Introduction

This paper analyzes the case of the construction by Kiros Slonis SA of a small specialized hospital with 100 beds for patients with COVID-19. The project’s duration is strictly limited to six months due to the urgency required by the situation. The total budget of the project is 10 million euros. Detailed analysis and the construction of appropriate graphs and diagrams are necessary to visualize the project’s structure under consideration. Accordingly, tasks with time and budget constraints will be considered, but at the same time, high-quality, responsible implementation of each goal is required since the project is related to medical issues.

The paper presents the design stages, according to the scope model, namely the first three phases, up to the purchase of materials. Management will review the construction through various control systems that are no longer part of this report. However, the presented design will be pretty exhaustive, including the presentation of the WBS, Gantt diagram, budget discussion, and HR plan. In addition, the paper presents an analysis of the project’s main stakeholders. The order in which topics are reflected in the report is summarized: stakeholders, critical path, WBS, Gantt diagram, HR plan, and risks analysis. Below is a description of the principal terms used in the work and a brief description of these structures and analysis frameworks.

Stakeholder identification is essential for every project. First, this step is necessary to consider and adjust the requests’ tasks and correctly form a budget and time frame to fully meet the customer’s requirements (Heagney, 2011). In this case, a project planning framework is often integrated with SMART goals, contributing to a better understanding of the tasks and their specifics in their achievability (Wells & Kloppenborg, 2018).

Then, a critical path graph is built to determine the longest task chain to correctly estimate the scope and timing of implementation (Lock, 2014). The hierarchical structure of work facilitates visibility in the process of differentiation and classification of tasks to determine the possibility of conducting, for example, parallel works to reduce time or understand the overall scope through decomposition (Mishra, 2015). The Gantt chart is the most commonly used and proven technique, reflecting the problem-solving period (Kumar, 2005). These frameworks provide a comprehensive project assessment to minimize risks through planning during the implementation phase.

The specificity of the work performed in the individual components is carried out with the help of resource analysis. It usually requires developing an HR plan and allocating a budget. This step is critical if there are certain restrictions on the selected items for various reasons. If the above methods, such as the Gantt chart and critical path, are aimed at assessing the time frame for achievement, then the basics of specific planning can reduce risks for other resources. This project is limited in time and budget; therefore, there are limits in the involved human resources. Therefore, to exclude the possibility of a delay in implementation, which in this respect is critical and burdened by social responsibility requirements, this complete and multi-criteria assessment is mandatory.

Project Development

To construct a hospital, it is necessary to divide the project into several key stages, according to which planning will develop. The first stage will include earthworks, geological studies of soil, soil, assessment of the stability of the foundation, and the creation of an architectural plan. The second requires expertise to calculate the quality and safe construction of pile, wall, and roof structures.

The third step reflects the engineering activities for planning heating, water supply, ventilation, fire infrastructure, sewerage, landscaping, and electricity. The fourth stage is financial and involves calculating estimates for equipment purchase and constructing an HR plan to understand the required human resources. Finally, the fifth stage includes quality control on labor protection and the life safety of workers and future employees with patients. After the completion of construction work, the stage of filling the hospital with appropriate equipment and furniture is underway to comfortably perform the operational functions of future employees and accommodate patients with appropriate safety conditions for COVID-19.

The following persons represent the project stakeholders. Firstly, these are customers represented by the local government; therefore, it is necessary to consider all sorts of legal factors that affect the work and are prescribed in the contract. Secondly, construction workers and sellers of building materials are often employees of Kiros Slonis SA. Thirdly, future hospital staff and patients will be accommodated in 100 beds for quality treatment.

The interest of the first group is focused on meeting the global social mission to reduce the incidence and availability of quality services in the designated suburb (Wang et al., 2021). Better conditions for labor protection and remuneration should accompany the second group. Finally, medical professionals should have comfortable, safe, and high-quality rooms to perform their operational functions, and patients should receive COVID-19 treatment services comfortably.

