Abstract

The modern business environment is characterised by the increased complexity and sophisticated patterns of cooperation between multiple agents needed to attain success. At the same time, the high level of rivalry preconditions the importance of the competitive advantage. Under these conditions, the supply chain management as one of the fundamental aspects of companies’ functioning acquires the top priority.

The paper delves into the central elements of this topic by revealing two different supply chains and critically analysing the ways they are organised. At the same time factors impacting the choice of this very approach and their organisation are assessed. Finally, the analysis of the cross-functional drives that are utilised by organisations is conducted. The emphasise on the achievement of positive outcomes regarding the triple bottom line approach is made. The paper contributes to the improved understanding of the concept of the supply chain, its management, and existing types that are used in various settings depending on the peculiarities of industries.

Introduction

The efficiency of companies’ functioning depends on multiple factors that impact firms’ performance and the final result. With the development of the modern world and the emergence of new ways to work, the business environment becomes more complex. It means that corporations face a significant challenge which is to remain competitive by gradually improving their equipment and management.

The given process also presupposes the need for the utilisation of the most efficient management tools and approaches to ensure the choice of the appropriate strategy. Under these conditions, the increased attention to the supply chain becomes apparent as it is one of the elements guaranteeing the stable functioning of firms and the ground for its further evaluation. The paper is devoted to the in-depth investigation of this aspect of companies’ functioning and its discussion. The efficient management of the supply chain is fundamental for modern companies, but its organisation is a complex problem because of the critical differences in schemes used for various products.

Aims

Regarding the thesis formulated above, the paper has several aims. First of all, the comprehensive analysis of the modern approach to the organisation of supply chains for various products is investigated. It contributes to the improved understanding of the way they function. Second, how the efficient management of this aspect can lead to the attainment of the competitive advantage is investigated.

The paper aims at the deep assessment of the existing methods to the organisation of this element. Another purpose is to consider all factors that affect the company’s strategy and approach to supply chain management regarding the triple bottom line approach and the existing business environment. The given model is one of the topical issues, which means that it is critical to acquire its improved understanding. Finally, the paper’s significant goal is to discuss the importance of the supply chain regarding the differences in business models and approaches to the organisation of companies’ functioning.

Objectives

The given project’s aims also impact the formulation of particular objectives that are introduced to guarantee the in-depth investigation of the topic and offer credible results. In such a way, the following list is suggested:

- Critically assess the existing approaches to the supply chain management;

- Formulate how efficient models impact the companies and help them to acquire the competitive advantage;

- Investigate the modern literature to formulate the theoretical background for the investigation;

- Analyse two end-to-end supply chain models for fuel and a piece of furniture appropriately;

- Analyse the concept of the triple bottom line;

- Investigate factors affecting the development of companies and the formation of their supply chains;

- Formulate conclusions regarding the investigated issue.

In general, the given objectives are introduced with the primary aim to attain the high credibility of findings and present readers with the structured information about the supply chain management and its importance in the modern business world.

Literature

The modern literature devoted to management and the business world is united in the opinion that the supply chain is one of the fundamental elements of the companies’ functioning. For this reason, the task to align its efficient work acquires the top priority. There are various approaches to how it can be accomplished. However, the central idea is that all stages of the supply chain have the same importance because of their critical impact on the final result (Armstrong & Kotler 2016). For this reason, the existing end-to-end approach presupposes consideration of the activity of all stakeholders, including the manufacturer, transported, and retailer (Kotler & Keller 2015).

At the same time, these actors are not the only forces impacting the supply chain management (Kotler & Keller 2015). The existing prices on the delivery of products and their storing precondition the choice of companies that can provide options that fit the demanding correlation between the quality and price (Gamble, Thompson JR & Williams 2016). Moreover, the demand for the product and the term of its delivery affect the choice of the most appropriate shipping method to satisfy customers’ demands and ensure their positive feedback.

