Chipotle’s Original Supply Chain

Chipotle Mexican Grill (CMG) differentiates itself as a quick-service restaurant chain that uses natural ingredients produced in a socially and environmentally responsible manner. However, the restaurant has faced a food safety crisis following contamination incidents with “E. coli, norovirus, and Salmonella” that affected over 514 people (Berfield par. 6). CMG’s ‘Food with Integrity’ initiative reflects its sourcing practices from local suppliers employing sustainable and ethical production.

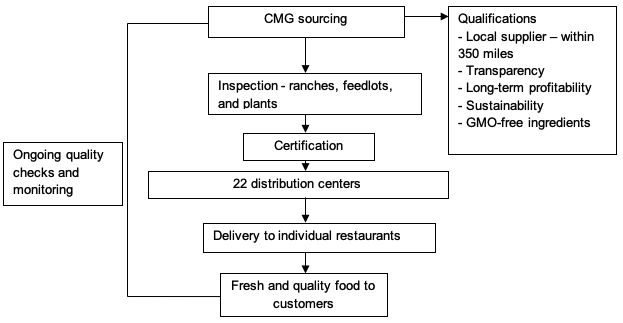

Its original farm-to-table supply chain consists of meat suppliers raising animals naturally. The flow chart (figure 1) below illustrates CMG’s original supply chains. CMG utilizes a network of organic farmers located within a 350-mile radius of the distribution centers to minimize supply chain interruptions associated with inventory outages. It establishes close supply chain relationships, especially with family-owned farms to ensure quality and ethically produced ingredients. Examples include the Niman Ranch and The Chef’s garden (Tuttle par. 7).

Supplying the Restaurant Chains

CMG is renowned for its intensive supply chains involving only a few certified suppliers. Its 1,316 restaurants receive ingredients from 22 autonomous distribution centers distributed across the US (Tuttle par. 7). Certified local farmers employing concentrated animal feeding practices deliver meats, including pork, chicken, and beef to the distribution centers.

CMG approves all the farmers that deliver supplies to the strategically located distribution centers using certain quality specifications. Also, the distributors have to buy based on CMG’s pricing guidelines and handling practices. The distributors deliver fresh supplies to the restaurants depending on the demand, which eliminates the need for refrigeration and ensures fresh, quality dishes for the customers.

In my view, while sourcing from a few distributors minimizes transportation costs, it creates a traceability challenges. According to Torrence, the E. coli contamination of CMG’s food may have originated from improper sanitizing practices of items, such as tomatoes and lettuce, by one of its big suppliers (par. 10). The actual source of the contamination could not be traced because CMG has no control of supply chain processes such as sanitization and packaging. Certifying the packers and slaughterhouses could eliminate the risk of food contamination through the supply chain.

A New Way to Supply the Restaurant Chains

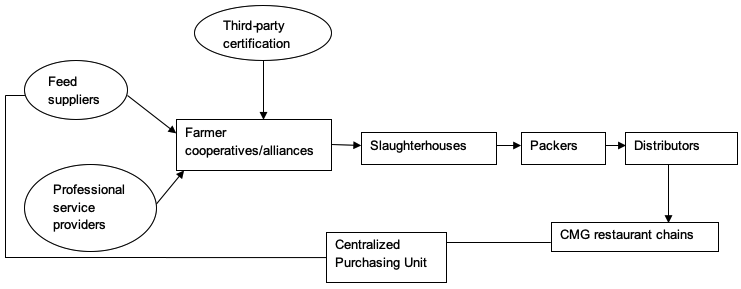

Sourcing ingredients from a few certified suppliers makes it difficult for CMG to replace a farmer without causing supply chain interruptions. Moreover, Chipotle’s growing list of ingredients brings a traceability challenges. CMG should adopt third party certification and farmer cooperatives/conglomerates to overcome these challenges and enhance its SCM capabilities. Also, it should certify feed suppliers and slaughterhouses to ensure a purely organic and ethical production, minimize SC risk, and enhance traceability. A new farmer-distributor-CMG approach suggested for the restaurant chains is summarized in figure 2 below.