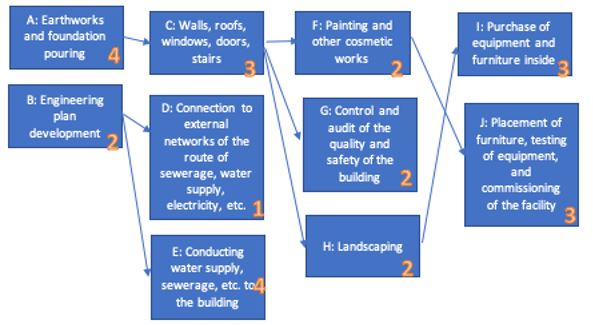

Design work is differentiated into ten main steps for the implementation of requirements. For a clear understanding of the time frame, a critical path analysis was carried out: it is worth noting that each step is performed after the completion of the previous one; however, some states require additional time to attract appropriate resources, search for suppliers, and other organizational issues. Accordingly, in this analysis, only critical links in the project development are indicated, according to the table stated in the task. The diagrams were constructed using Microsoft Word and ProjectLibre. Figure 1 shows an analysis of the critical path of an object.

According to this analysis in Figure 1, it can be seen that the longest path is A-C-F-J, which reflects the main construction work and placement of equipment up to the commissioning of the facility, which is 12 weeks. The engineering branch includes a six-week journey, while the quality control audit and landscaping take up a smaller amount. This segregation allows starting development of the various steps of the project immediately after completing the critical process along the arrows, but the actual implementation of the plan will still be approximately 26 weeks. Such an approach allows unforeseen risks to be considered in advance during the work process and their consequences to be mitigated due to the free time of the relevant experts and workers (Okpala, Nnaji, and Karakhan, 2020). A more detailed time view is reflected in the Gantt chart shown in Figure 2.

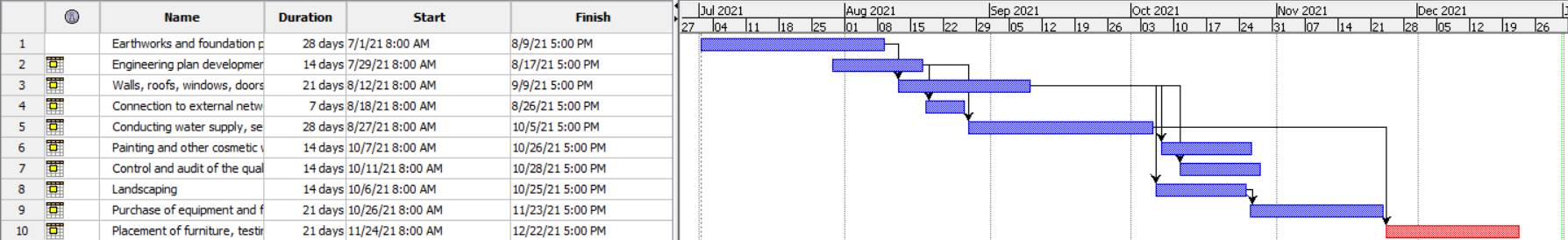

This diagram shows that some of the work is carried out in parallel with others. These changes are necessary to comply with labor protection requirements for a classic working day of 8 hours. Therefore, to complete work that takes, for example, 28 days, it is necessary to consider the days off for employees and expand the possible range of dates for implementation. According to the predecessors developed in the critical path analysis, the work can be completed by December 22, corresponding to the stated deadlines. The extra nine days that remain in reserve are an option in case of unforeseen circumstances. Similar stock gaps are left after almost every stage of the hospital’s construction.

A sufficiently large period has been allocated for land work, and it is no coincidence that a margin of time has been left for the transition to engineering planning, which will include constructing sewerage schemes, water supply, fire safety, and other facilities. The construction itself, including the construction of walls, roofs, windows, and door openings, begins on a poured foundation at the final stage of creating an engineering plan. At this stage, as a rule, approval, and coordination of documentation with experts take place; therefore, to save time, construction begins earlier since a certain period remains until the moment of these amenities.

In parallel with the construction, the approval and routing of engineering networks are coordinated with the local authorized state suburban companies responsible for electricity, water supply, and much more. At the time of the construction of the building frame, carrying out these amenities begins to identify possible pitfalls against the background of the approved architectural plan and make urgent changes to the process if necessary. Plumbing, electrical, and other work will continue without parallel tasks so that workers such as painters do not interfere with the activities of engineers.

Then, the cosmetic work begins with plastering the walls, painting, and providing the interior with doors, windows, and other facilities. Here, it is already possible to simultaneously launch quality control of construction, engineering networks, and landscaping of the territory, which will no longer be filled with various construction equipment. As these tasks are implemented, it is possible to move to the purchase of medical equipment and furniture, the placement of which is the final stage and ends with the commissioning of the facility. Preparatory procurement work can be started in parallel with the three processes going before it by searching for suppliers, planning budget estimates, and agreeing with the customer on relevant issues related to medical specifics.

