Introduction

The manufacturing business environment has undergone considerable evolution over the years. The transformations have been spurred by different causes. Technological development is one of the critical forces that have changed the industry significantly. Manufacturing firms are progressively integrating different computing technologies in the quest to achieve efficiency in their operation.

The implementation of the various innovative technologies has further been increased by the industry shakeups that have arisen from the intense competition amongst the industry players. Erdinc and Vayvay emphasise that despite the view that the shakeouts might be catastrophic, they also present a critical source of opportunity for manufacturing firms that integrate proper foresight into their management processes (728). Bloom, Kretschmer, and Reenen argue, “One of the common precipitators of an industry shakeout is a shift in the core technologies driving the manufacturing processes” (343).

Past studies on the survival of manufacturing firms emphasise the importance of adopting effective production processes. The management processes range from the integration of diverse management philosophies such as lean manufacturing, flexible operation, and gradual or continuous improvement (Erdinc and Vayvay 728). The incorporation of effective process management constitutes a fundamental component in quality-related initiatives, for example, total quality management.

One of the areas of focus that businesses should focus on entails ergonomics. Bloom, Kretschmer, and Reenen define ergonomic to include “the interaction between humans, technology, organisation, work environment, and the influence of these interactions on quality” (344). Business organisations must establish a link between quality management and ergonomics. Despite, the integration of technology in organisations’ operations, firms need to focus on establishing a balance between human and technological capital.

Problem statement

Efficient operation is critical in firms’ quest to achieve sustainable performance. Nevertheless, achieving this outcome presents a major organisational challenge. Despite the development of technology and the subsequent substitution of human capital by computer technology, no organisation can succeed in sustainable performance without the input of human capital. One of the issues that can contribute towards the attainment of sustainable performance entails providing clients with high-quality products and services. However, delivering quality products is subject to the skills and knowledge of the employees.

Erdinc and Vayvay support this perspective by asserting that human capital plays a critical role in promoting efficient operations and deliverance of the quality promise (728). To promote the employees’ performance, it is critical for the organisations’ human resource management teams to ensure that the job roles assigned to the employees are aligned with their specific skills and knowledge. This aspect requires effective work designing.

In the recent past, KEMYA has implemented diverse reforms in its manufacturing process such as debottlenecking some of its manufacturing plants. The reforms contributed to a remarkable improvement in the firm’s manufacturing capacity. For example, phase 1 of the debottlenecking process led to the improvement of the firm’s production capacity by 280-kilo tons annually. The second debottlenecking on the LDPE plant increased the production capacity to 325-kilo tons annually. Nevertheless, the firm encountered a challenge in undertaking the final debottlenecking on its plant, as the process was unsuccessful. The firm encountered leakages in its reactor, quality issues, increase in failure rate and process issues such as tube fouling. Debottlenecking can contribute to remarkable improvement in downstream manufacturing activities.

Despite its quest to achieve competitiveness in the petrochemical industry through the implementation of crossover projects and debottlenecking, KEMYA has continued to experience a high rate of plant shutdown and reduction in the quality of its products. The problem has been spurred by the high rate of employee turnover and inefficient employee knowledge and skills. The available literature affirms that human error is a major factor that increases the incidences of poor quality in the manufacturing sector (Erdinc and Vayvay 728). Despite the faced challenges, the firm can attain sustainable competitive advantage through the adoption of effective human resource management practices. Ergonomics is one of the HR aspects that the firm should take into account in delivering quality and sustainable performance.

Aims and objectives

The purpose of this paper is to examine how KEMYA’s management team can revamp the performance of its LPE plant regarding quality by applying the concept of ergonomics.

Research objectives

To achieve the research purpose, the study will focus on the following objectives.

- To examine how KEMYA can improve the quality of its products by focusing on human capital.

- To investigate how the application of ergonomics can lead to a reduction in the rate of employee turnover.

- To explore how ergonomics can enhance KEMYA’s efficiency in achieving sustainable quality and performance.

Research question

In line with the research objectives, the study will seek to respond to the following questions.

- In what ways can KEMYA leverage human capital in improving the quality of its products?

