Abstract

The presented paper is devoted to the discussion of operations management and production system. The given field of knowledge delves into the peculiarities of organizations’ functioning with the primary goal to outline problematic areas and offer positive changes to align the sufficient work. At the same time, as a fundamental element of the work of any modern company, the production system is analyzed by using the case of Olive Garden restaurant.

The scheme of the unit’s functioning is created to visualize information about the creation of products and all stages peculiar to this process. The paper also offers the discussion of the outlined pattern to understand how production systems work and problematic issues can be improved by applying the basic concepts of operations management and lean approach that is popular and effective today. In the end, the main findings are offered to summarize all the information provided in the paper and conclude about the importance of aligned production systems for modern companies.

Introduction

The functioning of any modern organization is a complicated issue because of the existence of multiple factors that should be considered by top management to align the sufficient work of a unit. Moreover, regarding a severe rivalry and the tendency towards the constant appearance of new actors, there is a need for a competitive advantage that will help to compete with other firms working in the same marking segment. Under these conditions, modern management offers multiple tools for organizing the functioning of a company, evaluation of its critical elements, and creation of a background for the substantial growth.

At the same time, the work of any company can be evaluated by using the appropriate theoretical framework to determine the existing problems and offer solutions to eliminate them. The paper is devoted to the in-depth analysis of the production system as one of the fundamental elements of modern firms, its role in their evolution, success, and achievement of outlined goals.

Operations Management

Prior to analyzing the way current production system functions, it is critical to create the theoretical framework for the discussion. First of all, the concept of operations management should be analyzed. It can be determined as a field of knowledge related to designing and controlling the vital processes of production and redesigning business operations in the production of goods and services (Heizer, Render and Munson, 2019).

This broad definition evidences that the scope of the term and its critical importance for modern companies. Accepting the fact that any company has a significant number of operations that are performed to ensure its effective functioning, operation management can also be considered as a multidisciplinary functional area that acquires the top priority (Stevenson, 2017). It guarantees that input, or materials, labor, and resources, will be managed effectively and used to generate a competitive advantage needed to evolve and enter the next development stage. For this reason, operation management becomes one of the most effective tools to align the work of firms.

Production System

Production systems can be taken as an integral element of the concept mentioned above. It is a framework that describes the transformation of input into desired outputs (Production system, n.d.). For this reason, the given term can be applied to explain how a unit works, including all processes that are vital for this evolution. Production, in its turn, can be defined as a gradual conversion of one form of a material into another to create the final product that can be offered to a user (Kenton, 2019).

In such a way, the production system becomes a critically important element of the work of any company as it describes how it manages to manufacture goods or create services that differentiate it from the rest of companies working in the same segment. From the definition, one can also realize the fact that the effective production system can contribute to the increased performance levels and generate the income needed to guarantee the evolution of the organization. For this reason, much attention is devoted to the in-depth analysis of this component as one of the ways to achieve outlined goals.

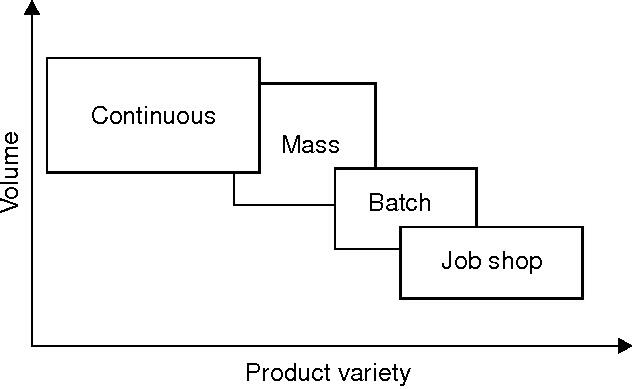

There are several types of production systems that depend on the amount of goods that should be produced and their differentiation.

