Introduction

Due to changes in the tastes and preferences of customers, most companies face intense pressure to develop new products and update the current products to meet the present needs in the market. Companies are fully aware that to compete in the market, they must conduct research and learn to address the challenges within the industry or sector they operate. Improving a product requires the companies to offer new features to the existing products, use new technologies, and improve the product’s appearance to boost its quality before it is launched in the market. Companies are always keen on using marketing analytics tools that are key in identifying and predicting the current and future needs of customers.

The rapid development of technology and the pace at which the consumer demands the advancement or improvement of the current products compel the manufacturers to ensure that their products remain at the cutting edge of technology. To achieve an optimum result, any company must ensure that its products are continuously redeveloped based on the client’s needs and advancements in technology. It is believed that most of the products being developed currently are redesigned based on other products with some redesign process intentional or unintentional replica of the existing products. Product redesign involves a systematic process that guides the work of the designer and the project development team from the initial stage, such as the problem identification process, to the final process, and this increases the chance of success.

Reverse engineering is an integral part of product improvement, and it involves the dismantling of a product to observe how each of the functions of its elements. In most cases, reverse engineering provides insight into how a product functions by analyzing the elements (Buonamic et al., 2018). It is frequently used by engineers and designers to duplicate or enhance a product. Various products can undergo the process of product reengineering, for instance, household items, military equipment, software, physical machines, and other biological functions such as gene operations (Buonamic et al., 2018). Regarding the technology being used, firms can use reverse engineering to revive obsolete objects and gain a competitive advantage over their competitors or teach their employees how the machines operate.

Reverse engineering is vital to companies and customers, and it helps to increase the quality of parts of an item. Most components of the products usually bought from a store are not always designed to the highest levels of quality. They sometimes break down easily and often require replacement. Reverse engineering enables people to customize ways to ensure they replace the broken components of the items and understand how they can improve the element to become sturdy. The reversed-engineered components of a product are always durable, making them less expensive in the long run than the parts purchased off the shelf. The process improves the efficiency of a product and provides a business opportunity for the designer as they become the source of cheap replacement spares.

Reverse engineering was used in this project to disassemble the household study desk and redesign it to form an adjustable desk. The target was to reduce the extra weight exhibited by the previous version to increase its portability. The initial table design did not consider the ergonometric aspects and was large; thus, it was unsuitable for the limited space.