- How can the application of ergonomics assist KEMYA in reducing the rate of employee turnover?

- How can KEMYA enhance its efficiency in achieving sustainable quality and performance through the application of ergonomics?

By focusing on the research objectives, the study will seek to test the following hypothesis.

- H0: Ergonomics is positively related to the performance of a firm.

- H1: There is no correlation between ergonomics and the firm’s performance.

Significance of the study

Investigating the relationship between ergonomics and the firm’s performance will provide KEMYA’s management team with additional insight on how to achieve sustainable performance by leveraging on the concept of ergonomics. Thus, the study will lead to a remarkable decline in the firm’s understanding of the significance of the internal environment in the organisation. Subsequently, the firm will reduce its over-focus on the implementation of technology as the only strategy towards achieving competitive advantage.

Limitations of the study

The study is based on a survey on the application of human resource management practices at KEMYA. However, the study might be limited by resource constraints such as time and finances. The study intends to eliminate these limitations through the application of sampling technique and the integration of information communication technologies in conducting the study.

Literature review

The available literature on manufacturing reveals the existence of a strong link between ergonomics and quality. Ergonomics underscore the importance of establishing a fit between the work environment in a particular organisation and the human capital. The importance of establishing this fit is to promote the well-being of an organisation’s human capital.

Despite this recognition, Bloom, Kretschmer, and Reenen argue that organisations consider the link between employee and performance to be obvious (344). However, most firms are only concerned with improving the employees’ productivity as an avenue towards enhancing value such as by gaining high-profit returns. This approach might be counterproductive in an organisation’s quest to achieve sustainable performance.

Pierre and Adelaide affirm that establishing the requisite fit in an organisation’s performance stimulates high-performance amongst the workforce (3857). Subsequently, quality is improved. Bloom, Kretschmer, and Reenen argue that quality depends on human performance (347). Moreover, Bloom, Kretschmer, and Reenen emphasise that the concepts of quality and ergonomics are concerned with one outcome, which entails enhancing the efficiency of an organisation’s systems and the employees’ performance. The concepts of ergonomics and quality are based on similar practices and processes such as continuous improvement and employee participation.

Erdinc and Yeow affirm that whilst “good ergonomics leads to good quality performance, quality management systems like total quality management or ISO 9000 facilitate the improvement of ergonomics such as better working conditions” (950). Findings of a study conducted on the application of ergonomic and quality management amongst companies in Bursa, Turkey, showed that 88% of all the firms that have adopted the concept of total quality management experienced a remarkable improvement in their ergonomics. Additionally, the level of employee participation in the firm’s quality management system was enhanced substantially.

One of the approaches that firms should take into account in ensuring participation entails entrenching an effective communication plan. The communication plan should entail a two-way communication approach. Providing employees with an opportunity to share information on work-related issues would lead to the development of a strong degree of employee retention (Erdinc and Yeow 950).

The fundamental role of ergonomics in an organisation’s operation is to strengthen the working environment hence promoting high-performance amongst the workforce. Furthermore, quality deficiencies and human errors are reduced significantly. Some of the aspects of working conditions that ergonomics emphasises in promoting quality and efficient performance entail safety. For example, manufacturing firms should ensure that the workstations are well lit and free from other hazards that might affect the employees’ concentration in undertaking their job roles (Erdinc and Yeow 950). A survey conducted in a Swedish car assembly plant in 2005 showed that 66% of the quality deficiencies in the final product were due to ergonomically demanding tasks.

Studies on the role of ergonomics in improving the employees’ performance and quality have led to the development of diverse ergonomic interventions. Some of the ergonomic interventions proposed include training, installation of effective workstations, the formulation of operations manual to be used in instructing employees on the correct work method, and the installation of reminders on work posture in the workstations.

Erdinc and Vayvay affirm that ergonomics training should focus on equipping employees with knowledge on issues related to occupational health and safety (734). Conversely, Gorny supports the view that occupational health and safety is fundamental to achieving organisational success (1708). The working environment comprises one of the essential aspects of fostering occupational safety and health. The extent to which safety and health aspects are observed in the work environment influences the level of employee satisfaction.

