Abstract

The purpose of this project is to implement radio frequency identification and automated materials handling systems in a new public library building. RFID and AMH technologies allow for automatization of several essential processes that would otherwise have to be conducted by people. AMH equipment is capable of sorting and transporting books from collection quickly and efficiently, and RFID gates are a powerful and modern security tool. The systems offer numerous opportunities for optimization, but they also have some limitations. Advanced AMH complexes can occupy several rooms, and purchasing the equipment can be costly. The amount of work to install and learn to operate the new technology could also be substantial. These factors, as well as some other points, will be considered in this proposal.

Motivation

The public library that this project proposal is aimed at is the leading institution in its region, where the technologies mentioned above have never been implemented. On the one hand, this might be an indicator that the 50,000 people community is not large enough to warrant installing such powerful systems. Perhaps the libraries are already capable of serving their customers quickly due to the flow of readers being relatively manageable. One might even argue that not using machines to sort books is necessary to give people jobs. On the other hand, the largest library in the region is likely to be the first to adopt such systems, as it has more resources to do so. The use of AMH and RFID would also improve the experience of library users by enabling easy returns and self-service. Overall, from the standpoint of setting the direction of library development in the area, installing the automated systems in the new building is a good idea.

Project Details

Environment:

- The project will use standard commercially available hardware and software.

- Most world languages can be installed in the terminals

- The types of hardware that will be used include: return terminals, conveyors, automatic sorters, sorting bins, carts, RFID gates, RFID tags

Issues and Challenges for implementation:

- High upfront costs

- Large space required

- Systems need to be easy to operate

- Long installation time

AMH offers a broad range of useful features that improve the library experience; however, it has some drawbacks and limitations. The upfront cost of such a system is one of the primary concerns, as automatic material handling equipment can be extremely expensive. The price for a complete AMH system can change substantially with the scale of the library, which makes it impossible to provide an accurate estimate without any concrete data about the institution. Sources suggest that a basic AMH setup can cost less than $50,000 and fit a small library (Ayre, 2012). Adjusting for inflation and taking into account the fact that the subject of this paper is the most extensive library of its region, one can project the price to be about $100,000-150,000. Under normal circumstances, this would be difficult to fund, however, since the library is already planning a new building, which will cost significantly more, it should be possible to allocate some finances to purchasing equipment.

The system will also require space for optimal operation, which should be accounted for during the planning stage. A large room will be necessary to house all the conveyors and bins while leaving enough space for carts to move from said bins to the shelves. The room will need to be located in a way that minimizes the length of conveyors from internal and external return terminals in order to use space and funding efficiently. Alternatively, the system could be placed in a common area, which will save space, but introduce visual and auditory noise for patrons.

Finally, the library must consider the usability of the system for its employees. AMH technology is meant to help the staff be more efficient at their work, so it is crucial for the equipment to be easy to use and maintain. If this is not the case, the benefits of using AMH will be minimal, and the cost of the system will not be justified. Consequently, such systems are designed to be ergonomic, minimizing lifting and other physically straining tasks (“Automated Materials Handling in Partnership with Lyngsoe Systems,” n.d.). They also do not require special skills for everyday operations, as the sorting processes work autonomously. Maintenance might be more complicated, but breakdowns are unlikely, as the machines will work with relatively low and stable loads while being located in a dry climate-controlled room.

