Introduction: Company X Background

Company X has been operating in the environment of a retail business or quite long. After gaining the experience of five years of consistently hard work, the leaders of the entrepreneurship assumed that it had warranted an entry into the global market and the design of a unique brand product that will make it popular among the target audiences. However, the above goal will require improving quality standards significantly.

Although the current error rate can be viewed as admissible in the context of the local market, the global economy environment will require an enhanced performance of the employees and an increased quality rate along with a reduction in the percentage of defective items (Pyzdek & Keller, 2014). Particularly, the increase in the reproducibility rates of the company members employed can be viewed as the process of enhancing the communication process. Particularly, the time taken to transfer the data will have to be reduced, whereas the accuracy of the information acquired must be increased. The above steps can be carried out by updating the technology used by the employees.

Moreover, the promotion of a more reasonable attitude towards the data sharing process, along with the acknowledgment of the significance of customer satisfaction rates, will have to be performed. At present, the organization is facing a set of challenges concerning the choice of tools for the provision of the change, the means for maintaining the staff motivation rates high, and the methods of supervising the production process so that the possible inconsistencies could be identified and addressed immediately (Okampo & Estanislao–Clark, 2014).

Determining the Project Components: The Steps to Be Taken

Needless to say, the project’s feasibility hinges on the identification of its components. From the perspective of the eight-component PBL model (Bender, 2012), there is a consistent need for maintaining the inquiry consistent and iterative. Thus, the problem can be heard, and the employees will engage in addressing it in a more active manner, therefore, creating prerequisites for a rapid change in the organizational behavior and triggering a quick rise in product quality.

Challenging the Problem

In the course of the project, the communication issue must be addressed on a regular basis. It is crucial that the employees should participate in designing the approaches that will help them manage the data transfer in a more accurate manner. Moreover, the staff members are welcome to locate the factors that contribute to workplace conflicts, as well as propose the tools for managing the conflicts in question.

Keeping a Sustained Inquiry

Apart from addressing the problem identified above, one must locate the emergent issues. It is highly possible that new issues will become evident as the training program starts. Therefore, it is crucial that new problems should be investigated carefully and that a new solution should be sought.

Maintaining Authenticity

Although adopting a uniform approach might seem a tempting suggestion, it will be necessary to make sure that each staff member is taught in a unique manner that helps take their unique characteristics into account. As long as the training process is customized, the outcomes will remain positive.

Making Choices, Keeping the Voice

The significance of a proper decision-making framework should also be brought up. It is expected that a range of decisions concerning communication issues such as conflict management, negotiation strategies, cross-cultural communication, etc. should be addressed. Therefore, it is crucial that a decision-making model based on the rational approach should be adopted (Krogerus & Tschäppeler, 2011). The above tool helps address the needs of all stakeholders involved and, therefore,

Doing Reflections on the Outcomes

It is assumed that the training program will allow for a rapid increase in productivity rates as well as reduce the percentage of defective items. More importantly, the program is bound to address the communication issue, which will make quality improvements possible.

Critiquing and Revising

Before the program is released, it is essential that it should be scrutinized carefully for the possible disadvantages. Particularly, the opportunities for every staff member to participate, the volume of the information, and the time frames should be analyzed carefully.

Releasing the Public Product

It is expected that the brand product, which the company will be able to release in the end will become a success among the target audiences after the average error rates are reduced by 60%, and the number of company customers is increased by 15% (from the current 19,000,000 to 22,000,000 people).

Problem Statement: When Communication Goes Wrong

A closer look at the current issues in Company X will show that the drop in quality and the lack of consistency in the data management process, which it must have been caused by, are, in fact, defined by a variety of factors, the lack of proper leadership being the primary one.

Because of the disorganized communication process that occurs at Company X, and the lack of an appropriate leadership strategy, which might have affected the above communication issues, the quality of the output produced by the staff members is far too low to meet the current global standards, and so are their motivation rates. The number of errors made in the course of the production process, though admissible by the local standards, will make the company unable to withstand the pressure of the global competition, therefore, ruining its chances to expand in larger markets.

Therefore, it is imperative to introduce a framework that will allow for a significant increase in the quality of the goods. More importantly, it is necessary to create premises for the design of the brand image, name, and product that will represent the organization in the global economic environment. Particularly, a training program that will provide the members of the company with the key competencies and essential knowledge on the subject matter will have to be adopted.

The introduction of the above program, however, may be hindered significantly by the lack of motivation among the employees. The further promotion of the corresponding information will have to be carried out with the help of a strong and efficient tool that will serve as the basis for changing the employees’ values and encouraging them to adopt a more responsible attitude toward the training process.

