Introduction

Technology is redefining the approach that manufacturers take to run various activities. One of the main areas of manufacturing that has been redefined by the emerging technologies is in warehousing. Firms are moving away from the manually-managed warehouses to automated warehouses because of the need for efficiency and reliability. In this project, ABC Manufacturing Company is planning to put up a new warehouse that uses Automated Storage and Retrieval System (AS/RS).

The company realised that it was losing a lot of time and resources using the manually controlled warehouses. In most of the cases the firm would be forced to purchase raw materials that were still available in the warehouses because of poor management. The current warehouse requires numerous employees to manage and operate, besides being inefficient. The planned automated warehouse will be easy to operate because it will be computerised.

Once the materials are delivered into the warehouse and their data captured in the system, all other activities will be carried automatically. The budget for this project is capped at USD 10 million and with a time limit of 12 months. In this paper, the researcher will look at the specific project management activities that will be needed to ensure that it is a success.

Project Management

Managing a successful project requires an understanding of the activities that should be undertaken, the timeline awarded to the project, and the budget within which the project must be undertaken. According to Smith (2013), projects can only be successful if they are carefully planned for and executed by a team of experts who understand what is expected of them. In this project, it will be important to ensure that the automated warehouse that is to be constructed meets all the basic criteria set out by the management unit of ABC Manufacturing Company. Based on the guidelines given in the Project Management Body of Knowledge (PMBOK), the following are the main sections that will be followed in planning for and executing this plan.

Project Conception

Project conception is the primary foundation of any project. It is the stage where a firm identifies a need that should be fulfilled based on the current internal and external environmental forces. ABC Manufacturing Company has already identified the need. The firm needs an automated warehouse that is more efficient than what it is currently using. After identifying the primary reason for undertaking the project, the next step is to evaluate the project’s needs.

The project manager must clearly indicate the resources needed for the project to be successful. Developing project charter helps in giving the project a sense of direction. It defines what the project shall achieve and how it shall achieve it within a given period. The project manager will then be expected to make a submission of project charter to the top management unit of the ABC Manufacturing Company.

The top managers are responsible for making approval of the mega expenses such as the one that will be needed in this project. As such, they need to be convinced that the project is viable to make them approve the project. As such, the project charter must be as convincing and clear as possible to eliminate any doubts in the minds of these top managers. Review of the project charter by the top managers who are expected to be the sponsors of the project will take place.

The sponsors will weigh the benefits against the cost, the timeline for the project, and any other relevant issue that can help them make a decision on whether to approve the project or not. Approval of the project charter is the last stage of project inception. At this stage, the sponsors give their approval after a thorough review of the project charter. They will be confirming their willingness to support the project financially or otherwise till the project comes to its closure. It is this approval that will make it possible for the project manager and the team to move to the next stage of project definition and planning as discussed in the section below.

Project Definition and Planning

According to Lester (2013), project definition and planning is the most important stage of project management. When a project is planned for properly and all the deliverables defined, then it becomes easy to execute it. Defining the project scope is the first stage that should be conducted with precision. In this project, ABC Manufacturing Company intends to put up a modern warehouse that is automated.

The project will involve construction of the warehouse and installation of all the necessary components that will automate it. Maintenance and related activities are outside the scope of this project. After defining the scope of the project, the next step is the identification of the project’s team members. Different projects require different skills and knowledge based on their nature. In this project, it will be necessary to have two teams that will work closely together to ensure that this project is successful.

The first team will be the construction experts such as the architects, engineers, and masons who will be directly responsible for the construction of the warehouse. This team will work closely with the second team of IT experts responsible for installing the system. These two teams must work together from the initial stage of drawing the plan for the warehouse. The project manager will be in charge of controlling both teams and ensuring that the activities are properly coordinated (Goodpasture, 2010).

After defining the project’s scope and identifying the members who will be actively involved in the execution, the project manager and his team will then focus on the implementation of the project plan. According to Goodpasture (2010), this is one of the most challenging stages of project management. The project manager will develop a blueprint that will be used in executing the project (Lester, 2013). The blueprint must be realistic, actionable, specific, measurable, and convincing to the approving authority.

A project charter may get an approval, but if the plan fails to convince the relevant authorities, it may be rejected at this stage even if the scope and project members have been defined and identified. At this stage, the primary aim is to come up with main activities that will be undertaken by the project members to ensure that ABC Manufacturing Company has an automated warehouse that meets the criteria set in the project charter. At this planning stage, it is necessary to clearly define the project deliverables and their relevance in ensuring that this project is a success. The table below shows an outline of the main milestones and project deliverables.

Table 1: Milestones and deliverables of the project.

The proposed budget

According to Lester (2013), one of the major tasks when developing a project plan is to draw a budget that will be used in the implementation process. The budget must be realistic to convince the sponsors. It must also cover all the costs, taking into consideration that issues such as inflation or other risks may occur that may inflate the prices of the items needed in the project. In the budgeting section of the project plan, it is necessary to provide a summary of the approximated expenses that will make it possible to meet the set goals of ABC Manufacturing Company as specified in the project charter.

