goods on transit for the primary purpose of stealing (Chin, Hamid, Rasli, & Baharun, 2012, p. 615). ML has introduced a new technology that is meant to enhance the security of products while they are in transit. Face recognition is a technology that requires drivers and authorized individuals to show their faces before special in-built cameras on the trucks before one can access the cargo section. It means that unauthorized individuals cannot have access to the cargo section of these trucks. When one tries to make a forced entry without using face-recognition technology, information is sent directly to the security agencies.

The technology can also be used to ensure that drivers do not allow unauthorized passengers into the cabin because they can also be a security threat to the employee and goods on. The tool is also widely used in enhancing security at warehouses transit (Singh, Kumar, & Shankar, 2012, p. 174). Only those whose faces the machine can recognize are allowed into the warehouse. The technology not only helps in eliminating the possibility of unauthorized persons having access to goods and raw materials but also makes it possible to identify employees who are stealing from the firm. The technology records time an employee entered the warehouse or the cargo section of the truck, the time they took before leaving, and what they carried when leaving. The chances of stealing from a firm are significantly reduced in such instances, which means that the cost of operation will be dropped significantly.

Object detection is another ML technique that is gaining relevance in logistics. Using special sensors, the machine can detect when an object is approaching and take necessary action. The technology is currently used to automate various activities in warehouses (Lawson, 2021, para. 7). A common application is controlling the security lights. Instead of security lights being on at all the sections of the warehouse, the sensor can be trained to detect when people are in the store and it will automatically switch on the lights. When people are not within the warehouse, the sensor automatically switches off the lights. The technology helps in saving the cost of energy. Object detectors can also be used to enhance security.

When an object, which in most cases is a human, is detected moving into a warehouse, information will be relayed to the security unit immediately. If the object is considered suspicious, immediate action can be taken to inspect it and determine if indeed it is a security threat. Smart driving technology is making it possible for trucks to identify objects on their paths. The technology, although not fully developed, makes it possible for a vehicle to make emergency breaks when it is about to hit an object on its path. Such technologies will significantly increase safer working conditions (Jacobs, 2020, para. 13). It will significantly reduce losses of lives, trucks, and goods on transit caused by these accidents. The insurance premium that MSMEs have to pay on such smart trucks and goods on transit will be significantly low. Object detection technology is directly related to motion detection, both of which work together to enhance the capability of ML.

Advanced ML technology is currently capable of emotion recognition. When a driver, a captain, a pilot, or warehouse employees are in their place of work, AI is capable of detecting their emotions. The ML can recognize when one laughs a lot or specific words that they use in their conversation to express their emotions. Advanced AI has become critical in making important supply chain management decisions (Stinson, 2021, para. 3). They can tell when one is distressed or frustrated while they are on their official duties. Mental stress compromises the ability of one to reason.

Emotion recognition technology is meant to eliminate such cases by identifying employees who are emotionally distressed while at work. When they are captains, drivers, or pilots, measures can be taken to ensure that they are not allowed to be fully in control of the transport vessel. If possible, such an individual should be temporarily relieved of their duties to get the relevant assistance before they can resume work. When it is not possible or the threat is assessed to be negligible, they can be allowed to work alongside a colleague who can help them navigate the vessel and to talk about the issue of concern.

ML has made it possible to convert text to speech in a conversation. Texting while driving is a major cause of road accident in the United States. It is significantly more dangerous than making a call because one has to take their eyes off the road to write a text (Pournader, Ghaderi, Hassanzadegan, & Fahimnia, 2021, p. 2). Such an action makes it easy for a driver to lose focus on the road. ML has introduced a technology where a text can be converted easily into a sound and vice versa. It means that a driver can communicate with others easily without having to constantly take their eyes off the road. Their speech can then be converted to a text in case the person on the other end of the phone prefers chatting. Another benefit of this technology is that a driver, a captain, or a pilot can make their reports easily without having to type them. At every stage, they can verbally report what has taken place at a specific time. Their verbal report is then transformed into texts, which can then be documented for further references. It eliminates the need to develop a written report, which saves them time.

Automatic speech recognition is another aspect of ML that is proving to be crucial in the logistics sector. Like face recognition technology, speech recognition is also gaining relevance as a tool that can be used to identify employees within a firm (Hellingrath & Lechtenberg, 2019, p. 67). The AI has developed a unique capacity that enables it to identify a unique sound of an individual, just like a fingerprint. Unlike a signature that can be forged, one cannot defeat a well-trained machine by faking another person’s voice. It is also not possible to steal the voice as one would steal a password.

One would need to say their name or utter a specific statement when they want to have access to the warehouse or a transport vessel. The voice recognition tool will then determine if they are authorized to have access to the store or the vessel. If they have the permission, the tool will state their identity, time of entry, and activities conducted. If they lack the authority to do so, the machine will make a report of an attempted breach of security (Isensee, Teuteberg, Griese, & Topi, 2020, p. 2). Relevant authorities can then investigate the issue immediately. This technology is meant to eliminate or significantly reduce cases of theft of goods on transit or those that are already in the warehouse.