Affinity Diagram and Interrelationship Diagram

Affinity Diagram

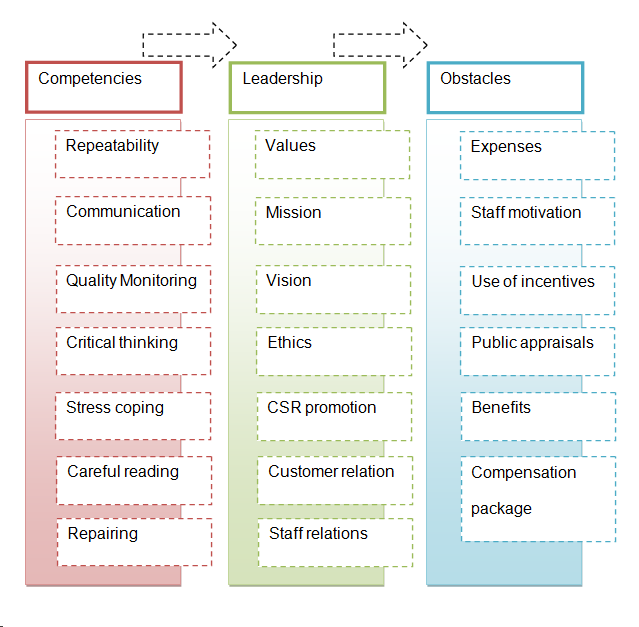

As the Affinity Diagram shows, it is imperative to identify the primary tools for motivating the staff members to participate in the quality improvement program by changing their current values and pointing to the significance of self-development. The above step should be preferred to putting the emphasis on the Corporate Social responsibility (CSR) significance, as the employees are primarily driven by personal interests and do not seem to be very loyal to the company.

In addition, the Diagram permits asserting that the essential skills to be taught to the staff members can be split into two large groups, i.e., the operational processes-related ones, and the skills associated with the communication process. Particularly, a very string emphasis must be placed on the process of conflict resolution. As it has been stressed above, the employees seem to lack the communication skills necessary to transfer data efficiently.

Therefore, a range of conflicts spurred by misconceptions is expected at the earliest stages of the program implementation. The above issues will have to be dealt with by introducing the staff members to the existing array of negotiation techniques and conflict management approaches (Corvette, 2013).

Interrelationship Diagram

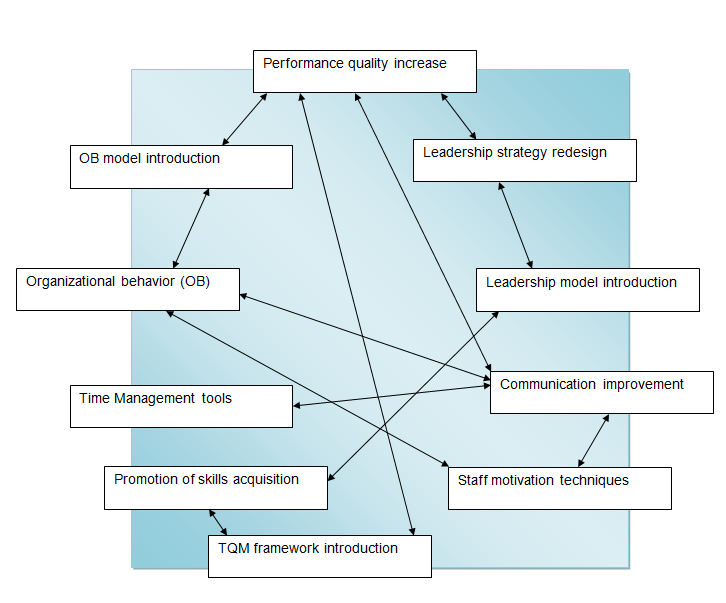

The Interrelationship Diagram, in its turn, makes it very clear that the organization will have to focus on the promotion of incentives and the idea of the program is the platform for the further acquisition of competencies and self-driven learning (Marthinsen, 2015). In other words, Company X should make it very clear that the program will allow the employees to benefit greatly as it will increase their market value as knowledgeable and resourceful experts in the target area.

Define Phase: Where Company X Went Wrong

Investigation: Processes and Work Environment

A closer look at the processes that occur in the company will show that the communication issue, which manifests itself in the lack of tools required to get the message concerning CSR to the staff defines the drop in quality. Indeed, the Interrelationship Diagram provided above points quite graphically to the fact that the company has lost its touch with its members. Particularly, the lack of a strong leadership figure predetermines the current deplorable state of affairs and prevents the company from integrating into the environment of the global economy. The current quality rates and the fact that the number of defected items remains the same, in its turn, can be interpreted as one of the outcomes of the poor data management approach adopted at the firm (David, 2013).

