Introduction

Nuclear science has proved to be of great importance in contemporary society as far as energy is concerned. Nuclear is regarded as a clean source of energy. The source finds relevance in a world faced with increasing demands for power.

However, nuclear processing is faced with a number of challenges. One of the biggest problems associated with the generation of this form of energy involves the disposal of the resultant waste products (Simpson and Law 5). It is important to address these challenges if the benefits of this clean source of energy are to be realised.

The current paper revolves around this issue of the advantages and disadvantages of nuclear energy. To this end, the author examines the possibility of making this energy renewable. The author will analyse nuclear reprocessing as one of the strategies to be adopted in making nuclear a sustainable source of energy.

Specifically, the writer examines how nuclear reprocessing applies to waste disposal and transportation of the material. Different aspects of reprocessing are discussed with regards to their benefits and associated costs.

The author of this paper examines the nuclear fuel cycle in a bid to explain the said reprocessing. A review of the front and back ends of the cycle is provided. According to Stewart and Stewart (5), reprocessing of nuclear is a strategy adopted to ensure that the fuel’s cycle is complete.

In addition to the advantages and disadvantages of reprocessing, the author examines the safety considerations of the entire process. Finally, the writer looks at the global perspectives regarding this reprocessing and the associated fuel cycle. In light of this, the economic and political aspects of this issue are discussed.

The Nuclear Fuel Cycle

Nuclear energy is produced with the help of several sequential processes that have different steps. The production of energy starts with the mining of the raw materials and proceeds to the chemical processing stage. Other stages include the production of electricity and waste management.

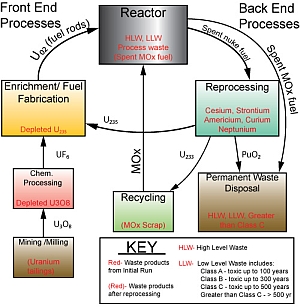

Simpson and Law (17) argue that any nuclear power plant must factor in all the steps and processes involved in energy production. Simpson and Law (17) add that the fuel cycle is realised through the said steps and processes. Figure 1 is an illustration of a conventional nuclear fuel cycle:

The nuclear fuel cycle comprises of 7 different steps (Won and Ho 757). As illustrated in figure 1 above, the process begins with the mining (or acquisition) of raw materials. Crossland (23) argues that radioactivity is the crucial principle behind nuclear energy production. Radioactive elements like uranium act as the primary raw materials for this process.

Before the inputs are fed into the reactor, they undergo three preliminary processes. The three are referred to as the front end processes. As illustrated in figure 1, the said procedures comprise of different activities. The activities include mining, chemical processing, and enrichment of radioactive materials. Uranium is the ideal radioactive element for the process.

Once the enriched material is fed into the reactor, energy is produced. The by-products of the said processes constitute what is regarded as nuclear waste. Miller (23) argues that the activities carried out on nuclear waste constitute the back end processes. As indicated in the figure above, reprocessing, permanent waste disposal, and recycling are some of the back processes. The fuel cycle is completed when all of the said steps are properly executed.

Nuclear Waste Disposal

Overview

Nuclear energy is discussed against the backdrop of the radioactivity of the materials required for its production. The nuclear waste produced is similarly radioactive. The nature of the material is explained by the continual decaying of the elements long after the fission has been initiated. Ojovan and Lee (130) suggest that radioactive waste is harmful to humans and to the environment for a number of reasons.

For example, it is dangerous owing to the ionising radiation it is associated with. The waste comprises of alpha, beta, and gamma radiation. The three have high frequencies that enable them to penetrate other forms of matter. As a result, the disposal and handling of such waste should be discussed in the context of the fuel cycle.

The Front and Back End Processes

Disposal of nuclear waste focuses on the back end processes of the fuel cycle. As mentioned in the previous section, the waste is generated as a result of the processes involved in the production of energy. The radioactive nature of the material informs the direction of the back end process that it should undergo. In essence, the disposal of nuclear waste is carried out once the degree of its radioactivity is determined.