Artificial Intelligence Opportunities and Benefits for MSMEs in the Logistics Sector

The concepts of AI and ML are rapidly gaining relevance and acceptance in the field of business. According to Belhadi et al. (2021, p. 10), it has become evident that AI has a unique capacity that is beyond that of humans when it comes to making accurate data-based predictions. The machine can process Big Data within a relatively short period, and then use it to address a specific problem that is affecting a given business entity. Kersten et al. (2019) state that AI has immense opportunities and benefits for micro, small, and medium business entities (p. 49). They only need to understand how to correctly apply it in specific operations of their businesses. It is necessary to discuss the specific opportunities and benefits that AI presents to these firms.

AI Opportunities for MSMEs in the Logistics Sector in Logistics Sector

MSMEs face some unique challenges, which make it necessary for them to find ways of competing favorably against some of the larger competitors. For a firm to succeed in the integration of AI into its operations, it should understand the opportunities that the new technology presents and how it can fully take advantage of them. The following are some of the specific opportunities that using this technology presents to a firm.

New strategies of reaching out to new suppliers. One of the unique opportunities that AI presents to MSMEs in the SCM is the ability to identify, select, and reach out to new suppliers. According to Singh et al. (2012), one of the most important factors that a firm has to consider is effective ways of identifying suppliers and communicating with them effectively (p. 171). Changes in the market make it necessary for a firm to regularly evaluate suppliers that can offer the best deals in the market. Using AI, a small or medium company can process large volumes of data within a short period and select suppliers than offering the best deals in the market. It can easily conduct a comparative analysis to determine how it can get the best value for every purchase that it makes.

Improved processing of clients’ orders. According to Klumpp and Ruiner (2018), large organizations handle numerous transactions every one hour as they struggles to serve its customers in the most efficient way possible (p. 7). Such a large volume of a transaction within that short period cannot be possible if technology is not applied. Small and medium enterprises must understand the significance of AI in making such large volumes of transactions possible. Using AI, the logistics department can easily interact with the sales department, process clients’ orders, and facilitate their delivery within a short time.

The technology creates a unique opportunity for expansion for these small companies. Instead of hiring more employees to process customers’ orders, the task is delegated to the machines. It means that the firm will have an increased capacity in terms of processing clients’ orders, without necessarily increasing the size of its workforce. Belhadi et al. (2021, p. 20) also reiterate that customers can track their orders once they make their payments. Instead of constantly calling the firm to make such inquiries, they can easily use their mobile phone apps or personal computers to know when their products will arrive. Such services tend to increase customer satisfaction, which creates further opportunities for growth.

Better ways of exploring new markets. One of the primary goals of every MSME is to achieve consistent and sustainable growth in a highly competitive business environment. However, expanding to new markets beyond the primary or understanding future market trends one often presents numerous challenges, one of which is how to manage the supply chain in the new market (Pournader et al., 2021, p. 16). AI can help address such a problem when correct data is collected and processed. AI can provide various simulations about possible logistics strategies that can be used in the new market. The machine will collect and analyze data about the new market, and then propose ways in which the firm can address specific challenges in the market. If a firm in the United Kingdom or the United States seeks to start operations in China or India, it has to understand socio-cultural, economic, and political forces in the new country, and how they influence a firm’s supply chain. Using AI, a firm can easily assess these forces and determine how they can be managed to ensure that operations of the firm are not negatively affected.

Ability to conduct detailed market research. At the initial stages of AI development, there was a general belief that one had to educate the machine by continuously feeding it the right data. However, that has changed as technology keeps advancing. AI has gained the capacity to self-educate (Toorajipour et al., 2021, p. 511). It can easily gather data from the public domain, learn from it, and make critical decisions and predictions without any significant human input. This new characteristic of AI makes it an effective tool for conducting market research. In SCM, one only needs to specify the nature of the research that should be conducted. The machine is capable of gathering information available in online databases and answering specific questions of concern to the firm. It can go a step further to inform the management of the best path to take based on several simulations conducted. In such an environment, the company will always base its decisions on actual data instead of personal feelings and rumors.

Identifying and eliminating wastage and theft. One of the major challenges that small and medium enterprises face is pilferage when goods are in transit. Some unscrupulous employees believe that the best time of stealing from their employer is when delivering materials to the firm or when delivering finished products to customers. The firm losses a lot of resources when such cases of theft are rampant. Using AI, the firm will have clear data of materials purchased. The machine can autonomously check if what was delivered to the firm is consistent with what was purchased (Belhadi et al., 2021, p. 2). It can also accurately determine if products leaving the firm are those fully paid for by the client. The strategy significantly reduces and in some cases completely seals loopholes that employees may be using to steal from the firm.

The technology can also help in eliminating wastes within the firm. According to Aarstad and Saidl (2019), automates the filing system, which improves efficacy and eliminates wastage. One of the main causes of waste generation within a firm is offering excess raw materials that cannot be consumed within a specified period. When supplies are in excess, a significant amount will be wasted within the firm. It also encourages theft, and the management may not even realize that workers are stealing from the firm. There is also the additional cost of warehousing. Using AI, the firm will be ordering only what is needed and consumable within a specific period. It will not only reduce the cost of warehousing but also the wastage and possible theft among employees. The management can use the savings made in facilitating the expansion of the firm to new markets.