Supplier, Input, Process, Output, and Customer (SIPOC) Diagram

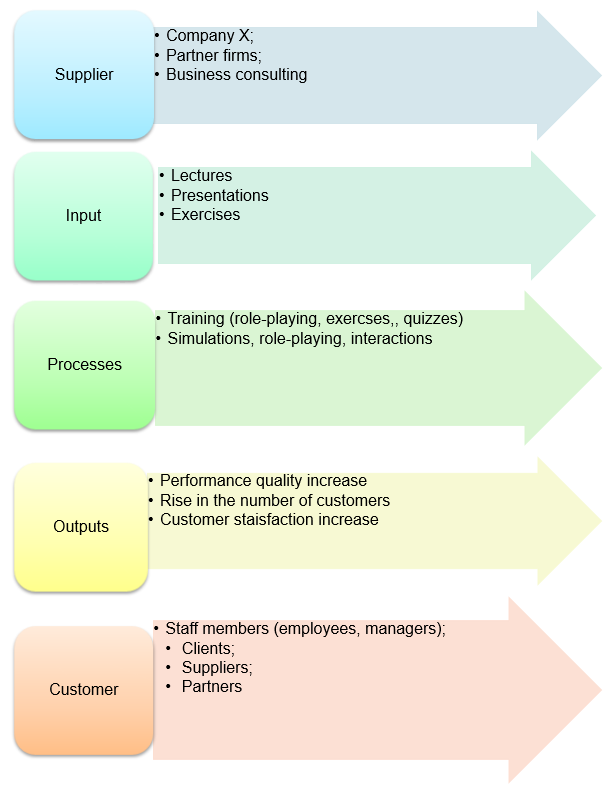

As the SIPOC diagram provided above shows, the project to be carried out can be viewed as twofold, since it is aimed at retrieving internal (increase in staff’s competencies, reduction of defects) and external (customer satisfaction, increase in the number of clients) outcomes (Lao & Thejaswini, 2014). Therefore, the company can be viewed as the primary supplier in the case in point, seeing that the program aimed at increasing the competency levels of the staff’ will be designed by the entrepreneurship managers.

Additionally, the input provided by the company will range from verbal to the one including supplementary material. It could be argued that the interaction process and, therefore the instructions that the staff members will receive in the process can be deemed as a specific kind of input. The processes, in their turn, will be primarily interactive, though some of them, such as lectures, will require substantive listening skills from the employees.

The outputs, in their turn, can be deemed as measurable and quite tangible, as they will involve three primary types; the increase in the staff competency rates, the rise of consumer satisfaction, and the drop in the defective production. Finally, both the staff members and the clients can be viewed as the primary customers in the above design. Since the training and the provision of the corresponding knowledge is aimed at the staff members, they are the primary consumers in the above design. However, given the fact that the entrepreneurship strives for a rapid rise in the consumer satisfaction rates, the above audience can also be viewed as the SIPOC customers.

In other words, the diagram above allows differentiating between the effects that the training program will have on the staff (i.e., the internal operations of the company) and the customer relationships (the external domain) (Ranjan & Vora, 2012).

Preliminary Data Collection

The data will be collected in two ways. First and most obvious, tests must be run to identify the efficacy of the staff and the increase in their performance rates – or the lack thereof. The tests will imply collecting the data regarding the number of defective items produced over the course of a week of operations, and comparing it with the output produced during a week prior to the training program. The above information will have to be analyzed with the help of the two-way ANOVA test so that the effects of several variables could be identified.

Apart from the quantitative analysis mentioned above, a qualitative evaluation of the employees’ attitude toward the changes in the production processes, the organizational issues, the overall training, etc., must be conducted. The above analysis will be possible once surveys are distributed among the staff members. The surveys will include ten Likert-scale questions inviting the employees to evaluate the efficacy of the program and the challenges that they may face in the future.

Problem Statement

Because of the lack of a proper communication strategy and the inconsistent leadership approach, the staff may feel unmotivated to participate in the training program designed to improve their competencies and allow for a rapid increase in quality rates of the company’s goods. Therefore, it is imperative to incorporate the tools that will allow the employee to realize the significance of the program as well as the benefits that it will offer to them. However, apart from the above steps, the firm’s managers will have to consider incentives as the means of promoting the above concept to the target audience.

