Project Life Cycles

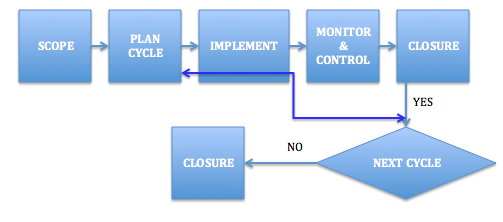

Adaptive Project Life cycle model

If the functionality of a project was not vividly defined at the beginning, then this is the best model to use (Meredith & Mantel, 2011). It assists in solving the problems or fixing the mess caused by missed functionality. An example of a project that this model can be applied to is an emergency rescue mission that lasts between 2-4 weeks.

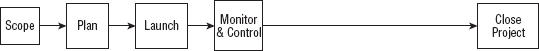

Linear

This type of project life cycle relies on the conventional project management approach. This is the simplest type of project life cycle model that can be used.

It is also considered to be the most intuitive among the different types of project life cycles. In a linear model, perfect information exists regarding the objectives of a project (Meredith & Mantel, 2011). It is also possible to obtain the required solution as quickly as possible. This type of project management life cycle does not accept deviations. When any form of deviation is used in this type of project life cycle, it might lead to serious interruptions of the project schedule (Kerzner, 2013). The scope change request is one of the deviations that cannot be permitted when applying the linear model. The chart below shows the process group level detailing how the above project life cycle works.

This model should be used when carrying out projects that do not require changes or deviations once they are started. An example of a project that can use this model is constructing a story building.

Incremental

Although this type of project life cycle bears several similarities to the linear model, it offers solutions once a project has come to an end. This model is best used in construction projects that go in phases (Meredith & Mantel, 2011). Once a particular phase has been completed, an incremental model can be used to offer the much-needed solution of the moment. An example of a project that can use this model is road construction.

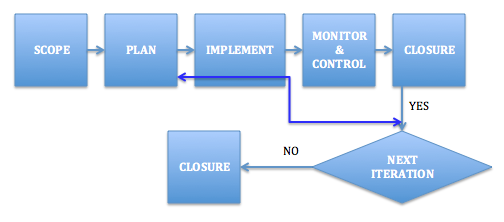

Iterative Project Life Cycle

This model is well utilized when a working solution is required in each of the delivered iterations. In other words, a solution that is not complete yet is dispatched to the customer and thereafter, the response or personal take is requested especially if they feel some changes are required (Meredith & Mantel, 2011). A client who might require some changes to a project is then allowed to offer his or her feedback. Large construction works such as building roads or bridges can use this type of project life cycle (Kerzner, 2013). Should there be any additions or changes to be made, they are incorporated into the prototype as shown below:

Extreme

Research and Development projects can best utilize the extreme type of project life cycle (Meredith & Mantel, 2011). A case example is a research activity into a vaccine that can prevent the transmission of Tuberculosis from one person to another (Kerzner, 2013). A client is greatly involved during the entire project. It is vital to mention that this model is applied when the anticipated objectives and workable solutions are well known.

Schedule Delay Analysis Techniques in Industry & Research

Abstract

Delay in both research and industry projects is a worldwide aspect that can hardly be avoided at times. Whenever delays happen, delay analysis methods are sought by the contracted parties in order to find out the party responsible and the measures that can be put in place to fast-track the project. In research and construction industries, delay analysis methods can be used to solve emerging issues between or among parties that have entered into legally binding contracts.

These methods have unique requirements and capabilities. As a result, they might constrain their application in either the research or construction industries. This paper seeks to explore and analytically discuss schedule delay analysis methods introduced in industry and research. In order to avoid project delays in research and industry, it is vital for project partakers to develop a comprehensive work-plan that can be monitored and followed to the end of the project.

Introduction

Various reasons often cause delays in the construction of projects. Regardless of the reason, any form of delay may lead to massive financial loss and negatively impact the financial projects at hand. In the event of a delay, the contesting party may file a delay claim. When it comes to making claims, it is crucial to mention that it may take a very long and complicated legal process especially when the cause of the delay and impacts are put into consideration.