AI Benefits for MSMEs in the Logistics Sector of MSMEs

AI remains to be relatively new technology, and many business entities are yet to fully integrate it into their operations. Toorajipour et al. (2021) believe that most executives are not yet fully aware of the benefits that they may get from it (513). They still look at AI as a technology that is limited to data processing and making predictions when directly assisted by humans. However, recent developments in this field have empowered this technology, and its capacity to make accurate predictions and effective data-based decisions are unmatched. Small and medium enterprises can benefit significantly from this technology if they apply it correctly in supply chain management. The following are the direct benefits of AI to MSMEs’ SCM.

Eliminating the need for large warehousing units. One of the obvious benefits of AI to small and medium enterprises is that it eliminates the need for large warehousing units at a firm. MSMEs cannot afford to have large warehouses to store raw materials or finished products. As such, most of them have been relying on a just-in-time (JIT) system of inventory management to ensure that the needed materials are made available only when they are needed (Kersten et al., 2019, p. 65). AI improves this system by providing relevant data. It can make an accurate prediction about the flow of materials on the production floor, making it possible to know the specific time that the procurement department needs to purchase the relevant materials.

AI has also become a powerful tool in making sales forecast in the market. This capability makes it possible for it to have accurate data about the entire flow of inventory, from purchasing raw materials from suppliers, moving them to the plant, processing them, and finally releasing finished products to the market. Having an accurate demand forecast means that the firm will only produce what the market can consume within a given period. As such, there will be a reduced need to store finished products in the warehouses.

Optimization and automation enhance productivity. Supply chain management is one of the critical functions that define the success of a firm. MSMEs must ensure that they source the relevant materials in time to avoid cases where production is stopped. Similarly, finished materials have to be made available in the market at the right time and volume. Traditionally, decisions and predictions would be made by humans (Toorajipour et al., 2021, p. 506). The problem that firms often face is that human error is common when there the machine does not support the process. Human bias and limitations mean that they cannot always be accurate as would be desired.

AI optimizes SCM activities through automation, which enhances productivity. Although humans are still expected to be actively involved in the process, the automation process makes work easy. The production department can easily monitor the flow of products based on sales made within a given period. As such, they can determine the volume of products they need to make available within a certain period. The same information will be immediately available to the procurement department, which will be able to predict when to make raw materials available to the production unit. At the same time, the finance department will be informed about the needed resources in each of these departments to facilitate smooth and effective operations.

Real-time data facilitates real-time supply chain management. One of the benefits of using AI is that it makes it possible for a firm to have real-time data. Through machine learning, it is possible to train AI to collect real-time data about market demands and the availability of specific materials needed for the production process. Pournader et al. (2021) explain that one challenge that MSMEs face is that sometimes they use obsolete data to make decisions (p. 41). As such, they make errors because the information upon which they base their decision is not accurate.

AI can be trained to constantly collect data in the market. It will provide updated information, enabling the management to accurate predictions. With real-time data, the management can make real-time supply chain decisions. Christiansen and Skrinjaric (2021) warn that when using AI to collect data from the public domain, care should be taken to identify and avoid misleading or biased data (p. 39). It is also essential for the user to ensure that third parties are not allowed control of the AI because they can manipulate it in a way that may provide misleading information.

High business continuity is enhanced by advanced monitoring and maintenance possibilities. A significant number of firms in the United States fail to reach the third year of operations. One of the primary factors that lead to the failure of these start-ups is the inability of the manager to effectively monitor and control various operational activities. At this initial stage, the proprietor is often forced to hold several managerial positions because of the few numbers of workers. It is easy for the manager to fail to maintain effective monitoring and evaluation of employees’ work. AI makes it possible for the proprietor to monitor the performance of employees. AI also enhances the capacity to monitor inventory and how it is used within the firm (Belhadi et al., 2021, p. 9). The enhanced monitoring and maintenance that is facilitated by this technology minimizes wastage, cuts costs of operation, and enhances efficiency in supply chain management, which in turn, enhances business continuity.

Improved and sustainable working conditions. Procurement and logistics can be challenging, especially when for a firm in the manufacturing sector. In small and medium enterprises, these tasks are often assigned to a few employees because of limited resources within the firm. Having to collect data, process it, and use the information to make critical decisions and actions can be demanding. AI helps in creating sustainable working conditions for these MSMEs by simplifying most of the procurement tasks. The machine can collect and process data, then use the information to make accurate procurement decisions. Employees can then focus on other tasks that cannot be conducted by the machine (Toorajipour et al., 2021, p. 510). The reduced workload makes it possible for employees to focus on innovative ideas in their workplace.

Employees’ safety is one of the main challenges that MSMEs face in their supply chain management. Some of the activities that workers engage in expose them to dangers. The occupational health and safety of employees are some of the major requirements that the government has set for firms irrespective of their size. When a worker sustains an injury while they are in their official duty, it is the employer will be held fully liable. The introduction of intelligent robots reduces cases of such accidents happening. They are less likely to make mistakes that may cause an accident in the warehouse (Klumpp & Ruiner, 2018, p. 5). It means that the firm is less likely to face litigations related to accidents in the workplace environment.