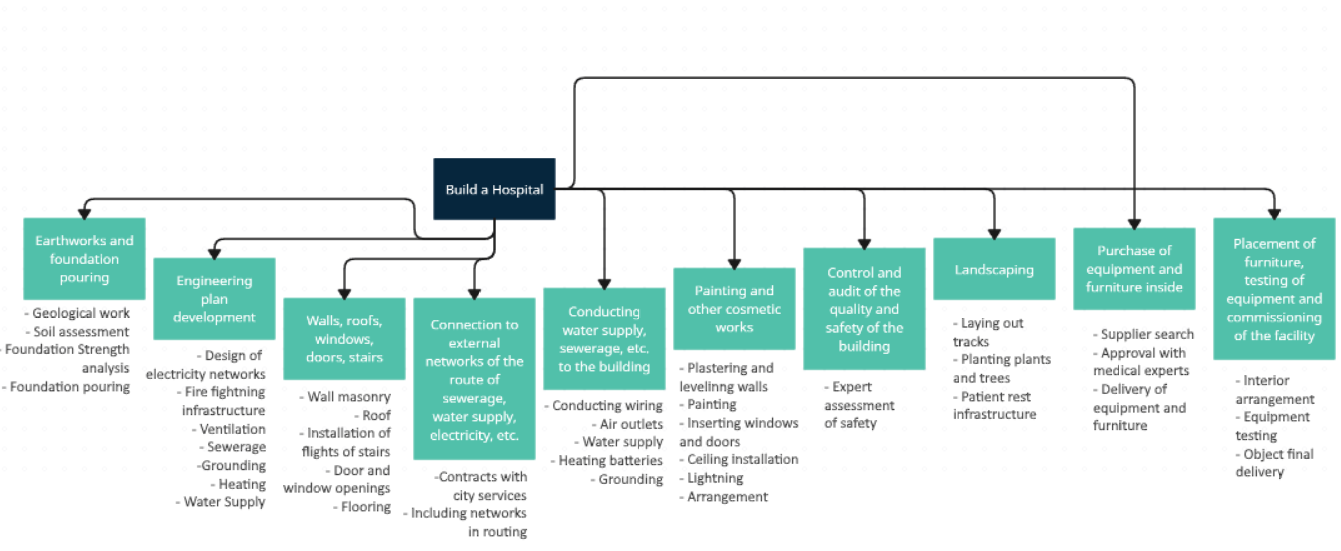

Work breakdown structure is necessary to decompose tasks according to the time frame analysis. Figure 3 shows the main points of the classification of each central process, which will be further analyzed for the availability of human and financial resources and potential risks. As a consequence of this generalized diagram, there is a clearer understanding of each process, making it easier to find potential delays to mitigate the effects of problems subject to compliance with the requirements.

This structure reflects the differentiation of tasks: engineering work includes several important amenities necessary for patients’ comfortable accommodation and specialists’ work. Many of these issues are primarily related to the classical safety requirements of any building. Construction work reflects the main stages of the frame’s construction and further interior decoration. As a result, a comprehensive picture of project activities has been obtained, which will be further delegated to the appropriate responsible persons for each stage, from directors to the builder.

The analysis of costs and human resources is presented comprehensively since both sources are critical to achieving the result. The results are presented in Table 1 and reflect the required number of people and money for each of the identified ten project phases. The budget calculation is given at market prices and the average salaries of specialists following the WBS decomposition above.

In addition, operating expenses are included in the budget, which includes the cost of electricity and water supply during construction, the creation of temporary infrastructure of a pure nature for workers, all necessary aspects of creating a safe environment, and taxes. The number of employees is given in terms of workload and the need to complete each step on time. A special reserve fund has been created in the financial resources, which will be used in case of unforeseen expenses due to some external risks, which will be described below.

Table 1 – HR and Budget Plan.

As seen from Table 1, most of the budget will go directly to construction, engineering networks, and cosmetic work on interior decoration. This is because most human resources are involved in these stages – from 14 to 33% of the total project personnel- and these steps also include purchasing building materials. The only stage at which it is supposed to resort to outsourcing services is the independent quality control of the building, as well as the involvement of medical specialists for equipment testing and installation advice. Planning and design work is a small part of the budget, most of which is specialists’ salaries.