The job shop model is characterized by the creation of a limited amount of products that are designed to meet diversified clients’ demands in a fixed period and per determined cost. By using this approach, a wide variety and low volume of products can be manufactured (Production system, n.d.). For this reason, it is used in small shops, restaurants, or other similar units.

Batch production is determined by the creation of an established number of items at regular intervals to fit the model of awaiting sales (Production system, n.d.). It is characterized by the existence of multiple departments and stages that should be considered when organizing the work of companies.

The mass production model is used to manufacture a high number of products to meet the growing demand. Usually, specific devices and product lines are used to achieve the goal and offer a wide range of various goods.

Finally, a continuous production system is characterized by decreased flexibility and the need to create an outlined number of similar items in a specified period of time. The majority of processes are automated, which means that there is a low diversity of final products (Production system, n.d.).

The importance of the correct choice of the appropriate production system can hardly be overestimated. Regarding the fact that the use of resources and equipment, its distribution preconditions outcomes, the employment of an inappropriate system will lead to the failure of the company and its inability to achieve outlined goals. For small shops or firms, the continuous or mass production systems have a pernicious impact on their work, and, on the contrary, the use of a batch system cannot suffice organizations with multiple requests for particular items (Krakewski, Malhotra and Ritzman, 2018).

Under these conditions, the effective and useful alignment of all elements of a production system and their management can precondition the achievement of success and create the basis for further growth. Otherwise, the disregard of the current needs will precondition the collapse of a firm and its inability to meet clients’ demands to the quality, quantity, and diversification of goods. The given assumptions can be evidenced by the following analysis of Olive Garden restaurant production system.

Restaurant’s Production System

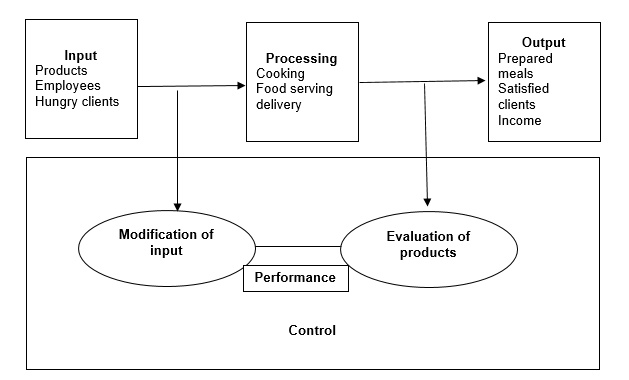

The given scheme can be used to demonstrate the production system of Olive Garden restaurant that is focused on the provision of clients with diverse and high-quality products of Italian-American cuisine. In accordance with the given scheme, input includes several elements.

These are products or raw materials, that should be processed to turn into ready meals that can be served to clients; employees and their work as these two aspects are a critical element of the work of any company, and clients, who should also be considered as input because of their importance of the initiation of the production cycle. Due to the peculiarities of the given business, the restaurant will not work without orders made by hungry individuals. For this reason, they should also be related to the input category.

The next element of the scheme is processing. During this very stage, products from the previous step are used in various activities to prepare dishes ordered by clients. Moreover, the food should be served to all guests or delivered if they request it to a specific place. In such a way, the given stage includes the transformation of raw materials into the ready product that is later offered to all customers.

Finally, as for the output, it includes such aspects as ready products, satisfied clients, and income. The whole production process is focused on this final stage as the purpose of any company is to acquire outputs that can be used to support the further evolution of the company. Thus, for the selected restaurant, satisfied clients and appropriate income will be the desired output.

Thus, the scheme also outlines two critical elements of the production system, which are the modification of input and evaluation of products. These aspects a vital for Olive Garden as they guarantee the existence of the improvement incentive that is vital for achieving the high level of clients’ satisfaction and attraction of new customers. The modification of input presupposes the use of new equipment, training for the staff, and better products to guarantee that the final items will be appreciated by clients.

At the same time, the evaluation of the quality of these very products is vital because of the direct correlation between their taste and other features and clients’ satisfaction. That is why these elements of control should be introduced to the production system with the primary goal to ensure the achievement of desired outcomes.