Customization and personalization for clients. Amazon.com and other large corporations have learned the importance of collecting information from clients and then customizing and personalizing products to meet their specific needs. Alexa has become a powerful tool that Amazon.com uses to collect information from its clients to understand their preferences. Small and medium enterprises can use similar technologies to understand the specific needs of their clients. Some individuals prefer having their products delivered at their offices while others want the product delivered at home or in social settings at specific times. Understanding these specific customers’ needs and finding ways of meeting them can help a firm to create a pool of loyal customers (Belhadi et al., 2021, p. 9). Having such a database, the logistics unit will have clear information about the best time and place of delivering customers’ orders. The ability to maintain constant communication with these clients also helps in ensuring that cases of lost products are eliminated.

Enhanced creativity and innovation. In the current competitive business environment, firms are under immense pressure to find ways of meeting the needs of customers in ways superior to those of competitors. They also need to introduce better ways of operations that can cut the cost of operations to help improve profitability without necessarily increasing the product price. It means that they have to constantly find unique ways of operation. Creativity and innovativeness can only be enhanced when workers have some free time at work to test and actualize new ideas. It also thrives in an environment where there is a steady flow of relevant and updated data (Kersten et al., 2019, p. 75). AI can be trained to undertake most of the tasks in the logistics department.

While large computers are used to collect and process data and use the information to make complex predictions, simulations, and predictions, robots can be used to handle physical tasks in warehouses. It means that enough time will be available for employees to think creatively and test their ideas to enhance their productivity (Klumpp & Ruiner, 2018, p. 6). The processed information made available by the AI also makes them understand emerging needs in the market, making it possible for them to develop relevant concepts that the firm needs to prosper.

Reduced human error. One of the biggest promises of AI and ML is the elimination of human errors. Ceyhun (2020) notes that even when people are presented with accurate data, they are likely to be influenced by personal biases and stereotypes when making decisions (p. 76). However, machines tend to be highly objectives when presented with accurate data. When properly trained, AI makes very accurate forecasts and decisions that can help a small or medium enterprise to achieve rapid growth. Cases of human error are sometimes caused by the inability to collect and process data accurately. This challenge is effectively addressed by AI technology (Christiansen & Skrinjaric, 2021, p. 121). In supply chain management, employees can use AI to select the best suppliers in terms of the quality they offer and pricing. Accurate simulations can also be conducted to determine how to move products from the supplier, store them within the firm, and then deliver them to the market. Elimination or a significant reduction of human error lowers the cost of operations while at the same time increasing productivity and efficiency.

Reduced number of employees needed. Small and medium enterprises cannot afford to have a high number of employees. However, they still have to compete against large multinational corporations that employ thousands of employees. There is a need for these firms to find ways of working effectively with their limited number of workers. AI makes it possible for these small firms to operate successfully with a handful of employees. Robots can now undertake most of the physical jobs that were previously conducted by humans in the procurement sector (Toorajipour et al., 2021, p. 505). On the other hand, complex computers can be used to collect and process data. Doing so makes it possible for a firm to function efficiently without the need to have a large number of workers. The fact that machines can operate for more than 24 hours without the need for a break, as is always the case with humans, means that a great amount of work can be completed within a relatively short period.

Enhanced consistency and reliability. MSMEs need to be consistent and reliable when meeting the needs of their customers. When clients approve of a specific quality of products, it is essential to ensure that it is maintained until such a time when it can be improved based on changing tastes and preferences. AI makes it possible for a firm to maintain consistency in many ways. First, it will ensure that information about the best suppliers in the market is maintained. Products can only be of the right quality if the standards are met when sourcing for raw materials. Secondly, AI can be used to ensure that delivery methods are standardized (Hellingrath & Lechtenberg, 2019, 91). It can also facilitate close coordination among all the departments within the firm to ensure that clients’ expectations are always met.

Training and collaboration. AI and ML create an environment where it is easy for a small or medium enterprise to conduct training and enhance collaboration among employees. AI creates a system where a firm can easily assess the knowledge gap of its employees and job market requirements. It means that targeted training, which focuses on addressing the identified gaps, is possible (Dash et al., 2019, p. 49). AI significantly enhances data sharing within departments of a firm and in the entire organization. Sharing of data also encourages collaboration among workers. They can identify a specific problem and then work closely to find an effective solution. Targeted training and collaboration among workers enhance the efficiency of a firm and its ability to achieve sustainable growth.

Environmental protection. Global warming and climate change have become major concerns in the 21st century. Many governments and scientists are struggling to find ways of reducing the emission of greenhouse gases and eliminating harmful industrial effluents. In the United States and many other countries around the world, strict policies have been introduced to ensure that companies do not pollute the environment. Some of these countries have introduced limits of carbon emissions that every firm cannot go beyond within a specific period. AI promises to help firms to operate optimally without going beyond these limits (Pournader et al., 2021, p. 13). The use of robots that can use green energy instead of heavy machines that use diesel is one of the best ways of protecting the environment. AI can also be used to develop simulations of how a firm can operate optimally with the least possible production of industrial effluent and greenhouse gases. The same technology can also help in developing effective ways of managing wastes. Figure 4.1 below summarizes the main benefits of Industry 4.0 to small and medium enterprises.

Artificial Intelligence Challenges for SMEs in the Logistics Sector

When embracing AI, micro, small, and medium enterprises must understand that there are some challenges that they have to manage. The previous chapter has outlined benefits and opportunities, which make this tool an effective one in enhancing supply chain management among these entities. Holistic analysis also focuses on challenges that exist, and how they can be managed to ensure that these firms can use them effectively. The following are the primary challenges that these firms have to put into consideration.