Several uncontrollable external factors can determine significant implementation risks despite constructing a comprehensive project assessment. First, macroeconomic indicators show broad dynamics during the pandemic (McKibbin & Fernando, 2021). Due to inflation or changes in the exchange rate, building materials can significantly rise in price, for which a reserve fund was created that does not participate as resources in any of the stages.

Secondly, there are risks of the human factor: the write-off of damaged materials and errors that lead to injuries to builders or deaths. The budget for this case includes the insurance cost for each employee, which meets the labor protection requirements, and a 10% markup on the cost of building materials due to potential marriage or damage during operations. Finally, the risks of weather conditions and insurmountable environmental factors that impede construction can be mitigated by the existing nine-day temporary airbag, which will allow, if one of the stages is delayed completed construction on time.

Conclusion

As a result of the project development of a hospital for patients with COVID-19 for 100 beds, an approximate but comprehensive assessment of the construction implementation was obtained. The division into stages allowed for multiple decompositions of individual heterogeneous project processes from planning to delivery. The development considers all the security measures prescribed by law and optimization methods implemented in this work.

As a result, it was found that with the chosen project planning method, nine days are left in case of the risks indicated above. In addition, the budget was also used to form a particular fund in case of unforeseen circumstances that may arise during the project’s implementation phase. External factors primarily determine risks since Kiros Slonis SA’s rich experience virtually eliminates internal errors through a well-thought-out planning approach.

The introduction of critical path analysis made it possible to estimate the longest chain of events that must be completed within the project. The resulting value of 12 weeks is optimal and has a sufficient margin for the above Gantt chart. This framework, in turn, was compiled based on the need to coordinate some aspects of similar activities and deliberately separate some events from each other to account for potential error factors.

The work breakdown structure showed the main stages of each central process. A similar decomposition approach defined the scope of activities, allowing for a comprehensive budget analysis and the HR plan evaluation. This analysis revealed the most expensive stages of the project, as well as the total number of employees and specialists – 130 people, four of whom are involved based on outsourcing.

Given the risk assessment, the management of this project has certain limitations, as described in the part above. First, external factors can have a complex impact on each source of resources for implementation. Secondly, the study of individual tasks is now the delegated responsibility of specialists, as it requires appropriate knowledge, for example, in the geology field or the building materials market. Such work requires further implementation of the opinion of experts, coordination with the board of directors, and presentation to the customer in the form of a roadmap. The implemented SmartArt visualization tools in the Microsoft Word environment contribute to a better understanding and presentation of the frameworks, and the special ProjectLibre software made it possible to build a Gantt chart and visually optimize the given tasks.

As a result, despite many limitations, this work can be used as a starting point for launching a project to save time due to tight deadlines. Potential weaknesses should be eliminated thanks to the work of experts, which is supported by an additional reserve fund in finance and nine days in time. Management must put appropriate control systems in place to keep track of unforeseen circumstances promptly and deliver the project on time without delays that are not possible by convention.

Reference List

Heagney, J. (2011). Fundamentals of Project Management. New York, USA: AMACOM.

Kumar, P.P. (2005) ‘Effective use of Gantt chart for managing large scale projects’, Cost Engineering, 47(7), p. 14.

Lock, D. (2014). The Essentials of Project Management. New York, USA: Taylor & Francis.

McKibbin, W., and Fernando, R. (2021) ‘The global macroeconomic impacts of COVID-19: Seven scenarios’, Asian Economic Papers, 20(2), pp. 1-30.

Mishra, R.C. (2015). Modern Project Management. New Delhi, India: New Age International Ltd.

Okpala, I., Nnaji, C., and Karakhan, A. A. (2020) ‘Utilizing emerging technologies for construction safety risk mitigation’, Practice Periodical on Structural Design and Construction, 25(2), p. 04020002.

Wang, W., et al. (2021) ‘How the COVID-19 outbreak affected organizational citizenship behavior in emergency construction megaprojects: Case study from two emergency hospital projects in Wuhan, China’, Journal of Management in Engineering, 37(3), p. 04021008.

Wells, K. and Kloppenborg, T. (2018). Project Management Essentials, Second Edition. New York, USA: Business Expert.