It is important to note that nuclear waste is generated at the exploratory stage. It is not possible to extract the entire ore of uranium at the mining phase.

Consequently, the residue, which is made up of slurry and gaseous material released during the mining process, constitutes the nuclear waste (International Atomic Energy Agency The Nuclear Fuel Cycle 7). The radioactivity of such material is relatively low. However, an accumulation of this waste poses a danger to the environment. As a result, it is essential to handle it with care.

Radioactive waste is also generated during the operation of a nuclear power plant. According to Choppin, Rydberg, and Jan-Olov (23), radionuclides are produced at the reactor phase of the nuclear cycle. The radionuclides are brought about by the nuclear fission occurring in the reactor.

When the fuel elements within the reactor begin to decay, it is essential to reprocess them. As indicated in figure 1, the initial uranium decays to several elements. The resultant elements include Cesium, Strontium, Americium, Curium, and Neptunium. The said materials can yield more energy if they are processed. In light of this, it is advisable to reprocess them instead of disposing of them.

During the reprocessing phase, a significant portion of waste is also produced. The residues of plutonium and uranium, which are produced after the nuclear fission, are temporarily stored. According to Choppin et al. (16), the radionuclides produced in the reactor, together with other nuclear fission products, constitute the waste at this stage of the fuel cycle.

In Europe, this highly radioactive waste is often melted in a furnace. The molten material is later strained into a steel canister. Evidently, the canisters are radioactive given the nature of their content. As such, they are dealt with by storing them in a facility with lead.

Nuclear waste is also brought about when the facilities producing this form of energy are decommissioned. The establishments range from the uranium enrichment facilities and power plants to repositories and reprocessing plants used in handling these materials.

According to the International Atomic Energy Agency, the facilities must have a specific ‘lifespan’ (Safety of and Regulations for Nuclear Fuel Cycle Facilities 13). To this end, the agency has set a universal standard of 15 years for nuclear power plants. However, there are other jurisdictions where the timeframe is longer than this set standard.

Notwithstanding the duration of the facilities, their decommissioning entails physical destruction of the entire structure. It is important to note that the resultant debris is radioactive. However, the waste has a relatively low degree of radioactivity relative to the ones produced in the reactor.

The radioactive nature of nuclear waste, as mentioned above, poses a health hazard to the environment. As such, it is essential that their disposal is done in a manner that is responsive to the environment. A look at the front and back end processes of the fuel cycle makes it evident that there are various degrees of nuclear waste.

The variance is brought about by the radioactivity of each of the categories of fuel waste products (Choppin et al. 23). As a result, it is important for the selection of the disposal option to be informed by the nature of the waste.

Fuel Reprocessing and the Advantages

Reprocessing is one of the major steps in the back end processes of a fuel cycle. In their description of this process, Miller (3) argues that there is a misconception as far as reprocessing and recycling are concerned.

Miller (3) demystifies the two procedures by describing reprocessing as the process where uranium and plutonium are separated from the residue that emerges from the reactor. In essence, once the two elements are separated from the fuel (which is already spent), the radionuclides and other radioactive wastes are conditioned.

The difference between reprocessing and recycling is that the former is seen as the first stage of the re-usage of radioactive waste. The latter, on the other hand, is considered as the second phase of the re-usage process. In this phase, the uranium and plutonium, which had been stored, are mixed with oxides or fed back into the reactor.

They are recycled into the reactor as reprocessed uranium. According to Miller (43), the reprocessing only occurs after a period of approximately 20 years after the reactor has been discharged. The recycling process, however, relies on reprocessing.

Reprocessing is associated with a number of advantages. One of the primary benefits of this process is seen in the military field. In their analysis of the non-proliferation procedure, Miller (34) mentions that reprocessing was practised as way back as in the 1940s. Miller (45) suggests that at the time, there was a felt need to recover plutonium.