It is important to note that the budget is a preliminary one and that it may be necessary to make adjustments in case issues such as inflation or cost of labour go up at the time of the implementation. The budget is defined based on the current financial market forces, and in case the external environmental factors (especially the financial environment) remains unchanged, then it may not be necessary to make any adjustments. As mentioned before, this project should not be more than USD 10 million.

Table 2: The proposed budget.

As shown in the table above, this project is expected to cost USD 3,010,500 if the current inflation rate is not affected. The value is determined based on the current wage rates and cost of the materials in the market. It is important to understand that ABC Company is a for-profit organisation that competes with other manufacturing firms in the market. In every project that it undertakes, the primary aim is always to achieve financial benefits that will not only reward its owners but also help it achieve growth in the market.

The project must either help in cutting costs of operation or in increasing its profitability. This project is specifically focused on reducing the cost of operation. Inasmuch as the initial investment is relatively high, the expected returns outweigh the costs.

According to Haughey (2013), when developing a project plan, it is often important to clearly define the activities involved in a work breakdown structure. The structure helps in identifying the sequence of activities for ease of monitoring them. When the structure is clearly defined, then supervision becomes easy. As Lester (2013) notes, a work breakdown structure may be given in form of a flowchart or in a systematic tabular form. The table below shows the work breakdown structure provided in a tabular form identifying the individual activities that will be undertaken.

Table 3: Work Breakdown Structure.

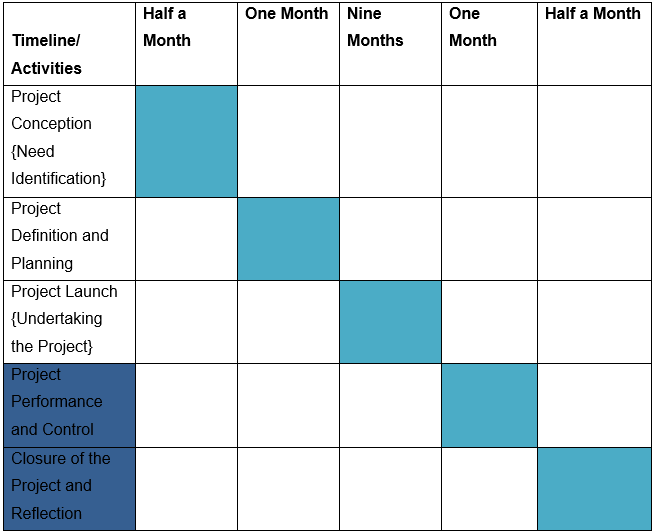

The activities shown in the work breakdown table above are expected to last for about 12 months from the time of initiation to the time of the closure. The Gantt chart below identifies the activities and the time within which they are expected to be completed.

Likely risks of delays

It is important to be very realistic when developing a project plan both in terms of resources and time allocations. The Gantt chart above has clearly defined the timeframe within which this project should be completed. However, issues may arise that may cause unperceived delays. Hindsight may help predict the possible causes of delays. For instance, past cases of failure of the sponsors to give the needed resources in time may cause the delay.

The project manager must take into consideration that other past problems such as employees’ strike may also occur when undertaking this project and that is another potential factor that may cause delays. Natural factors such as excessive rains that were not expected, tornadoes, earthquakes or other related destructive forces may cause delays in the project. Contemporaneous factors such as the need to expand to overseas markets may also divert the attention of the firm from the project. For instance, the management may deliberately decide to delay the project so that it can spare enough resources for its expansion to new international markets.

The project manager should also have a foresight of the possible factors that may cause delays. A possible factor that may affect this project within the period of implementation is change in technology. Portny (2013) says that technology keeps changing and it forces firms to keep up with these changes so that they can remain relevant in the market. As at now, the plan is to construct an upgraded warehouse using Automated Storage and Retrieval System (AS/RS) technology.

However, it is possible that a new better system may arise and it may force the members to switch from the planned system to the new system. It is the expectation of all the stakeholders that none of the risk factors that may bring about delays will occur. In case of their occurrences, then it may not be possible to complete the project within the initially planned timeline.

Submission of the Project Plan

After preparing such a detailed plan, the project manager and his team members will compile the report and submit it to the top management unit of ABC Company. The project members will wait for the response from the approving authority. They should be ready to adjust the document in case the top management makes such suggestions. The official launch of the project is not expected to take place until such a time that the top managers and the shareholders, who will be the sponsors of the project, give their approval.

Approval of the Plan

In the plan given above, it is very clear to the top managers of ABC Company what to expect from the project in terms of expenses, time of completion, and some of the risk factors that may occur when undertaking the project. It will be their responsibility to critically evaluate the plan and ask any relevant questions about the plan. The management can make recommendations about the possible changes needed at any of the stages specified. It can also recommend the adjustment of the schedule or budget. If it is convinced with the plan, then it will be expected to make an approval and prepare for the launch.