Organisational managers have to examine the nature of the working condition within their respective firms. Therefore, a comprehensive ergonomic criterion should be adopted in assessing the prevailing working conditions. The criteria should focus on the anthropometric, physiological, psychosocial, and hygienic requirements (Stanton, Young, and Harvey 118). Anthropometric requirement entails examining the technical equipment used in the working process such as examining how the equipment promotes the adoption of a rational working position. On the other hand, physiological requirements involve ensuring that the technical tools are adapted effectively to the employees’ psychological needs such as optimum load on muscles, limbs, and joints. Concerning hygienic requirements, organisations should ensure that the work environment is adapted effectively to address human needs to prevent the environment from affecting the employees’ comfort adversely.

The work environment has a significant impact on the effectiveness and efficiency with which an organisation’s workforce undertakes the assigned roles and responsibilities. According to Bellagamba et al., the work environment can lead to a significant increase in the level of job strain and the employees’ levels of job-related stress (357). Bellagamba et al. add that work-related stress adversely affect the employees’ mental and physical stress (357).

The outcome is that an organisation might incur a significant financial cost due to the high rate of absenteeism, employee turnover, and a decline in the rate level of employee productivity and social climate. A study conducted to examine the financial cost of occupational stress on an organisation’s performance showed that the prevalence of occupation stress increases the incurred financial cost. In 2001, the US lost approximately US$ 42 billion while France lost US$14.81 billion in 2008. On the other hand, French firms lost between 2-3 billion Euros in 2007 (Bellagamba et al. 357). This aspect underlines the importance of developing an effective work environment.

In the process of leveraging on ergonomics as an approach towards improving quality, organisations’ management team must take into account the technical and managerial dimensions of ergonomics and quality. Despite the different studies conducted on the relationship between poor quality and ergonomic problems, the studies have failed to establish the magnitude to which ergonomics culminates in the reduction of quality defects.

Erdinc and Yeow posit, “A positive contribution of ergonomics to quality is proven in the labour-intensive manufacturing processes” (950). Due to the labour nature of the manufacturing industry, the probability of human error is substantially high. Moreover, the poor ergonomics increases the employees’ job strain and fatigue hence limiting their concentration. However, the application of ergonomics tends to increase the level of concentration. The importance of KEMYA’s management team developing a significant understanding of how it can leverage on ergonomics to deal with the high rate of employee turnover and human errors in the manufacturing process is critical.

Research methodology

This study intends to develop additional insight into the causes of the high rate of quality defects and employee turnover at KEMYA’s LDPE plant. To achieve the research purpose, the study will adopt the exploratory research approach. The rationale for adopting this design is to gather sufficient data on the subject hence increasing the likelihood of the study being conclusive. Jha corroborates that exploratory research design contributes to the development of critical insight on the research subject (106). Moreover, the research study will further be enhanced through the adoption of the concept of triangulation.

This goal will be achieved through the adoption of hybrid research design. Thus, qualitative and quantitative research design will be considered. The quantitative research design will aid in managing the voluminous qualitative data collected from the field.

Data collection

The research process will specifically target employees working in the different departments at the KEMYA’s LDPE plant. The rationale for targeting the firm’s employees is to gain sufficient understanding of the fundamental issues that are increasing their turnover intention and the high incidents of quality defects. For example, the inclusion of plant managers will enable the researcher to gather reliable insight into the nature of quality problems currently being encountered at the LDPE plant.

The research data will be gathered by surveying KEMYA’s employees. The decision to conduct a survey is to increase the likelihood of gathering adequate data regarding the research topic. Simple random sampling technique will be adopted in constructing the survey. This aspect will provide employees with equal chances of being included in the study. The data collection process will be actualised through the integration of a questionnaire as the core data collection process. A set of questions on the research topic will be designed and distributed to the research respondents.

The collected data will be effectively analysed and presented using descriptive and inferential statistics. Descriptive statistics will enable the researcher to condense the qualitative data (Marshall and Gerald 57). One of the tools that will be used in analysing the qualitative data entails the Likert scale (McNabb 45). Moreover, the integration of data analysis tools such as Microsoft Excel will enhance the data analysis and presentation process using graphs and tables.