Burgerville Restaurant Chain

Burgerville is a quick-serve restaurant affiliated to Holland Inc., an ice cream company. The family-owned restaurant chain is guided by three philosophies: local sourcing, good employee relations, and emphasis on fresh, sustainably produced food. Since opening its first store in 1961, it has grown to 39 locations and a “mobile restaurant dubbed ‘The Nomad’ operating in Oregon and Washington” (Brown et al. par. 2). Burgerville sources ingredients primarily from local farmers and growers that adhere to sustainable and ethical production practices. Its primary suppliers are those that use the Food Alliance certification guidelines in their production.

Apart from ethical sourcing, the restaurant chain has adopted sustainable practices, including wind energy and recycling. According to Brown et al., all the materials, including food wrappers, used in Burgerville’s 39 locations, an equivalent of 50% of its waste, are compostable (par. 3). Each location’s management team comprises of a manager and two assistants. Their role is to place orders for the store from authorized distributors who deliver ingredients thrice a week. Invoices from the transactions are received by the head office that remits payment to the distributors.

Since 2008, Burgerville has been continuously refining its dishes by including vegan options on a rotational basis. This strategy resonates with the Six Sigma model that focuses on continuous quality improvement (Hitt, Ireland, and Hoskisson 71). It employs the services of local ‘foodies’ and chefs to develop new menu items, such as ‘The Roasted Turkey & Cherry Chutney Wrap’ created by an Oregon environmental agency under the ‘healthy foods’ program (Hitt, Ireland, and Hoskisson 73). Customers also anticipate Burgerville’s seasonal menu items such as Fried Asparagus Spears. The ingredients for seasonal dishes are not sourced from its regular distributors. In contrast, the sourcing of materials for its standard dishes involves a local farmer network that supplies to Burgerville’s distributor system.

In this supply chain system, the restaurant identifies a farm that grows the ingredients it needs sustainably. Burgerville then contacts either of its distributors, i.e., Fulton Provisions and Sysco, to facilitate the delivery to the distribution center. Subsequently, Burgerville includes the ingredient in its order list when ordering from the distributor.

This sourcing strategy ensures that farmers and distributors focus on their core businesses while optimizing inventory control. The consumer-producer relationship creates value for both the restaurant and the farmers. It provides a ready market to farmers and provides Burgerville access to quality ingredients through its regular distributors.

Recommendations on how Burgerville can Improve its Current Supply Chain

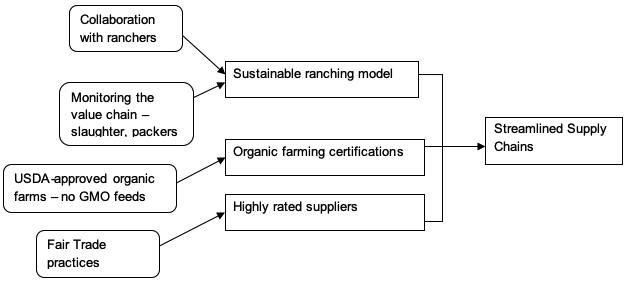

Burgerville should use a sustainable ranching model to ensure an adequate supply of quality organic meat products. It should collaborate with local ranches to produce beef ethically. The ranches should retain the ownership of the animals throughout the supply chain to promote the traceability of products and quality meat.

Since customers require quality and competitor restaurants increasingly use ethical products, a TQM approach is needed to create a culture of quality throughout the meat value chain. TQM entails a system of “practices and tools” for managing a production process to deliver value to customers (Andersson, Eriksson, and Torstensson 285). Burgerville should monitor the cattle feeds at the ranches, the slaughterhouse practices, the packaging, and transportation of meat products to reduce the risk of bacterial contamination and ensure quality, naturally produced meat for its customers.