In such a way, the literature states that the consideration of all peculiarities of the market along with the current demand is one of the ways to create an effective supply chain that will contribute to the development of a company. There are many other factors that precondition the choice of one or another element to guarantee the generation of revenues (Bowen 2017). Nevertheless, the analysis of the two chosen products in terms of their manufacturing, distribution, and sale should help to demonstrate the peculiarities of supply chain management and the presence of multiple issues affecting the final result.

First Supply Chain Analysis

The investigation of the end-to-end supply chain involved in a customer’s purchase of a litre of fuel demands the improved understanding of the fundamental peculiarities of the sphere’s functioning. It means that all way the final product passes from the beginning to the end should be analysed regarding the existing aspects of the field and approaches utilised by companies to manufacture it. At the moment, the petroleum industry is one of the most powerful ones at the global level because of the strategic character of the final product and the increased demand for fuel as the source of energy (Jones & George 2014).

It means the high level of rivalry between all agents functioning in the sphere and the need for the improved strategic planning of basic operations, including supply chain management. That is why, in some cases, the increased complexity of the utilised pattern can be observed.

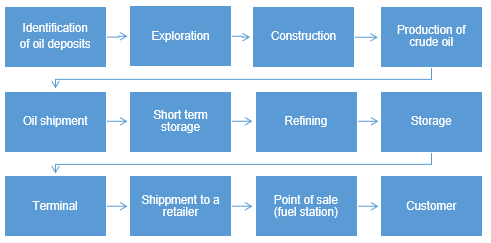

Nevertheless, the end-to-end supply chain involved in a customer’s purchase of a litre of fuel at the petrol station can be presented in the following way:

Analysing the given figure, several critical aspects should be mentioned. First of all, it consists of 12 points demonstrating the increased complexity of the sphere and the necessity to consider a number of points to ensure that a customer will acquire an opportunity to by a litre of petroleum to satisfy his/her needs. At the same time, the scheme shows that a retailer or a company that is responsible for sales in a certain location is not the central element of the process as its functioning becomes impossible without the effective cooperation with other agents. In such a way, the creation of such chains becomes necessary for the improved understanding of how the industry or the market works and what elements should be considered.

Analysing this very supply chain, it is essential to outline several critical peculiarities. In the majority of cases, the place of sale does not coincide with the area of exploration and production (Hugos 2018). It is explained by the fact that there are particular areas rich in oil deposits that provide the crude oil needed for the petroleum industry and the raw material should be delivered to the refinery factory to create petroleum (Jones & George 2014).

Moreover, the final product should also be shipped to retailers located in various regions (Hugos 2018). Double shipment can explain the comparatively high price for fuel and difference its oscillations regarding the area (Kotler & Keller 2015). Moreover, planning the needed supply, a company working in the sphere should also consider the fact that both the crude oil and the refined product are stored at various stages of its production to accumulated amounts appropriate for shipment and further distribution. This factor should also be considered when creating a business strategy and planning sales.

The complexity of the given supply chain can be considered as one of the guarantees of its efficiency. The fact is that too simple schemes consisting of a limited number of elements can create the basis for the emergence of particular problems because of the lack of attention devoted to other stages of products’ manufacturing, delivery, and sales (Mangan & Lalwani 2016). At the same time, an effective manager should analyse all aspects that affect the product at all stages of its lifecycle.

It means that developed and broad supply chains create the basis for the improved outcomes because of the ability to delegate activities in the most appropriate way and attain the enhanced results. Moreover, the given supply chain can be considered an example of the existing pattern peculiar to the petroleum and oil industry as it involves all critical elements and activities topical for all companies.

The main advantage of the given supply chain is that it provides multiple opportunities for effective management at different stages. In other words, regarding the fact that there are many elements included in the pattern mentioned above, a manager acquires the opportunity to interfere with their functioning at all levels and organise cooperation in the most effective way. For instance, this model presupposes direct contact with an agency responsible for the refinery of crude oil.

Exclusion of intermediate parties guarantees that the agreement will be achieved faster (Mangan & Lalwani 2016). At the same time, the reduced price can be expected because of the absence of the need to pay mediators and other negotiators. Moreover, the existence of short-time storages simplifies the task because the company utilising this supply chain will not have to wait for the accumulation of the needed amount or, on the contrary, will have an opportunity to ask for some additional time to ship the final product.

