Introduction

Cooling towers are heat exchange devices that remove excess heat from different components in industries and plants by making use of the concept that water evaporation creates a cooling effect. The setup can be in form of a simple heating and air-condition system in a small structure or a complex setup on an industry. Cooling towers are found in heavy industries or energy production plants, fir instance, in the oil processing plants or chemical factories. They can vary in size according to the size of the industry and can be up to 0.25 km tall and 0.15 km in diameter for hyperbolic towers while rectangular structures can have a height of 50 m and measure 90 m long.

Forms of cooling towers

There are two major types of cooling towers: the natural draft and the mechanical draft cooling towers.

Natural draft cooling tower

It is also known as a hyperbolic cooling tower. It helps in utilizing temperature difference between the external and internal environments in cooling processes. Since hot air moves up the tower, cold air goes into the tower via the inlet located at the base. Fans are not used in this setup since there is very little circulation of hot air. In the second type of cooling tower, crusts are typically made of concrete with heights that can reach 20 meters. However, these towers are normally constructed out of withstand more since large structures of concrete costly to build. There are two major types of natural draft cooling towers namely: the cross flow tower and the counter flow tower.

The first type is an arrangement in whereby the airflow is perpendicularly bound for water flow while in the second setup, air and water move in parallel but opposite directions. Air first goes into an open area that is under the fill then moves perpendicularly downwards.

Mechanical draft cooling tower

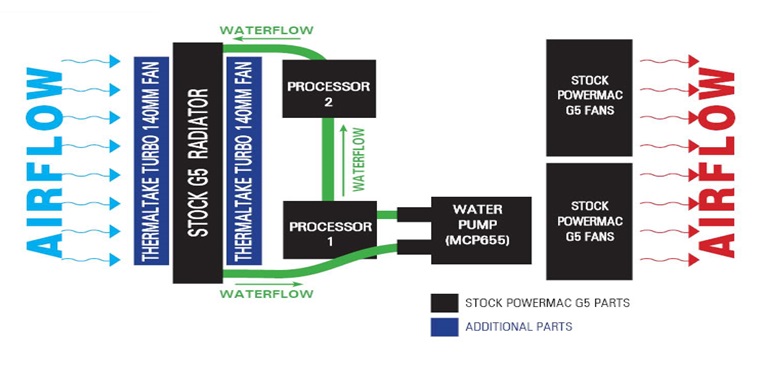

This tower can be distinguished from the previous model in that it includes fans located outside the tower. The fans help to force air into spread out water. This process facilitates the time of contact with water, which maximizes heat transfer (Bradshaw & Pankhurst 2005). However, the degree of cooling is proportional upon variables, such as the fan dimensions and the process velocity. This model exists in three designs as described below:

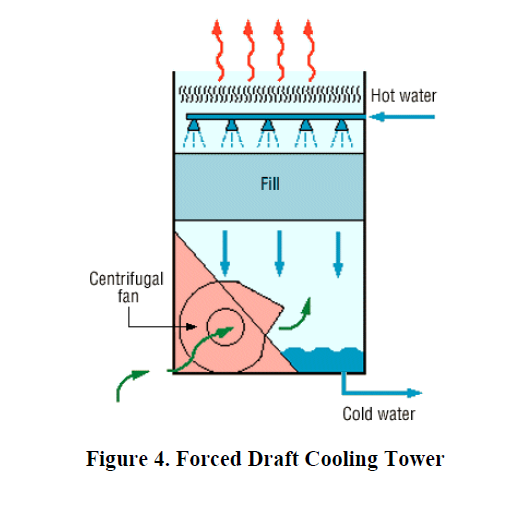

Forced-draft cooling tower

This includes a fan mounted at the air entrance to blow the air and run it inside the tower. During the whole length of the process, slow-moving air is horizontally pushed throughout the packing by the fan, then perpendicularly against the water flow heading downward. Other types have an elimination drift placed at the top that helps in removing moisture that is present in the air.