The recovered element was later used in weapons. The advantageous aspect of this development is best understood from a military perspective. Miller (34) argues that the said nuclear waste would have been harmful to the environment. However, appropriating it for military purposes was seen as a temporary protective measure to the environment. By the year 2000, 280,000 tonnes of discharged nuclear waste had been reprocessed for military use.

The reprocessed nuclear waste can also be used in other nuclear power plants as fuel for the production of electricity. An example is evident in the United Kingdom. For close to 5 decades, 1500 tonnes of this waste is reprocessed in the country per annum.

The waste was then used in power plants (Miller 33). The Sellafield plant is a classic example of this process. In general, the reprocessing of nuclear waste is seen as a method of reducing environmental radiation. As a result, the disposal of such material is made easy with the help of the reprocessing procedure.

Reprocessing of Nuclear Waste: Safety Considerations

As already indicated, the disposal of waste materials occurs at various stages of the nuclear fuel cycle. The same calls for a number of safety considerations owing to the hazardous nature of the radioactive waste.

The International Atomic Energy Agency (Safety of and Regulations for Nuclear Fuel Cycle Facilities 1) is charged with, among other duties, the promotion of universally accepted safety standards regarding the handling of nuclear waste. The agency has formulated a number of safety principles that oscillate around the aspect of radiation ionisation. In general, there are three main safety principles that should be adhered to. The three are listed below:

- All safety practices are adopted only when they have a nett positive effect.

- Exposure to radioactive waste must be kept at an absolute minimum. The same is with respect to socio-economic factors.

- Each country must have a nuclear regulation authority that sets out a specific dose equivalent, which must not be exceeded.

The nuclear fuel cycle requires extremely high safety standards. Many nuclear facilities are faced with the possibility of hazardous scenarios, such as explosions and spillage of radioactive waste. In line with this, the first safety consideration revolves around the physical structure of the nuclear plant.

Crossland (239) points out that the facilities must be constructed with materials that have the potential to absorb the radiation generated. Lead is an ideal material for these purposes. The compound meets the radioactive absorbance requirement.

Safety considerations in the disposal of nuclear waste require oversight. To this end, it is essential for governments to put in place frameworks that promote safety as far as this disposal is concerned. Crossland (187) argues that countries should formulate laws to outline safety measures.

The governments must ensure that the laws cover radiation protection for the workers and the environment. In addition, the law must provide for a training criterion. The criterion must be adhered to by the personnel involved in the disposal of nuclear waste.

Licensing is another major safety consideration as far as nuclear waste disposal is concerned. The International Atomic Energy Agency (The Nuclear Fuel Cycle 17) proposes that countries should establish a licensing body tasked with the responsibility of authorising the establishment of a nuclear facility.

Such a body should carry out regular safety checks on nuclear facilities and their respective disposal mechanisms. Crossland (432) argues that licensing bodies should have the necessary professional capacity to provide training on safety. The inspectors are also important as they carry out regular assessment of safety measures in nuclear facilities.

A nuclear facility can be affected by environmental threats like floods and hurricanes. Such disasters call for emergency preparedness. The International Atomic Energy Agency (The Nuclear Fuel Cycle 23) insists that all countries must have a framework that ensures such facilities can respond to emergencies. Such levels of preparedness require a multi-agency approach.

As a result, countries with nuclear capacity are required to carry out regular emergency drills. Such drills are essential in ensuring high safety standards during disasters. An example of such preparedness involves training on how to reduce radiation when disaster strikes.

In general, safety considerations with regards to radioactive waste disposal are meant to ensure that exposure is minimised. In most European countries, there exists a joint policy framework that ensures safety matters are promoted across the region.

Crossland (542) is of the opinion that the disposal of nuclear waste needs to be enhanced to ensure that there is minimum exposure to radiation. As a result, it is preferable to recycle such waste as often as possible to ensure they remain within the nuclear fuel cycle and not in the environment.