Cyber-Security Issues

One of the major issues when using AI to facilitate operations in the logistics sector is cyber-security threats. A major cyber-security threat is system manipulation. It is a situation where the system is deliberately fed with misleading and malicious inputs. The intention is to expose the machine to a picture that does not reflect real-world forces. According to Toorajipour et al. (2021), AI and ML rely on data to learn about what it is expected to do (504). It takes time for the machine to learn about what it is expected to do. The process involves feeding it the correct data so that it can make correct decisions and predictions based on the information gathered. Cyber-criminals can manipulate the system by exposing it to wrong information.

The outcome is that the decisions and predictions that the AI makes will be based on wrong information. Instead of helping the logistics department in making the right decisions, it will misguide the whole process based on the data it was fed. Data corruption, also known as data poisoning, has become a major problem in AI, especially when an attacker has a specific malicious goal to achieve, and easy access to the AI data system (Belhadi et al., 2021, p. 8). A competitor can easily attack a firm will poisoned data to mislead them into taking actions that do not reflect realities in the market. MSMEs are at a greater risk of being attacked because of their limited financial power to establish strong data security measures.

AI machines are trained to sometimes gather data independently from the public domain. As Dash et al. (2019, p. 49) observe, they do not necessarily need to rely on their users to feed them with the data they need to make decisions and predictions. The problem is that it exposes them to misleading information on online platforms. A significant amount of information available online is biased, misleading, and sometimes meant to achieve the selfish goals of some individuals or entities. When AI has access to such data and fails to realize that it is untrue, it may base its decisions on the information gathered. In such a case, the machine will end up serving the interest of external parties, which may be the competitor, instead of the user. Kersten et al. (2019) also warn against the possibility of adversaries retraining the AI to meet their selfish goals (p. 82). In such a case, the AI is gradually fed inputs that shifts their focus from their primary purpose. Eventually, they become irrelevant tools that cannot perform specific tasks assigned to them.

Data privacy is emerging as a major concern when using artificial intelligence and machine learning technologies. AI relies on large volumes of data to function appropriately. The data has to be stored in a database to ensure that the machine can have access to it whenever it is necessary. The problem that arises is that external parties may target the database and extract information. In such a case, the cybercriminal will easily predict all the decisions that the machine is likely to make in specific scenarios. In such a case, the AI will be a major weakness to the firm instead of being a strength because its predictions will be obvious to the rivals. Some private data about suppliers or transporters may be released to the public domain in such attacks (Klumpp & Ruiner, 2018, p. 12). The outcome will be a lack of trust with important partners in the market.

It is crucial to find an effective way of addressing these challenges. Toorajipour et al. (2021) advise that when a small or medium-sized enterprise decides to use AI in its logistics department, one of the factors that have to be considered is the protection of data from cybercriminals (p. 515). AI and ML highly rely on data that they have access to when making crucial decisions and predictions. A firm must understand that rivals can easily target the machine and manipulate it to their benefit. As such, it is essential to protect the system from any form of attack. If it is necessary to allow the AI system to have access to information in the public domain, some measures may need to be taken to protect it from malicious data. The system can be protected by directing it to specific websites while limiting its access to others that are not credible.

A firm must ensure that it is always in control of the AI system. Measures should be taken, using the latest data protection software, to ensure that any breach is detected as soon as it occurs, and appropriate measures taken to address the identified problem. Christiansen and Skrinjaric (2021) recommend the use of resilient cyber security solutions that can provide end-to-end data encryption and protection, such as Hardware Security Module (p. 144). They significantly reduce the threat of external parties having access to the AI system, including its database.

Computing Power

Artificial intelligence and machine learning are rapidly gaining popularity in many parts of the world. However, Kersten et al. (2019) admit that AI and ML are relatively new concepts (p. 39). Although many people in the business sector have heard about them, their applications remain a mystery to many people. The main problem is that implementing AI in a firm requires intensive training and a significant investment in Big Data and related technologies. A firm must be willing to spend time and financial resources to take their employees through rigorous training on how to feed data to the system and train it to make critical decisions and predictions. They should also learn how to work alongside the machines without having any conflicts and making important decisions.

Large multinational corporations have the financial capacity to embrace AI with ease. They can spend money on research to understand how to use the new technologies in its logistics sector. However, the same cannot be said about micro, small, and medium enterprises. These small firms are struggling to meet various financial needs in their operations (Hellingrath & Lechtenberg, 2019, p. 49). They may not afford the high initial cost of installing the system. They may also lack the capacity to equip their employees with the computing skills needed to operate the system. The option that they may have is to hire individuals who already have the needed skills. The challenge that they are likely to face is that some employees may demand higher salaries because of their unique skills.

The MSMEs must find ways of overcoming this challenge because ignoring AI and ML is not an option. One of the best ways of addressing this challenge is to have a gradual process of embracing the new technology. It can select a few loyal and techno-savvy employees to learn more about AI and ML, and how they can be applied in a normal operation of a business (Dash et al., 2019, p. 48). Instead of making a heavy initial investment into the system at a time when the firm is financially strained, it can make small steps towards understanding and embracing the system. One of the best ways of achieving the intended goal is to embrace best practices in the industry. Instead of spending a lot of time and resources trying to define how to use this new technology, these small firms can use models that have already been developed by large corporations. Poaching talented employees with skills in AI and ML may be another way through which they can enhance their computing power.