Repeatability and Reproducibility Assessment

As it has been stressed above, it is imperative that the staff members should display enhanced rates of repeatability at the end of the training process. It is assumed that, by the end of the training process, the reproducibility rates will increase by 20%. The assessment of the subject matter will be carried out with the help of the Minitab software.

In addition, the reproducibility rates will have to rise as well. The above process, however, will occur by reconsidering the current approach toward resources allocation and the following purchase of the new equipment that will allow for a closer monitoring of the production process. Moreover, the devices that will help reduce the number of errors made by the machinery will be purchased so that the overall quality rates could be increased significantly. Therefore, the reproducibility will be addressed as well.

Statistical Process Control

The statistical process control will allow for measuring the ROI of the organization. Thus, the practical implications of the training program adopted by Company X will become instantly visible. More importantly, the specified strategy will create premises for reducing waste, which is clearly one of the greatest concerns for Company X at present. It could be argued that the promotion of the SPC as one of the integral elements of the manufacturing process mean that there will be no need to carry out an inspection of the production process outcomes and the identification of the amount of waste produced (Scott, 2013).

However, the SPC should be viewed as a supplementary tool for maintaining the sustainable approach toward the use of resources. Therefore, the following assessment mentioned above will still have to take place to make sure that Company X exhausts every possibility of reducing waste. The incorporation of the SPC tool, therefore, should be interpreted as the attempt to facilitate faster and more efficient responses from the organization to the emergent issues, such as the increase in the percentage of defects (Larteb, Haddout, & Benhadou, 2014).

Measure Phase: Determining the Effects

The measure phase will require the application of a comparison framework. Pas it has been stressed above, qualitative tools, including the ANOVA test, will be adopted to locate the correlations between the use of the TQM approach and the changes in the percentage of defects produced by the employees. Moreover, the customer satisfaction rates will be analyzed while viewed through the lens of the training program and its effects. Thus, the efficacy of the program can be located.

Analysis Phase: Evaluating the Effects

The analysis, in its turn, will imply a comparison between the initial performance indices and the current ones. The ANOVA tool will be used as the primary means of carrying out the analysis.

Improve and Control Phase: What Else Can Be Done

The phase involving the improvement will concern primarily the provision of the latest technological tools, the training of the staff and the promotion of the values related to customer satisfaction among the staff members.

In other words, a significant amount of the improvement process will be aimed at enhancing the communication process. Seeing that the lack of directions can be interpreted as the main problem of Company X and its employees at present, the reinforcement of data management processes will help the employees receive more detailed instructions. Moreover, the process of information transfer from one department to another will be improved; particularly, the possibilities for the misinterpretation of the data and the following production of faulty goods will be driven to zero.

The phase involving the execution of control over the essential manufacturing processes will require that consistent supervision of the production processes should be introduced into the framework of the organization. It is imperative that the information regarding the percentage of defective tools manufactured should be made available to the managers; thus, the efficacy of the training program and the provision of incentives mentioned above will become evident.

Appendix A: Costs

Reference List

Bender, W. N. (2012). Project-based learning: Differentiating instruction for the 21st century. London, UK: Corwin Press.

Corvette, B. A. B. (2013). Conflict management: Pearson new international edition: A practical guide to developing negotiation strategies. London, UK: Pearson Education Limited.

David, A. (2013). Competitive intelligence and decision problems. New York, NY: John Wiley & Sons.

Krogerus, M., & Tschäppeler, R. (2011). The decision book: Fifty Models for strategic thinking. London, UK: Profile Books.

Lao, H. J., & Thejaswini, M. L. (2014). Six sigma concept for food industry. International Journal of Engineering Technology and Management (IJETM), 2(2), 52-58.

Larteb, Y., Haddout, A., & Benhadou, M. (2014). Successful lean implementation: the systematic and simultaneous consideration of soft and hard lean practices. International Journal of Engineering Research and General Science, 3(2), 1258-1270.

Marthinsen, J. (2015). Managing in a global economy: Demystifying international macroeconomics. Boston, MA: Cengage Learning.

Okampo, L. A., & Estanislao–Clark, E. E. (2014). Developing a framework for sustainable manufacturing strategies selection. DLSU Business & Economics Review, 23(2), 115-131.

Pyzdek, T., & Keller, P. (2014). Measurement systems evaluation. The Six Sigma handbook (pp. 393-426) (4th ed.). New York City, NY: McGraw‐Hill 4th Edition.

Ranjan, G., & Vora, T. (2012). Implementing lean Six Sigma in 30 days. India: Packt Publishing Ltd.

Scott, D. T. (2013). The new rules of lead generation: Proven Strategies to maximize marketing ROI. New York, NY: AMACOM.