Global Capacity

Economic perspective

Disposal of radioactive waste is one of the main challenges facing the entire industry of nuclear energy. Nikitin, Andrews, and Holt (23) argue that the cost of nuclear waste disposal is extremely high. Nikitin et al. (23) point out that direct disposal is more costly than reprocessing.

As a result, nuclear waste disposal is an international concern considering the need for global economic growth. Nikitin et al. (23) are of the opinion that an internationally agreed-upon mechanism of waste disposal has the potential to reduce the overall cost. The same explains why countries like Australia, which have no nuclear plan, are forced to secure disposal sites. The same reduces the need to export such waste to other countries.

The expenses incurred during the disposal; notwithstanding, there is a positive economic angle. Fuel leasing is seen as a method through which nuclear waste materials can be traded.

Roo (56) observes that the transaction can be enhanced when the reprocessed material is exported to other countries that do not have the capacity to enrich uranium. Fuel leasing is seen as a method of reducing direct nuclear waste disposal.

It can also be used to earn revenue to a given country. However, the flip side of this phenomenon is that the ‘leassee’ will end up with a stockpile of nuclear waste. The trade is gaining momentum in leading nuclear-enabled countries like Russia, Britain, and France.

Political perspective

The subject of nuclear energy became a great concern in the years following the end of the Second World War. At the time, nuclear waste was largely generated from the enrichment of uranium.

Roo (45) argues that there is an increasing demand for the non-proliferation of nuclear arms. The same is brought about by the conundrum of what to do with the ever-increasing, yet dangerous, radioactive waste. As a result, the subject is highly controversial in the international political arena.

There is also an assertion that nuclear waste is being disposed of secretly in countries that do not have the capacity to handle such material. However, such claims remain largely unsubstantiated.

In spite of this, Nikitin et al. (33) argue that the IAEA should be strengthened to increase its international oversight on matters touching on nuclear waste. However, the agency is laced with political undertones that end up restricting its mandate. As such, situations like the dumping of nuclear waste in underdeveloped countries may be going on unabated.

The IAEA is an international body that derives its authority from the United Nations. Given that the UN is an association of countries with different political interests, IAEA may suffer from competing for political interests. Roo (87) suggests that competing interests are likely to affect disposal policies in the world.

The same is currently being witnessed in Iran and North Korea. The IAEA has taken a soft stance in these countries and allowed political power to manipulate the process. Going by that example, it is plausible to argue that political undertones divert attention from the actual process of nuclear waste disposal. As such, the practice is inefficiently checked.

Transportation

Overview

The transportation of nuclear waste is an essential aspect of all the processes in the fuel cycle. Once the uranium ore is mined, it is transported to the plant where enrichment will be carried out. In other cases, the entire back end process is carried out in different locations. The same calls for a transport policy that respects the radioactivity of nuclear material.

The transport-related advantages of reprocessing and the safety considerations are discussed in this section. It is a fact that nuclear transport has environmental and economic ramifications. As a result, there is a need to examine the global capacity of the subject matter (Greenhalgh, Garn and Law 478). The reprocessing suggested in this paper cannot be complete without the element of transport.

Front and Back End Processes

The nuclear fuel cycle suggests a sequential mechanism through which the fuel moves from one step to the other. There are certain instances where nuclear material requires transport from one phase to another. Figure 1 reveals this reality since the ore must be mined for chemical processing to occur.

The radioactive nature of nuclear fuel informs the kind of transport that should be undertaken. Just like in the case of nuclear waste disposal, transportation of this material is determined by the level of radioactivity. Table 1 below illustrates how nuclear material is transported across various processes:

Table 1: Transport of Nuclear Material

Adapted from: Smedts (215)

The mining, chemical processing, and enrichment make up for the front end processes. As illustrated in table 1, the various points have a corresponding medium in which the material is transported. Once the uranium ore is mined, it is transferred to the mill (Smedts 220).