The claim analysis usually requires an experienced professional who has a vast knowledge of handling such cases (AbouRizk, 2010). The expert should also be in a position to carry out analysis, a sound methodology for the claim process, and understand various means and methods on how to approach the case at hand. It implies the original construction documents, terms, and condition of the project and any other arising issues should be comprehensively studied (Yang & Kao, 2012). All these considerations cannot be put into consideration without assessing various delay analysis methods. The paper offers an in-depth discussion and analysis of delay analysis methods.

Literature Review

How can project delays be avoided? This section of the paper will first evaluate some of the causes of delay. It is common to have the following problems:

- Change in the original specification,

- Team Change

- Estimation errors

- Time allocated for the project and

- Lack of resources.

The above problems are common, but let us assume for a moment an ideal project, in which none of these problems exist. Can such a project be immune to delay? Not necessarily, because although there is still a factor that may not have been mentioned namely planning and monitoring. For the purposes of this article, it is crucial to consider an ideal project without external factors and no specification errors, and accurate estimates (Yang & Kao, 2012).

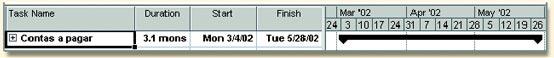

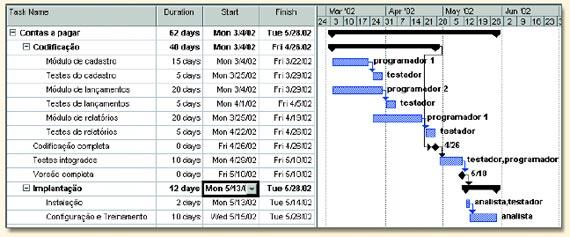

Let us begin by assuming a simple design of accounts payable. We have a period of three months, a registration module, module releases, and reports. Our team consists of a systems analyst, three programmers (1 for each module), and 1 tester.

How can we ensure that the project is under control and exactly takes the stipulated time? We need to manage this project. Therefore, it is necessary to have a clear view of what the project is and its overall nature. The first step is to create a work plan. This plan consists of the division of tasks among the available team members, as well as details of the tasks and time estimate for each sub-task. For example, the registration module can be divided into supplier registration, registration materials, and so on (AbouRizk, 2010).

Each of these subtasks has an estimated beginning and the end, as well as the tasks that depend on them (such as tests). Ideally, these subtasks have between 2-4 days. The basic principle is to divide and conquer the work or project at hand.

Thus, our 3-month project can be seen as several short tasks each taking 2-4 days. What is the advantage? It is much easier to manage because we can control the project progress. Each task generates some results, which may be a function implemented as a test done on a given document (Yang & Kao, 2012).

Any delay in the project will be quickly identified and appropriate measures can be taken to reduce or eliminate their impact. It is much better to find out that the project is only delayed at the end (Keane, Keane & Caletka, 2015).

Tools

When we talk about the work plan, it is inevitable to think of a schedule. And to create schedules a well-known tool can be Microsoft Project. The Project offers several features such as:

- Simple and quick editing, allowing the user to quickly test various scenarios;

- Definition of milestones in time (see complete coding milestone in Figure 2);

- Definition of the team and assigning tasks, with identification of allocation;

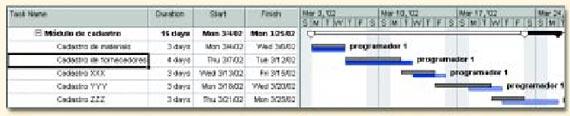

- Break a task into subtasks (see Figure 3);

- Compare performed vs. planned tasks (see Figure 4).

For example, in Figure 4, we present one of the visions of the Project showing the progress of the project in the second week. The dark blue bars show complete tasks. The sections in light-blue show the tasks or parts of tasks to be done.

The gray bars show the initial planning. Note that the register of suppliers, scheduled for three days, ended up taking four days, generating a 1-day delay in all subsequent tasks. With this information, another programmer can relocate to one of the overdue tasks and thereby eliminate the delay.