Design and Development Adjustable Household Study Table

Table Component and Construction Process

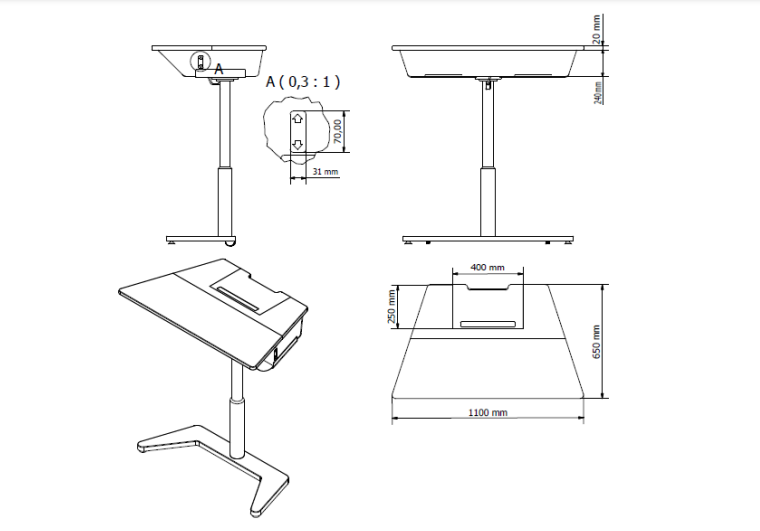

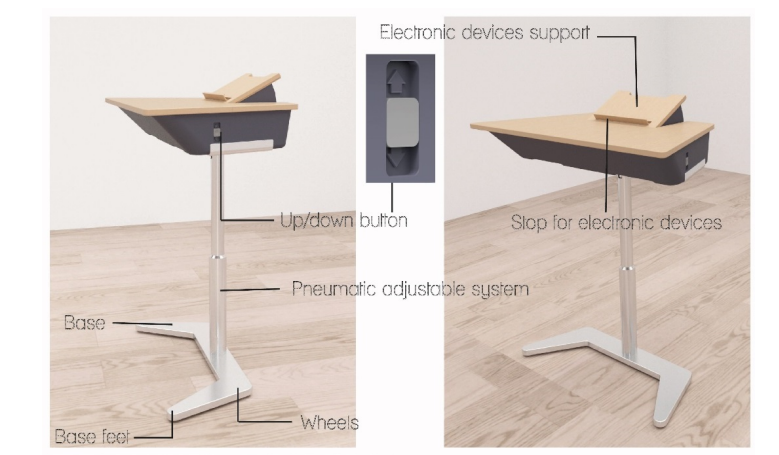

The newly redesigned table consists of the following parts: the adjustable parts, which comprise the gas lifting system at the bottom of the table. The gas lift element was placed at the bottom of the table, with support placed on the top to provide stability for the entire table. On top of the support is where the tabletop and the drawer are placed. The parts joining the tabletop and the support system of the table are made up of metal, and the joints are tightened using screws. The table support is fixed with a drawer that is trapezoidal. For the table used to adjust the table to fit their needs, the gas lift system is connected to a sliding button using a cable that passes through a hole specifically designed for its passage.

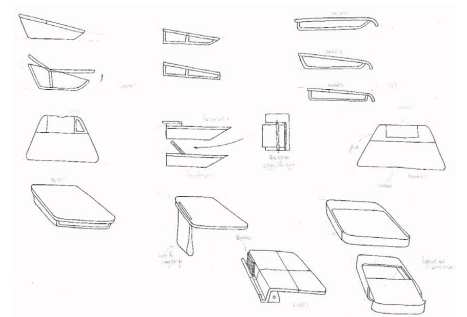

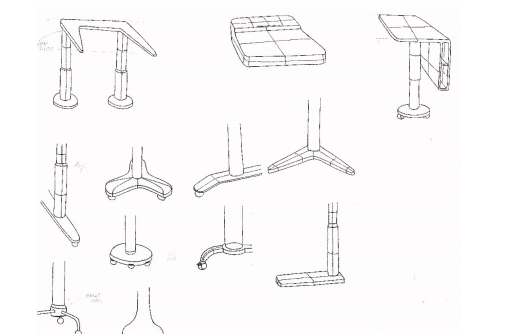

The drawer is another key component of the product; it allows the users of the products to ensure that their belongings are safely kept. It is part of the tabletop, and it is attached to the tabletop using screws and support made of metal. The top of the table is made up of a drawer attached to the table using two soft-closing hinges, enabling the drawer to open and close. At its highest point, the soft hinges lock, preventing the risks of injuries to users such as pinching. The locking of the hinges also enables desk users to place their items in the drawer easily. The other part of the tabletop is the system that allows for the placement of the electronics, which can be used at a tilted position. It is also attached to the tabletop drawer using the soft hinge. It functions by a user grabbing it at a hole designed for that and placing it at a perpendicular angle to the surface. The design process began by first sketching the various parts of the table, which helped in coming up with the final design for the adjustable desk.

Material Selection

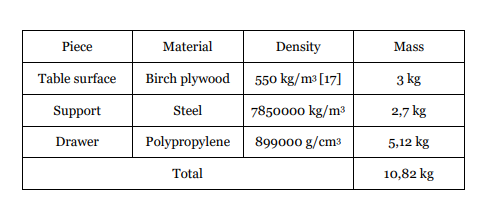

The construction items required for the redevelopment of the adjustable study desk are part of the key consideration in this project. The selection of the materials used in the process was a critical restriction since they had to be environmentally friendly. For the development of the tabletop, birch plywood was selected. This was due to its properties: wood is a naturally renewable resource, which qualifies it to be ecologically friendly.

Birch plywood also possesses key structural properties such as great values in strength, tension, bending, and compression and its ability to enable any form of finishing depending on the customer’s request. The other factor contributing to the selection of birch plywood is the environmental factor. The base of the desk consists of a lifting cylinder and a steel structure at the top where the drawer and other parts are joined together to form the desk. These materials were selected because they were original components of the initial table, and it was done to help keep the same aesthetic of the company product line.

The table drawer was made from plastic, and the chosen material will possess the best surface quality; it will look robust and of good quality. The material which was identified to suit the project within the classes of plastic was polypropylene. The plastic material was chosen because of its high resistance properties. It has always been used to manufacture plastic toys and children’s seats. The material can also be easily colored and has a low density, thus allowing the production of the molding parts with low density, and it is also environmentally friendly.

