Introduction

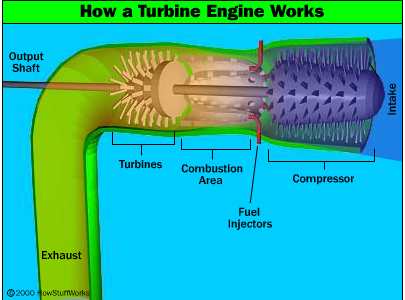

Since the end of the Second World War, the world has registered remarkable growth in science and technology, which has led to the development of both simple and complex machines that help humanity in various ways. Among these machines is a gas turbine (combustion turbine). This machine, a rotary engine, extorts power (energy) from a stream of combustion gas to generate energy. A gas turbine divides into three major parts: the combustion chamber, the downstream turbine, and the upstream compressor. Each of these there regions performs a specific role in the gas turbine process. For instance, the combustor plays a major role in the process in that this is the region of mixing air and fuel before setting it to ignition to release energy. When the pressure within the combustor increases, the temperature of the fuel also increases forcing the products to enter the turbine section. The gas flow enters the turbine section at high velocity spinning the turbine, which then energizes the compressor to generate the mechanical output.

The Gas Turbine Process

As mentioned earlier, a gas turbine has three parts: the compressor, which squeezes the arriving air to make it have high pressure; the combustion area whose function is to heat the fuel and generate high-pressure, high-velocity gas; and the turbine whose function is to haul out energy from the high-pressure, high-velocity gas coming from the combustion area. The axial-flow gas turbine illustrated above can drive the rotor of a helicopter. Let us explain how the gas turbine works. To start with, air enters the turbine through the compressor, of course by sucking. The compressor comprises small fan blades and a cone-shaped cylinder. Once air at normal pressure enters the compressor, it compresses it until its pressure rises considerably, maybe, by a factor of 30 (Smith and Jones, 2009, pp. 10-40).

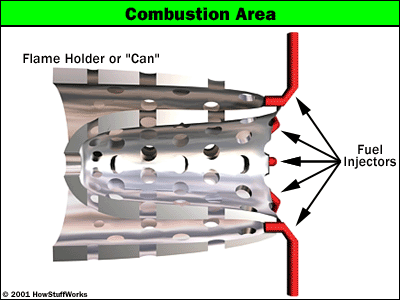

Combustion Area

The high-pressure air from the compressor enters the combustion area. Inside the combustion area, the fuel injectors situated on the right will add fuel (in form of kerosene, natural gas, propane, or jet gas). On the left side of the combustion area, is an exit for exhaust gases. Though there is a slight loss in pressure due to friction, the high volume gas leaves the combustion area for the turbine.

The Turbine

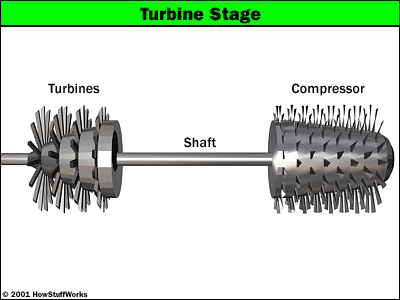

On the left side of the engine lies the turbine section characteristically defined into two sections. The first set of the turbine comprises the turbines, the shaft, and the compressor, while the second part drives the compressor. All of these function as a single unit by propelling the output shaft. It is imperative to note that the turbine stage and the output shaft are entirely unconnected, freewheeling entities. The two, turbine stage and output shaft, can rotate to rotate freely without any correlation to the rest of the engine. The operation of the turbine is so amazing drawing the fact that it is not connected to the rest of the engine. The hot gases blowing via the turbine blades carry a high amount of energy, which is able to generate over 1,500 horsepower—power that can propel a 63-ton M-1 Tank into motion. In fact, this is how simple a gas turbine works (Kerrebrock, 1992, pp. 8-33).

Conclusion

A gas turbine is advantageous when compared with a diesel engine. For example, the power-to-weight ratio is high compared to other engines. In addition, a gas turbine engine takes small space due to its small size as compared to reciprocating engines. However, as compared to other reciprocating engines, gas turbines are expensive simply because they operate at high speeds and temperatures. This property makes turbine gases excellent in transcontinental jet aircraft and also in power plants.

References

Kerrebrock, J., 1992. Aircraft Engines and Gas Turbines. (2nd ed.).The MIT Press.

Marshall, B., 2001. How Gas Turbine Engines Work.

Smith, A., and Jones, B., 2009. Gas Turbines. Journal of Engineering for Gas Turbines and Power, 130(1), 10-40.