Trust Deficit

Trust is a major concern among business executives who are interested in embracing this new technology. AI and its capabilities are relatively new, and some still believe that they cannot fully trust it to make decisions (Toorajipour et al., 2021, p. 511). A section of business executives considers AI to be too complex to be applied successfully in the business sector. Its success in the security and health sectors has not convinced these stakeholders. Some of them argue that they do not understand how employees can easily and successfully interact with AI and its levels of automation without causing conflicts. As such, those who are expected to lead and facilitate automation have expressed their lack of trust towards the new system. The resistance has had a major challenge in the implementation of AI in the supply chain sector, especially among MSMEs. When the management and employees feel that they cannot trust the system to perform its functions effectively, they are less likely to support its implementation.

The current problem of lack of trust among some stakeholders should be addressed to ensure that AI and ML are embraced as tools that can enhance operations in the logistics sector. Kurt Lewin’s change model can be used to help address this problem. This model identifies three stages of introducing change within an organization. The first stage, known as unfreezing, involves preparing the entire team for the change. They need to understand the weaknesses of the current system, and how the proposed change will help solve the problems. It also involves undertaking the necessary training so that the team can understand what is expected of them. The next step is to undertake the actual change. The team is expected to use the already established plan to introduce the relevant change. The last stage involves refreezing. The team will focus on assessing the new system, identifying new challenges, and then finding solutions to them. Using this model will help eliminate possible resistance to change by ensuring that everyone is adequately prepared for it.

Limited Knowledge

AI and ML have a huge potential that MSMEs should fully take advantage of to manage stiff competition in the market. However, a major challenge arises from the fact that there is limited knowledge about this emerging technology (Aarstad & Saidl, 2019, p. 134). The first challenge that most small businesses face is that their executives have limited knowledge about it. They might have heard about AI and ML, but they lack detailed knowledge about their relevance in business settings. The controversies about this technology witnessed in the recent past, especially on its capacity to replace humans in decision-making, have also caused confusion among these executives, making it difficult for them to embrace it.

Most of the employees who are already in the job market have limited knowledge about artificial intelligence. They may be having the interested to know more about it and how it can be implemented. However, they lack the academic background to fully understand the system. As such, some may develop the fear that instead of AI making their work easy, it can potentially eliminate the need for their services in their current firm (Hellingrath & Lechtenberg, 2019, p. 53). Another concern is that employing a large number of fresh college graduates with some background training in AI would mean trading experience and loyalty for one aspect of technology.

Micro, small, and medium enterprises must find ways of addressing such challenges. According to Toorajipour et al. (2021), the number of institutions of higher learning that offer training in AI is increasing (p. 510). This technology is gaining relevance in various fields and many colleges currently offer some form of training related to it. Firms should consider enrolling their current employees in these colleges so that they can sharpen their skills in this field. Executives can also enroll themselves in online classes to enable them to enhance their understanding of this new technology. When hiring, a firm can emphasize the need for the recruits to have some basic skills in AI and ML.

The Problem of Bias

AI machines learn from the data to which they have access. One of the main challenges that an organization may face when using AI in the supply chain is bias (Kersten et al., 2019, p. 57). Sometimes the system is exposed to bias against or towards some people or some things. It is common to find cases where many organizations prefer hiring male employees for engineering jobs while females are given priority for secretarial or marketing jobs. There is also a common bias in the United States and other parts of the world in favor of whites at the expense of other races, especially blacks. When AI is exposed to such data during the learning process, it will base its decisions based on such bias.

In logistics, a firm may prefer to source materials from specific individuals or regions for particular reasons. Dynamics in the industry creates a situation where some of the best suppliers or transporters today may not be the best in the future (Dash et al., 2019, p. 50). However, when the machine is exposed to such bias, they may continue making choices, which may not be the best for the firm. In such a case, instead of facilitating optimum decision-making, it will become a misleading tool that causes loss to the firm.

It is essential to find a way of addressing the problem of biases of AI to ensure that it remains as effective as possible. One of the best ways of doing so, as Klumpp and Ruiner (2018) note, is to ensure that the AI is exposed to unbiased data during the training process (p. 2). The user must ensure that the machine learning process is free from any racial, religious, or gender biases. Continuous learning is another essential tool that can be used to help the machine make optimal decisions and accurate decisions. As the forces in the market continue to change, the data that the machine uses should also be updated accordingly. Data on factors such as the best suppliers, reliable transporters, and security issues should be regularly updated to enhance the efficiency of these machines.

Infrastructure

The infrastructure needed to have a fully functional AI system in the logistics department may be a challenge to micro, small, and medium enterprises. A firm needs to have large and secure databases to facilitate the creation of Big Data. It will then require an AI system that is specifically designed to facilitate operations in the logistics department (Ceyhun, 2020, p. 119). For large corporations, developing such an infrastructure may not be a major challenge because of their financial capacity. However, the same cannot be said about smaller firms with a small budget. Sometimes they may be forced to choose between installing the infrastructure or facilitating expansion or hiring more employees. The decision will always be based on what the management considers more urgent and important to the firm. Sometimes having the AI infrastructure may not be considered a priority when the firm is faced with a financial constraint. Singh et al. (2012) also warn against poor AI systems that cannot function efficiently as expected (p. 172). Some of these AI systems are developed by individuals who are still under training, which means that their creation may have several weaknesses.