The schedule is an important and powerful tool, but it must be used properly. It is not just enough to create a schedule at the beginning of the project and forget it. It is necessary to monitor the project and adjust the schedule according to the unexpected (Yang & Kao, 2012). Therefore, one of the team members should have the responsibility for this task, in general, the team leader.

Managing the Schedule

Apart from a comprehensive work-plan, schedule management is another vital process of avoiding project delays (AbouRizk, 2010). The process of controlling the schedule is to ensure that it is in accordance with what was planned and within the acceptable limits as defined in the schedule baseline. It also ensures that the changes made in the schedule during project execution are met at the appropriate time. However, the above cannot be fully executed without systematic process entries and a well-developed project management plan. The latter plan is contained in the schedule management plan. The baseline project schedule contains all the information about what was planned in relation to the schedule that is extremely important so that it can be possible to control the project at any point of development.

In addition, the project schedule should be updated as activities that are being completed with information about the progress and/ or phases, the status of activities. Based on this information, it is possible to check the progress of the project whether it is in line with the planned schedule and if the schedule will be fulfilled by each activity, phase, and the project as a whole (Yang & Kao, 2012).

Project Performance Information

Any other information about project performance beyond those that have been properly included in the project schedule can also be used in the same way.

Organizational Process Assets

The organizational process assets that can influence the process of controlling the schedule are those related to procedures regarding the schedule control, schedule control tools, other project monitoring methods as well as any other asset that is related to the control schedule (AbouRizk, 2010).

The project performance analysis can be used to evaluate the project status at the time of analysis and therefore check on the progress of the project and measure the performance of the capacity schedule. Moreover, the analysis of variance is based on the baseline project schedule and performance indices. The measured schedules are compared with those planned and documented to verify that there is no possibility of the measured levels exceeding the acceptable limits.

Project management software can also be very useful in effective schedule management, especially software that has schedule graphical analysis (Gantt chart for example), as well as those that enable direct interaction with those responsible for each of the activities. Such software can greatly aid in the assessment of the schedule and performance upgrades of the same when conducting a research study (Yang & Kao, 2012).

When it is determined that activity will probably not be done within the allotted time and other activities that will probably use fewer resources have been identified than was planned, then these features can be transferred from one activity to another for a quick leveling of resources without the need for additional complex design reviews.

Scenario Analysis is usually used to review the data on the schedule based on different possible scenarios of events that relate to a particular activity or project phase. The most likely scenarios are checked in order to have a broad view of what can happen when performing these activities (Keane et al., 2015).

Prepayments and expected adjustments

The leads and lags previously planned for the project can relate to other activities, internal processes, or acquisition of a particular resource that may be performed before or after the expected completion of the task. If the latter happens, these leads and lags should be reviewed keenly (AbouRizk, 2010).

Schedule compression

If there is some delay or possibility of a delay in the schedule, the same compression techniques used during the planning phase can now be applied based on the new piece of information. At this point, it is fundamental to emphasize that nearly all construction projects are carried out after the concerned parties have signed contracts (Yang & Kao, 2012).

Research Objective

To explore, discuss, and critically analyze different schedule delay analysis techniques in both industry and research and determine how to delay projects can be avoided.

Schedule Delay Analysis in Industry

In order to carry out a successful delay analysis in the industry, it is crucial to peruse through the project papers and other vital documents. This might help in establishing the cause of schedule delay. The following are some of the schedule delay analysis methods.

Critical, Non-Critical Delays and Float

There are two types of activities that constitute a schedule. These include non-critical and critical. In the case of non-critical activities, there is usually adequate time allowance for any delay that may catch up with the project at hand. In other words, portions of the project can be delayed for a couple of days without necessarily affecting the rest of the entire project. A ten days float implies that the given operation may be delayed up to a period of ten days.

In the case of critical operations, no delays are allowed. The sequence of activities and duration are the two main factors that determine activities that are critical and those that are non-critical (Yang & Kao, 2012). In order to meet the two requirements, hi-tech research is necessary. In other words, the project documents should be keenly studied and analyzed. During the analysis, judgments and assumptions might be necessary.