Analysis

The given model can be determined as a job shop production system as it presupposes the creation of a few quantities of products with a high level of diversification and increased quality. The work of Olive Garden restaurant assumes employment of this scheme because of the clients’ demands and some advantages that can be guaranteed by it. First of all, every job performed within this paradigm demands specific technological requirements and skills from employees, for this reason, the effective delegation of tasks will help to improve results.

Moreover, highly skilled chefs or other workers can contribute to the generation of competitive advantage by using their unique skills and abilities. In such a way, creativity in employees is encouraged. The use of machines and other equipment is also not a critical factor as the majority of operations are performed by the staff responsible for the processing of products and their preparation. In such a way, the use of this model helps to provide clients with customized products in a short period of time.

At the same time, there are several disadvantages that should be considered. First of all, skilled workers might demand additional payment because of their increased value for the segment. Second, frequent changes in clients’ demands presuppose a higher level of stress and importance to fulfill their needs, which can be challenging regarding the given environment. Finally, production planning and calculation of outcomes can also be complicated because of the direct correlation between the level of clients’ satisfaction and generated revenue. For this reason, there are also some limitations associated with the use of the given scheme that should be considered by the restaurant when planning operations and its future rise.

Problematic Issues

The existence of some limits also means that there are points where the organization’s delivery system might fail to align its operational performance measures and precondition the appearance of significant problems that should be solved. From the given scheme, the following problematic areas can be outlined. First, Olive Garden might fail in meeting clients’ demands when preparing specific meals because of the poor quality of products, low skills among workers, lack of equipment, and other issues.

Second, questions with the effective management of resources and their distribution might also arise as many restaurants face the challenge of high amounts of waste. These two aspects should be considered questions that can be improved by using various approaches to operation management with the primary goal to minimize risks of the inappropriate functioning of the firm and insufficient delegation and distribution.

Application of the Lean Approach

One of the ways to improve the work of any firm is the application of the basic concepts of lean management. Regarding the tendency towards the sophistication of companies’ structure, diversification of clients’ demands, and the need for competitive advantage, the employment of this model acquires the top priority today. The lean approach presupposes the continuous improvement of an organization via the minimization of waste without losing productivity (Mann, 2014).

The given goal can be achieved by sharing responsibilities and encouraging shared leadership that is vital for improved control over the most critical procedures to guarantee that resources are utilized effectively and contribute to the enhancement of outcomes (Mann, 2014). In such a way, the paradigm includes the three fundamental ideas, such as the delivery of value from the customer’s perspective, waste elimination, and continuous improvement (Silverio, Trabasso and Pereira Pessoa, 2019).

The correct identification of the current value and mapping of the value stream become the steps demanded to create specific flow and engage the stuff in the continuous improvement process (What is lean management? Definition & benefits, n.d.). For this reason, the application of the lean principle to the production system of the selected restaurant is expected to demonstrate appropriate outcomes.

The inability to meet clients’ demands because of the inappropriate quality can be analyzed by using the lean methodology. First of all, the generation of value from the client’s perspective remains the core of the selected paradigm. For this reason, an improved understanding of the current visitors’ demands might help to solve the given problematic issue. It can be recommended for Olive Garden to ask customers for feedback outlining their expectations and ideas about meals and their quality. Additionally, to avoid problems with products and their inappropriate quality, the monitoring of visitors’ orders should be implemented. The staff should be ready to prepare food that is the most popular among all clients at the moment and possess all resources such as raw materials, skills, and equipment to provide hungry people with the products they need (McNamara, n.d.).

Considering the fact that the high-quality and unusual meals are the principal value for all clients who visit Olive Garden, the given method will help to integrate lean management elements into the work of the restaurant and minimize the risk of being unable to meet individuals’ requirements because of the absence of the demanded products or their inappropriate quality.