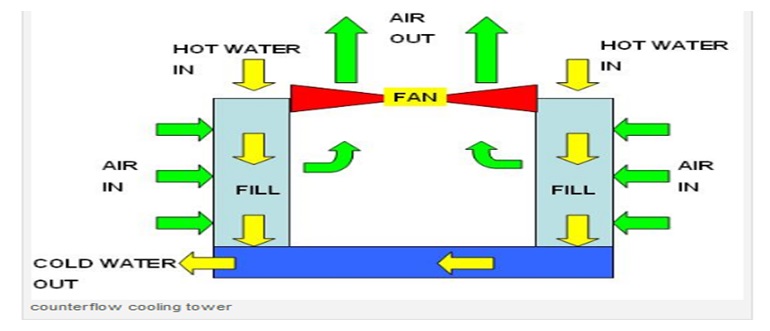

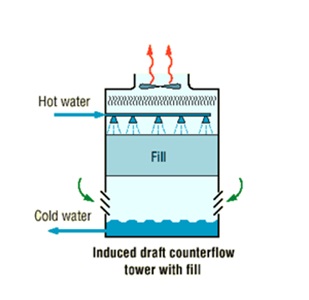

Included draft counter-flow cooling tower: Here, hot water gets into the tower and the two-sided slots let the air enter from the base and discharge it through the pinnacle fan. Subsequently, forced and induced draft fans are used.

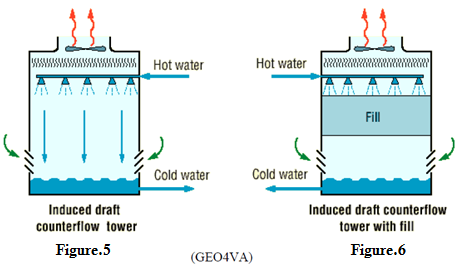

Induced draft counter flow cooling water with fill

In this type, towers may include one or two slots to allow air comes into the tower whilst hot water goes from the elevated entrance and then passes through the fill. Finally, a fan positioned at the top of the tower blows departing air.

Concepts of Energy Efficiency

Choosing the right cooling towers

This section discusses the elements of cooling towers that can aid in efficient use of energy. The most commonly used energy efficiency concepts include choice of the right cooling towers, fills, fans, motors, and water circulation systems. A number of factors affect the performance of cooling towers and these include volume, range, heat load, wet bulb temperature, and a combination of these variables.

Fill Field Impacts

In cooling towers, as the hot water cools down as it looses the latent heat of vaporization, and consequently cools the air. The fill field affects energy use in two ways:

- Electricity is used in to thrust the water over the field of fill and in generating air that sets the fans in motion.

- The exchange of heat between air and water is affected by three factors; the rate of heat substitution for a specific area, the length, and disturbances in the water which aids intermixing. Greater heat exchange consequently improves the cooling processes.

Pumps, Fans, and Water distribution

As a way of minimizing water use, raising the cycles of concentration through the cooling process aids in lowering water use. Bigger industries and energy plants should institute more water conservation measures as they use most water. Today, a large number of the end user specifications lead to a 0.06% drift loss.

The most important function of fans is to exchange hot air inside the system with cool air. Fans help in cooling the air and prevents the loss of pressure.

Conclusion

Water towers can reduce temperatures more than any other devices using air only to reject heat hence are more cost effective. It is important to select an appropriate cooling tower because once installed, the structural characteristics of a cooling tower are not modifiable or changeable. The two major types of cooling towers are natural draft tower, mechanical draft tower. Energy efficiency in a cooling tower can be increased by selecting the appropriate tower several other features of the cooling system such as fills, fans, motors, and water circulation systems. Besides, water conservation must be the focus of large industrial plants.

Reference

Bradshaw, P. & Pankhurst, R. C. (2005). Electrical Energy Equipment: The design of Cooling Towers, prog. Vol.5 (36), pp 1-64.