Dimensions

Critical dimensions can be defined as the dimension of the product that must meet the standard requirement by industry or regulatory authorities to avoid compromising dimensions. The critical dimension or the critical function ensures that the product is properly assembled and provides values that can be interchanged for the parts of the object while assembling them. The European standards were complied with throughout the design and are to be adhered to during the construction process of the desk. The table’s dimensions are based on the 5th and the 95th percentile male and female respectively of the European standards for the office desk users’ group. Under this category, the measurement of the table can be 1493mm to 1913mm for the stature height (Esmaeel et al., 2020). Table thickness was based on the materials used in the table’s construction.

The dimension of the tabletop values had to make sure that all types of users could fit into it without any challenges and use the desk. For the other tabletop component, the tilted support for the electronic device, the measurement was determined based on the size of the normal laptop. The measurement was made assuming that the laptop was the biggest electronic device on the component. The dimension of the drawer is slightly smaller than that of the tabletop by 2cm on each side of the desktop to protect the users from pinching. The tabletop size determined the dimension of the drawer component since it resembles it in shape. The length of the table was determined through approximation, while the depth of the drawer was calculated to allow the user to store up to a maximum of five books. The adjustable system for the desk is standard as they are determined by the manufacturer, while other parts of the table take the same measurements of the pieces they are attached to and their elements.

Table Weight and Density

The drawing of the table was done using a CAD program inventor the program has enabled the analysis of the weight of the table. The analysis was conducted, putting a lot of consideration on the weight of the materials and the dimensions of the same materials. The measurement of the pieces was carried out separately, and the approximated results were as follows:

Market

Target Market

This product offering focuses on individuals with limited office space at home for study tables. The targeted clients for this product are business owners, students, home offices, and schools. The product will be marketed through social media and catalog distribution. Word-of-mouth marketing will also be incorporated into the marketing strategies. The goal of the marketing strategy for redesigned products will be to convey information about the product’s availability to those who wish to purchase quality desks with specific technology.

This product is well-positioned in the market; the table is high-quality based on the materials. The design considered quality and ergonomics, making it suitable for clients who prefer quality and value environments and high technology. Unlike the previous version of the product, the updated version or the redesigned version focuses on using advanced technology in development. Therefore, it does incorporate any cheap laminates and other cheap manufacturing technology.

Marketing of this product focuses on majorly making the information about the new product readily available to the targeted consumers. The information about the product will convey the right information about the value and technology used in the development. The targeted consumer for the products is both high-end consumers and low-end consumers with limited space and value quality and technology. The product’s advertisement will be tailored to relay information about the availability of this product to these categories of clients.

The marketing tools to be used will convey information about the quality of every picture, illustration, promotion, and other applications. The product will only be featured in high-end catalogs and will never be featured in a low-rate catalog with poor illustrations, making it valued less than its actual value. The aim of featuring this product in such a high-rate catalog is to ensure that it only attracts the attention of the right clients. They are willing and able to purchase fine products manufactured using the latest technology accompanied by art and other woodworking skills.

The competitors’ analysis for the re-engineered table was also conducted. All the companies dealing in furniture have not been directly involved in the production of adjustable desks. None of our competitors have given special attention to ergonomics the same way this product has given it special attention. Most of the designers have given special attention to the portability of the desks by fixing them with wheels and mainly designed them to facilitate group work. Our product stands out among its peers in the market due to its selection of materials, its minimalist design, and flexibility. Our competitors are concerned about how they can improve the communication about teams working together and do not give factors such as special space attention, giving our product a lot of potential in the market.

Conclusion

Reverse engineering is important to companies because it helps increase the quality of parts of a product. It enables people to customize ways to ensure they replace the broken components of the products and understand how they can improve the item to become durable. The process also improves the efficiency of a product; the designed desk stands out among its peers in the market due to its selection of materials, minimalist design, and flexibility. Our competitors are concerned about how they can improve the communication about teams working together and do not consider factors such as space, giving our product a lot of potential in the market. They only build enormous desks that can only be used in large halls and boardrooms, thus missing out on meeting the demand for furniture that can be used at home offices and study areas, leaving us with a niche market to exploit.

References

Buonamici, F., Carfagni, M., Furferi, R., Governi, L., Lapini, A., & Volpe, Y. (2018). Reverse engineering modeling methods and tools: a survey. Computer-Aided Design and Applications, 15(3), 443-464.

Esmaeel, A., Starovoytova, D., Maube, O., & Asad, R. (2020). Design of Classroom Furniture for Use at Tertiary Institutions.