There are also certain drawbacks of the given model. The increased number of agents at all stages of the supply chain means the high sophistication of their collaboration and the necessity of the improved monitoring to ensure that all elements interact in the needed way (Mangan & Lalwani 2016).

It demands better knowledge and skills from managers responsible for this very supply chain management. They should be ready to meet the requirements of numerous actors engaged in the cooperation. Second, from the process views perspective, the functioning of a company can be described as a set of processes that precondition final results (Armstrong & Kotler 2016). Regarding the given supply chain’s structure, the number of these processes increases significantly, which might generate additional difficulties for the company and its managers. In such a way, a particular problem considering the organisation of interactions might emerge.

Second Supply Chain Analysis

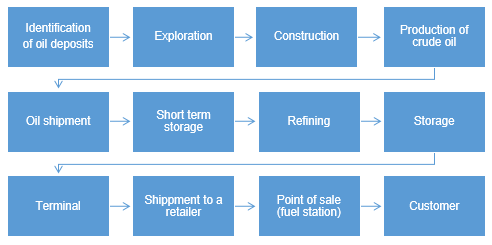

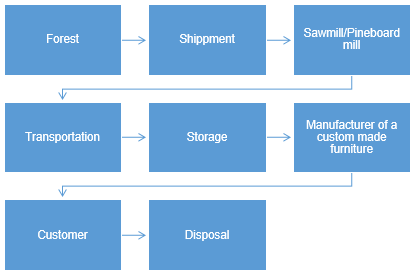

The second analysed supply chain involves a customer’s purchase and disposal of a custom-made sofa.

The given supply chain includes only 8 elements which are preconditioned by the comparatively simple manufacturing cycle. First of all, the resources needed for the creation of a sofa can be found in multiple areas. It means that fewer stages from the extraction of raw materials to the emergence of the final product are needed. The given pattern provides more opportunities for a small business as the supply chain management becomes less complex compared to the previous industry. At the same time, the given scheme means more flexibility as manufacturers have an opportunity to acquire the needed materials in shorter terms.

Applying the process-view approach, it is possible to state that the given supply chain consists of the four main processes such as the timber harvesting, woodworking, delivery, and creation of a final product. The effective management of all these processes means that improved outcomes and the high level of customers’ satisfaction (Armstrong & Kotler 2016). For this reason, it is essential to critically assess all stages. For instance, a master responsible for the creation of a customised sofa should choose the most appropriate wood material to provide a high-quality product. If there are some mistakes at previous stages, the substance will be spoiled.

Nevertheless, the efficiency of the suggested supply chain and its management rests on the alignment of direct and fast access to materials and the ability of a manufacturer to provide a final product in short terms because of the existence of a solid raw material base. The given pattern guarantees that the master will be able to satisfy various customers’ demands and improve their devotion to the company. At the same time, it means high revenues and acquisition of a particular competitive advantage needed to struggle with rivals and create the basis for the further evolution of a firm.

As it has already been stated, the given supply chain has a limited number of elements which can be considered its central advantage. It means that managers do not have an opportunity to engage in negotiations with multiple agents having their own demands to the terms of cooperation (Mangan & Lalwani 2016). At the same time, it also means reduced spending and time needed to acquire all materials to start manufacturing. Simple supply chains can demonstrate the high efficiency in various conditions regarding the goals and demands of organisations (Mangan & Lalwani 2016). For this reason, the utilisation of the given model can generate particular benefits for a company.

There are also some drawbacks in this model. First of all, the cooperation with the local manufacturer can result in the lack of unusual wood material. It can prolong the terms of the creation of various pieces of furniture. Moreover, extra procurements might cost a lot because of the urgent character of a deal and the absence of needed materials at the closest storage. Finally, there is a risk of increased rivalry as local manufacturers might use the same channels to acquire wood. It can impact the final result and undermine the company’s work.