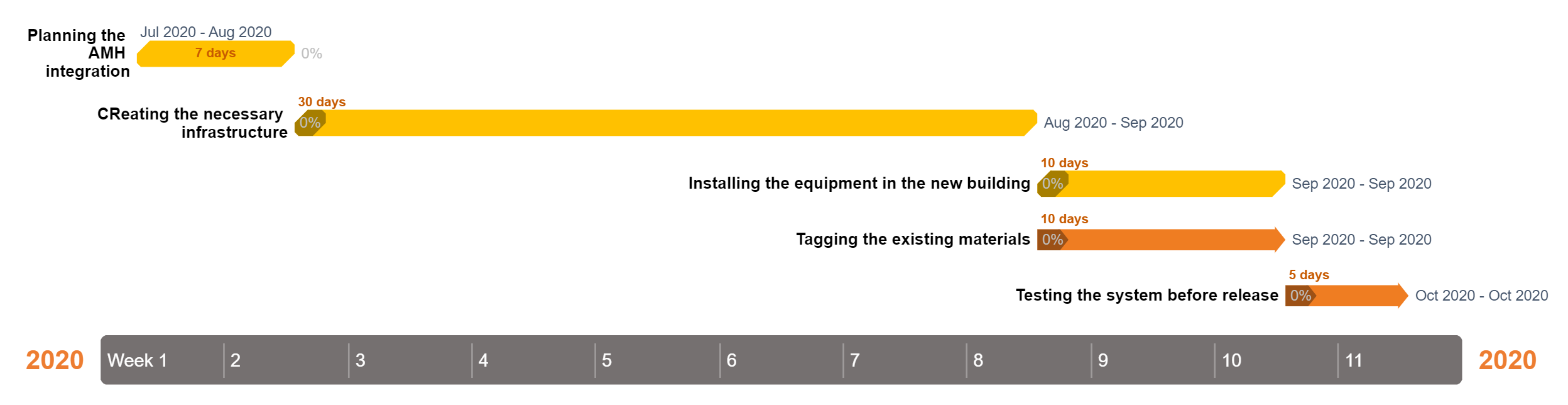

A major issue with including an automatic material handling system is the amount of work that is required to install it. The machines will need to be assembled and configured, which can be a long process for a relatively large system. However, the most challenging part of adopting an AMH system is setting up the RFID components required to automatically detect and sort books. RFID tags are used both to allow security gates to sense books passing through them and to enable the return and sorting systems to identify the material and transfer it to the proper location. The amount of work required to equip each book with a tag depends on the extent to which the library wishes to take advantage of the AMH system. Security gates could work with basic RFID strips that do not require any additional programming for each book, although installing them will still be a challenge. More advanced sorting applications and automatic returns will require additional unique information about each book to be added to its tag, making the setup time significantly longer; the chart in Figure 1 accounts for that.

Deliverables:

- Scalability for different applications

- Modular AMH systems

- Simple interactions between staff and AMH systems

- Equipment designed with ergonomics in mind

- Easy-to-use return terminals

- Minimizing human contact

- Increased security

A key advantage of AMH systems is their modular structure and the resulting boost in adaptability for various purposes. Although it may be common to think that automated sorting and transporting systems are only used in the largest libraries, companies claim that their solutions can be scaled to fit the need of even the smallest institutions (“Automated Material Handling,” n.d.). Depending on the volume of materials circulated, the library could configure the perfect combination of different machines to address its needs. In any case, using an AMH system is likely to result in a significant reduction in the time returned books are unavailable for other users after they have been collected.

The use of a large amount of mechanical equipment operated automatically might also have some implications for workplace safety. Since sorting solutions only need to interface with humans at the beginning and the end, the potential hazards are minimal. In addition, using ergonomic carts, as well as other similar devices, will have noticeable long-term benefits for the health and wellbeing of workers (“Lyngsoe Ergo Cart,” n.d.). AMH also has the added benefit of minimizing human contact, which is increasingly important in the midst of the COVID-19 pandemic and will likely be a common practice in the future. Returning books is a simple operation, and there are numerous solutions that can allow people to perform it without entering the library or interacting with the employees (“Automated Return & Sorting Library Handling Systems,” n.d.). Combined with frequent disinfection of the self-service touchscreens and adherence to other safe practices, AMH can significantly increase both workplace and public safety.

Self-service and external terminals for returning books are also highly attractive services for library patrons for several reasons. Firstly, they can often be quicker, compared to coming inside and waiting in a line to be served by a library worker. With the use of RFID tags and advanced facial recognition technology, a patron could deposit their books in only a few seconds. Secondly, since the collection terminals are fully automated, they can remain operational at all times, allowing people to return books whenever it is most convenient for them. Lastly, having the option to interface with an electronic device instead of a human is a practical privacy feature. Those who might otherwise feel uncomfortable about other people seeing them with a particular book can use self-service to avoid exposing the information they might consider sensitive.

Many modern users prefer working with computers for simple operations, so the traditional collection could be significantly downscaled or eliminated, leaving employees with less routine tasks. Security could also be simplified with the use of RFID gates, that can accurately detect if a book was carried through them without authorization, at the entrance (“Security & Detection Library Solutions | Protect Your Materials,” n.d.). The library could then configure an automatic response, such as emitting warning sounds, showing visual indicators, or even locking the doors. This would make the job of security personnel significantly more manageable, as they will have a dependable way of negating any type of disguise a potential thief might use.

Timeline:

Figure 1 shows the estimated timeline for the completion of the project.

References

Automated Material Handling. (n.d.). 2020, Web.

Automated Materials Handling in Partnership with Lyngsoe Systems. (n.d.). 2020, Web.

Automated Return & Sorting Library Handling Systems. (n.d.). 2020, Web.

Ayre, L. B. (2012). RFID Costs, Benefits, and ROI. In Library Technology Reports (Vol. 48). Web.

Lyngsoe Ergo Cart. (n.d.). 2020, Web.

Security & Detection Library Solutions | Protect Your Materials. (n.d.). 2020, Web.