There is no medium of transport at this phase given the fact that the steps are on the same site. However, from the mill to the chemical treatment (and to the fabricator), the nuclear material is transported in metallic drums and special containers. As illustrated in table 1, such containers have lead casings to minimise exposure to the environment.

Once the nuclear material gets to the fabricator, it hardly requires external transport. According to Barre (2903), the reactor and fabricator must be situated within the same facility. The same explains why there is no need for a transport medium, as depicted in table 1. After this, the back end processes kick in.

As mentioned in the previous section, there are large volumes of highly radioactive nuclear waste generated during this phase of the fuel cycle. According to Ojovan and Lee (163), the radionuclides produced in the reactor require large specialised mediums of transport. The same explains the usage of the casks mentioned in table 1.

During the reprocessing phase, the production of nuclear waste involves a number of processes. They include fission by-products, plutonium oxide, and uranium oxide. Barre (2897) illustrates the toxicity of the said materials and advice for extreme caution when transporting.

Table 1 recommends the use of lead pipes to transport most of the reprocessed materials. The transportation applies to materials that are stored within the same site as the reactor. However, when the material requires to be moved out of the facility, the waste is vitrified and transported in special types of glass.

Fuel Reprocessing and the Advantages

As mentioned earlier, fuel reprocessing is quite essential in the nuclear fuel cycle. According to Irvine (81), uranium oxide and plutonium oxide can still be used as fuel for the production of electricity. However, it should not be forgotten that these materials are highly radioactive.

As such, transportation should be carried out in a manner that ensures that there is minimum exposure to the environment. In the event that the reprocessing is carried out in the same facility as the reactor, a system of pipes is recommended to transport the material easily. Table 1 illustrates the use of lead pipes that can serve this purpose

The reprocessing, as mentioned earlier, also produces radioactive waste from the fission that occurs in the reactor. The high radioactive nature of such materials requires direct disposal. As such, it is essential that the transport medium is designed to minimise radiation to the environment (Irvine 63). Consequently, such materials are vitrified and transported in special glasses.

The main advantage of reprocessing is realised in the process of recycling. The availability of diverse transport mediums necessitates further reprocessing. The same helps in minimising the direct disposal of radioactive nuclear waste.

Safety Considerations

During the transportation process, it is essential for the spillage of the materials to be kept at an absolute minimum. Nash and Lumetta (312) observe that the movement of radioactive material has a direct impact on the environment. The personnel handling the material are in constant risk of exposure to radioactivity. As a result, it is important to ensure that there are very few incidences of movement of such materials (Nuclear Energy Agency 129).

However, in the front end processes, there is a need to move the material, especially the uranium ore, from the mine to the mills. The material is further transported to the fabricator. In such circumstances, it is advisable for the personnel to be well protected. In addition, it is important to have a legal policy that stipulates the framework for transporting radioactive materials.

Global Capacity

Economic perspective

Globally, the transportation of nuclear material is a largely expensive affair. The expense is largely associated with the transportation of waste materials. Yamamoto and Okumura (569) suggest that the high cost of transporting nuclear waste encourages direct disposal.

The study by Yamamoto and Okumura points out that the specialised vessels required for the transportation of nuclear materials are costly. As a result, the process is economically unsustainable (Wolfgang, 68). However, the element of fuel leasing makes the transportation of these elements an important economic activity.

Political perspective

Movement of nuclear material is characterised by several political constraints. For instance, there are certain countries that may not allow transit of the uranium ore across their territory owing to its toxicity. Ojovan and Lee (38) illustrate cases where a country may be facing trade embargos. The embargo may inhibit any form of transportation.

As a result, such a country will continue to have a pile-up of radioactive waste, which is hazardous. Political influence with regards to the transportation of nuclear material should be avoided. The objective can be realised if the IAEA is given more powers.