Project Launch

This is the most important stage after project planning. It entails putting into practice the blueprint that had been developed and ensuring that all the planned activities are undertaken as per the schedule and using the assigned resources. Commencement of project team meetings is the first activity that takes place during the launch. All the team members, led by the project manager, will organise a meeting to review the proposed activities and the time allocations.

During the first meeting, the team involved in the construction and that involved in the installation of the automated warehousing system will discuss the design of the warehouse. They will have to reach an understanding on issues such as the vertical and horizontal space of the warehouse, the entrance and exit, the floor plan, among other activities. This will ensure that the warehouse is suitable for the new system that will be installed.

Determination of all the requirements for users is the nest stage during the launch of the project. The project manager and the team members can help fight the problem of inflation by purchasing most of the highly involving tools and equipment early enough so that the project does not get adversely affected in case of an inflation. The contractor responsible for the construction of the warehouse will need to define all the resources required at this stage (Heldman, 2011).

The head of IT responsible for the installation of the new automated system must also define the needed resources for the project. When the materials have been defined, the team will then procure these materials, hardware and software. Heldman (2011) says that sometimes it may force the team to purchase most of the items in bulk, especially the construction materials. However, this can only happen if there is space for storage within the firm and if the management releases the funds in time.

Commencement of the warehouse construction will then begin- a process which is expected to take about seven months. The warehouse must be designed to meet the specified needs of ABC Company in terms of size, spacing, shape, among other factors. The construction process will be closely supervised by the project manager and the top officials of the company. The team of IT experts will be expected to be around to ensure that the house plan is compatible with the system that will be installed.

Installation of the hardware and software to automate the system will be undertaken by the IT experts. They will ensure that the warehouse can be easily controlled using a computerised system. The team will then test the system to ensure that it works as planned. It may be necessary to make adjustments based on the unique needs of the ABC Company. The team will address any shortcomings to ensure that the entire system functions properly. The process of training the users will then begin. The team will be expected to initiate the use of the warehouse after the training.

Project Performance and Control

Project performance and control is conducted once the warehouse has been put into active use. The project manager and his team will determine the initial performance of the warehouse to determine if it is in line with the expectations of the firm. The warehouse is expected to be more efficient, and it should be operated by reduced number of employees. The project manager and the top management unit will conduct scope verification. This involves determining whether the new premise meets the specifications as defined in the project charter. Berkun (2008) notes that a project that was thoroughly supervised at all the stages of its development may rarely fail to meet the expected objectives.

The management of the firm will then be expected to work closely with the project members to identify and manage risks. Risk such as data theft or interference are real when this firm embraces the new concept of Automated Storage and Retrieval System (AS/RS) where data is shared using various computer systems. Other risks such as physical damage of the system should also be put into proper control. The project members may be requested to make relevant changes in the system in line with the identified risks to make it easy for the employees of ABC Company to control them with ease.

Project Closeout

As per the guidelines of Project Management Body of Knowledge (PMBOK), the last stage of project management is project closure. This happens when the team is fully satisfied that the activities defined in the project plan have been successfully completed as per the desire of the client. The project manager and his team will need to assess the project outcome and make relevant reports to the top managers of ABC Company. In this assessment, the team will compare the outcome and the project objectives as defined in the project charter. The detailed assessment will help the team determine if their process was a success or not. Success is determined by a number of factors.

The main determinant of success is to know whether the outcome of the project is exactly what was expected. Meeting or exceeding the expectation is considered a success. The second approach is to determine the budget that was used to complete the project. If the expenses were within the set budget, then such a project will be considered successful. Projects completed within the set timeline are also considered successful.

The top management may then consider making the necessary rewards in line with the agreements. The rewards may be meant to motivate the participants or to pay them for their work if they were contracted to take part in the project. All the stakeholders will be expected to draw specific lessons from this project that will inform the approach taken to handle future projects. The project will finally be brought to a close after all the issues have been addressed. ABC Company will be handed over the responsibility of managing the automated warehouse.

Conclusion

Companies all over the world are currently using project management approach when they plan to make major changes in their operations. ABC Manufacturing Company initiated a project of constructing and equipping an automated warehouse to meet its current needs. The current manual warehouse is no longer giving the service expected of it and as such, it is necessary to come up with this new system. Project Management Body of Knowledge (PMBOK) provides a detailed guide that this firm should follow to ensure that it achieves success when undertaking this project.

References

Berkun, S. (2008). Making Things Happen: Mastering Project Management. Melbourne, Australia: O’Reilly Media.

Goodpasture, J. (2010). Project Management the Agile Way: Making It Work in the Enterprise. New York, NY: Ross Publishers.

Haughey, D. (2013). Project Management Body of Knowledge (PMBOK).

Heldman, K. (2011). Project Management Jumpstart. Hoboken, NJ: Wiley.

Lester, A. (2013). Project Management: Managing Engineering, Construction and Manufacturing Projects to PMI, APM and BSI Standards. Oxford, UK: Butterworth-Heinemann.

Portny, S. (2013). Project Management for Dummies. Hoboken, NJ: John Wiley & Sons.

Smith, K. (2013). A guide to the project management body of knowledge (PMBOK guide). London, UK: Project Management Institute.