Abstract

Industrial processes have advanced due to demanding tasks and continued inventions. The methods may require the use of fifth-generation wireless (5G) communication technology that allows the support of industrial IoT (Internet of Things). Current technologies in modern industrial processes face several challenges, including wireless connection reliability, device energy consumption, end-to-end delay, and accommodating extreme devices’ density. 5G implementation and use in complex industrial activities can eliminate the limitations, allowing firms possibilities for growth and success. 5G is a crucial technological capability relevant to IoT through functions such as network slicing, resource efficiency, energy efficacy, positioning services, and high reliability (Varga et al., 2020). Ultimately, the innovation can successfully solve the limitations facing Industry 4.0.

Introduction

5G, also known as the mobile innovation of the fifth generation, came after 4G, 3G, 2G, and 1G. All of its predecessors are variations of less capable mobile communications architecture. The technology’s development is motivated by different factors, including the need to serve highly populated regions with faster mobile access speeds and the requirement to increase battery life to no less than ten years. Traffic-related reasons entail the increased necessity for enhanced mobile broadband (eMBB), ultra-reliable and low-latency communications (URLLC), and massive machine-type communications (mMTC) services. Industrial IoT is an essential aspect of futuristic technologies where fifth-generation wireless can be applied (Varga et al., 2020). It is critical to analyze how 5G can support the fourth industrial revolution by exploring its technical capabilities and aspects and present performance on Industry 4.0 applications.

The major problem facing the current industrial processes is the need for reliability in terms of wireless connectivity, which is almost impossible with existing infrastructure. In addition, wireless innovations created to facilitate industrial communication are undependable. Such inventions are unreliable since they have limited scope and can only be used in low-rate or low mobility localized industries. For example, WirelessHART and ISA1 100.11a standards are designed for mesh connectivity and process automation in short-range situations. IO-Link Wireless is used for wireless networking instead of Bluetooth in control systems involved in factory automation. In addition, the Siemens’ industrial wireless LAN is utilized in factory mechanization, transportation, and automotive. Enterprises are incentivized to use such standards by energy efficiency and the ability to operate using unlicensed frequencies (Mahmood et al., 2021). The existing industrial sectors such as mining, utilities, and other industries require real-time automation, which is hindered by current communication technologies

Conversely, current low-power network technologies covering broad areas, including Sigfox, 4G narrowband, and LoRa (Long Range), support low-mobility applications only and are unsuitable for accommodating extreme devices’ density. Thus, to meet high Industry 4.0 demands, 5G is introduced in industrial applications. Industry 4.0 refers to the recent trend of data exchange and automation in manufacturing technologies. Vertical industries cannot guarantee fail-safe operations and industrial-grade connectivity due to a lack of capable technologies. In addition, vertical industries fail to satisfy the heterogeneous and diverse connectivity requirements using 4G technology and prior architecture (Varga et al., 2020). Without fifth-generation wireless, enterprises cannot integrate various industrial networks and securely manage wireless networks. The invention’s unified connectivity for mMTC, URLLC, and eMBB services can support indoor and outdoor coverage and service demands caused by industrial communication (Mahmood et al., 2021). With beamforming and the massive multiple-input multiple-output (mMIMO) technologies, 5G can utilize augmented and virtual reality, imaging, as well as centimeter-level positioning to allow real-time situational consciousness in manufacturing settings.

Technical Description

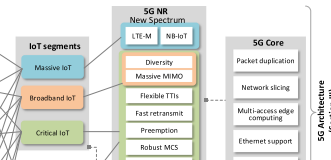

5G delivers exceptionally high speeds with very low latencies by leveraging radio frequencies such as FR1(sub-6 GHz range) and FR2, occurring between 52 and 24 GHz. The evolution and design of fifth-generation wireless can allow numerous IoT segments to serve a sole vertical sector together. The cutting-edge innovation works in industrial settings using different IoT segments, including massive IoT (mIoT), critical IoT, and broadband IoT, as shown in figure 1. Many medium- to low-end industrial tools such as trackers, sensors, and meters are connected by mIoT (Mahmood et al., 2021). Although the demands of mIoT devices on reliability and latency are noncrucial, mIoT supports extreme densities of devices in multiple industries.

In the 3rd Generation Partnership Project (3GPP), narrowband IoT and LTE-M (Long Term Evolution for Machines) were identified as mIoT solutions in 3GPP’s release 13. LTE-M enables low complexity Category M (Cat-M) devices for mMTC, whereas NB-IoT is built to facilitate low-capability radio access. A new 3GPP item, NR-lite, was created for use in low-capability devices, enabling integration with URLLC. In addition, NR-lite utilizes high 5G frequency bands and takes advantage of network slicing (Mahmood et al., 2021). 5G NR frequencies can support old and new fourth-generation wireless bands, which enables NB-IoT, LTE-M, and LTE devices to operate in a disruption-free environment where 5G and 4G coexist.

Broadband IoT enables services requiring high data rates in data-intensive industrial applications. Broadband IoT offers extra IoT-related features, including improved battery saving, low latency, and uplink data coverage and rates. New mmWave frequencies with wide bandwidths enable broadband IoT to provide precise device positioning. In contrast, critical IoT is used for time-sensitive industrial settings which demand specific reliability and latency requirements. Critical IoT can be utilized in mining, logistics, utility, and manufacturing sectors. 5G New Radio (NR) introduces multiple URLLC features that support essential data flows, including ultra-reliable and low-latency communications (Mahmood et al., 2021). Low-latency communications include fast processing, preemption, and flexible scheduling.