Conclusion

The nuclear fuel cycle illustrates the importance of reprocessing. In the earlier sections of this paper, the disposal of radioactive waste was seen as one of the major challenges associated with the use of nuclear energy. However, through reprocessing, most of the waste can be reused as fuel for further production of energy.

Cadenas (14) argues that reprocessing is important in enhancing the recycling of radioactive waste. The challenges involved in the transportation and eventual disposal of these materials; notwithstanding, the process is essential in ensuring that nuclear energy is a completely clean alternative.

Works Cited

Barre, Bertrand. “Front End of the Nuclear Cycle.” Handbook of Nuclear Engineering. Ed. Dan Gabriel. New York: Springer, 2010. 2895-2933. Print.

Cadenas, Juan. The Nuclear Environmentalists: Is there a Green Road to Nuclear Energy?, Denver: Copernicus, 2012. Print.

Choppin, Gregory, Jan Rydberg, and Liljenzin Jan-Olov. Radiochemistry and Nuclear Chemistry, Massachusetts: Butterworth-Heinemann, 2001. Print.

Crossland, Ian. Nuclear Fuel Cycle Science and Engineering, Cambridge: Woodhead Publishing, 2012. Print.

Greenhalgh, Mitchell, Troy Garn, and Jack Law. “Development of a Hydrogen Mordenite Sorbent for the Capture of Krypton from used Nuclear Fuel Reprocessing Off-Gas Streams.” Journal of Nuclear Science and Technology 51.4 (2014): 476-481. Print.

International Atomic Energy Agency. Safety of and Regulations for Nuclear Fuel Cycle Facilities, Vienna: IAEA, 2001. Print.

—. The Nuclear Fuel Cycle, Vienna: IAEA, 2011. Print.

Irvine, Maxwell. Nuclear Power: A Very Short Introduction, Oxford: Oxford University Press, 2011. Print.

Miller, Stephen. Nuclear Collisions: Discord, Reform & The Nuclear Non-Pproliferation Regime, Cambridge: American Academy of Arts and Sciences, 2012. Print.

Nash, Kenneth, and Gregg Lumetta. Advanced Separation Techniques for Nuclear Fuel Reprocessing and Radioactive Waste, Cambridge: Woodhead Publishing, 2011. Print.

Nikitin, Mary, Anthony Andrews, and Mark Holt. Managing the Nuclear Fuel Cycle, Washington DC: Congressional Research Service, 2011. Print.

Nuclear Energy Agency. The Safety of the Nuclear Fuel Cycle, Paris: OECD, 2005. Print.

Ojovan, Michael, and William Lee. An Introduction to Nuclear Waste, Amsterdam: Elsevier, 2013. Print.

Roo, Guillaume. Economics of Nuclear Fuel Cycles: Option Valuation and Neutronics Simulation of Mixed Oxide Fuels. Diss. Massachusetts Institute of Technology, 2009. Print.

Simpson, Michael, and Jack Law. Nuclear Fuel Reprocessing, Idaho: Idaho National Laboratory, 2010. Print.

Smedts, Bart. “Iran’s Nuclear Programmer: Civil and/or Military Goals?.” Defence and Security Analysis 28.3 (2012): 213-225. Print.

Stewart, Richard, and Jane Stewart. Fuel Cycle to Nowhere: U.S. Law and Policy on Nuclear Waste, Tennessee: Vanderbilt University Press, 2011. Print.

Wolfgang, Neumann. Nuclear Waste Management in the EU: Growing Volumes and no Solution, Brussels: The Greens. 2012. Print.

Won, Ko, and Kim Ho. “Analysis of Nuclear Proliferation Resistance of DUPIC Fuel Cycle.” Journal of Nuclear Science and Technology 38.9 (2001): 757-765. Print.

Yamamoto, Kento, and Keisuke Okumura. “A Study of the Generation of 232U in UO2 and MOX Fuels.” Journal of Nuclear Science and Technology 51.4 (2014): 568-573. Print.