Comparison

Comparing these two supply chains, some important issues should be noted. First of all, the increased complexity of the first one devoted to fuel compared to the second pattern should be admitted. This divergence comes from the radical differences in the ways these industries work. The fact is that the manufacturing of petroleum is a complex and technological process that presupposes multiple stages needed to refine crude oil and deliver it to retailers.

As for the creation of furniture, the need for wood can be satisfied in simpler ways because of the less complex process. Moreover, there is the problem of shipment as oil deposits can be found in a limited number of regions. Finally, differences in industries also impact the supply chains and their management. For this reason, there are many radical differences in the models created for the discussed domains.

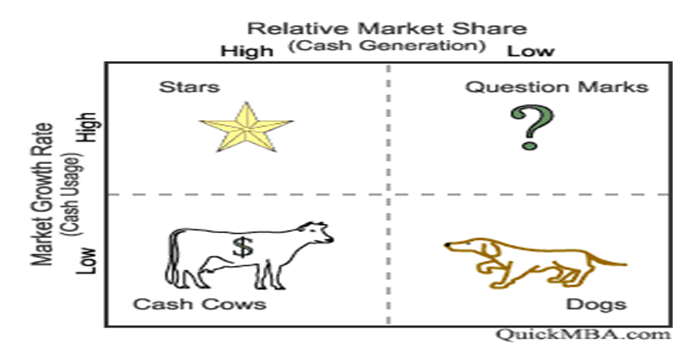

Competitive Strategy

Using examples of the above supply chains, we can also prove the idea that any organisation can introduce an appropriate marketing strategy to generate a competitive advantage and continue its evolution. The fact is that the selection of the supply strategy is preconditioned by a set of factors that impact its functioning and the market in general. In such a way, effective managers can introduce appropriate changes to the existing approaches to meet new challenges that come from the alterations of conditions peculiar to the market.

For instance, if the quality of the provided petrol does not meet the company’s standards, it can make a decision to change a partner to engage in cooperation with the more beneficial agent. The same idea can be applied to transporting company if the terms are inappropriate. All these elements are a significant part of a competitive strategy, which means that it is critical to monitor their state and craft the supply chain strategy regarding these issues.

Cross-Functional Drivers

To optimise performance and achieve better outcomes, companies can also utilise various cross-functional drivers peculiar to both types of supply chains discussed above. These elements include information, sourcing, and pricing (Mathis, Jackson & Valentine, 2015). Regarding the existing business environment, they play a critical role in the acquisition of competitive advantage and creation of the basis for further growth.

For instance, using credible information about the existing demand for fuel or customised sofas, organisations can introduce appropriate alterations to their strategies to increase or decrease the amount of final product suggested to customers. Moreover, pricing, as a part of competitive planning, plays a fundamental role in the functioning of companies. Offering appropriate prices for high-quality goods, firms can acquire new customers which is critical for the improved outcomes. Effective pricing can be achieved only regarding the well-thought-out sourcing strategy. It means that considering these three basic cross-functional drivers, organisations can improve their results by providing consumers with more appropriate products and prices.

