Abstract

Solar turbines have dominated industrial market all over the globe for decades thanks to their high efficiencies in conversions as well as elevated solar shares. In Solar turbine systems, compressed air is heated for up to 1000 degrees Celsius, this is instrumental in delivering between 40% and 90% of solar share and as much as 30% yearly at the base load (Fernandez 1). This is greater compared to other hybrid based, fossil-solar turbines. Modern gas plants like solar Saturn have a conversion of between over 40%, which has been influential step in the reduced use of solar-thermal turbines. Its advantages that include 24-hour operation, changeable solar share, and fully transmittable power, among others are vital in the overall market potential throughout the globe (Caterpillar Inc. 1). This report analyses the technical and thermodynamic capabilities as well as limitations of a solar Saturn 1MW gas turbine generator.

Introduction

International commitment to reduction of CO2 in the atmosphere has been boosted by the use of solar power; this has effectively led to gradual but steady reduction in utilization of fossil-based power plants. The 20th century advancements in engineering technology has led to progression into gas turbines with their utilization trickling as early as 1930s through static electric power plants. Their earlier use was mainly in propulsion of airplanes with the most recent rigorous use being in power plants. Gas turbines are examples of internal combustion engine, which are viewed as conversion devices. This is because the engines convert fuel energy into a valuable mechanical energy in rotational power form. Gas refers to the atmospheric air used in these conversions (Caterpillar Inc. 1).

Gas turbines are usually available in various models and designs depending on their sizes or power outputs. Among them is Saturn, which can be used for generation of power only and CHP (combined heat and power). It is a simple –cycle system with LHV (Low heat value) of about 40%. In most cases, it was used in peaking capacities, although currently it is commonly applied as a base-load power. It is environment friendly with NOx emissions of single-digit ppm (parts-per-million), its emission of CO2/kWh is very little compared to other fossil-based turbines. It is therefore quite viable, and reliable for industrial use (Fernandez 1). This report will try to investigate the technical and thermodynamic capabilities as well as limitations of a solar Saturn 1MW gas turbine generator.

Objectives

- To analyze the technical capacities of solar Saturn 1MW gas turbine

- To analyze the thermodynamics capacities of solar Saturn 1MW gas turbine

- To investigate the benefits and limitations of Solar Saturn 1MW gas turbine

Scope

This report gives a brief history of the development of solar Saturn 1MW gas turbine system , it goes further to unveil an in depth analysis of its design, technical and thermodynamic capacities. It then proceeds to investigate the advantages and disadvantages of using this power generator over other fossil-based plants and finally provides a generalized description of the generator, its cost, power output, efficiency, work rate as well as its market need throughout the globe.

Background information

Solar Saturn gas turbine system was first developed by a San Diego based company, known as solar aircraft in 1950s following a successive contract awarded to them by the United Sates navy with specifications to develop a 750-kW. The company had previously struggled to remain viable forcing it to look into new products as well as change its name from Prudden-San Diego to Solar. This opened doors for commercial industry as their new product found other uses due to its massive advantages (Delatte 1). This new model gas turbine was lighter, smaller, reliable and easier to manage than the other engines previously used in industrial applications. Its application is currently approximated to be in over 80 countries with an estimated number of 4800 units sold. Its configurations are currently enhanced and up-rated to improve its efficiency (Caterpillar Inc. 1).

In 1973, the company shifted to full concentration on gas turbines, developing several models of them like, Centaur, Taurus, mars and Titan among others. Having merged with international Harvest in 1960, it was acquired by Caterpillar Inc. later on in 1981. Saturn gas turbines ranks as the most widely used of turbines engines, and even overshadows the other models at the firm (Ben Wiens Consulting Inc. 1).

Analysis

Solar/Saturn 1MW Gas Turbine Generator

Saturn is the most widely used of gas turbines in the world, with 4800 units in over 80 countries, it has also managed to log over 620-million hours in operation. Saturn gas turbines are made in single-shaft with a constant speed configuration used to drive the generators. It is ISO certified and has a power of 1185 kW, heat rate of about 14670 kJ/kW-hr, exhaust flow of 23410 kg/hr and exhaust temperatures of about 520 degrees Celsius. It has an axial exhaust with high residual temperatures. Saturn has high thermal outputs, wide fuel flexibility with a time overhaul of between 25000 to 50000 hours of operation. It also has high performance characteristics due to its application of Brayton cycle, whose efficiency depends on pressure and temperature ratios (Caterpillar Inc. 1).