The second problem of the discussed production system can also be analyzed by using a lean approach to management. The reduction of waste is one of the major ways in which the company can improve its functioning and achieve satisfactory results that will also help to generate a competitive advantage. For this reason, in accordance with the lean approach, the shared responsibility model can be implemented. Employees working with products should be aware of the ways to minimize waste and use all provided resources effectively as it will help to achieve higher effectiveness levels (McNamara, n.d.).

At the same time, it is essential to have a specialist responsible for the distribution of resources and monitoring of their utilization by all workers with the primary goal to guarantee that all members of the staff realize the critical importance of waste management. Furthermore, the solution offered previously can also be a practical approach in reducing waste as a better understanding of clients’ demands might help to avoid extra use of resources or their poor use.

Major Findings

Customers’ Perspective

Thus, the analysis of the given production system and lean approach contributes to the formulation of the three major findings. First, the work of a firm should be organized by considering the customer’s perspective as it is one of the critical determinants of success in the modern business world. The organizations’ inability to meet clients’ demands will result in the reduced effectiveness of production and a decline in sales and incomes.

For this reason, accepting the lean paradigm, it is essential to remain informed about the existing requirements to the quality of products, their diversification, and features that are considered by customers as the major value. It will help to avoid deterioration of the company’s image, its reduced effectiveness, and contribute to the improved collaboration with the target audience.

Waste Management

The second takeaway presupposes the critical importance of waste management. The majority of companies might have too high spending because of the inability to use resources effectively and avoid their wasting. In terms of lean management, this aspect also acquires the top priority because of its fundamental role in the production system. Under these conditions, the primary goal of an effective firm is the analysis of its current approach to manufacturing and creation of value with the pivotal aim to reduce waste and use all materials effectively (Kotler and Keller, 2015). It will contribute to the reduction of costs devoted to this aspect and their use for other processes or demands. Effective waste management is vital for the growth of organizations as it also helps to generate a competitive advantage.

Operations Management

Finally, the case proves the critical importance of operations management as an integral element of modern companies. The given theoretical framework helps to critically evaluate the work of any firm and outline areas that can be changed to attain better outcomes. The existence of a set of useful tools that can be used regarding this paradigm simplifies the task and offers multiple options on how the desired goal can be achieved. The enhanced understanding of the production system as an aspect of operations management will also help to discover problematic issues and resolve them by using the most effective tools or lean approach, which remains a potent tool to improve the work of any organization by touching upon the most significant aspects of its work.

Conclusion

Altogether, the analysis of the restaurant’s production system shows that the company might face various problems that might result in the deterioration of outcomes and decreased clients’ satisfaction. For this reason, the application of the basic approaches of operations and lean management will help to introduce creative solutions and methods needed to achieve the existing goals. The improved waste management, along with the generation of value from the clients’ perspective, will create the basis for further growth of any company and eliminate barriers that might limit its opportunities. The paper proves the complexity of the existing modern environment and the need for innovative and sufficient practices eliminating problematic issues.

Reference List

Heizer, J., Render, B., and Munson, C. (2019). Operations management: sustainability and supply chain management. 13th edn. New York, NY: Pearson.

Kenton, W. (2019) Operations management.

Kotler, P. and Keller, K. (2015) Marketing management. 15th edn. New York, NY: Pearson.

Krakewski, L., Malhotra, M., and Ritzman, L. (2018) Operations management: processes and supply chains. 12th edn. New York, NY: Pearson.

Mann, D. (2014) Creating a lean culture. 3rd edn. London, UK: Routledge.

McNamara, C. (n.d.) Introduction to operations management of products and services: overview and resources.

Production system – production and operations management (n.d.).

Silverio, L., Trabasso, L. G. and Pereira Pessoa, M. V. (2019) ‘A roadmap for a leanness company to emerge as a true lean organization’, Concurrent Engineering.

Stevenson, W. (2017) Operations management. 13th edn. New York, NY: McGraw-Hill Education.