The cost of installing an AI infrastructure for the logistics department may be significantly high. However, the technological trends witnessed in the recent past show that firms, irrespective of their size, cannot avoid embracing emerging technologies (Toorajipour et al., 2021, p. 504). It means that these MSMEs must find ways of overcoming the challenge of having the right infrastructure for their logistics department. Gradual planning for AI infrastructure development may be one of the ways of overcoming the challenge. The company can set aside a specific amount of its monthly income towards purchasing the infrastructure. It means that its installation can be categorized as a mid-term plan that should be realized within a year. Care should be taken when selecting the vendors who are selling the relevant system. It is advisable to select established vendors with a good reputation to avoid the problem of having an ineffective AI system.

Integration of AI into Existing Systems

When the management of a small or medium enterprise decides to embrace AI technologies, another challenge that it has to deal with is integrated into an existing system. The firm will have to find a way of introducing the AI system into an already existing system within the logistics department. Klumpp and Ruiner (2018) explain that the integration process may face various challenges (p. 21). First, the team of employees may lack the requisite skills needed in the new platform. Secondly, some employees’ jobs may have to be redefined, especially those whose roles will be taken by the machine. There is a possible threat that some of the employees may reject and deliberately frustrate the introduction of the new system if they feel that their position within the firm will be threatened. It is also possible that a firm may have to make a radical shift from traditional methods of operations to a new one that is based on the new technology.

The possible integration challenges will need to be addressed to ensure that these small firms can effectively embrace AI in their supply chain management. To address the challenge of inadequate skills among employees, the firm will need to train a section of the employees who will be operating the AI in the logistics department. They should be equipped with relevant skills necessary for them to feed and allow the AI systems to make decisions and predictions (Dash et al., 2019, p. 48). The firm may also find it necessary to recruit new employees with the right skills. When redefining the roles and responsibilities of employees in line with the changes introduced, the management should ensure that it is done in a way that does not cause fear among workers. They should be informed that the new system is meant to empower them instead of eliminating them from the firm. The goal is to ensure that all the relevant stakeholders support the new system. When it is necessary to make a radical shift from traditional methods to new ones, employees should be adequately trained and prepared for the change.

Inability to Reach Human-Level in Decision-Making

One last challenge of AI in the logistics sector for MSMEs worth discussing at this stage of the paper is its inability to reach human-level in decision-making. According to Klumpp and Ruiner (2018), there has always been a debate about whether AI has the capacity of a human when it comes to making rational decisions (p. 26). Some AI enthusiasts have even argued that these machines are superior to humans when it comes to making accurate predictions and data-based decisions. It may be true that AI, when fed with the right data, can make accurate predictions and effective decisions.

Sometimes their predictions may be more accurate than that of humans because of their capacity to process large amounts of data within the shortest period possible. However, they lack the compassion that humans have, making them relatively inferior (Singh et al., 2012, p. 178). Sometimes it may be necessary for a firm to make a decision that is seen to protect humanity and the environment as opposed to making profits. However, these machines are often trained to focus on maximizing profits while at the same time minimizing expenses and losses. Some of their decisions may have serious negative implications on a firm’s reputation because of the lack of compassion.

Small and medium enterprises should find a way of addressing this challenge. AI has proven to be a highly sophisticated system capable of doing what only humans can do. However, they need to be trained to do that which they are expected to do. Toorajipour et al. (2021) argue that it is possible to train the AI to be compassionate when making decisions (p. 514). Although these machines lack human feelings and some of their decisions may be considered self-centered and profit-oriented, they are still essential. To address this challenge, the management can ensure that the final decisions are made by humans. The machine can be allowed to develop a pathway to different possible actions. The management can then understand the possible outcome if a certain decision is made. Using the information that the AI has processed, the management can then make decisions that reflect other human needs the machine could have ignored. Figure 6.2 below identifies some of the major challenges that AI presents to MSMEs when used in supply chain management.

The Future of MSMEs’ Logistics in the World of Artificial Intelligence

The last century has seen rapid growth in popularity and application of AI in the corporate world. According to Christiansen and Skrinjaric (2021), the gaming industry helped in testing the efficiency of AI and ML. In the current stage, technology has advanced into the fields of healthcare, security, transport, manufacturing, and communication among others (p. 67). The need to use real-time data has made it possible for companies to use this technology in making important decisions that define their operations. As Ceyhun (2020) puts it, the world is moving towards a corporate world that is fully dependent on artificial intelligence (p. 183). It is becoming critical for companies to make decisions that are based on data to avoid mistakes and misinformation.

Micro, small, and medium enterprises have to embrace AI technology in their operations. As the competition stiffens, these firms find themselves in positions where they have to be accurate in making their predictions. They are moving into a world where every decision that they make has to be based on accurate data. It starts by investigating and determining specific customers’ needs in the market (Hanne & Dornberger, 2017, p. 85). The challenge that exists is that these needs may change depending on various forces in the market. The fact that these MSMEs are not industry leaders means that they may not dictate most of these changes. Once customers’ needs are understood, the firm must determine the demand size. The information will then be used to inform the production process. To help lower the cost, improve quality, and enhance productivity, a firm must find ways of embracing smart production. AI makes it possible for these small firms to embrace these new methods of manufacturing.