- Burgerville should also use organic farming certification to recruit suppliers, especially for its poultry products. This would require an ISO certification of farms that meet the USDA organic farming standards. USDA-certified organic farms do not use organically modified poultry feeds and observe a humane treatment of the birds. Sourcing from USDA-approved farms would ensure high-quality chicken meat and eliminate SC risks associated with the contamination or supplier accreditation.

- Burgerville should select its suppliers based on their national or international excellence standards or ratings. In particular, its coffee and meat suppliers should observe Fair Trade practices as opposed to cost. A Fair Trade certification indicates a commitment to socially and environmentally sustainable practices. The company should support farmers through technical expertise to enable them to mass-produce without causing adverse environmental and social impacts. The certifications should focus on the sustainable production of animals and crops to approve suppliers of various meats, eggs, fruits, beans, mushrooms, and spinach, among others. The recommendations are illustrated in the flow chart below.

A Summary of How I Came to My Recommendations

Burgerville prides itself on close farmer relationships and distributor partnerships that create value for the consumer and reduce the risk of contamination. To arrive at the recommendations, I examined Burgerville’s current sourcing strategy for its meat products and found that it buys from individual ranches.

I concluded that adopting a sustainable ranching model, whereby a certified conglomerate of farmers supplies meat to Burgerville’s two distributors, as opposed to sourcing from a single ranch, would meet its inventory needs. Additionally, this strategy could enhance adherence to the restaurant’s quality specifications and facilitate the traceability of meat products along the supply chain.

In my review, I also discovered that Burgerville sometimes resorts to purchasing from conventional ranches when the production capacity of its primary suppliers is low. I reasoned that one way Burgerville could expand its supplier base is by including USDA-certified organic farms. These farms do not use GMO-derived feeds or antibiotics to raise their crops or animals.

Therefore, sourcing from these USDA-certified farms would ensure that the restaurant receives quality ingredients and provide cost savings associated with developing and certifying new organic farms. Similarly, for products such as coffee or raspberries that may not be locally produced, sourcing from large suppliers known to embrace fair trade practices would ensure that Burgerville obtains ethical products.

Rationales

The Six Sigma methodology essentially aims at improving the production processes by minimizing variation (Andersson, Eriksson, and Torstensson 285). Therefore, the model applies to Burgerville because achieving customer satisfaction requires supply chain improvements to ensure timely delivery and avoid food contamination.

ISO quality benchmarking ensures that firms strive to achieve specified quality standards in their internal processes. The methodology applies to Burgerville because it is a quick-serve restaurant specializing in high quality, fresh, and organic food. ISO certification of organic suppliers would enable the restaurant to purchase quality and ethically produced ingredients.

The lean supply chain focuses on minimizing waste in the production process. I did not use lean principles because Burgerville operates in the service industry, wherein supply chain performance determines customer satisfaction. TQM is a continuous quality improvement model that involves company employees (Andersson, Eriksson, and Torstensson 287). Therefore, TQM implementation at Burgerville could help the restaurant achieve high customer satisfaction through quality, fresh food, and lower contamination risk.

Works Cited

Andersson, Roy, Henrik Eriksson, and Hakan Torstensson. “Similarities and differences between TQM, six sigma and lean.” The TQM Magazine 18.3 (2006): 282-296. Print.

Berfield, Susan. Inside Chipotle’s Contamination Crisis: Smugness and Happy Talk about Sustainability aren’t Working Anymore, 2015.

Brown, Darren, Phil Berko, Patrick Dedrick, Brie Hilliard, Joshua Pfleeger. Burgerville: Sustainability and Sourcing in a QSR Supply Chain, 2011.

Hitt, Michael, Duane Ireland, and Robert Hoskisson. Strategic Management: Concepts and Cases: Competitiveness and Globalization. New York: Cengage Learning, 2014. Print.

Torrence, Eric 2016. The Chipotle Question: How Good Is Your Personal Supply Chain? 2016.

Tuttle, Hilary. Dia de la Crisis: The Chipotle Outbreaks Highlight Supply Chain Risks, 2016.