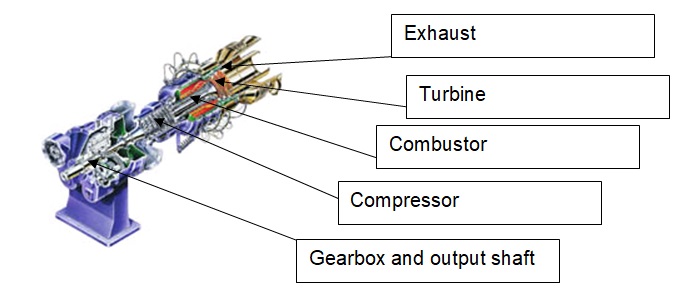

Basic Components of Saturn

Compressor

This component of Saturn draws in atmospheric air, compacts and then pressurizes its molecules. It does this through a process of rotating and static compressor blades.

Combustor

It is in this component, that fuels are mixed with air molecules under great pressure, and then ignited. What follows is the high velocity movement of heated molecules through turbine sections.

Turbine

Turbine has a function of converting high velocity energy into the valuable rotational power. It does this via expansion of hot compressed air over a sequence of rotor blades.

Gearbox and Output-Shaft

This is utilized to lessen the speed of revolving power in output shaft. Output shaft is the medium through which rotational gas is delivered and its speed reduced.

Exhaust

Exhaust, is a component in the engine that acts to direct used gas outside the turbine to the atmosphere. It is therefore a cyclic movement and continues to operate 24 hours a day.

The diagram below shows Saturn gas turbine.

Working Principle

Saturn gas turbine works like internal combustion turbines. This process is referred to as Brayton cycle. The gas is drawn, compressed , mixed with fuel and then ignited, hot air that results spreads out rapidity via a succession of blades, which are in the form of airfoil; the created energy then transferred to output shaft. The remaining thermal energy from the sizzling exhaust gas has various industrial uses (Caterpillar Inc. 1).

Power created is usually proportional to the gas’ absolute temperature; consequently, it is more beneficial to operate the system at the highest possible practical temperature while operating compressor with the lowest possible inlet gas flow. These corresponding high pressure and temperature ratios give specific power and high efficiency although; this increase manufacturing costs (ICF International Company 4-26).

Below is a diagram of Solar Saturn 20 gas turbine generator set (Giese 1)

Advantages

Saturn turbines are reliable with more than 620 million hours of operation throughout the globe. Their small size and lightweight makes them easily movable, as this is vital in transportation. They are environmentally friendly and are considered among the cleanest means of electricity production with very low emission of CO2 and NOx. Besides, their high temperature exhausts can be utilized, adding to its value.

Limitations

Saturn gas turbines are limited to simple –cycle applications in their productions and are usually used in small installations like those of 1MW. Its initial cost is very high since it is bought in components, which are complex, and requires technical expertise.

Applications

They are mostly utilized in gas or oil industries to propel compressors and pumps. Process industries also utilize them in driving large equipment as well as compressors. Institutions and other industries utilize them for electricity generation mostly exploiting its CHP capabilities.

Conclusion

Solar Saturn gas turbines have been a revelation since their introduction into the world market. It has high thermal outputs, wide fuel flexibility with a time overhaul of between 25000 to 50000 hours of operation. It enjoys high performance characteristics due to its application of Brayton cycle, whose efficiency depends on pressure and temperature ratios. Its application has been witnessed in over 80 countries with an estimated 4800 unit installations, this represents the highest of all models and practically stresses its benefits. Its massive prospects of saving the environment and residual output use mark it as one of the cleanest energy production turbines. However, it has limitations on its output configuration since it is a single-cycle system with very high cost of installation (ICF International Company 4-26).

Works Cited

Ben Wiens Consulting Inc. Second law analysis of gas turbines. 2008. Web.

Caterpillar Inc. Solar Turbines: Gas Turbine Overview. 2010. Web.

Caterpillar Inc. Solar Turbines: History-Founded in 1927 as Prudden-San Diego airplane company, the firm built only three all-metal airplanes before the great depression hit in 1929. 2010. Web.

Caterpillar Inc. Solar Turbines: Saturn 20 PG-Generator set. 2010. Web.

Delatte, John. Solar, Saturn 20, 1MW Generator Set. Equipmentmatching. 2010. Web.

Fernandez, Borja. Power Generation: Gas turbine combustors drive emissions towards nil. Powergen. 2008. Web.

Giese, Greg. Solar Saturn 20 Gas Turbine Generator Set. Infinityturbine. 2008. Web.

ICF International Company. Technology Characterization-Gas Turbines. 2008. Web.