In the logistics sector, it is becoming impossible for small and medium enterprises to ignore AI and ML. The numerous benefits that the new technology offers have been discussed in the previous chapters of the paper. The current trend shows that firms can no longer avoid this technology. One of the reasons why it is currently unavoidable is the need to deliver products in the market or to the manufacturing plants in time (Klumpp & Ruiner, 2018, p. 3). Using AI, drivers can know the best routes that they can take to reach their destination within the shortest time possible. Such high levels of efficiency are only made possible through the use of AI. There is also the need to cut the logistics cost of operations. Besides identifying the best routes that are cost-effective for a company’s trucks, AI also helps to fight theft and reduce the perishability of products. All these factors help in lowering the overall cost of operations. As such, any MSME that is keen on achieving sustainable competitiveness in the market needs to embrace the technology.

It is common for employees and other stakeholders to resist change, especially when they feel that their current position will be threatened. The management of these small and medium enterprises must realize that their employees may not support the introduction of AI in the logistics sector because it may not only replace junior officers but also mid to top management officers because of its capacity to make accurate predictions and data-based decisions (Singh et al., 2012, p. 175). Having en effective integration of AI is essential in eliminating such resistance. Lewin’s change model, discussed above, may help in introducing change in these organizations.

The Relationship between ML Adoption in Logistics and MSMEs Performance

Machine learning is gaining popularity among small and medium enterprises keen on redefining their logistics operations. Many firms have realized that they have to digitize their logistics as a way of remaining competitive. The new technology enables these firms to make critical decisions based on accurate predictions and scientific simulations (Isensee et al., 2020, p. 6). It helps in eliminating human errors, which may significantly affect the ability of a company to meet customers’ needs in the best way possible. In this section of the report, the focus is to discuss the relationship that exists between ML adoption in logistics and MSMEs’ performance. Figure 3.3 below identifies specific performance-related factors in logistics.

The performance of individual drivers will be significantly enhanced when ML is introduced in logistics management. The performance of a firm directly depends on the performance of an individual employee. In logistics, drivers play a critical role in ensuring that goods are delivered at the right time and without damage or theft. ML technology makes it possible for drivers to be efficient in their operations because of the assistance from deep learning and text/image processing technologies (Pournader et al., 2021, p. 11). Driver-assist technology helps drivers to make critical decisions while they are on the road. They can identify routes that may have traffic congestion and the technology can help suggest alternative routes. As such, delays that may disrupt normal operations within the firm or customer dissatisfaction are eliminated. Such delays may also affect the quality of goods on transit when handling perishable products (Belhadi et al., 2021, p. 7). The driver-assist technology makes it possible for the pilot, captain, or driver to monitor the conditions of products on transit and to set optimal temperature and moisture that can help preserve them in the best way possible while on transit.

Autonomous driving remains one of the most promising opportunities that AI and ML will offer to the logistics sector. For small and medium enterprises, this technology will offer a perfect opportunity to scale up operations and enhance productivity. Current development in autonomous vehicles, especially the one which is headed by Tesla, strongly indicates that driverless trucks will soon be a reality (Min, 2010, p. 16). If this is achieved, MSMEs will be able to facilitate the transportation of large volumes of products within a short period. Machines do not need to have a break in ways that humans do. They cannot complain or demand additional pay when they have to work for 24 hours a day. It means that a firm can easily enhance its productivity in the logistics department when this technology is applied.

Cloud computing is another major opportunity for growth that AI and ML offer to small and medium corporations. In logistics management, data has become a critical factor that defines a firm’s success. Making decisions based on real-time data is essential, especially when handling perishable products. A firm needs to have accurate information of demand in the market and other factors to know the number of products that should be made available (Kersten et al., 2019, p. 32). Cloud computing makes it possible for these firms to access, process, and utilize large amounts of data. Instead of relying on guesses and unfounded speculations, these entities can streamline their logistics operations based on real-time data.

Cloud computing also facilitates effective communication among stakeholders in value chain management. Once the demand is determined by the marketing department, the manufacturing unit will plan its activities properly and accurately make an order of materials needed. The information will be relayed to the suppliers through the procurement department. The logistics unit will then have clear information on the amount and nature of products that need to be transported from suppliers to the firm and from the firm to the market within a specific period (Pournader et al., 2021, p. 17). The increased coordination and cooperation of these departments and all the relevant stakeholders improves the performance of the logistics department and the entire firm.

Driver risk assessment is another way in which a small or medium enterprise can enhance its performance in the logistics sector. Aarstad and Saidl (2019) explain that driver risk assessment involves determining the likelihood of a driver being in an accident while on official duty (p. 43). Various factors may cause an accident while a driver is on official duty. They include fatigue that impairs the judgment of a driver when they are overworked, vehicles being in a state of disrepair, poor weather conditions, and poor conditions of roads, limited training, drunk driving, and carelessness or recklessness of a driver. Some of these factors are direct human errors while others are forces beyond the control of the driver.