5G architecture provides reliability through ultra-robust coding and modulation, medium scheduling or access, and diversity. 5G NR offers robust coding and modulation schemes for control and data channels to minimize errors in URLLC. Several diversity schemes like multiple carrier use, packet duplication, and multiantenna techniques are essential in achieving efficiency and reliability. The fifth-generation wireless architecture uses network slicing to allow mobile operators to make virtual networks in a single network (Mahmood et al., 2021). Network slicing supports varied service classes and isolate resources, increasing efficiency.

Performance

Despite the 5G hype and its benefits to businesses and consumers, the impact of fifth-generation wireless on performance in industrial settings has rarely been evaluated. The communication technology meets the requirements for connectivity with high reliability, low latency, as well as high data rates. However, it is critical to ask why various sectors should invest in fifth-generation wireless and deploy it in their processes. To illustrate the performance of telecommunications innovation in practical settings, a Lundgren et al. (2021) study is used. The research evaluated the key cutting-edge advancement features that have the most significant effect on the performance of manufacturing processes. The study used a mixed-methods approach to assess the influence of 5G on the manufacturing industry (Lundgren et al., 2022). The data analysis was conducted using the Technique for Order Preference by Similarity to an Ideal Solution (TOPSIS) method to guarantee robust results.

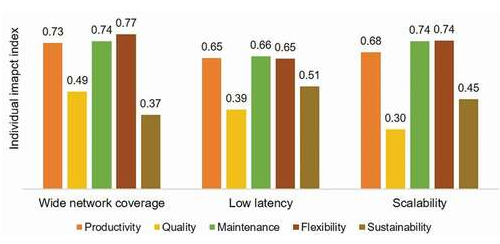

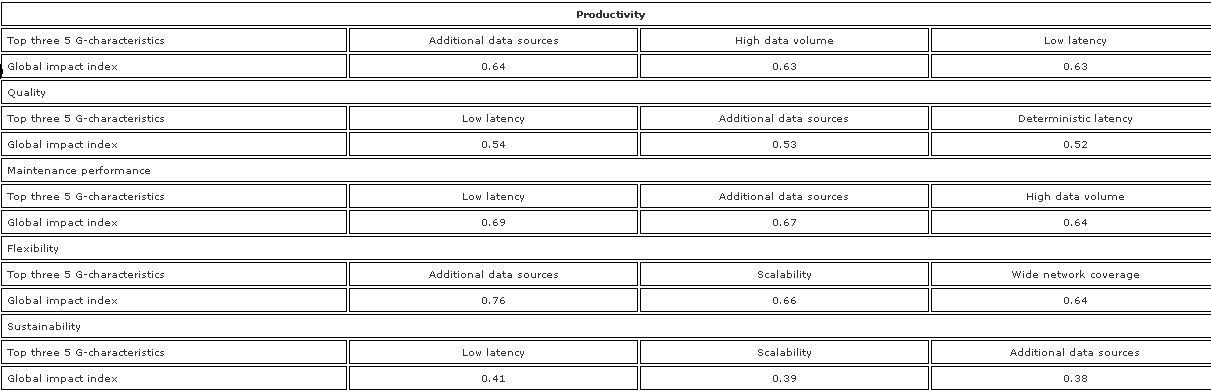

In one demonstration, network coverage, scalability, and low latency were the top fifth-generation wireless features indicated in figure 2. In summary, scalability, low latency, and extra data sources significantly affect maintenance, flexibility, and efficiency performance. The results show that 5G performance will benefit the engineering industry in terms of flexibility and productivity. As a result, it is reasonable to conclude that telecommunication innovation is associated with efficient manufacturing performance (Lundgren et al., 2022). However, the benefits of the cutting-edge technology differ across different applications, as shown in table 1.

Table 1: Top 5G Features in Each Category

Conclusion

In conclusion, it is essential to evaluate how 5G works, its effects on the performance of different sectors, and the problem it solves. The communication technology is associated with high speeds and reliability and promises to shape the world significantly. It can be applied to industrial IoT to solve the challenges of scalability, wireless connection reliability, and devices’ energy consumption. The existing technologies cannot sufficiently address the problems linked to Industry 4.0, which aims to automate many processes. The futuristic invention works through three dedicated segments: broadband IoT, mIoT, and critical IoT. Critical IoT is relevant because it can be utilized in time-sensitive industrial settings that require increased reliability and low latency. Ultimately, fifth-generation wireless affects performance by increasing flexibility and overall productivity in industrial processes, especially manufacturing. It has not yet achieved widespread adoption and still faces challenges such as security concerns; nevertheless, it is expected to affect people’s everyday lives in the coming years. In 10 years, 5G will have massive effects on industrial IoT which will benefit both consumers and businesses.

References

Lundgren, C., Turanoglu Bekar, E., Bärring, M., Stahre, J., Skoogh, A., Johansson, B., & Hedman, R. (2022). Determining the impact of 5G-technology on manufacturing performance using a modified TOPSIS method. International Journal of Computer Integrated Manufacturing, 35(1), 69-90. Web.

Mahmood, A., Beltramelli, L., Abedin, S.F., Zeb, S., Mowla, N., Hassan, S.A., Sisinni, E., & Gidlund, M., 2021. Industrial IoT in 5G-and-beyond networks: Vision, architecture, and design trends. IEEE Transactions on Industrial Informatics, 18(6), 4122-4137. Web.

Varga, P., Peto, J., Franko, A., Balla, D., Haja, D., Janky, F., Soos, G., Ficzere, D., Maliosz, M., & Toka, L. (2020). 5G support for Industrial IoT applications—challenges, solutions, and research gaps. Sensors, 20(3), 828. Web.