Triple Bottom Line Approach

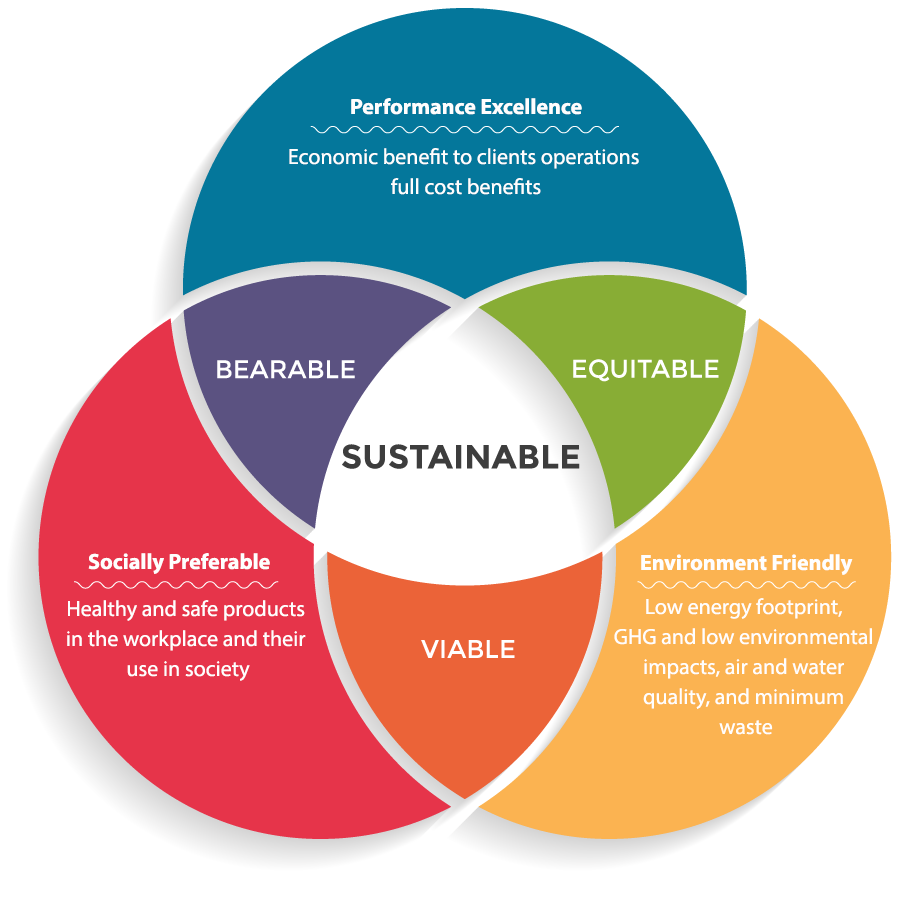

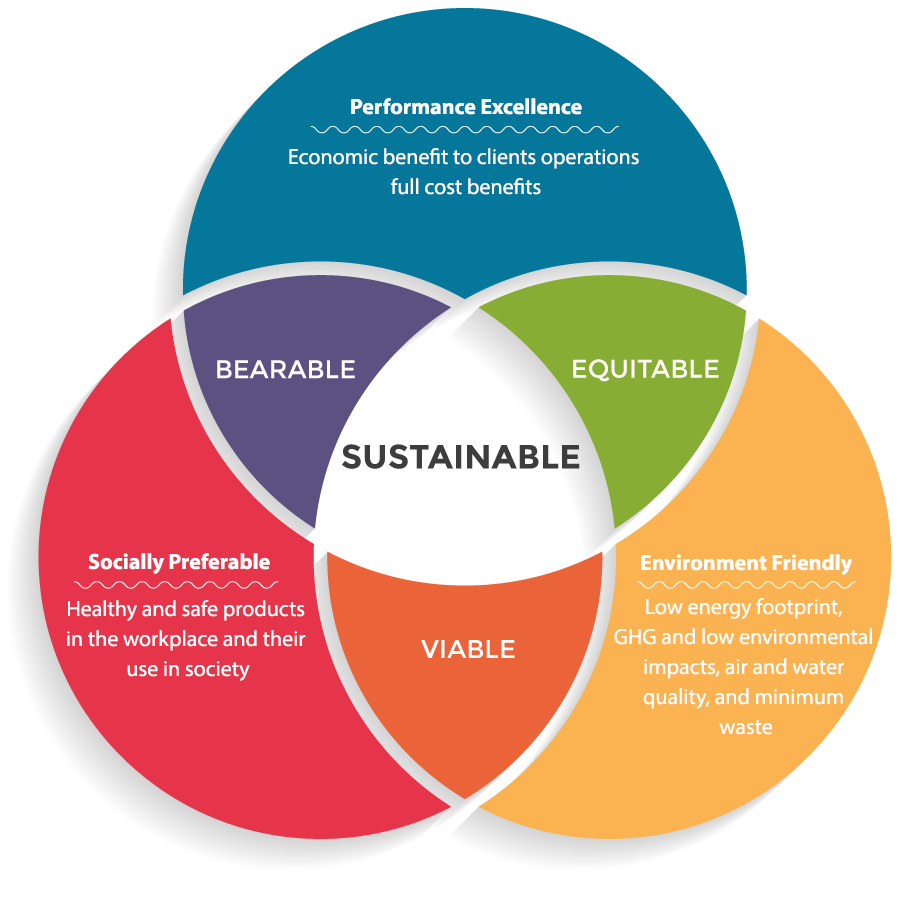

The idea of an effective supply chain management can also be associated with the concept of the triple bottom line. It can be determined as a framework presupposing the three parts: social, environmental, and financial.

In other words, the functioning of companies should be environmentally friendly, socially preferable, and appropriate for the generation of profit. Consideration of these elements becomes one of the critical tasks of modern managers as it remains the only possible way to build successful companies (Bals & Tate 2016). Applying the concept to supply chain management, the direct correlation can be admitted.

Considering the fact that the topic discussed in the paper encompasses a wide range of activities including the choice of a manufacturer, a way of shipment and prices, all three spheres of the bottom line approach can be impacted. Firms might restructure their supply chains to avoid cooperation with a manufacturer that disregards the existing environmental concerns or provides workers with poor working conditions (Bals & Tate 2016). It will help to exert pressure to improve social and environmental aspects. At the same time, the bottom line approach can be utilised to introduce alteration in the supply chain management to generate high income. It means that there is a direct interdependence between these two elements.

Conclusion

Altogether, peculiarities of the modern business world such as the increased level of rivalry and the focus on the satisfaction of customers’ diverse needs preconditions the increased importance of the supply chain management. It encompasses the most important elements of companies’ functioning such as the movement and storage of raw materials, inventory, and finished goods (Shaffer 2018).

Importance of the given aspect preconditions the existence of radical differences in supply chains preconditioned by the peculiarities of the market, industry, and existing demands to products. In such a way, it is critical to consider all elements including cross-functional drivers and the triple bottom approach to ensure the successful collaboration with central partners, in-time delivery of needed materials, and their efficient distribution. Only under these conditions, companies can preserve their competitive advantage and struggle with the closest rivals to create the basis for further development.