Considering that the study involves human subjected, it will be ensured that the requisite ethical issues are considered. First, authorisation to conduct the study involving the KEMYA LDPE plant will be sought from the company’s management team. This goal will be achieved by explaining the purpose of the study hence eliminating suspicion. It will also be ensured that a high level of respect is observed in conducting the study. This goal will be attained by ensuring that the respondents are not coerced to participate in the study. On the contrary, the firm will ensure that the respondents are free to pull out of the research study without any consequences. Moreover, the researcher will obtain informed consent from the respondents by informing them of the risks and consequences of participating in the study. The respondents will further be informed of how confidentiality will be attained.

Research schedule

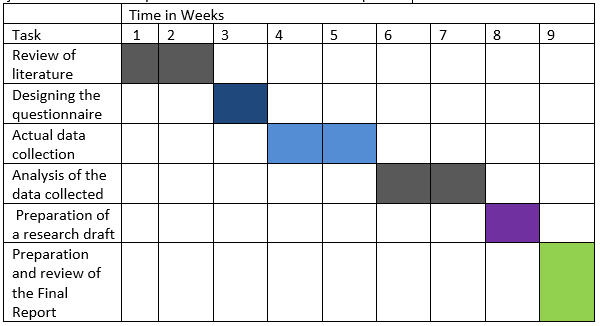

Approximately the research project will take about 14 months. The bar chart below shows the major tasks to be accomplished and the time of their completion.

Monitoring and evaluation

The research process will be evaluated progressively to determine whether it is aligned with the stipulated milestones. The monitoring and evaluation process will use the specified tasks in the research schedule as the milestones. One of the aspects that will be considered in evaluating the research data entails examining its validity. The different types of validity will be considered. This aspect will play a fundamental role in ensuring that the findings of the study are reliable in making decisions on ergonomics and quality in the workplace. Using the findings of the study, the value of the research in enhancing KEMYA’s capacity to address the quality and turnover challenges encountered will be remarkably improved. In summary, it is expected that the application of the proposed research approaches and techniques will lead to a significant improvement in the outcome of the study.

Works Cited

Bellagamba, Gauthier, Guillaume Gionta, Julie Senergue, Christine Bèque, and Marie Lehucher. “Organisational Factors Impacting Job Strain and Mental Quality Of Life in Emergency and Critical Care Units.” International Journal of Occupational Medicine and Environmental Health 28.2 (2011): 357-367. Print.

Bloom, Nick, Tobia Kretschmer, and John Reenen. “Are Family-Friendly Workplace Practices A Valuable Firm Resource.” Strategic Management Journal 32.1 (2011): 342-367. Print.

Erdinc, Oguzhan, and Ozalp Vayvay. “Quality Improvement through Ergonomics Methodology; Conceptual Framework and an Application.” International Journal of Productivity and Quality Management 3.3(2008): 311-326. Print.

Erdinc, Oguzhan, and Paul Yeow. “Proving External Validity Ergonomics and Quality Relationship through Review of Real World Case Studies.” International Journal of Production Research 49.4 (2011): 949-962. Print.

Gorny, Adam. “Ergonomics in the Formation of Work Condition Quality.” Work 41.7 (2008): 1708- 1711. Print.

Jha, Adam. Social Research Methods, New Delhi: McGraw-Hill Education, 2014. Print.

Marshall, Celten, and Rossman Gerald. Designing Qualitative Research, Thousand Oaks: Sage,2011. Print.

McNabb, Daniel. Research Methods for Political Science: Quantitative and Qualitative Methods, Armonk: M.E Sharpe, 2004. Print.

Pierre, Falzon, and Nascimento Adelaide. “Performance-Based Management And Quality of Work; an Empirical Assessment.” Supplement 41.6 (2012): 3855-60. Print.

Stanton, Neville, Mark Young, and Catherine Harvey. Guide to Methodology in Ergonomics: Designing for Human Use, Boca Raton: CRC Press, 2014. Print.