Excusable and Non-Excusable Delays

When the contractor has no fault in as far as a project is not completed at the right timeframe, it is referred to as an excusable delay. Therefore, a contractor has the privilege to request a time extension. However, non-excusable delays are caused by the contractor’s mistake (AbouRizk, 2010). The contract’s terms of engagement should be revised accordingly when carrying out the analysis.

Delay analysis techniques include Impacted As-Planned method, Collapsed As-Built, Window Analysis method, As-Built method, Contemporaneous method, As-Planned vs. As-Built method

As-Planned vs. As-Built technique

The selected project operations are analyzed in terms of duration and date comparison. The analysis is based on the document carrying the project plan.

This technique presents one of the simplest and straightforward methods of delay analysis. Usually, the difference between the documented timeframe for completing a project and the actual progress on the ground gives the delay duration of the project (Yang & Kao, 2012). Although this delay analysis technique is very simple, it poses several limitations by ignoring aspects such as logic sequence, the effect of concurrent delays, timing, and cause of the delays.

Impacted As-Planned Method

This technique requires an analyst to add more time to the excusable delays owed to the contractor. The extended duration becomes the new project timeframe for the contractor (Hegazy, Said & Kassab, 2011). The revised completion timeframe is put into consideration by the analyst. The number of days available between the said dates is computed by the analyst. He finally sets a new date for completing the project. Nevertheless, this technique bears some limitations. For instance, it does not put into consideration the events on-site and real as-built schedule. Inexcusable delays are also not accounted for by this method (AbouRizk, 2010).

Schedule Delay Analysis in Research

Collapsed As-Built

The total sum of the excusable delays is subtracted from the as-built schedule. After carrying out this revision, an analyst is left with the as-built schedule (the collapsed) (Yang & Kao, 2012). The new completion date is then read from the latter measurement. Some of the inevitable errors in this technique include lack of analysis of concurrences, causes and delays, ignorance of sequence of operations, and incorporating non-existing cases in the whole analysis (Keane et al., 2015).

Window Analysis technique

The whole schedule is analyzed using the window analysis technique. Monthly ‘window’ durations are sued to subdivide the project schedule. In order to come up with the correct analysis, operations within the selected timeframe are chosen and activities revised accordingly (AbouRizk, 2010).

As-Built Method

When reliable schedules are not available, this analysis technique is used. Hence, it implies that another schedule has to be recreated by the analyst. It demands adequate experience (Yang & Kao, 2012). Worse still, there is a need to scrutinize several judgment calls.

Contemporaneous Method

The analysis of most delays may be carried out using this technique. Two elements are considered by the analyst when employing this method. First, site progress must be established. Second, the project schedule as documented is also studied carefully. Any variations are noted in terms of the delays and the expected completion date. Delay days are very important when conducting the analysis using this method because they assist in resetting the new completion date for the project (AbouRizk, 2010). This method, however, lacks a true reflection of the site’s progress owing to poor documentation. Besides, the schedule updates lack accuracy.

Conclusion

To sum up, it is prudent for an analyst to select the most suitable analytical technique to use since each case is unique and sensitive. While a particular method may be applicable in a certain case study, the same method may completely fail in another project scenario. In addition, the process of analyzing delayed claims should be done with due diligence so that no party is left aggrieved. From the above discussion, it is evident that each methodology has its own merits and demerits. In some instances, method selection may be determined by the available budget, document availability, and the existing timeframe.

References

AbouRizk, S. (2010). Role of Simulation in Construction Engineering and Management. Journal of Construction Engineering and Management, 136 (10), 1140-1153.

Hegazy, T., Said, M., & Kassab, M. (2011). Incorporating rework into construction schedule analysis. Automation in Construction, 20(8), 1051-1059.

Keane, J. U., Keane, P. J., & Caletka, A. F. (2015). Delay analysis in construction contracts. New York: John Wiley & Sons.

Kerzner, H. R. (2013). Project management: a systems approach to planning, scheduling, and controlling. New York: John Wiley & Sons.

Meredith, J. R., & Mantel, J.S, (2011). Project management: a managerial approach. Boston, M.A: John Wiley & Sons.

Yang, J. B., & Kao, C. K. (2012). Critical path effect based delay analysis method for construction projects. International Journal of Project Management, 30(3), 385- 397.