Recommendations

The given paper contributes to the improved understanding of the concept of supply chain management and its importance in the modern world. However, the scope of the researched problem means that there are multiple opportunities for further research. For this reason, it is recommended to continue the investigation of the issue to achieve the enhanced comprehending of its role in the functioning of modern corporations and outlines opportunities for its improvement. At the same time, investigations of real companies and their supply chains can help to discover additional information regarding the problem and conduct the in-depth research of the most critical elements of the given topic.

Appendix

Reference List

Armstrong, G & Kotler, P 2016, Marketing: an introduction,13th edn, Pearson, New York, NY.

Bals, L & Tate, W 2016, Implementing triple bottom line sustainability into global supply chains, Greenleaf Publishing, Sheffield.

Bowen, S 2017, Total value optimization: transforming your global supply chain into a competitive weapon, Steve J. Bowen, Duxbury, MA.

Gamble, J, Thompson Jr, A & Williams, M 2016, Essentials of strategic management: the quest for competitive advantage, 5th edn, McGraw-Hill Education, London.

Hugos, M 2018, Essentials of supply chain management, Wiley, Hoboken, NJ.

Jones, G & George, J 2014, Essentials of contemporary management, 6th edn, McGraw-Hill Education, London.

Kotler, P & Keller, K 2015, Marketing management,15th edn, Pearson, New York, NY.

Mangan, J & Lalwani, C 2016, Global logistics and supply chain management, 3rd edn, Wiley, Hoboken, MA.

Mathis, R, Jackson, J & Valentine, S 2015, Human resource management: essential perspectives, 7th edn, Cengage Learning, Boston, MA.

Shaffer, G 2018, Creating the sustainable public library: the triple bottom line approach, Libraries Unlimited, Santa Barbara, CA.